Automatic feeding and dust removing integrating equipment of concrete pump for mine

A concrete pump and automatic feeding technology, which is applied to mining equipment, earthwork drilling, cleaning devices, etc., can solve problems such as easy generation of dust, impact on safety production, and large dust, so as to ensure airtightness and prevent dust from spreading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

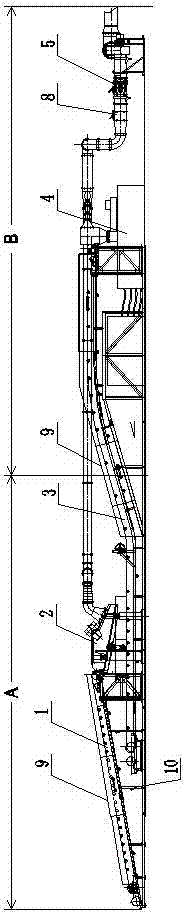

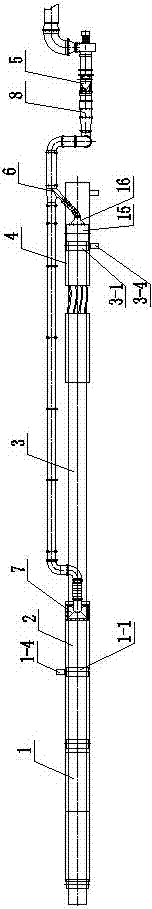

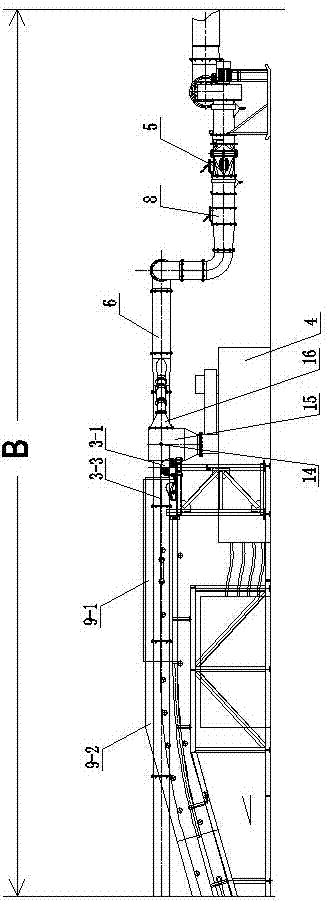

[0024] like figure 1 As shown in -4, it is the integrated equipment for automatic feeding and dust removal of mining concrete pumps, mainly including frame 10, primary belt conveyor 1, vibrating screen 2, secondary belt conveyor 3, filling pump 4, swirl Dust collector 8 and wet vibrating wire dust collector 5.

[0025] One-stage belt conveyor 1 is installed on the frame 10, and one-stage belt conveyor 1 comprises the first driving roller 1-1 and the first driven roller 1-2 arranged in parallel, the first driving roller 1-1 Both ends and both ends of the first driven roller 1-2 are supported on the frame 10, and the first driving roller 1-1 and the first driven roller 1-2 are connected by transmission through the first belt 1-3. One end of the driving drum 1-1 is connected with the first variable frequency motor 1-4. Several sensors 11 are connected to the frame 10 at the primary belt conveyor 1 along the conveying direction, and the several sensors 11 are arranged at interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com