Argon blowing protection ladle cover for metal smelting

A technology for metal smelting and protective cover, applied in the field of argon blowing in metal smelting, can solve the problems of working environment and health impact, poor video resolution of running monitoring equipment, high input cost, etc., and achieve the effect of saving volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

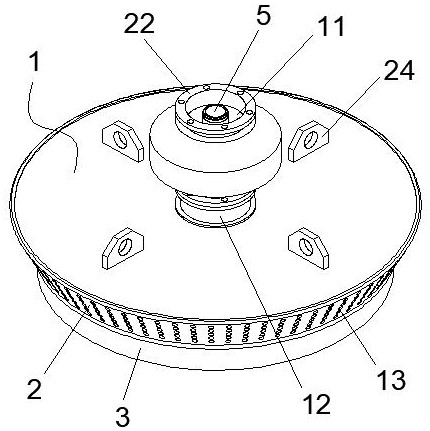

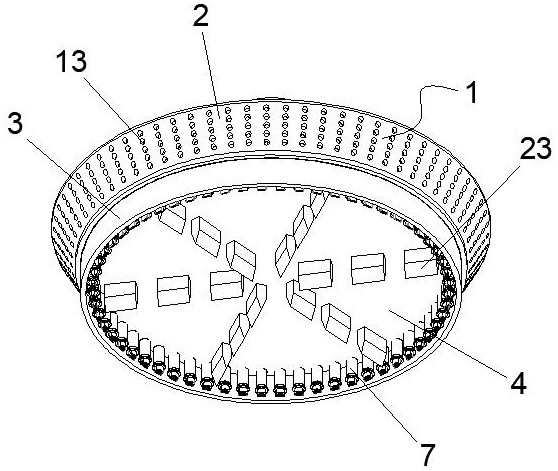

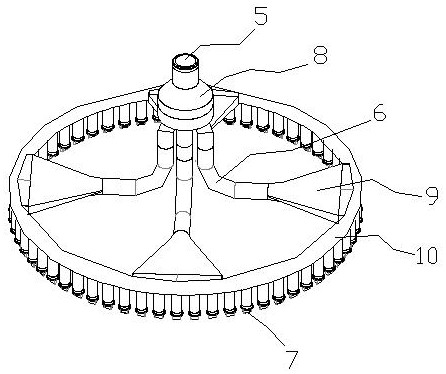

[0031] like Figure 1-6 As shown, a metal smelting argon blowing protective cover, the cover includes a cover body 1, an argon gas conveying mechanism and a dust removal mechanism. The included angle is 15-80°, the lower layer is the retainer 3, and the retainer 3 is provided with a thermal protection cover 4; the argon gas delivery mechanism sequentially includes an argon gas delivery port 5, a connecting pipe 6, an argon blowing chamber and a nozzle 7, and an argon gas delivery mechanism. The delivery port 5 is arranged above the cover body 1, the connecting pipe 6 includes multiple groups, the inlet end of the connecting pipe 6 is connected to the argon gas delivery port 5 through the branch cavity 8, and the argon blowing cavity is arranged in the cover body 1, including fan-shaped blowing. The argon chamber 9 and the annular argon blowing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com