Polygeneration system of thermoelectric hydrogen based on urban natural gas

A technology of natural gas and polygeneration, applied in the field of polygeneration systems, to achieve clean and efficient utilization, improve energy efficiency, and reduce pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

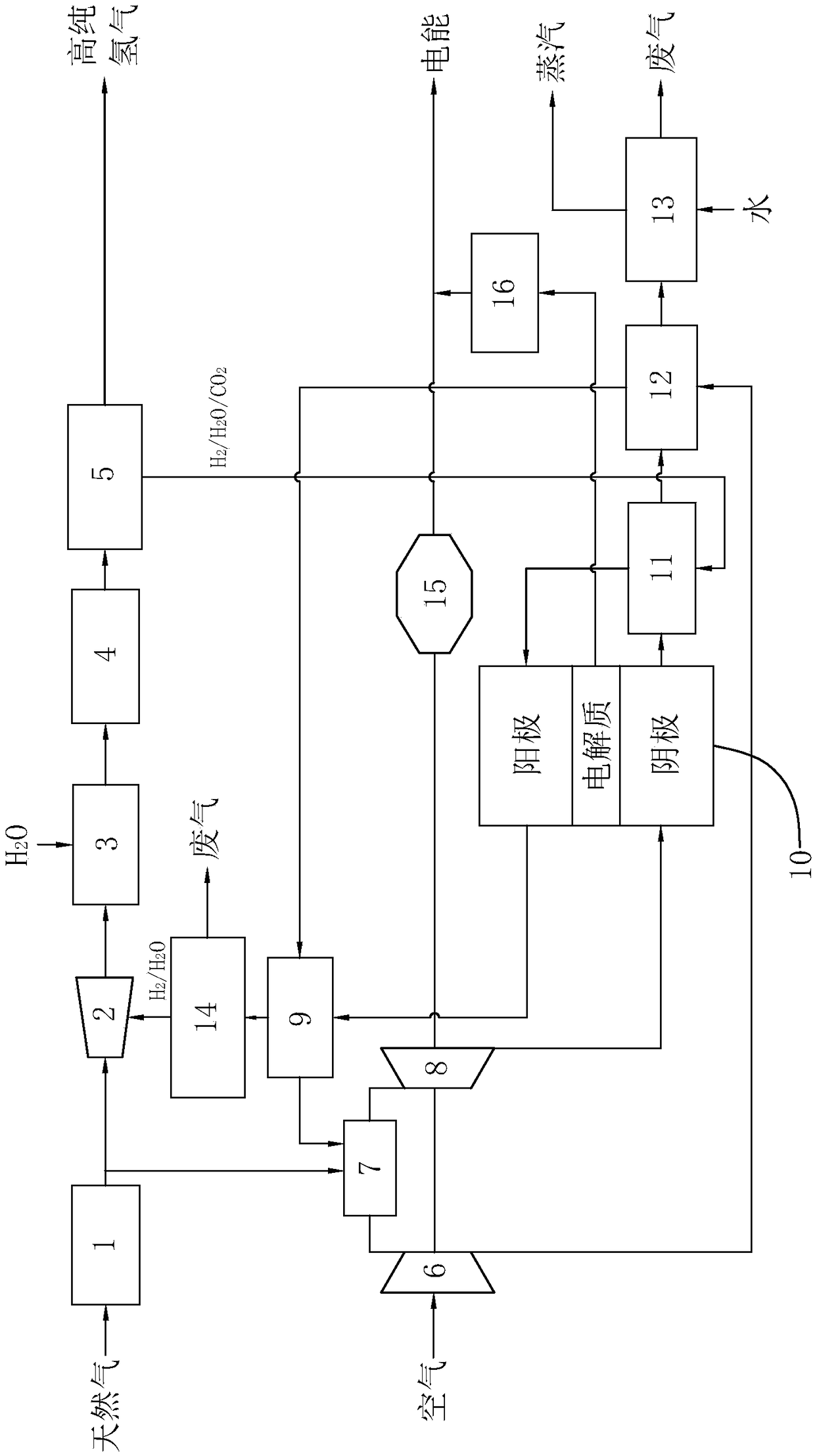

[0013] Such as figure 1 As shown, the thermal power hydrogen cogeneration system based on urban natural gas in the present invention includes a natural gas reforming hydrogen production sub-system, a micro gas turbine power generation sub-system and a solid oxide fuel cell 10 power generation sub-system, and the natural gas reforming hydrogen production sub-system includes A desulfurization device 1, an ejector 2, a reformer 3, a water vapor shift reaction device 4 and a palladium membrane purification device 5 connected in sequence, the palladium membrane purification device 5 is provided with a first outlet for outputting high-purity hydrogen and an outlet for outputting other gases The second outlet, the micro gas turbine power generation subsystem includes a compressor 6, a combustion chamber 7, a turbine 8 and a generator 15 connected in sequence, and the solid oxide fuel cell 10 power generation subsystem includes a solid oxide fuel cell 10, The current outlet of the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com