Co-hydrolysis hydrogenation process for coal and biomass

A biomass and common technology, applied in the field of co-smelting process of coal and biomass, can solve the problems of no mixing production technology, low liquefaction efficiency, limited coal powder content, etc., and achieve clean and efficient utilization and high fluidity. , the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

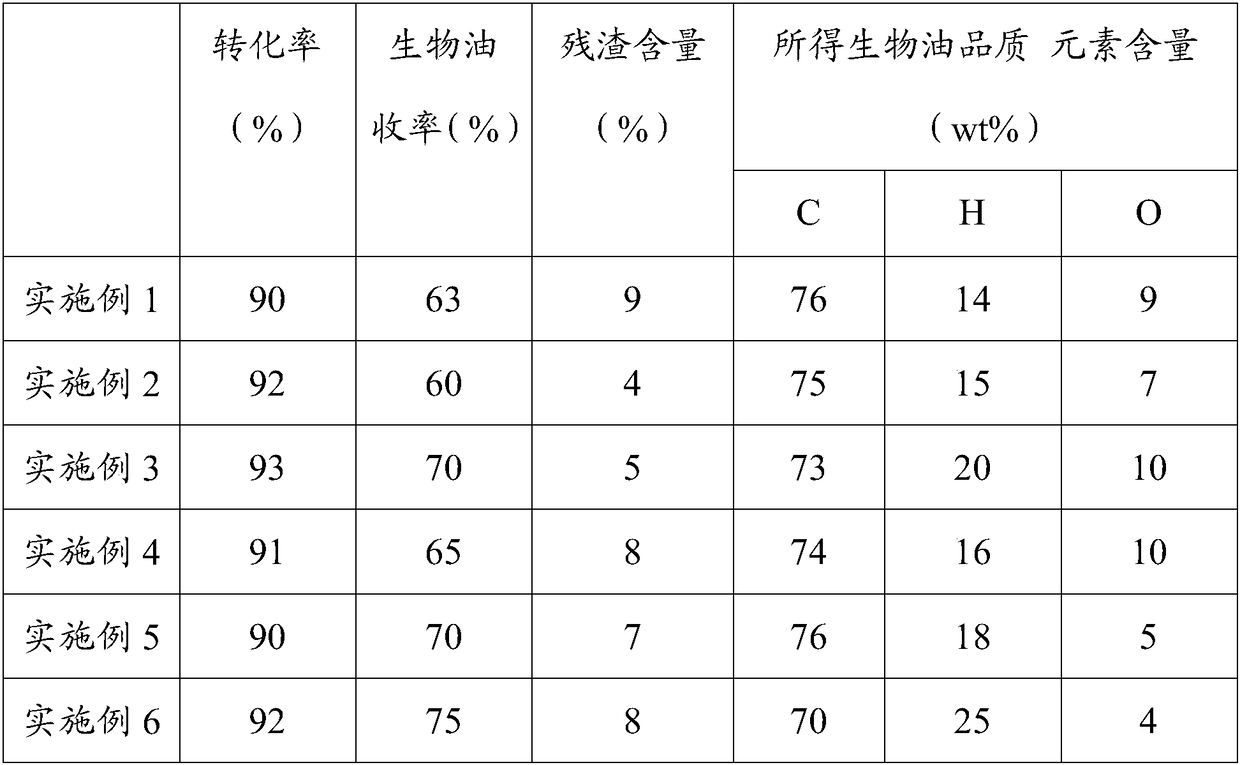

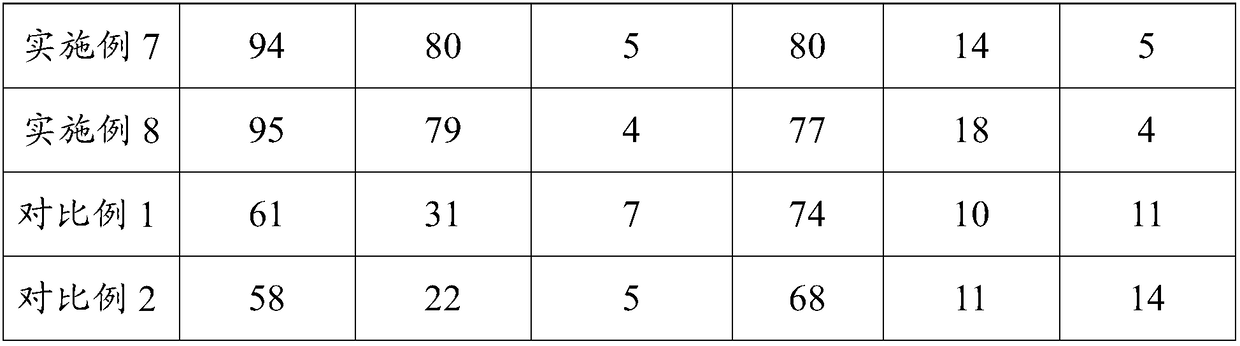

Examples

Embodiment 1

[0069] A joint hydrolysis and hydrogenation process of coal and biomass, comprising the following steps:

[0070] Lignite was taken, dried and dehydrated, crushed to a median particle size of 100 μm, and then sent to a briquetting machine for extrusion molding at a molding pressure of 15 MPa to obtain a lignite compressed material. The compressed lignite material is sent to a hammer mill for pulverization to obtain a pulverized lignite material with a particle size of 30 μm. The above-mentioned pulverized lignite material and the amorphous ferric oxyhydroxide after sulfidation treatment in the reactor are added to the mixture of feces and water to form a biomass coal-water slurry, and hydrogen gas is passed into the biomass coal-water slurry to generate react, and control the reaction pressure to 16 MPa, the reaction temperature to 420° C., and react for 35 minutes to finally obtain bio-oil.

Embodiment 2

[0072] A joint hydrolysis and hydrogenation process of coal and biomass, comprising the following steps:

[0073] Straw pretreatment:

[0074] (1) Take the straw, dry and dehydrate it, crush it to a median particle size of 100 μm, and then send it to a briquetting machine or a plodder for extrusion molding at a molding pressure of 2 MPa to obtain a compressed straw material.

[0075] (2) Send the compressed straw material into a hammer mill for crushing to obtain crushed straw material with a median particle size of 30 μm, which is ready for use.

[0076] Pretreatment of coal raw materials:

[0077] (1) Take lignite, dry and dehydrate it, pulverize to a median particle size of 100 μm, and then send it to a briquetting machine for extrusion molding at a molding pressure of 5 MPa to obtain lignite compressed material.

[0078] (2) Send the compressed lignite material into a ball mill for pulverization to obtain a pulverized lignite material with a median particle size of 10...

Embodiment 3

[0088] A joint hydrolysis and hydrogenation process of coal and biomass, comprising the following steps:

[0089] Pretreatment of biomass raw materials:

[0090] (1) Get the reed, dry and dehydrate it, and then send it to the jet mill for crushing to obtain the primary crushed material of the reed, with a particle size of D 50 is 200 μm.

[0091](2) Send the reed primary pulverized material into a briquetting machine or a plodder for extrusion molding with a molding pressure of 3 MPa to obtain a reed compressed material.

[0092] (3) The reed compressed material is sent into the jet mill, and secondary pulverization is carried out to obtain the reed secondary pulverization material, particle size D 50 40 μm, set aside.

[0093] Pretreatment of coal raw materials:

[0094] (1) Take Shendong long-flame coal, dry and dehydrate it, and then send it to a ball mill for crushing to obtain primary crushed material of Shendong long-flame coal, particle size D 50 is 80 μm.

[0095...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com