Technique and system for preparing low-nitrogen biomass gas from high-nitrogen antibiotic mushroom dregs

A technology of antibiotic bacteria residue and biomass gas, which is applied in the direction of gasification process, combustible gas production, combustible gas purification, etc., to achieve the effect of inhibiting the formation of NOx precursors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

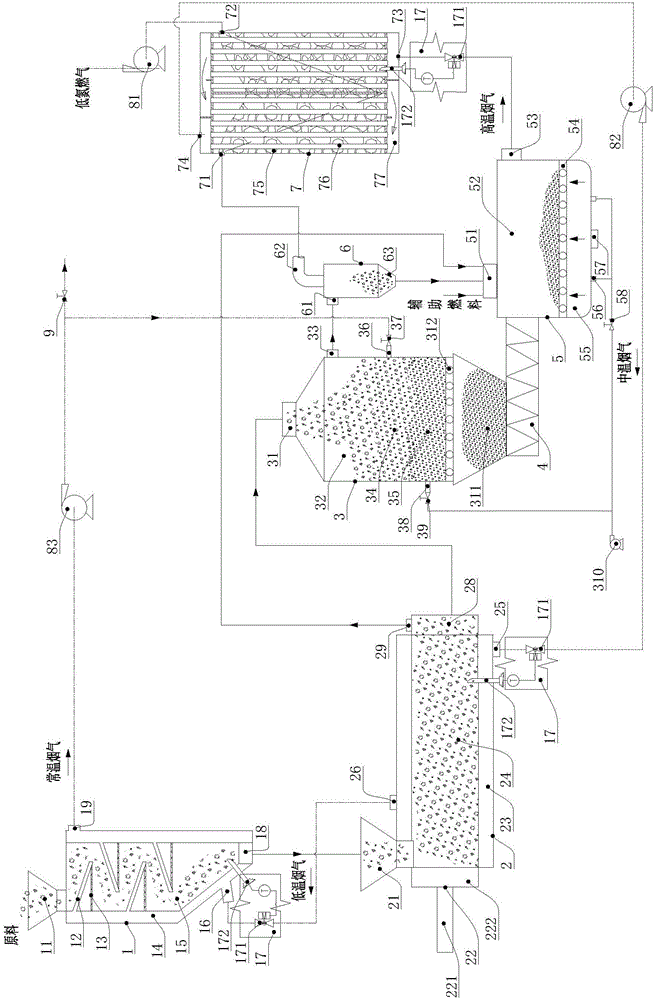

Image

Examples

Embodiment 1

[0029] A process for preparing low-nitrogen biomass gas from high-nitrogen antibiotic bacteria residues, comprising the following steps:

[0030] 1S. Bacteria slag passes through the drying chamber 1 to exchange heat indirectly with the low-temperature flue gas countercurrently to remove moisture;

[0031] 2S. The dried fungus slag is passed into the roaster 2 to exchange heat indirectly with the medium-temperature flue gas countercurrently, and the nitrogen structure of the unstable fuel is decomposed into gas-phase nitrogen, and the roasting gas is precipitated during the process;

[0032] 3S. The baked fungus slag enters the gasifier 3 to form fuel gas, and the updraft gasification is carried out under the action of the primary gasification medium, that is, air, and the secondary gasification medium, that is, normal temperature flue gas, is passed into the gasifier 3 Reduction zone, suppress NO in gas x (Nitrogen oxide) precursor generation; unreacted substances form carbo...

Embodiment 2

[0037] Such as figure 1 As shown, the system for preparing low-nitrogen biomass gas from high-nitrogen antibiotic bacteria residues includes a drying chamber 1, a roaster 2, a gasifier 3, a combustion furnace 5, a gas purification chamber 7, and a gas-solid separator 6. The drying chamber 1 is divided into an outer drying flue 14 and an inner fungus residue drying passage 15, the drying flue 14 is provided with a low-temperature flue gas inlet 16 and a low-temperature flue gas outlet 19, and the fungal residue drying passage 15 is provided with There is a fungus residue drying inlet 11 and a fungus residue drying outlet 18; the roaster 2 is provided with an outer baking flue 23 and an inner fungal residue baking channel 24, and the baking flue 23 is provided with a medium-temperature flue gas inlet 25 and a medium-temperature The flue gas outlet 26, the fungus dregs roasting channel 24 is provided with a fungus dregs roasting inlet 21 and a fungus dregs roasting outlet 28, one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com