Method for separating copper, chromium and zinc in acid leaching solution

A separation method and solution technology, applied in the direction of improving process efficiency, etc., can solve the problems of unfavorable chromium harmless disposal, efficient recovery and resource utilization, unsatisfactory separation effect of large-scale application, and no large-scale industrial application, etc. Ideal separation effect, low cost and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

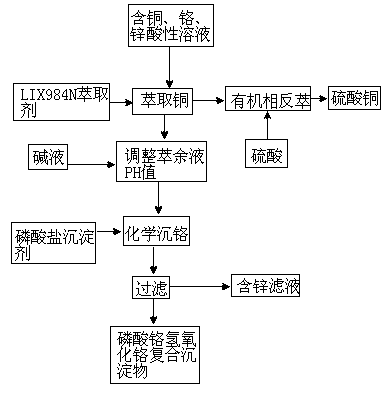

Image

Examples

Embodiment 1

[0026] After the electroplating sludge containing copper, chromium and zinc is leached by sulfuric acid, the content of Cu in the solution is 4.5g / L, the content of Cr is 5.0g / L, the content of Zn is 3.4g / L, and the pH value of the solution is 0.5. 20% (v / v) LIX984N was used as the extractant to extract copper, kerosene was used as the diluent, compared with O / A=1, the stirring time was 5 minutes at room temperature, and two-stage extraction was carried out. The organic phase uses sulfuric acid with a concentration of 10g / L as the detergent, compared with O / A=2, and the stirring time is 5min at room temperature for primary washing. After washing, the loaded organic phase uses sulfuric acid with a concentration of 180g / L as the stripping agent. Compared with O / A=1, the stirring time at room temperature is 5min, and the primary stripping is carried out. The stripping liquid obtains copper sulfate, and the separation of copper is first realized. extract. The copper content in th...

Embodiment 2

[0029] After the electroplating sludge containing copper, chromium and zinc is leached with sulfuric acid, the Cu content in the solution is 12g / L, the Cr content is 8.5g / L, the Zn content is 7g / L, and the pH value of the solution is 0.5. 30% (v / v) LIX984N was used as the extractant to extract copper, kerosene was used as the diluent, compared with O / A=1, the stirring time was 5 minutes at room temperature, and three-stage extraction was carried out. The organic phase uses sulfuric acid with a concentration of 10g / L as the detergent, compared with O / A=2, and the stirring time is 10min at room temperature for primary washing. After washing, the loaded organic phase uses sulfuric acid with a concentration of 200g / L as the stripping agent. Compared with O / A=1, the stirring time at room temperature is 5min, and a primary stripping is carried out. The stripping solution obtains copper sulfate, and the separation of copper is first realized. extract. The copper content in the raffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com