Method for preparing chromium-containing magnesia from magnesite light burning powder

A light-burning powder and magnesite technology, applied in the field of magnesia preparation, can solve the problem of uneven particle size distribution, achieve the effects of good uniformity, avoid falling off and separation, and reduce the calcium content of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A method for preparing chromium-containing magnesia from lightly burned magnesite powder, comprising the following steps:

[0066] Step (1): Pretreatment: first, lightly calcined powder is calcined at 900°C for 1 hour;

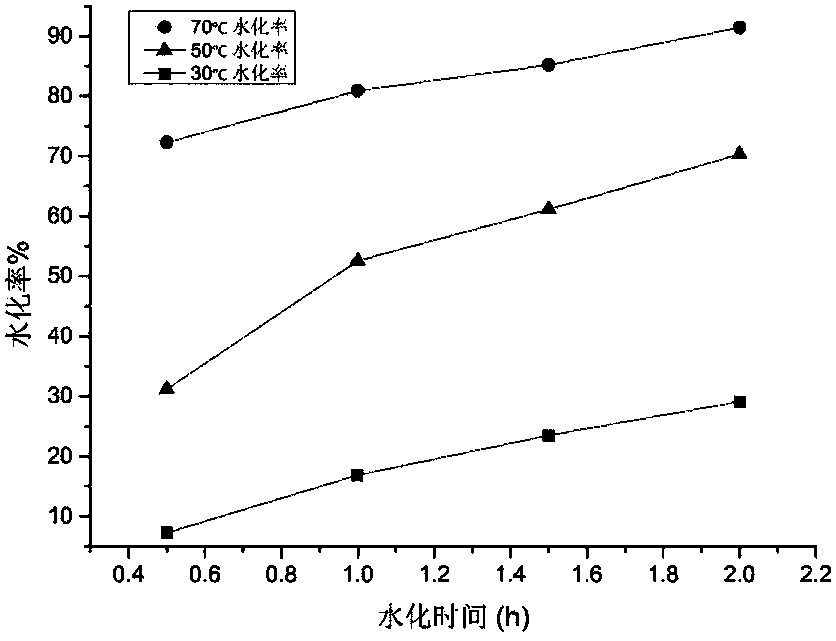

[0067] Step (2): Hydration and decalcification: hydration treatment of lightly burned powder, hydration temperature 30°C, stirring hydration time 0.5h at 200r / min, to obtain a solid content of 40wt% pulp (Ca 2+ Concentration 1.37×10 -4 mol / g), add 10ml1mol / L Mg to the pulp 2+ Salt solution, carry out decalcification, 200r / min carry out stirring and stirring 0.5h to obtain decalcification ore slurry (Ca 2+ Concentration 3.97×10 -5 mol / g);

[0068] Step (3): Precipitation of chromium: Add 5ml of 0.3mol / LCr to the decalcified ore slurry 3+ Salt solution, then stirred at 30°C and 400r / min for 0.5h to carry out chromium precipitation reaction, solid-liquid separation, to obtain the precursor filter cake:

[0069] After cooling to the same temperature, ...

Embodiment 2

[0075] Use more sufficient hydration process to carry out the following experiments:

[0076] Step (1): Pretreatment: first, lightly calcined powder is calcined at 900°C for 1 hour;

[0077] Step (2): Hydration and decalcification: Hydrate the lightly burned powder at a hydration temperature of 70°C and stir at 200r / min for 0.5h to obtain a pulp with a solid content of 40wt%, and add 10ml to the pulp 1mol / L Mg2+ salt solution for decalcification, stirring at 200r / min for 0.5h to obtain decalcified ore slurry;

[0078] Step (3): Chromium precipitation: Add 5ml of 0.3mol / LCr3+ salt solution to the decalcified ore slurry, then stir at 70°C and 400r / min for 0.5h to carry out the chromium precipitation reaction, and separate the solid and liquid to obtain the precursor filter cake:

[0079] After cooling to the same temperature, chromium salt was added for chromium precipitation. The composition analysis of the precursor filter cake is shown in Table 2.

[0080]

[0081] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com