Chromium base catalyst, and preparation method and use thereof

A chromium-based catalyst and catalyst technology, applied in the direction of dehydrohalogenation preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of shortened catalyst service life, high reaction temperature, pollution, etc., and achieve the suppression of catalyst carbon deposition , good repeatability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

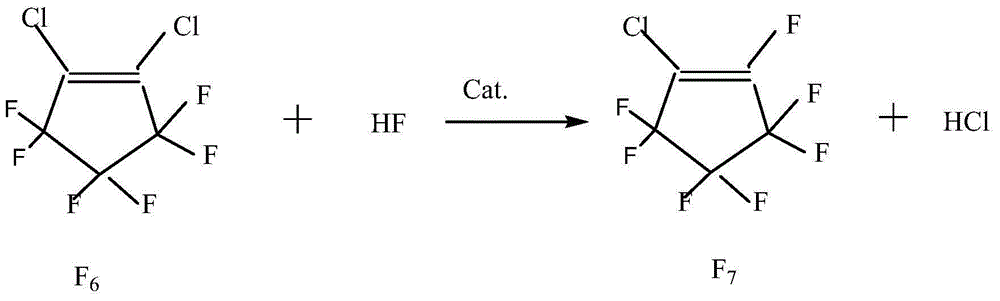

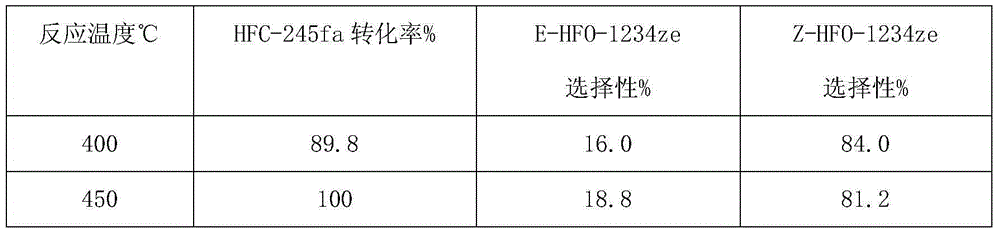

Method used

Image

Examples

Embodiment 1

[0037] Dissolve chromium nitrate in water, add precipitant ammonia water at 60°C, control the pH range of the solution to 7.5-8.5, make it fully precipitate under stirring conditions, filter the formed slurry, wash with deionized water until neutral , and then dried at 150°C for 12 hours to obtain chromium hydroxide.

[0038] The obtained chromium hydroxide and zinc silicate are divided into 95% and 5% by mass percentage and uniformly mixed, and pressed into tablets to obtain a catalyst precursor, and 60 mL of the catalyst precursor is packed into a SUS316 system with an inner diameter of 1 inch and a length of 23.6 inches. Tubular reactor, fed with nitrogen and roasted at 450°C for 8 hours, nitrogen space velocity is 200h -1 , to obtain the catalyst precursor. Then the catalyst precursor is at 300°C, and at the same time, a mixed gas composed of hydrogen fluoride and nitrogen with a mass ratio of 10:1 is passed through, and the total space velocity of the gas is 220h -1 , a...

Embodiment 2

[0043] The preparation process of the catalyst is basically the same as in Example 1, except that the mass percentages of chromium hydroxide and zinc silicate are 99.9% and 0.1%.

[0044] The results of BET detection processing are as follows:

[0045] Catalyst precursor: specific surface area = 365.8m 2 / g, pore volume=0.57cc / g, average pore diameter

[0046] Chromium-based catalyst: specific surface area = 176.4m 2 / g, pore volume=0.46cc / g, average pore diameter

Embodiment 3

[0048] The preparation process of the catalyst is basically the same as in Example 1, except that the mass percentages of chromium hydroxide and zinc silicate are 90% and 10%.

[0049] The results of BET detection processing are as follows:

[0050] Catalyst precursor: specific surface area = 406.7m 2 / g, pore volume=0.68mL / g, average pore diameter

[0051] Chromium-based catalyst: specific surface area = 186.8m 2 / g, pore volume=0.58mL / g, average pore diameter

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com