Treatment method and treatment equipment for remedying hexavalent chromium-polluted soil

A technology of polluted soil and treatment method, which is applied in the field of treatment method and treatment equipment for repairing hexavalent chromium-contaminated soil, can solve the problems of persistent environmental danger, hereditary gene defects, not very applicable, etc., and achieve good leaching effect, The effect of low cost and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

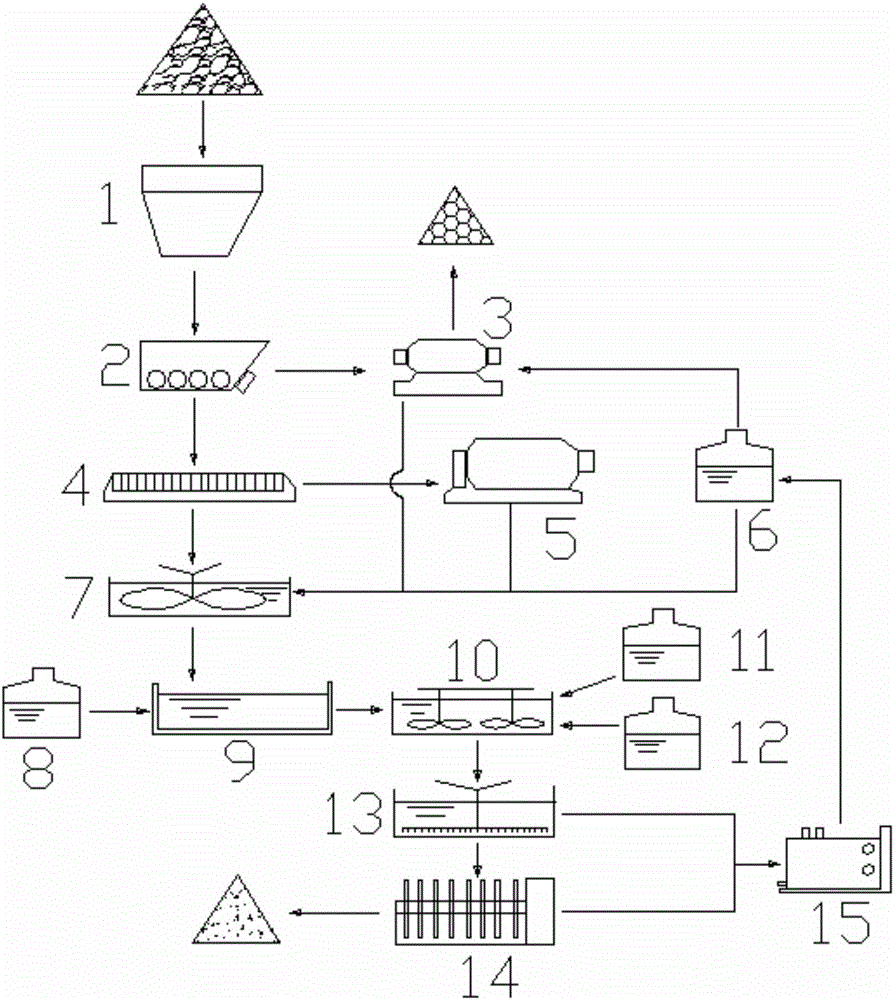

[0046] Taking a chromium salt factory in Gansu as an example, the above-mentioned method was used to treat low-concentration (Cr(VI) pollution concentration < 1000mg / kg) chromium-contaminated soil with ex-situ leaching. The specific process and repair effect are as follows:

[0047] After testing, the soil pH is around 7.2-8.8, and the concentration range of Cr(VI) pollution is 214.30-786.7mg / kg. For such acid-soluble Cr(VI)-containing chromium-containing slag-contaminated soil, only reduction and stabilization agents cannot be used to completely detoxify, and wet grinding must be carried out to destroy the physical structure of the slag particles, so that the acid-soluble, oxidizable state, reducible state and residue state are more fully reacted with the reducing agent after being leached by the agent.

[0048] The contaminated soil is transported to the ex-situ treatment area, and the contaminated soil enters the rod vibrating feeder to remove the gravel with a particle siz...

Embodiment 2

[0051] Taking a chromium salt factory in Gansu as an example, the above-mentioned method was used to carry out ectopic leaching treatment on medium-concentration (1000mg / kg

[0052] After testing, the soil pH is around 7.2-8.8, and the concentration range of Cr(VI) pollution is 1245.3-4866.5mg / kg. For this kind of chromium-containing slag-contaminated soil with high acid-soluble Cr(VI) content, only providing reduction and stabilization agents cannot completely detoxify, and wet grinding must be carried out to destroy the physical structure of the slag particles, so that the acid-soluble, The oxidizable state, reducible state and residue state are more fully reacted with the reducing agent after being leached by the agent.

[0053] The contaminated soil is transported to the ex-situ treatment area, and the contaminated soil enters the rod vibrating feede...

Embodiment 3

[0056] Taking a chromium salt factory in Gansu as an example, the above-mentioned method was used to treat high-concentration (Cr(VI) pollution concentration>5000mg / kg) chromium-contaminated soil with ex-situ leaching. The specific process and repair effect are as follows:

[0057] After testing, the soil pH is around 7.2-8.8, and the concentration range of Cr(VI) pollution is 6734.70-17883.2 mg / kg. For this kind of chromium-containing slag-contaminated soil with high acid-soluble Cr(VI) content, only providing reduction and stabilization agents cannot completely detoxify, and wet grinding must be carried out to destroy the physical structure of the slag particles, so that the acid-soluble, The oxidizable state, reducible state and residue state are more fully reacted with the reducing agent after being leached by the agent.

[0058] The contaminated soil is transported to the ex-situ treatment area, and the contaminated soil enters the rod vibrating feeder to remove the grave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com