Patents

Literature

35results about "Chromium halides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous solution of chromium salt and method for producing same

InactiveUS20070086938A1Overcome disadvantagesPigmenting treatmentNitrogen compoundsOXALIC ACID DIHYDRATEChloride

Disclosed is an aqueous solution of a chromium salt, in which the oxalic acid content is 8% by weight or less relative to chromium. In the aqueous solution of the chromium salt, the total organic carbon content is 4% by weight or less relative to chromium. The chromium salt is preferably a chromium chloride, a chromium phosphate, or a chromium nitrate. The chromium chloride preferably contains a basic chromium chloride represented by the composition formula Cr(OH)xCly (wherein 0<x≦2, 1≦y<3, and x+y=3). The chromium phosphate is preferably one represented by the composition formula Cr(H3−3 / nPO4)n (wherein n is a number satisfying 2≦n≦3). The chromium nitrate is preferably a basic chromium nitrate represented by the composition formula Cr(OH)x(NO3)y (wherein 0<x≦2, 1≦y<3, and x+y=3).

Owner:NIPPON CHECMICAL IND CO LTD

Porous material and method for producing the same

InactiveCN1798703AExcellent fluorination catalytic abilityHigh porosityMagnesium fluoridesCobalt halidesHydrogen fluoridePhysical chemistry

The present invention provides a raw material composition suitably used for synthesizing a porous metal fluoride having a large surface area and being stable even in a corrosive gas environment or the like. The porous metal fluoride obtained by reacting this raw material composition with anhydrous hydrogen fluoride has a larger surface area and is stable in a corrosive gas environment, etc., and can be used, for example, as a fluorination catalyst.

Owner:权恒道

Process for preparing chromic anhydride and dichromate by carbon ferrochrome liquid phase method

The invention relates to a process for preparing chromic anhydride and dichromate by a carbon ferrochrome liquid phase method and belongs to the technical field of preparation of chromic compounds, ferrum-series pigments, silicone new materials, photovoltaic new materials and new-energy chemical-industry new materials from industrial metallurgical products. The process disclosed by the invention is advanced, energy-saving and environment-friendly and is free of emission of waste residues, waste gases and waste water. Products such as the chromic compounds, the pigments, new energy sources and new-energy-source silicon-carbon battery materials are produced from ferrochrome by a liquid phase method in one time without high pressure and high temperature, so that a series of novel high-end industry chains are formed, and the original situation that the ferrochrome is single in use and pure in production is thoroughly changed; the out-of-date production process that heavy pollution generated by the original chromate compound roasting production heavily harms environment is changed, and the production of chromic anhydride, dichromate and the chromic compounds can be in a energy-saving, environment-friendly and high-benefit development path; and the field of diversified development and application of ferrochrome industry is extremely extended, the international competitiveness of enterprises is greatly enhanced, and the optimized upgrading and developing of national industries are promoted, so that the process is of far reaching importance. The process meets the modern requirements on environment-friendly development of economy and has very good enterprise economic benefit, perfection benefit and social benefit.

Owner:唐翔

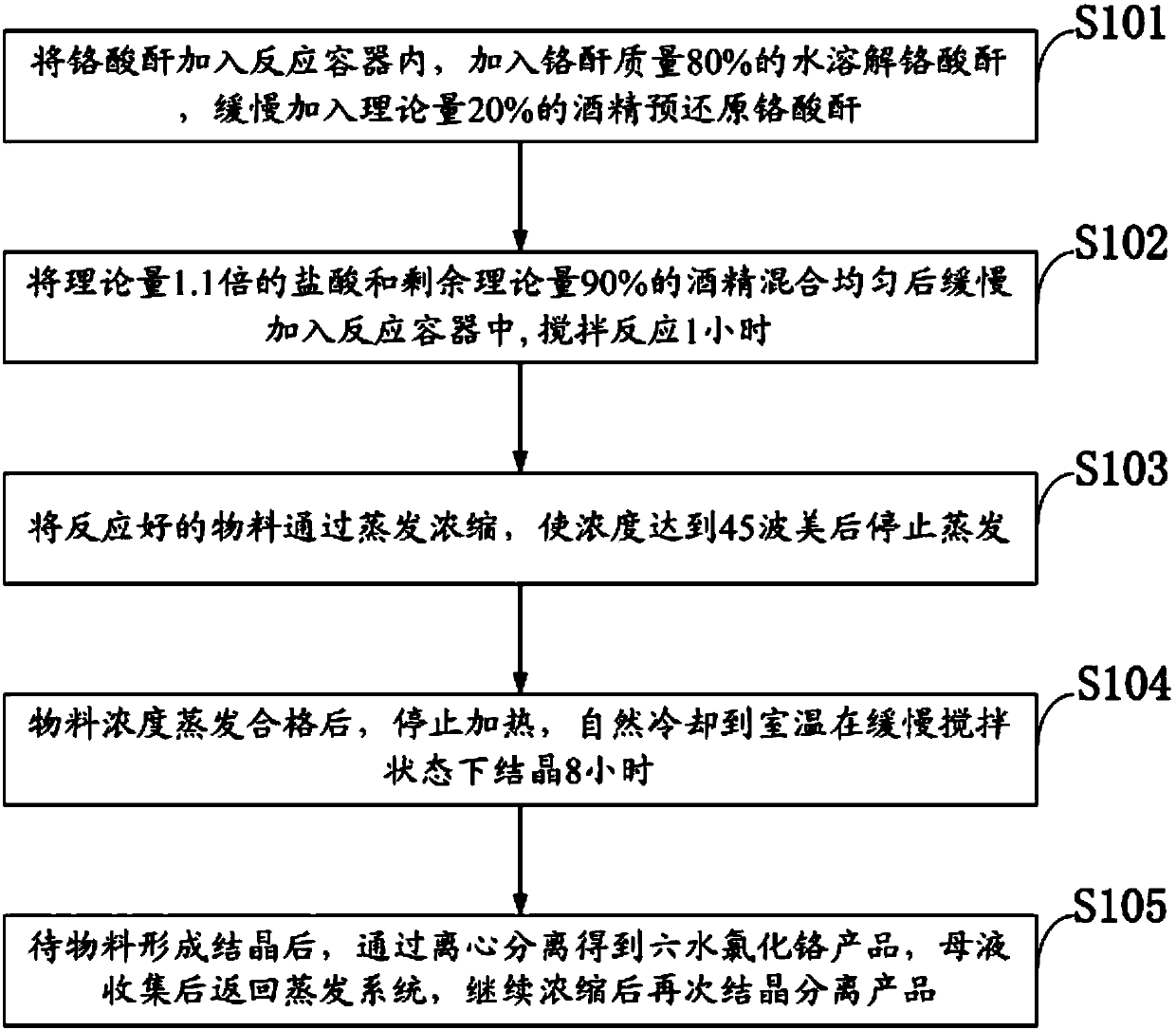

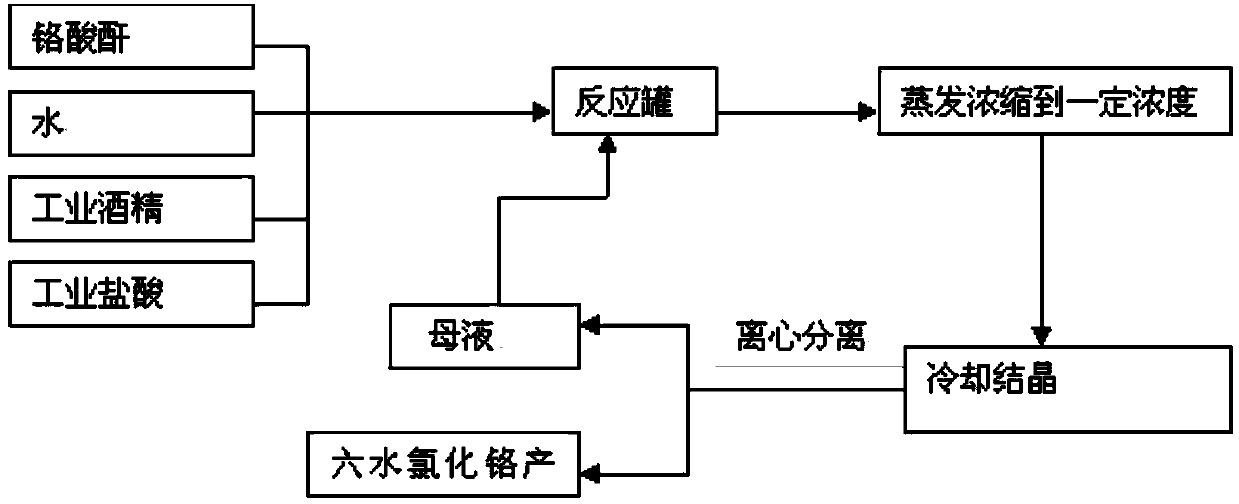

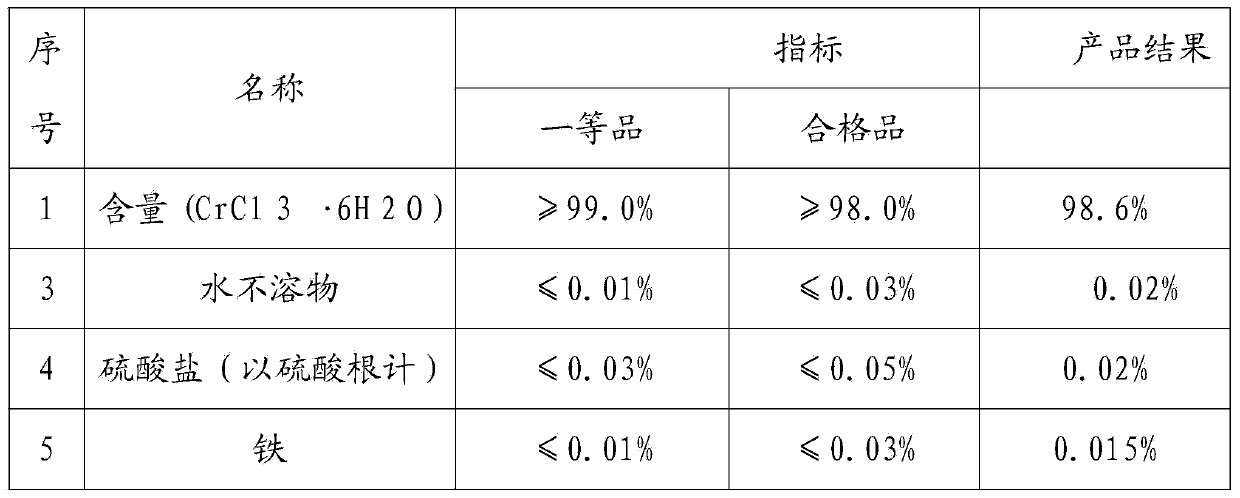

Production method of chromic chloride hexahydrate

The invention discloses a production method of chromic chloride hexahydrate, which comprises the following steps that chromic anhydride is added to a reaction vessel; water with 60-80% of the mass of chromic anhydride is added for dissolving chromic anhydride; alcohol with 10-20% of the theory quantity is slowly added for prereducing chromic anhydride; hydrochloric acid with 1.1-1.3 times the theory quantity and residual alcohol with 90% of the theory quantity are uniformly mixed, and then slowly added to the reaction vessel; stirring and reaction are performed for 1h; a reacted material is evaporated and concentrated until a concentration reaches 45 baume; after the concentration of the material is qualified by evaporation, heating is stopped; natural cooling to a room temperature is performed; crystallization is performed for 8h in a slow stirring state; after the material is crystallized, a chromic chloride hexahydrate product is obtained by centrifugal separation; a mother solution is collected, returns to an evaporation system, and is continued to be condensed; and the product is crystallized and separated again. The method is clean in production, environment-friendly in product and simple in technology; and chromic chloride hexahydrate can replace heavy-pollution hexavalent chromic salt, is widely applied to the industries of electroplating, mordanting, catalysts and the like, and is a revolution of chromic salt development.

Owner:GANSU JINSHI CHEM

Process for chlorinating resources containing recoverable metals

A process for chlorinating ore, slag, mill scale, scrap, dust and other resources containing recoverable metals from the groups 4-6, 8-12, and 14 in the periodic table. The process comprises: a) forming a liquid fused salt melt consisting essentially of aluminum chloride and at least one other metal chloride selected from the group consisting of alkali metal chlorides and alkaline earth metal chlorides, wherein the aluminum chloride content in the liquid salt melt exceeds 10% by weight; b) introducing the recoverable metal resources into said liquid salt melt: c) reacting the aluminum chloride as chlorine donor with said recoverable metal resource to form metal chlorides, which are dissolved in the salt melt; and d) recovering the formed metal chlorides from the salt melt.

Owner:P M TECH

Production method for coproduction of chromium chloride and chromic carbonate

ActiveCN102718260AImprove solubilitySave configuration timeChromium halidesChromium(III) hydroxideSulfide

The invention discloses a production method for the coproduction of chromium chloride and chromic carbonate, and the production method is used for solving the problems that the chromic carbonate produced through the existing method is easy to age, and the solubility of the chromic carbonate in acidic aqueous solutions is greatly reduced after the chromic carbonate is subjected to long-term storage. According to the production method, an alkaline solution of sodium chromate is taken as a raw material, sulfur and alkali sulfide are taken as reducing agents to be subjected to redox reaction in a reaction tank so as to obtain chromic hydroxide, the obtained chromic hydroxide is filtered and washed and then reacts with hydrochloric acid to produce the chromium chloride, and the chromic carbonate is produced in a manner that the chromium chloride is subjected to the precipitation of a soda solution. The production method has the advantages that the process flow is short, the operation is simple, the redox reaction is complete, the chromium yield is high, and hexavalent chromium is not detected in the filtrate, so that the pollution to the environment cannot be caused.

Owner:GANSU JINSHI CHEM

Carbon ferrochrome liquid phase method for preparing new energy battery raw material and new energy source hydrogen process

The invention relates to a carbon ferrochrome liquid phase method for preparing a new energy battery raw material and a new energy source hydrogen process. The process is advanced, energy saving and environmentally friendly, free from fire coal and high temperature and high pressure, the new energy source, a plurality of new energy source battery materials, pigments, chemical engineering chromium salt and the like products can be produced in disposable by using ferrochrome as the raw material by using the liquid phase method, a series of new high-end industry chains are formed, the situations that the original product use is single in use and the production is pure are changed, the enterprise international competitiveness is greatly enhanced, the upgrading and optimization and development of the nation industry are promoted, and the process has important significance.

Owner:唐翔

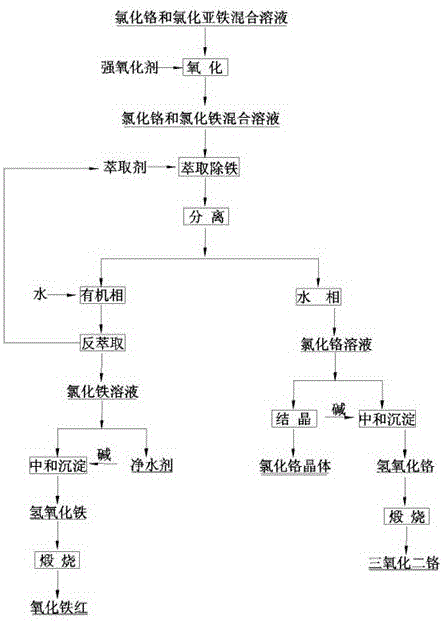

Separating method for chromium and iron in hydrochloric acid system

InactiveCN106756043AComply with cleaner production policySimple processChromium trioxideFerric oxidesFerric hydroxidePhase ratio

The invention discloses a separating method for chromium and iron in a hydrochloric acid system. The separating method comprises the following technology steps that firstly, a chromic chloride and ferrous chloride mixed solution is obtained through carbon ferrochrome leaching via hydrochloric acid, all Fe<2+> is oxidized into Fe<3+> through hydrogen peroxide firstly, then an extraction agent is added for extraction according to the content of iron in the solution and the proper phase ratio, a water phase obtained after extraction is a chromic chloride solution, reextraction is conducted on an organic phase through water, a ferric chloride solution and an extraction agent are obtained, and the extraction agent is circularly used; secondly, chromic chloride crystals are obtained from the chromic chloride solution via a direct crystallization method, chromic hydroxide can be prepared through an alkali adding neutralization and sedimentation method as well, the chromic hydroxide is then subjected to high-temperature roasting, and chromic oxide is obtained; and thirdly, the ferric chloride solution can be directly used as a water purifying agent, ferric hydroxide can be prepared through the alkali adding neutralization and sedimentation method, the ferric hydroxide is subjected to high-temperature roasting, and iron oxide red pigment is obtained. The technology is simple, operation is easy, and the iron removal rate reaches up to 99.95% or above.

Owner:中成致远有限公司

One-off manufacturing technology of chromium compounds and new products in many industries by liquid phase method of ferrochromium

The invention relates to a one-off manufacturing technology of chromium compounds and new products in many industries by a liquid phase method of ferrochromium and belongs to the technical field of new chemical materials with metallurgical products used as raw materials to manufacture chromium compounds, iron series pigments, new silicon materials, new photovoltaic materials and new energy. The technology provided by the invention is advanced, energy-saving and environmentally friendly, and there is no discharge of waste residues, exhaust gas or wastewater. High temperature and high pressure are not required. Ferrochromium is used as a raw material to produce products such as chromium compounds, pigments, new energy, new silicon carbon battery materials and the like by a liquid phase method at a time, thus forming a series of new high-end industrial chains and thoroughly changing situations of single application and pure production of ferrochromium in the prior art. The backward production technology that original chromate compound roasting production generates high pollution which is greatly harmful to the environment is changed. Production of chromate compounds has embarked on an energy-saving and high-efficiency development road. Diversified development and application fields of the ferrochromium industry are greatly expanded, international competitiveness of enterprises is greatly enhanced and national industrial upgrading and optimization and development are promoted. The technology provided by the invention is of great significance. The technology accords with requirements of modern green economic development and has great enterprises economic benefits, perfection benefits and social benefits.

Owner:唐翔

Oxyfluoride compounds for lithium-cells and batteries

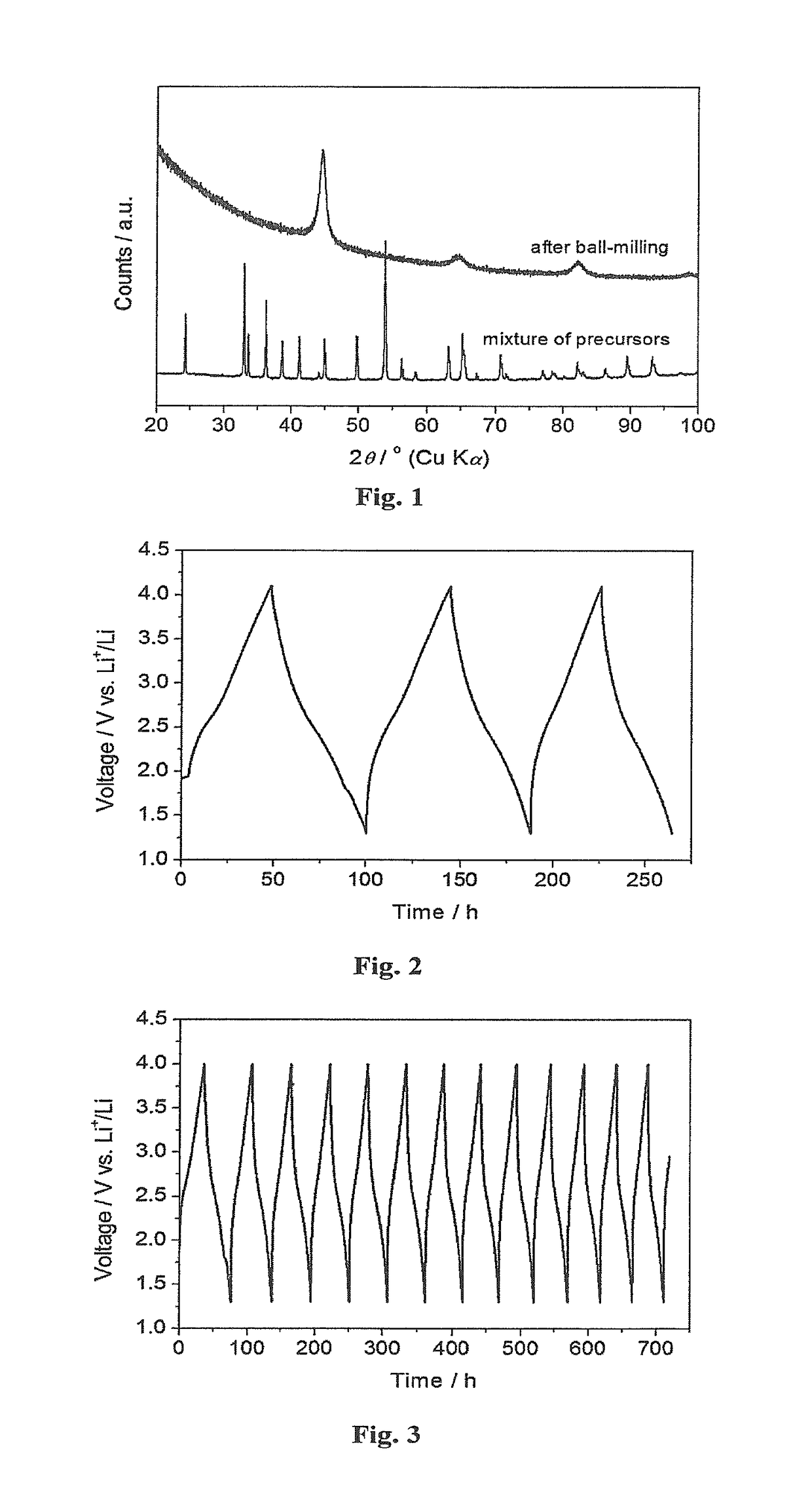

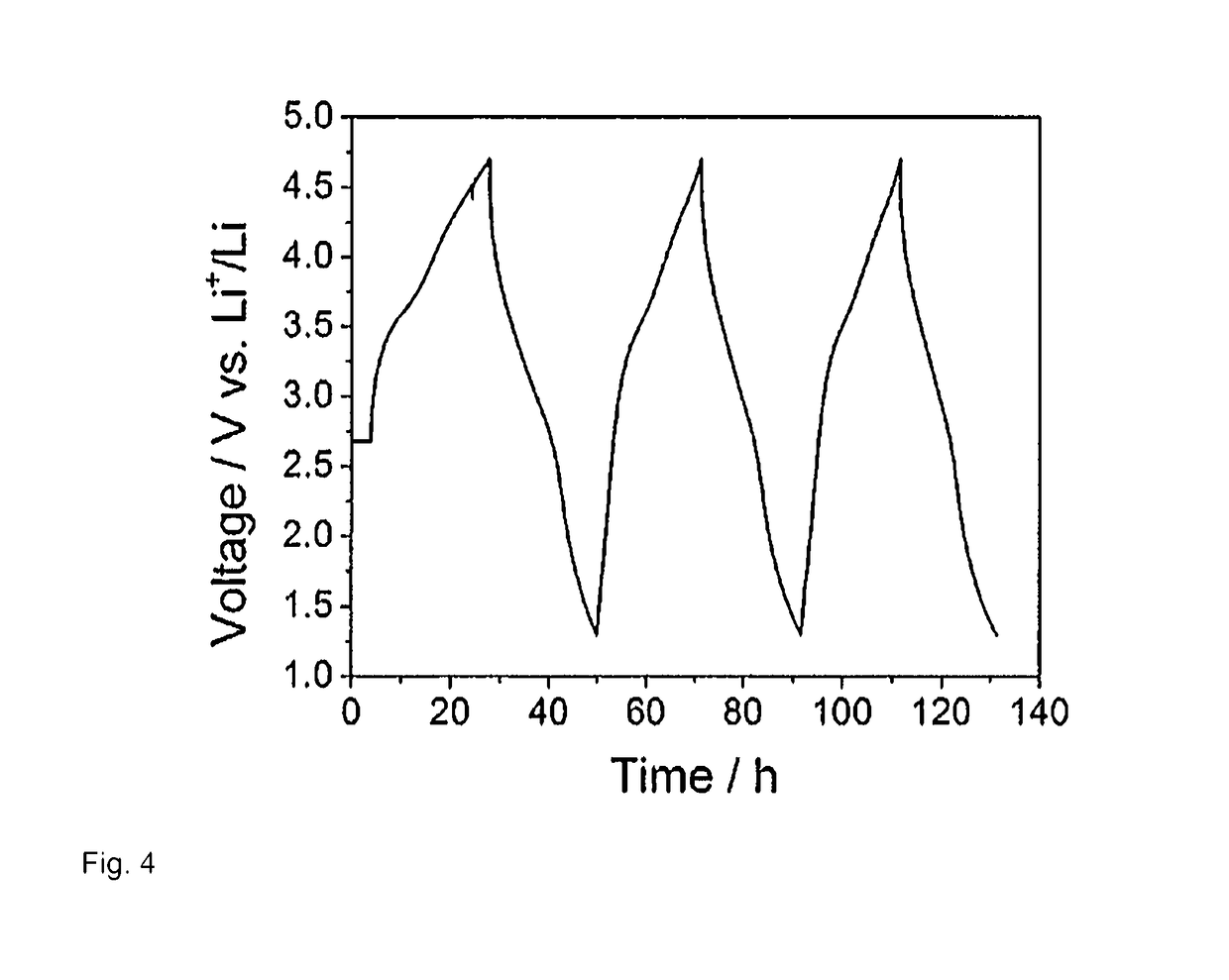

InactiveUS10199647B2Improve featuresHigh materialTungsten halidesTungsten oxides/hydroxidesMedicinal chemistryCathode material

The present invention concerns specific new compounds of formula Li(2−x)Na(x)MO(2−y / 2)F(1+y) (where 0≤x≤0.2 and −0.6≤y≤0,8 and M is a transition metal), cathode material comprising the new compounds, batteries and lithium-cells comprising said new compound or cathode material, a process for the production of the new compound and their use.

Owner:KARLSRUHER INST FUR TECH

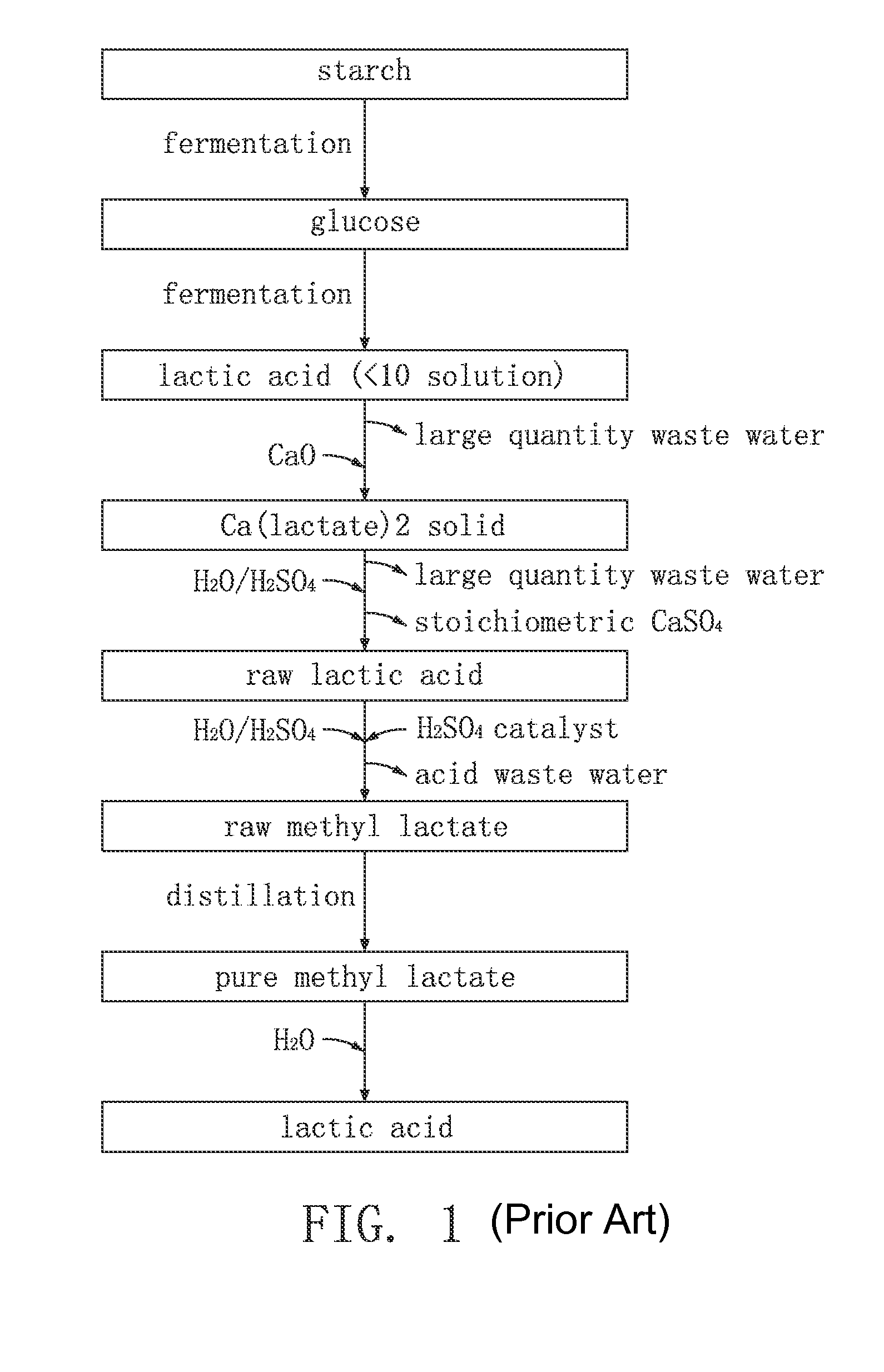

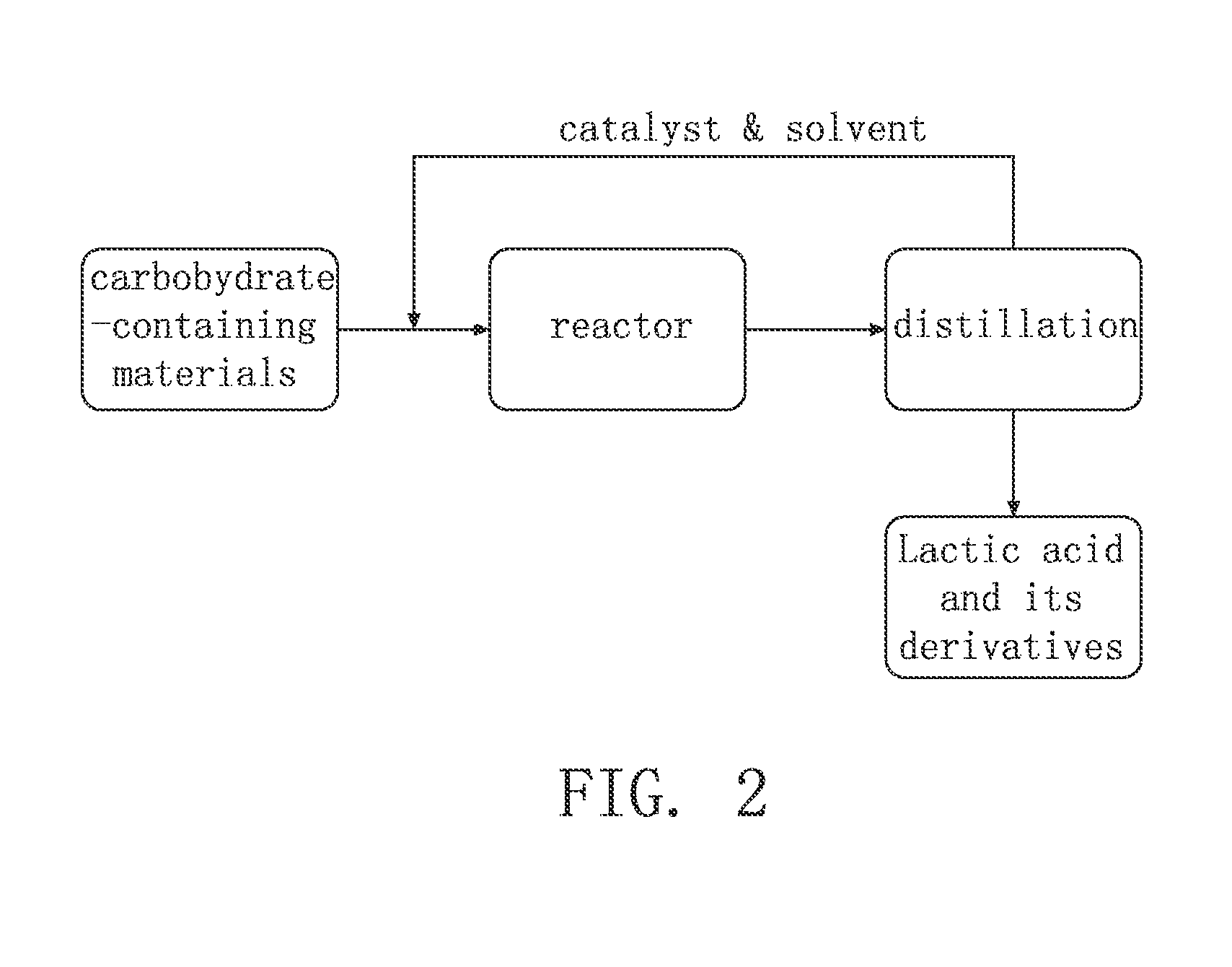

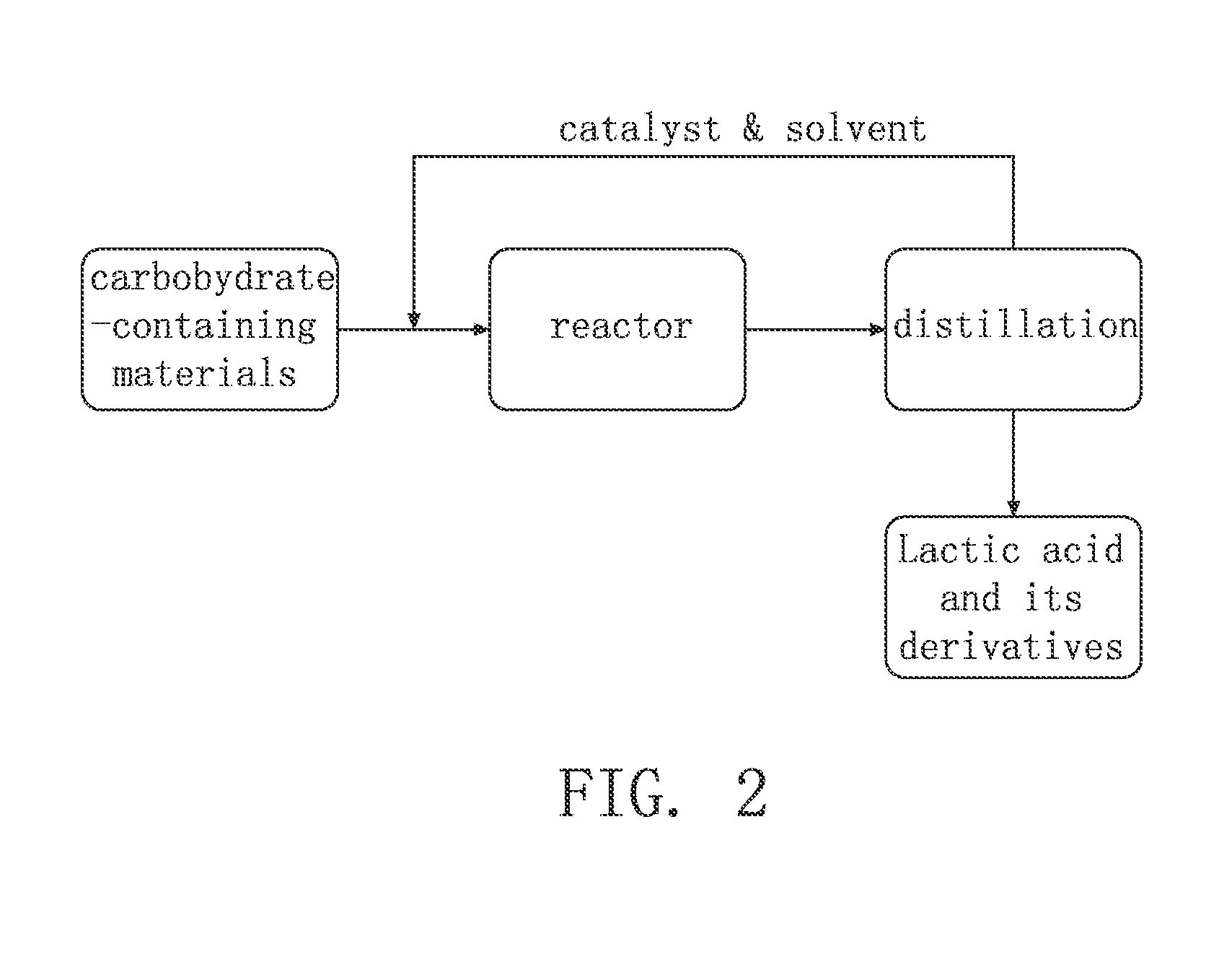

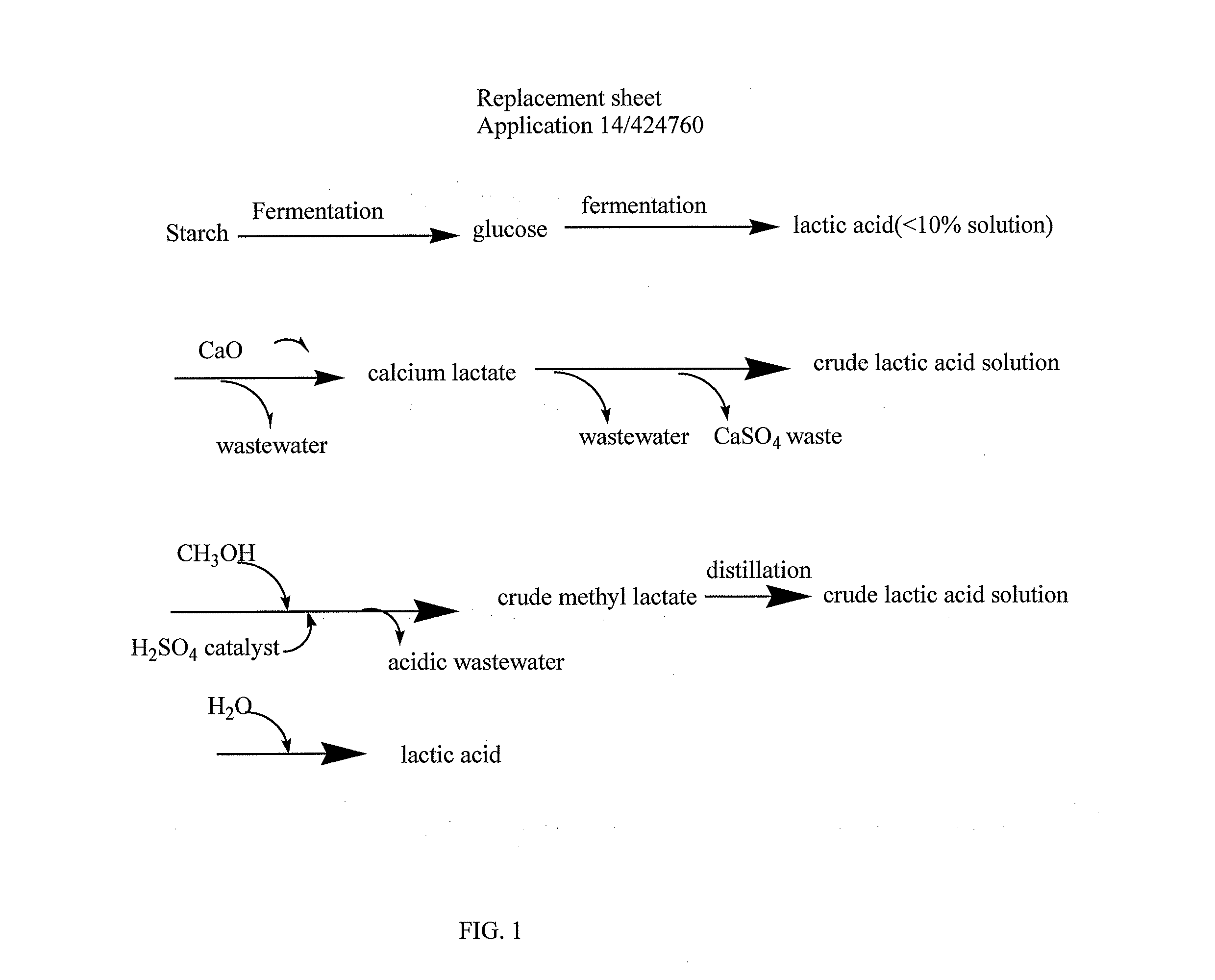

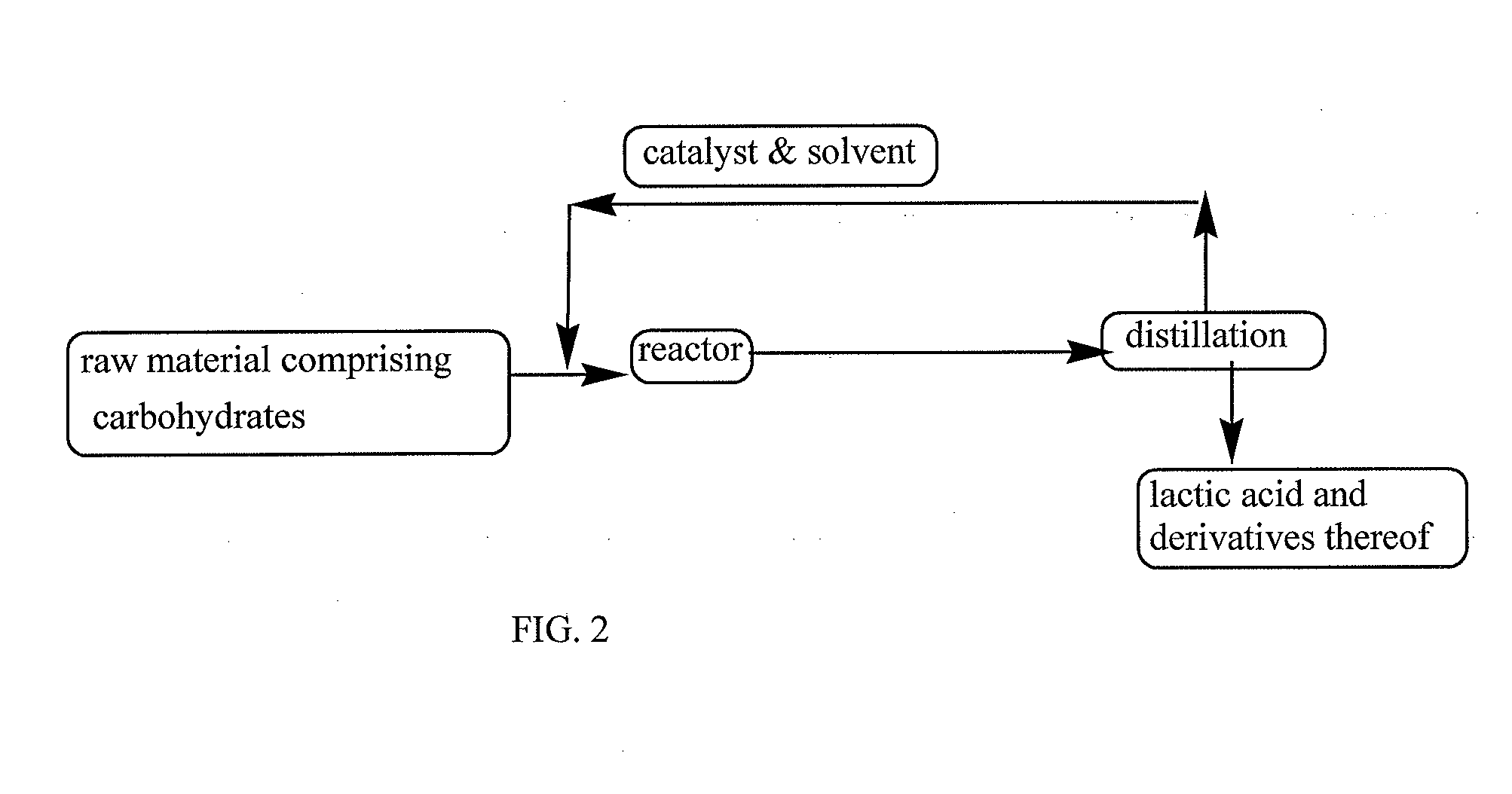

Method for synthesis of lactic acid and its derivatives

ActiveUS8835670B2Efficient and economicalMore environment-friendlyZinc halidesPhysical/chemical process catalystsMetal chlorideAlcohol

A method for synthesis of lactic acid and its derivatives is provided. First, a mixture is prepared, which includes: at least one carbohydrate-containing raw material, at least one alcohol, at least one composite catalyst containing metal chloride(s) (MCln) and tin-containing compound(s), and at least one solvent, wherein M is selected from a group consisting of Li+, Na+ K+, Mg2+, Ca2+, Sr2+, Ga3+, In3+, Sb3+, Bi3+, Cr3+, Mn2+, Fe2+, Co2+, Ni2+, Zn2+, and n represents 1, 2 or 3. Then, the mixture is heated to obtain lactic acid and its derivatives. By using the above catalyst and method, it is capable of converting carbohydrate-containing raw material to lactic acid and its derivatives directly in a more efficient and economical way.

Owner:MICROVAST POWER SYST CO LTD

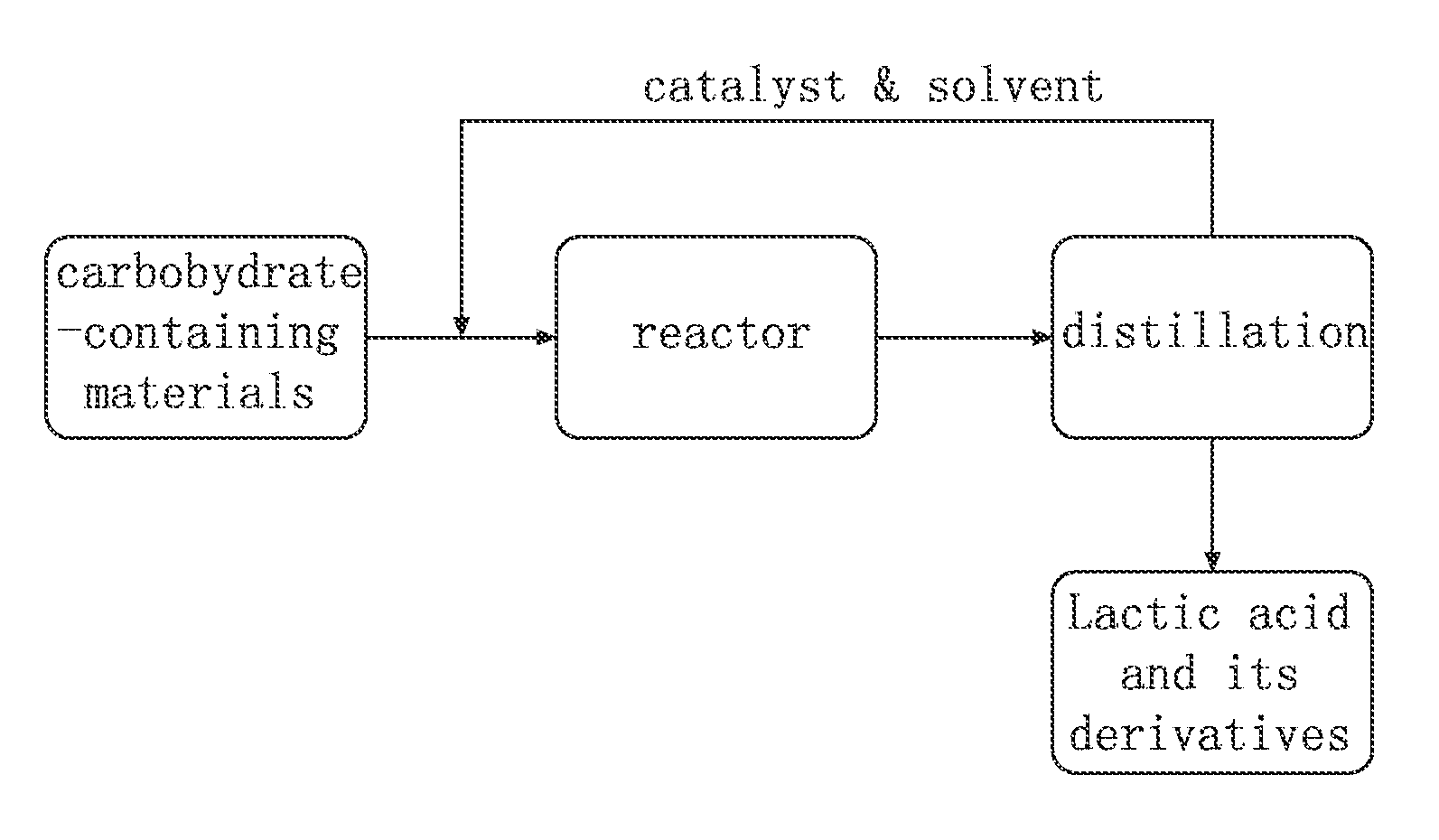

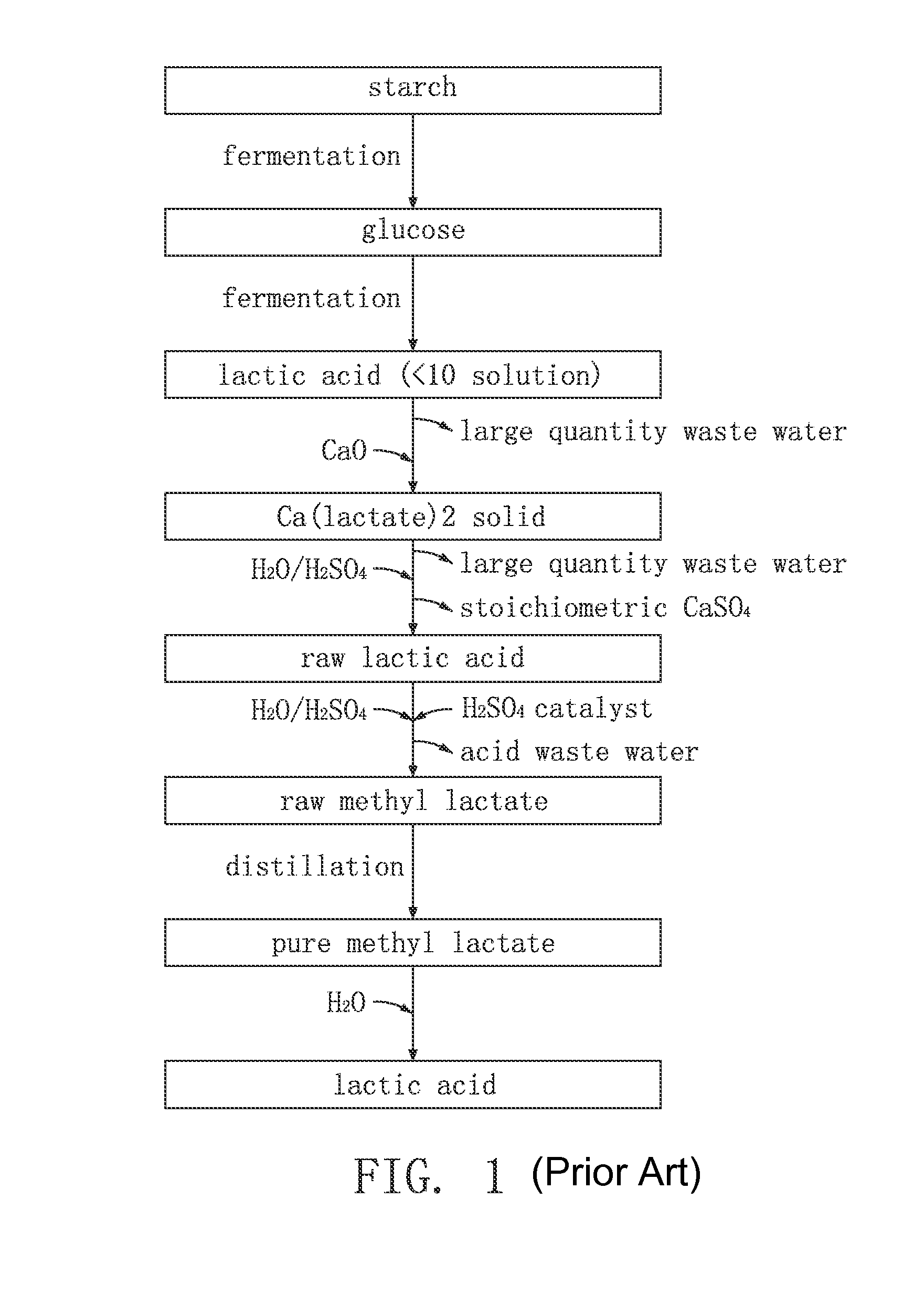

Method for Synthesis of Lactic Acid and Its Derivatives

ActiveUS20140058130A1Efficient and economicalMore environment-friendlyZinc halidesPhysical/chemical process catalystsMetal chlorideAlcohol

A method for synthesis of lactic acid and its derivatives is provided. First, a mixture is prepared, which includes: at least one carbohydrate-containing raw material, at least one alcohol, at least one composite catalyst containing metal chloride(s) (MCln) and tin-containing compound(s), and at least one solvent, wherein M is selected from a group consisting of Li+, Na+ K+, Mg2+, Ca2+, Sr2+, Ga3+, In3+, Sb3+, Bi3+, Cr3+, Mn2+, Fe2+, Co2+, Ni2+, Zn2+, and n represents 1, 2 or 3. Then, the mixture is heated to obtain lactic acid and its derivatives. By using the above catalyst and method, it is capable of converting carbohydrate-containing raw material to lactic acid and its derivatives directly in a more efficient and economical way.

Owner:MICROVAST POWER SYST CO LTD

Method for improving quality of industrial chromic chloride

The invention relates to a method for improving the quality of industrial chromic chloride. The method comprises the following steps: adding industrial chromic chloride as a raw material into high purity water for dissolving; carrying out membrane filtration on a dissolving solution by a modified kynoar polyvinylidene fluoride membrane to obtain a filtrate in which metal ion impurities are removed; removing water and cooling under normal pressure; drying a separated crystal to obtain chromic chloride with improved quality. Through detection, the purity of chromic chloride reaches 99.5% or more and meets the quality standard of HG3-935-81. The method is good in effect of removing the metal ion impurities, and an obtained chromic chloride product has stable quality and is suitable for industrial production.

Owner:SINOPHARM CHEM REAGENT

Process for chlorinating resources containing recoverable metals

A process for chlorinating ore, slag, mill scale, scrap, dust and other resources containing recoverable metals from the groups 4-6, 8-12, and 14 in the periodic table. The process comprises: a) forming a liquid fused salt melt consisting essentially of aluminum chloride and at least one other metal chloride selected from the group consisting of alkali metal chlorides and alkaline earth metal chlorides, wherein the aluminum chloride content in the liquid salt melt exceeds 10% by weight; b) introducing the recoverable metal resources into said liquid salt melt: c) reacting the aluminum chloride as chlorine donor with said recoverable metal resource to form metal chlorides, which are dissolved in the salt melt; and d) recovering the formed metal chlorides from the salt melt.

Owner:P M TECH

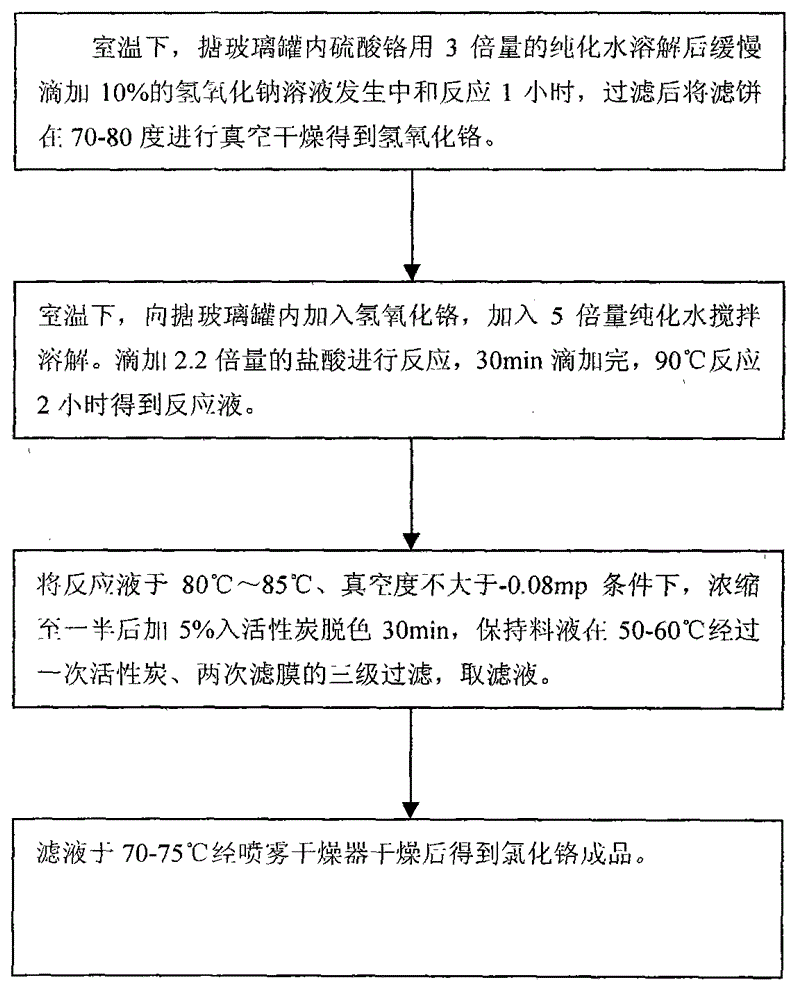

Preparation method of chromium trichloride

InactiveCN105883920AIncrease productionHigh yieldChromium halidesChromium(III) hydroxideWater chlorination

The invention discloses a preparation method of chromium trichloride. The preparation method includes the following steps: 1) neutralizing chromium sulfate and a 8-15% sodium hydroxide solution to obtain chromium hydroxide; 2) performing a reaction to the chromium hydroxide with 2-2.5 times of hydrochloric acid to obtain a reaction liquid; 3) concentrating the reaction liquid, adding activated carbon, and filtering the reaction liquid through three stages: one activated carbon and two filter membranes, with temperature maintained at 50-60 DEG C to obtain a filtrate; and 4) spray-drying the filtrate to obtain the chromium trichloride. The preparation method increases yield and reduces content of impurities through selection and optimization on reaction liquid concentration and material proportion. In a drying method of a crystallization machine, the spray-drying method is employed preferably to replace a conventional organic solvent crystallization and vacuum drying method, so that the preparation method is environment-friendly, saves working time, reduces energy consumption and effectively controls water content. The preparation method is short in process, is low in cost, is short in time, is high in yield and content, is low in environment pollution and is very suitable for industrial production. The method aims to provide high-quality raw materials for chromium (III) medicine preparations.

Owner:山西国润制药有限公司

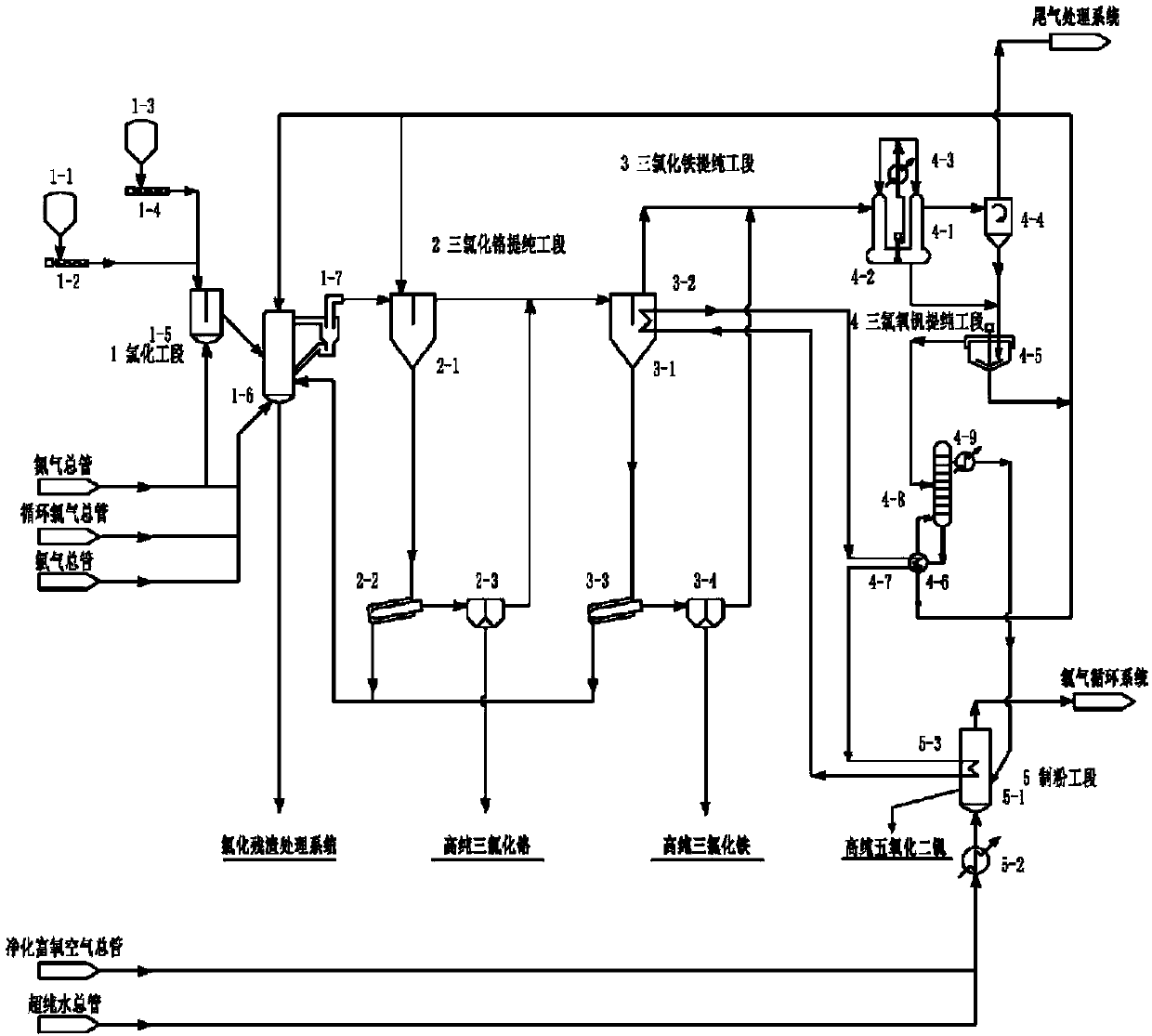

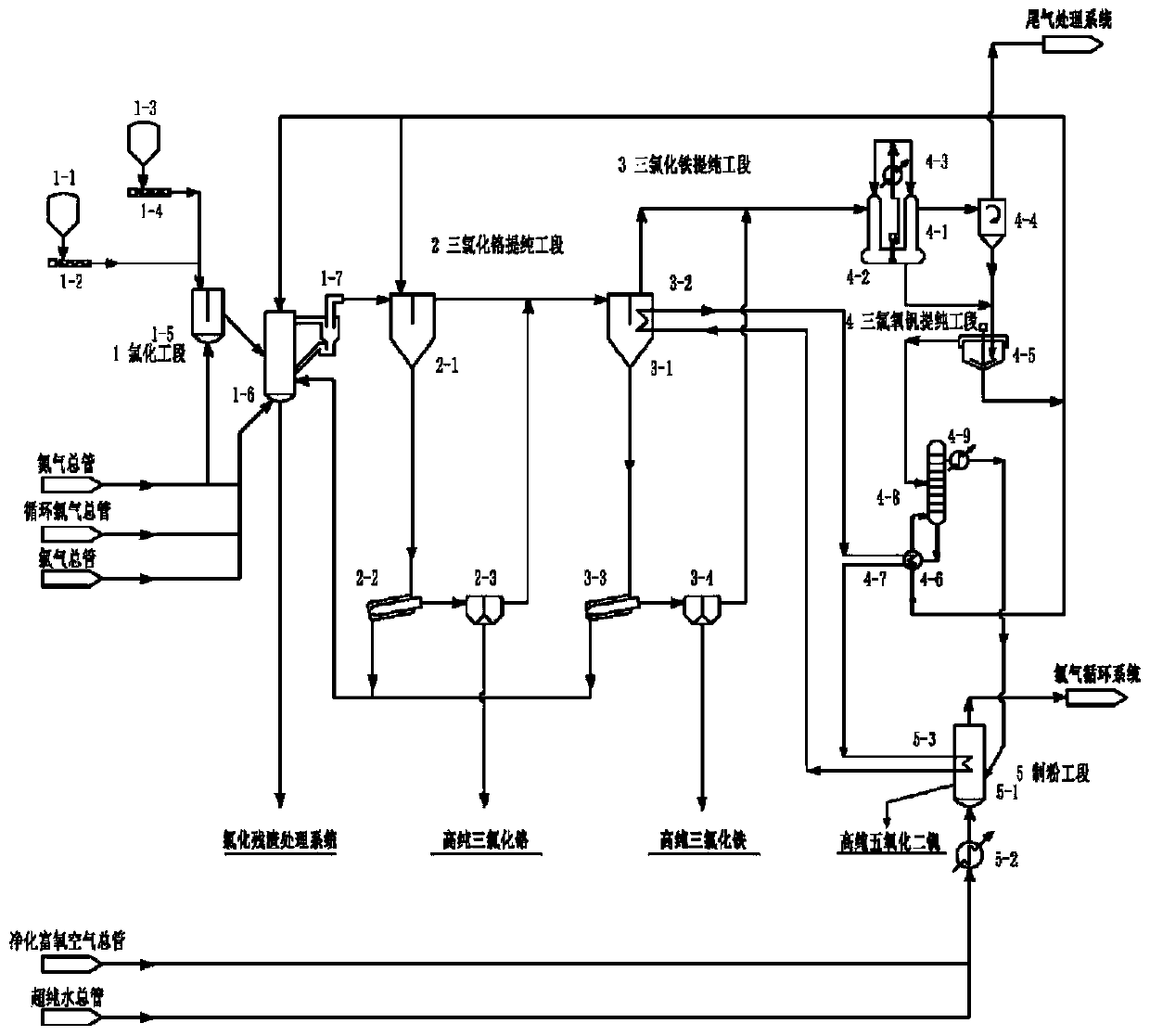

Method for producing high-purity energy storage material for liquid flow batteries by using high chromium type vanadium residue

ActiveCN109835948AReduce overflowImprove chlorination efficiencyRegenerative fuel cellsEnergy inputRecovery methodCatalytic oxidation

The invention discloses a system and a method for producing a high-purity energy storage material for liquid flow batteries by using high chromium type vanadium residue. According to the present invention, through selective chlorination in a circulating fluidized bed, vanadium, chromium and iron in high chromium vanadium residue are converted into corresponding gaseous chlorides, and most of impurities such as manganese, titanium, silicon and the like in the vanadium residue are remained in the chlorinated residue so as to separate the valuable elements from other impurities; the gaseous chloride is subjected to high temperature dust collection to separate crude chromium trichloride, is subjected to medium temperature dust collection to separate crude ferric chloride, and is subjected to low temperature leaching to separate crude vanadium oxytrichloride; the crude chromium trichloride is subjected to volatilization purification to obtain high-purity chromium trichloride; the crude ferric chloride is subjected to volatilization purification to obtain high-purity ferric chloride; the crude vanadium oxytrichloride is subjected to rectification purification and catalytic oxidation to obtain high-purity vanadium pentoxide powder; and with the system and the method, the high-value comprehensive utilization of the high chromium type vanadium residue is achieved, and the high-purity energy storage material for liquid flow batteries is obtained through the one-step chlorination multi-stage recovery method.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Aqueous solution of chromium salt and method for producing same

Disclosed is an aqueous solution of a chromium salt, in which the oxalic acid content is 8% by weight or less relative to chromium. In the aqueous solution of the chromium salt, the total organic carbon content is 4% by weight or less relative to chromium. The chromium salt is preferably a chromium chloride, a chromium phosphate, or a chromium nitrate. The chromium chloride preferably contains a basic chromium chloride represented by the composition formula Cr(OH)xCly (wherein 0<x<=2, 1<=y<3, and x+y=3). The chromium phosphate is preferably one represented by the composition formula Cr(H3-3 / nPO4)n (wherein n is a number satisfying 2<=n<=3). The chromium nitrate is preferably a basic chromium nitrate represented by the composition formula Cr(OH)x(NO3)y (wherein 0<x<=2, 1<=y<3, and x+y=3).

Owner:NIPPON CHECMICAL IND CO LTD

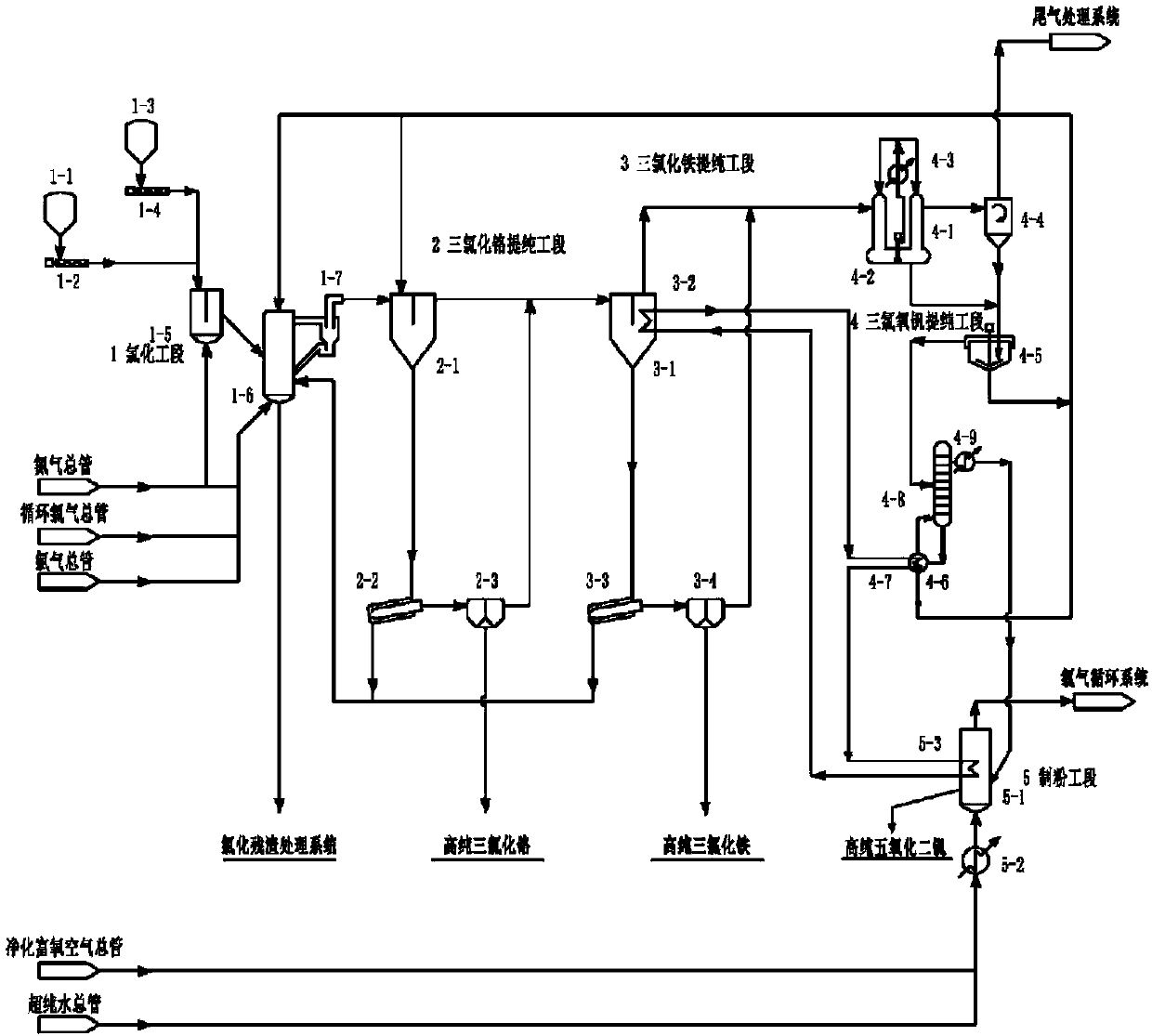

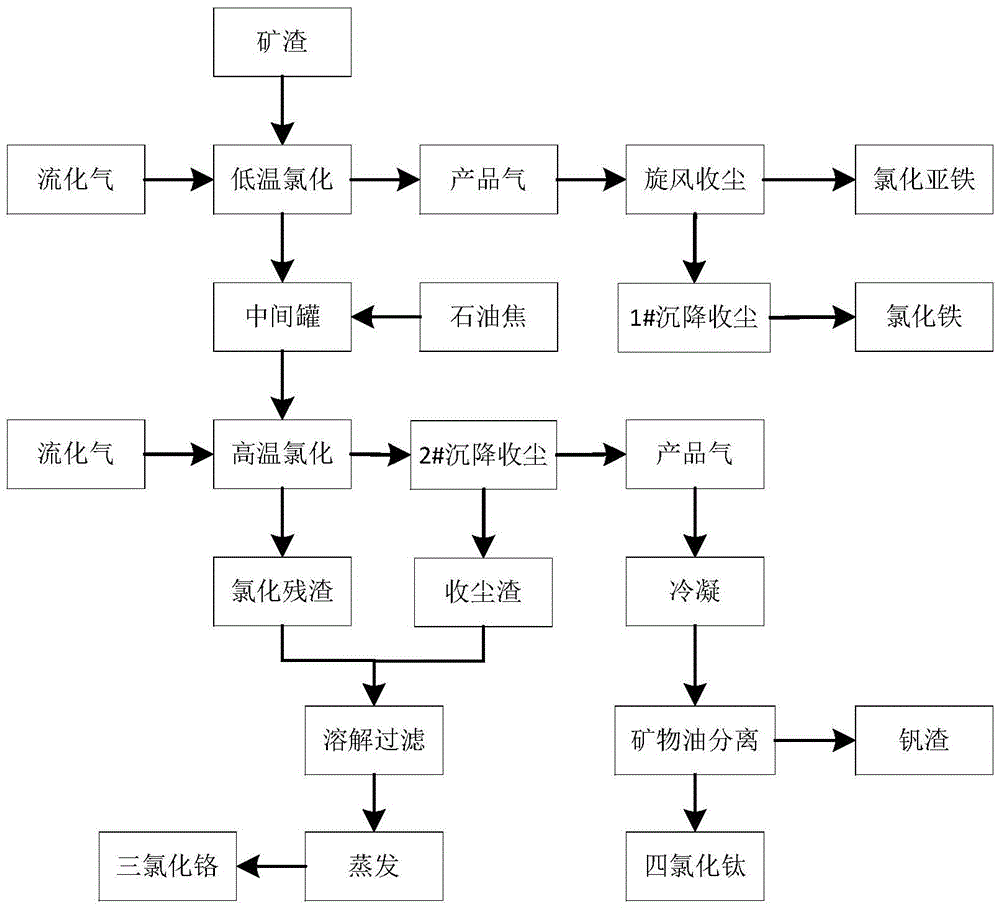

Purification process of mineral slag by chlorination process

ActiveCN105217682AEfficient separationRich ways to useTitanium tetrachlorideChromium halidesSlagMaterials science

The invention discloses a purification process of mineral slag by a chlorination process. The process comprises the following steps: carrying out low-temperature chlorination and recovering a solid product after reaction through a cyclone separation device; recovering a gaseous product through a first dust collector; carrying out high-temperature chlorination and recovering the gaseous product after reaction through a condenser; and settling the solid product after reaction through a second dust collector to form dust collecting slag. According to the process disclosed by the invention, elements in associated lean ores can be effectively separated to obtain a required corresponding product, so that the utilization mode of lean ore resources is enriched. According to the process disclosed by the invention, a chromium trichloride product of an industrial grade can be obtained, so that a problem of treating chromium slag after extraction of resources is avoided.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Process for producing anhydrous chromium chloride and chromium oxide green from ferrochrome through boiling chlorination

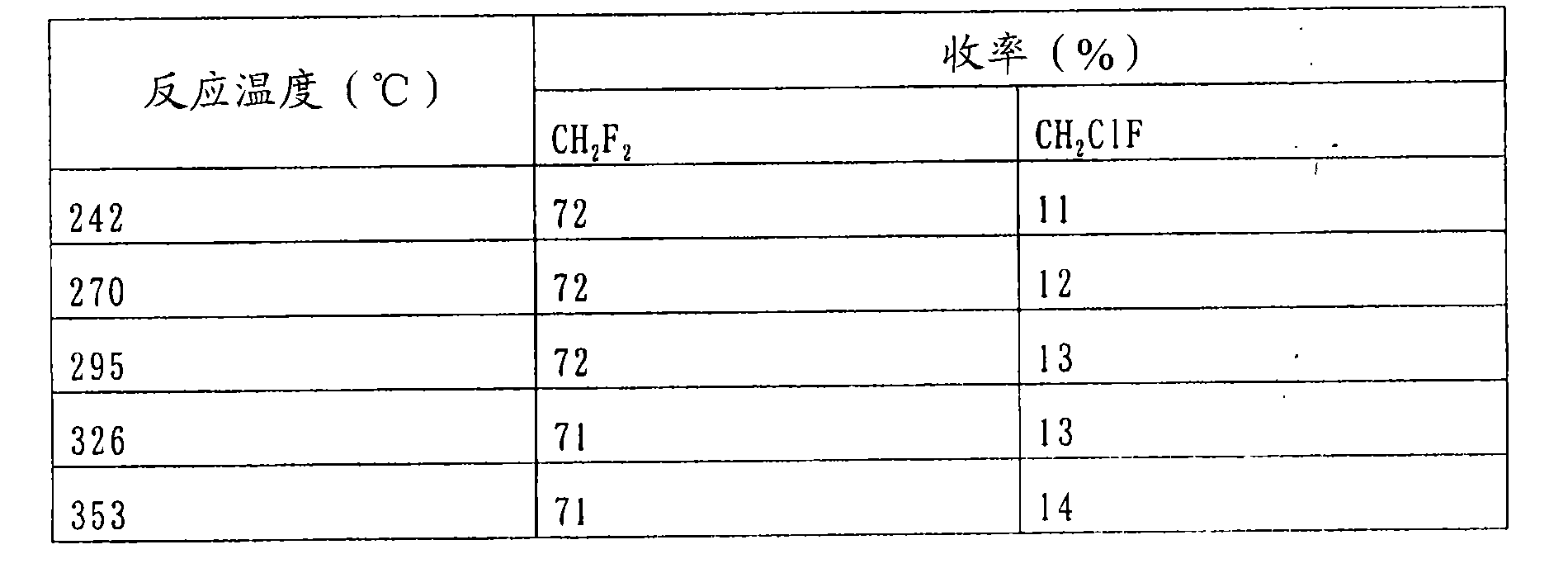

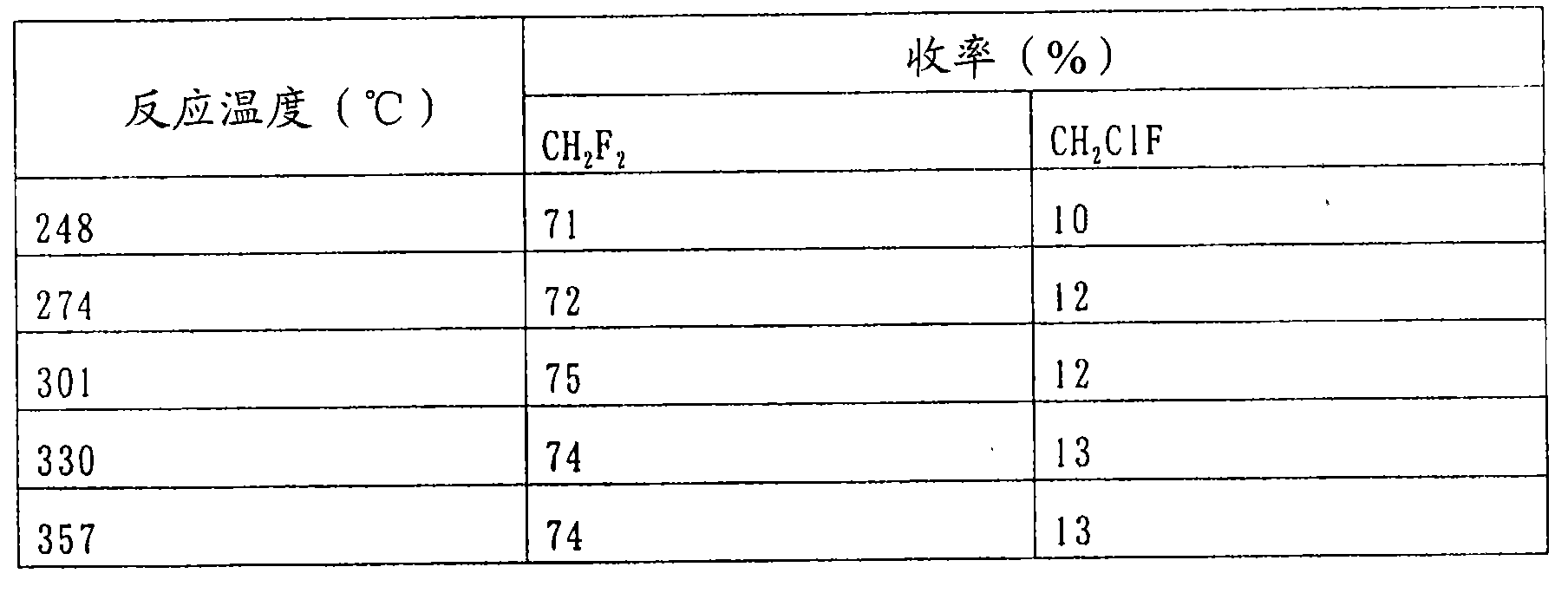

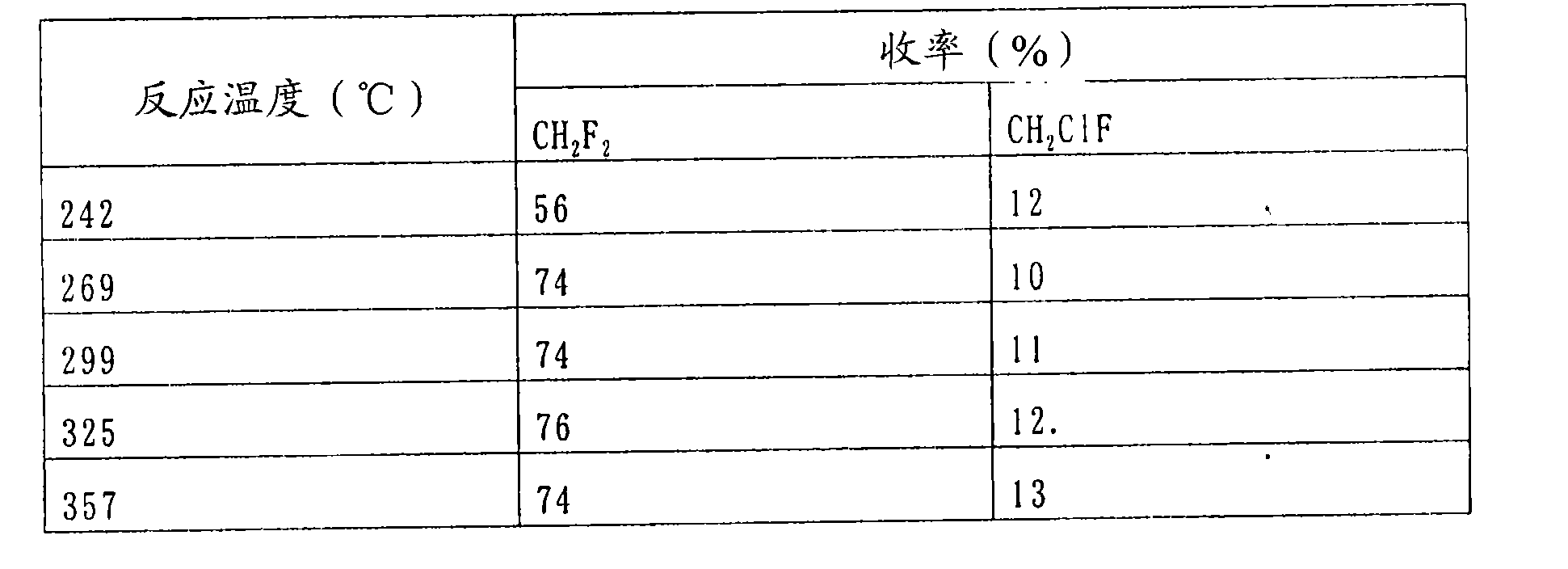

InactiveCN107840367ASolve pollutionShort production processChromium halidesIron halidesReaction temperatureChloride

The invention discloses a process for producing anhydrous chromium chloride and chromium oxide green from ferrochrome through boiling chlorination, belonging to the technical field of production methods for chromium salts. The process comprises the following steps: crushing ferrochrome and a heat supplementing agent, fully mixing the crushed ferrochrome with the crushed heat supplementing agent inproportion, adding the obtained mixture into a boiling chlorination furnace, introducing chlorine for a chlorination reaction with a temperature maintained at 850 to 1050 DEG C so as to produce anhydrous chromium chloride and iron chloride, and separating chromium chloride from iron chloride by controlling the temperature of a condenser; and refining and purifying chromium chloride so as to obtain purified chromium chloride used as a chromium-series chemical raw material, or calcining chromium chloride at a high temperature of 950 to 1100 DEG C to produce chromium oxide green. The process provided by the invention fundamentally changes conventional production process routes for chromium salts, shortens process flow, improves product quality, reduces production and manufacturing cost, doesnot produce Cr<6+> in the whole production process, thoroughly overcomes the problem of pollution caused by Cr<6+>, completely meets national industrial policies in China, is a typical novel clean production process and is easy to promote and apply.

Owner:中成致远有限公司

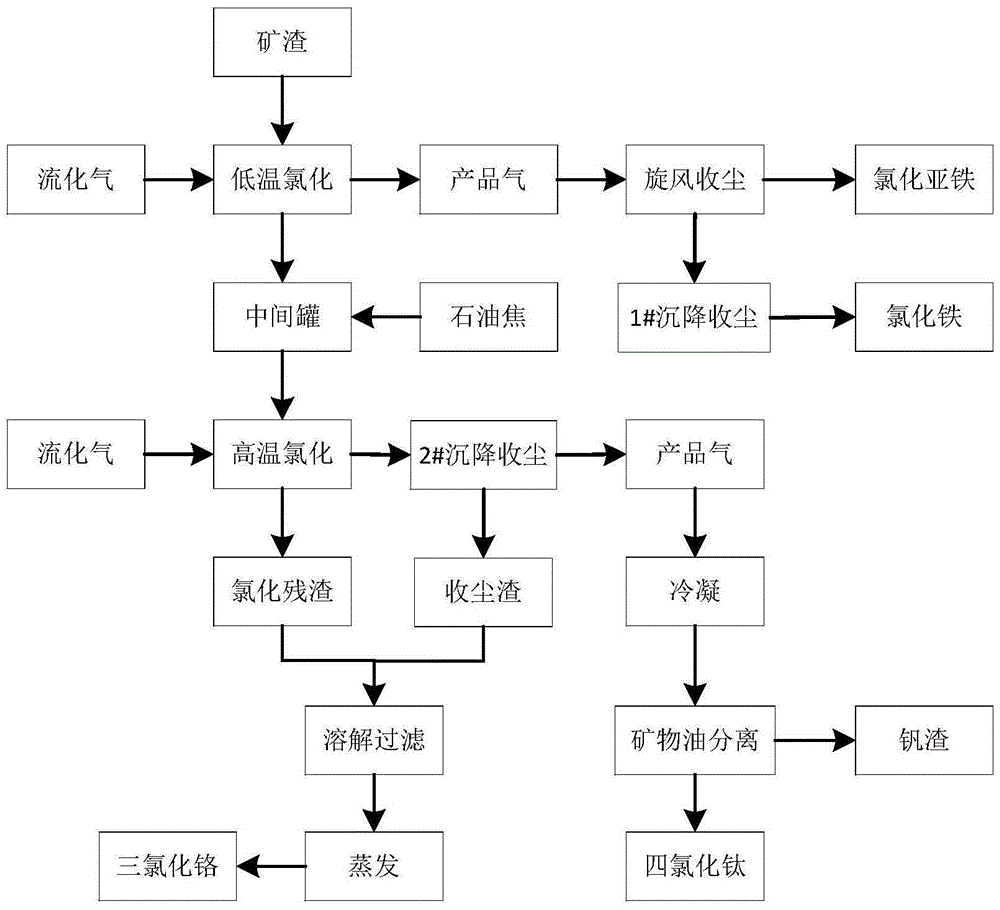

Recycling technology for sludge in aluminum profile processing

ActiveCN110066080ASolve processing problemsReduce pressure on environmental protectionSludge treatmentNickel compounds preparationMetallic aluminumSludge

The invention provides a recycling technology for sludge in aluminum profile processing. The recycling technology comprises the steps of slurry mixing, wherein the sludge generated in aluminum profileprocessing is subjected to acid leaching and filter pressing to obtain a filtrate and filter residues; extraction, wherein the filtrate is extracted, extraction can be divided into one-stage extraction and cascade-stage extraction, and after extraction, a loaded organic phase and a final raffinate are obtained; reverse extraction, wherein the loaded organic phase is subjected to reverse extraction, and an aluminum chloride solution, a nickel chloride solution and a chromium chloride solution are guided out at different positions of a reverse extraction system. By means of the recycling technology for the sludge in aluminum profile processing, the sludge is recycled into a chemical product, metallic aluminum in the sludge is converted into the aluminum chloride solution, metallic nickel isconverted into the nickel chloride solution, metallic chromium is converted into the chromium chloride solution, and after cascade-stage extraction and reverse extraction, the recycling rate of aluminum-nickel-chromium ions in the sludge can reach 99%.

Owner:广东兴发环境科技有限公司

Porous material and method for producing the same

InactiveCN1798703BExcellent fluorination catalytic abilityHigh porosityMagnesium fluoridesCobalt halidesHydrogen fluoridePtru catalyst

A material composition is disclosed which is preferably used for synthesizing a porous metal fluoride which has a large surface area and is stable in a corrosive environment. A porous metal fluoride obtained by subjecting such a material composition to hydrogen fluoride treatment has a larger surface area and is stable in a corrosive environment, and thus can be used as a fluorination catalyst.

Owner:权恒道

Production method for coproduction of chromium chloride and chromic carbonate

The invention discloses a production method for the coproduction of chromium chloride and chromic carbonate, and the production method is used for solving the problems that the chromic carbonate produced through the existing method is easy to age, and the solubility of the chromic carbonate in acidic aqueous solutions is greatly reduced after the chromic carbonate is subjected to long-term storage. According to the production method, an alkaline solution of sodium chromate is taken as a raw material, sulfur and alkali sulfide are taken as reducing agents to be subjected to redox reaction in a reaction tank so as to obtain chromic hydroxide, the obtained chromic hydroxide is filtered and washed and then reacts with hydrochloric acid to produce the chromium chloride, and the chromic carbonate is produced in a manner that the chromium chloride is subjected to the precipitation of a soda solution. The production method has the advantages that the process flow is short, the operation is simple, the redox reaction is complete, the chromium yield is high, and hexavalent chromium is not detected in the filtrate, so that the pollution to the environment cannot be caused.

Owner:GANSU JINSHI CHEM

Chlorination purification process of slag

ActiveCN105217682BEfficient separationRich ways to useTitanium tetrachlorideChromium halidesSlagCyclonic separation

The invention discloses a purification process of mineral slag by a chlorination process. The process comprises the following steps: carrying out low-temperature chlorination and recovering a solid product after reaction through a cyclone separation device; recovering a gaseous product through a first dust collector; carrying out high-temperature chlorination and recovering the gaseous product after reaction through a condenser; and settling the solid product after reaction through a second dust collector to form dust collecting slag. According to the process disclosed by the invention, elements in associated lean ores can be effectively separated to obtain a required corresponding product, so that the utilization mode of lean ore resources is enriched. According to the process disclosed by the invention, a chromium trichloride product of an industrial grade can be obtained, so that a problem of treating chromium slag after extraction of resources is avoided.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for synthesis of lactic acid and its derivatives and catalyst for preparing same

ActiveUS20150329458A1Cheap preparationImprove reaction speedCobalt halidesCarboxylic acid esters preparationPolymer scienceAlcohol

The present disclosure provides a catalyst for preparing lactic acid and derivatives thereof, comprising at least one of metallic compounds MXn, wherein M is selected from Na, K, Mg, Ca, Sr, Ba, Al, Ga, In, Sn, Sb, Bi, Cr, Mn, Fe, Co, Ni and Zn, and n is an integer of 1 to 6. The present disclosure further provides a method for synthesis of lactic acid and derivatives thereof, wherein at least one raw material including carbohydrates, at least one alcohol, at least one of the aforesaid catalysts and at least one solvent are heated to react to prepare lactic acid and derivatives thereof.

Owner:MICROVAST POWER SYST CO LTD

Manufacture of new energy battery materials and new energy hydrogen process by carbon ferrochromium liquid phase method

The invention relates to a carbon ferrochrome liquid phase method for manufacturing new energy battery materials and new energy hydrogen technology. The invention has advanced technology, energy saving and environmental protection, and does not require coal burning and high temperature and pressure. New energy, a variety of new energy battery materials, pigments and chemical chromium salts and other products have formed a series of new high-end industrial chains, which have changed the original situation of single-purpose products and simple production, greatly enhanced the international competitiveness of enterprises, and promoted The optimization, upgrading and development of the national industry is of great significance.

Owner:唐翔

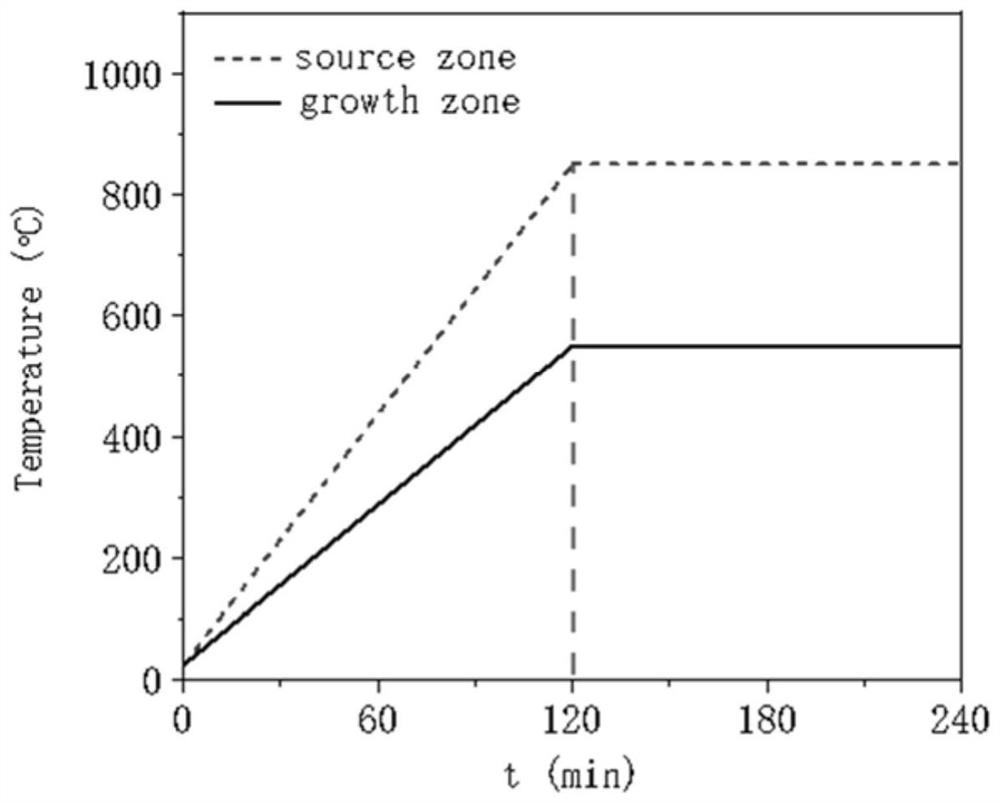

Single-layer CrI3 sheet prepared based on chemical vapor transport and method

PendingCN114735751AImprove production efficiencyConducive to the realization of industrialization dueChromium halidesPhysical chemistryFerromagnetism

The invention discloses a single-layer CrI3 sheet prepared on the basis of chemical vapor transport and a method, belongs to the technical field of two-dimensional ferromagnetic materials, and solves the technical problems of high preparation environment requirements, high experiment cost, low efficiency, small size and the like during preparation of single-layer CrI3 at present. According to the method for preparing the single-layer CrI3 sheet based on chemical vapor transport, the Cr raw material, the crystallized iodine powder and the transport agent powder are used for preparing the single-layer CrI3 sheet with the large area through the program control temperature condition, and the method has the advantages of being few in related materials, easy to operate, high in efficiency, low in cost and capable of achieving large-scale production in the preparation process. The single-layer CrI3 sheet prepared by the method is large in area, high in purity and wide in application range.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for improving quality of industrial chromic chloride

ActiveCN103130280BImprove qualityGood effect in removing impurity metal ionsChromium halidesFiltrationChloride

The invention relates to a method for improving the quality of industrial chromic chloride. The method comprises the following steps: adding industrial chromic chloride as a raw material into high purity water for dissolving; carrying out membrane filtration on a dissolving solution by a modified kynoar polyvinylidene fluoride membrane to obtain a filtrate in which metal ion impurities are removed; removing water and cooling under normal pressure; drying a separated crystal to obtain chromic chloride with improved quality. Through detection, the purity of chromic chloride reaches 99.5% or more and meets the quality standard of HG3-935-81. The method is good in effect of removing the metal ion impurities, and an obtained chromic chloride product has stable quality and is suitable for industrial production.

Owner:SINOPHARM CHEM REAGENT

Method for preparing chromium chloride hexahydrate by using sodium chromate

ActiveCN110817960AAvoid it happening againLarge crystalsChemical industryChromium halidesChromium(III) hydroxideWater chlorination

The invention discloses a method for preparing chromium chloride hexahydrate by using sodium chromate. The method comprises the following processes: dissolving sodium chromate into a certain amount ofhydrochloric acid A; heating to boil, acidifying, filtering undissolved sodium chloride, and pumping hydrochloric acid B and a reducing agent which are uniformly mixed according to a certain proportion while stirring the filtrate; after the reaction is completed, carrying out evaporation concentration, concentrating to Baume degree A; and carrying out secondary filtration to remove precipitated sodium chloride, supplementing water to Baume degree B, cooling to a temperature A, crystallizing, precipitating chromium chloride hexahydrate crystals, and centrifuging to obtain a chromium chloride hexahydrate finished product. According to the method, hydrochloric acid is used for acidification, so that generation of a byproduct mirabilite in a traditional chromic anhydride process is avoided; compared with mirabilite, the byproduct sodium chloride of the method has larger crystal particles and chromium is easy to wash, and in addition, an alkaline substance is not required to be added to adjust the pH to prepare chromium hydroxide, so that the alkaline substance is not required to be consumed and washed, the comprehensive recovery value is realized, and the production cost of productionenterprises is reduced.

Owner:SICHUAN YINHE CHEM

A system and method for producing high-purity energy storage materials for flow batteries from high-chromium vanadium slag

ActiveCN109835948BReduce overflowImprove chlorination efficiencyRegenerative fuel cellsEnergy inputElectrical batteryCatalytic oxidation

The invention discloses a system and a method for producing a high-purity energy storage material for liquid flow batteries by using high chromium type vanadium residue. According to the present invention, through selective chlorination in a circulating fluidized bed, vanadium, chromium and iron in high chromium vanadium residue are converted into corresponding gaseous chlorides, and most of impurities such as manganese, titanium, silicon and the like in the vanadium residue are remained in the chlorinated residue so as to separate the valuable elements from other impurities; the gaseous chloride is subjected to high temperature dust collection to separate crude chromium trichloride, is subjected to medium temperature dust collection to separate crude ferric chloride, and is subjected to low temperature leaching to separate crude vanadium oxytrichloride; the crude chromium trichloride is subjected to volatilization purification to obtain high-purity chromium trichloride; the crude ferric chloride is subjected to volatilization purification to obtain high-purity ferric chloride; the crude vanadium oxytrichloride is subjected to rectification purification and catalytic oxidation to obtain high-purity vanadium pentoxide powder; and with the system and the method, the high-value comprehensive utilization of the high chromium type vanadium residue is achieved, and the high-purity energy storage material for liquid flow batteries is obtained through the one-step chlorination multi-stage recovery method.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

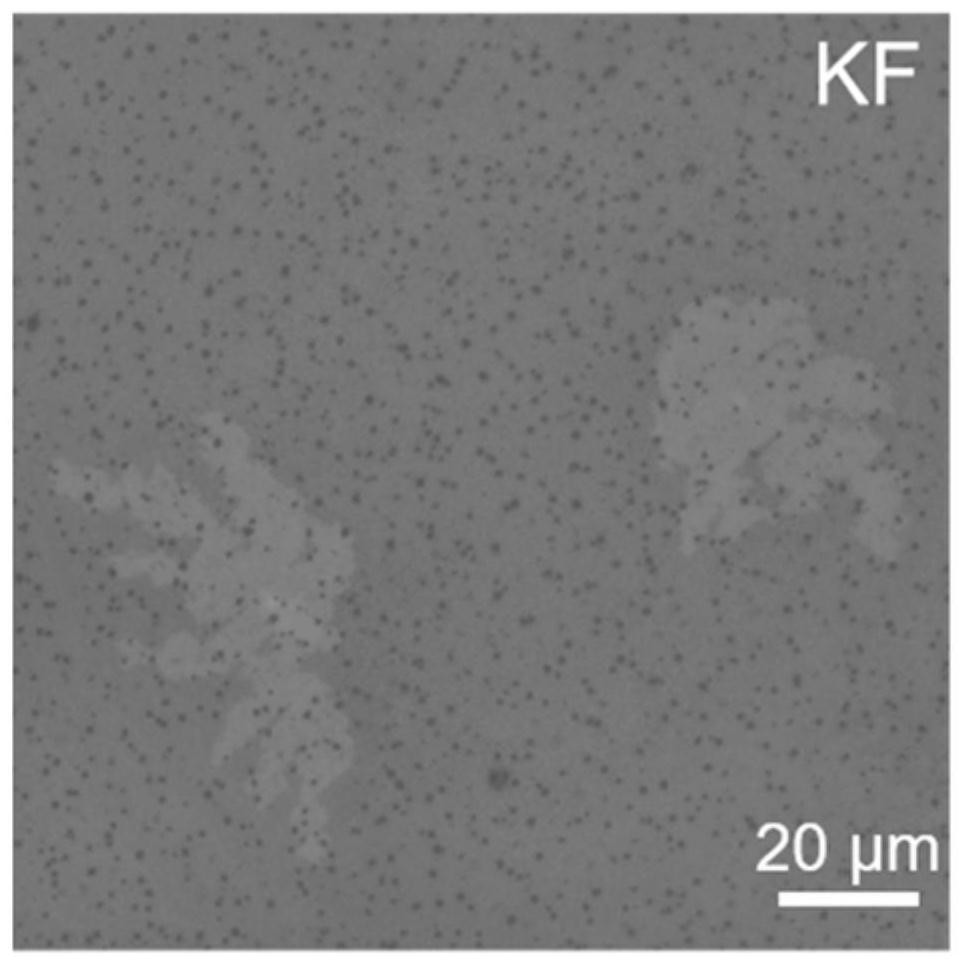

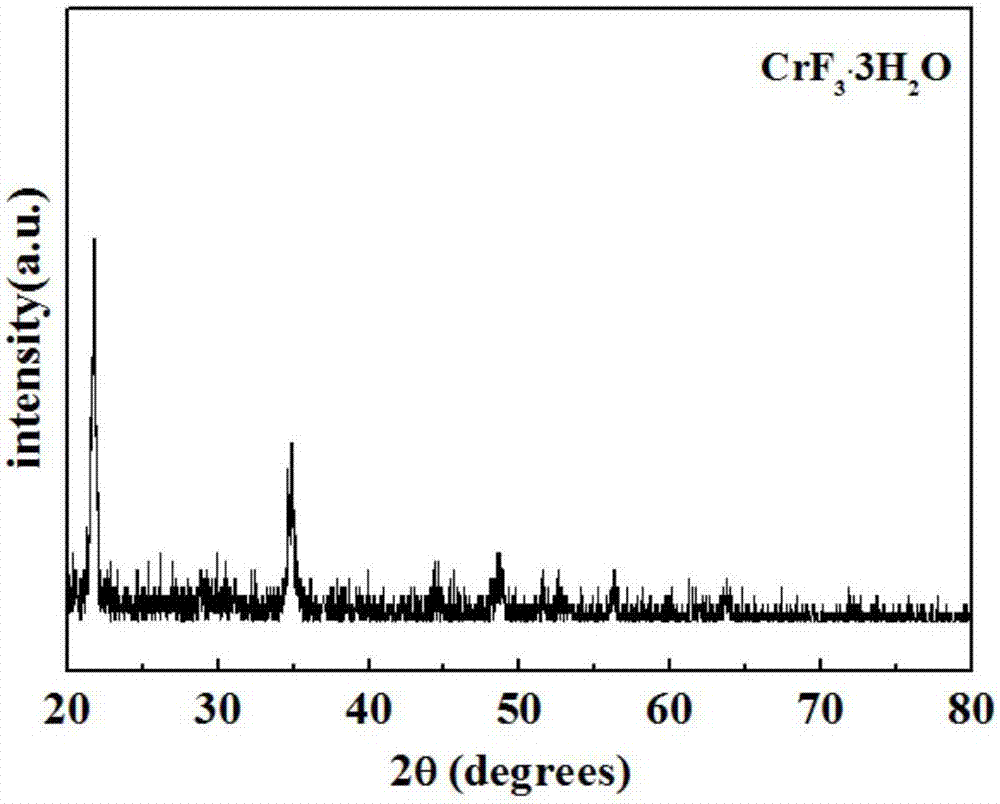

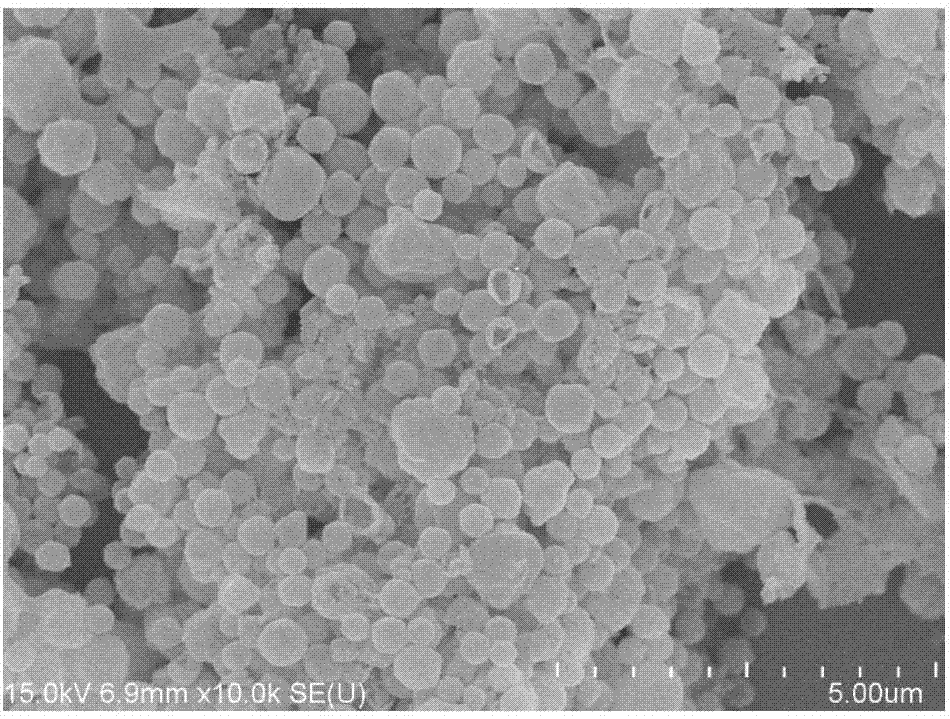

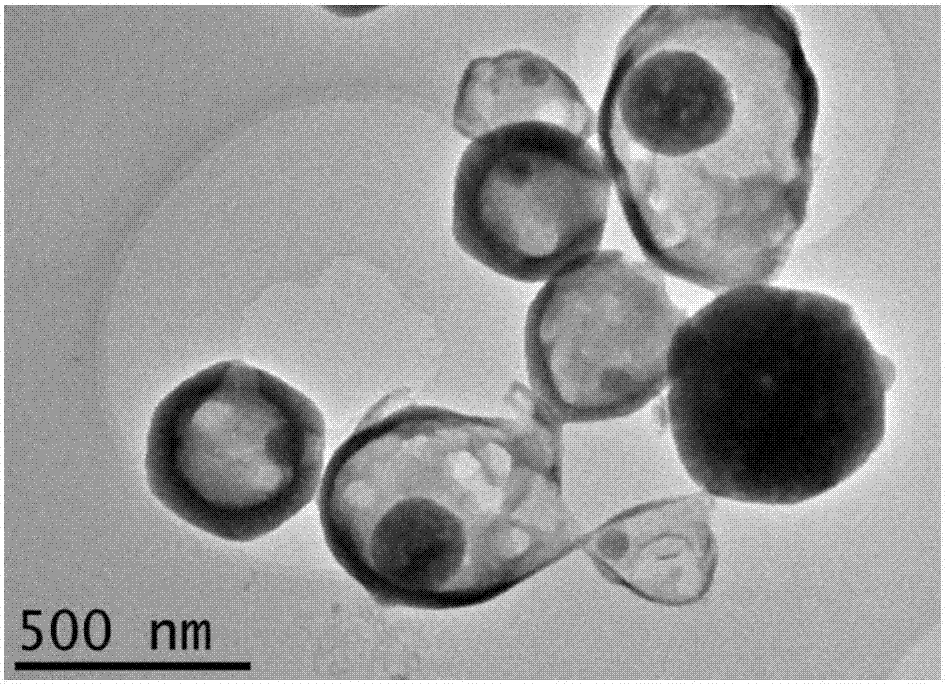

Preparation method of yolk-shell-structured CrF3.3H2O

The invention relates to a preparation method of yolk-shell-structured CrF3.3H2O, belonging to the field of functional nanomaterials. The preparation method comprises the following process flows: (1)respectively preparing a microemulsion from CrCl3.6H2O, a surfactant, a cosurfactant, octane and deionized water and a microemulsion from KF.2H2O, a surfactant, a cosurfactant, octane and deionized water in certain proportions; (2) carrying out ultrasonic treatment on the two prepared microemulsions for 5-30 minutes, continuously stirring for 5-30 minutes, and adding a KF.2H2O solution into CrCl3.6H2O, and stirring to react for 5-120 minutes; and (3) after the reaction is finished, adding a mixed solution of trichloromethane and methanol, and centrifuging and washing green precipitates generated in a beaker, so as to obtain yolk-shell-structured CrF3.3H2O spherical particles. According to the preparation method, the yolk-shell-structured CrF3.3H2O spherical particles can be prepared by controlling the reaction conditions, the process is simple, the method is novel, the production period is short, the dispersity of power is good, and the preparation method can be popularized in a largescale.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com