Recycling technology for sludge in aluminum profile processing

An aluminum profile processing and sludge technology, applied in the field of sludge resource recycling process, can solve the problems of limited commission, waste of aluminum resources, occupation of land, etc., and achieve the effect of solving processing problems, reducing environmental protection pressure, and reducing environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

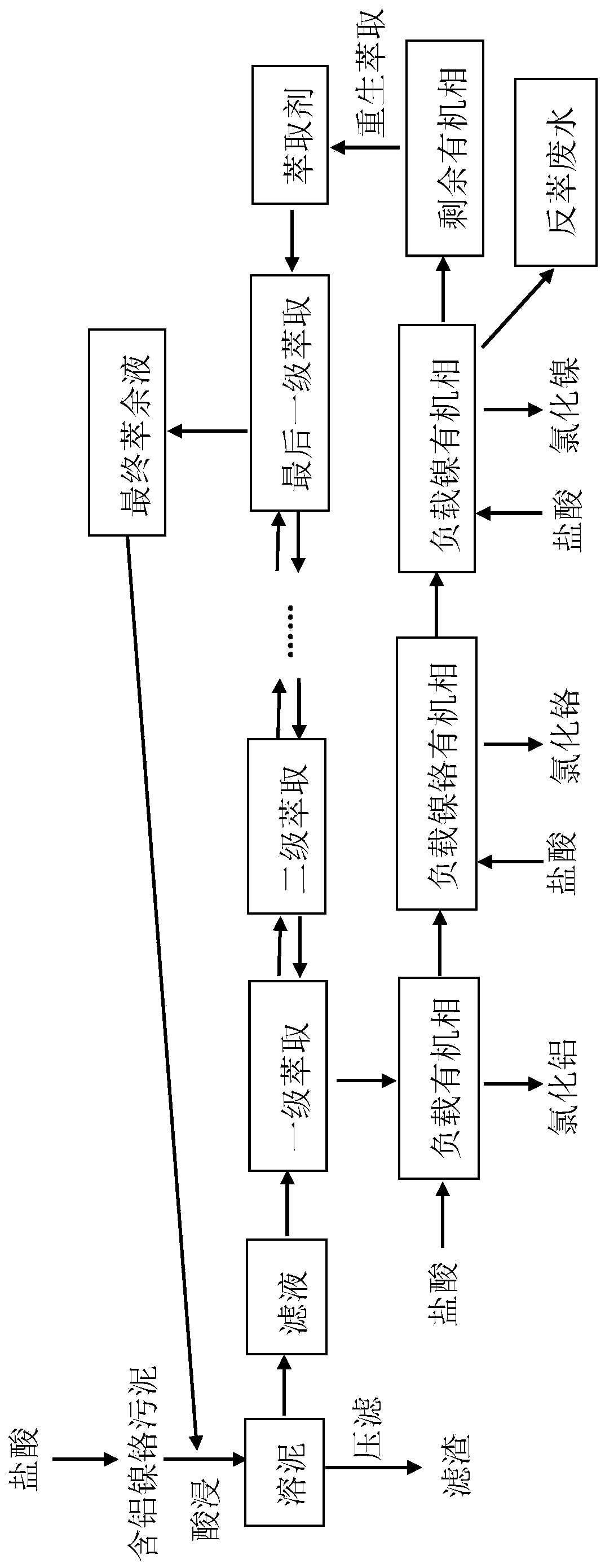

[0044] The invention provides a process for recycling sludge in the processing of aluminum profiles. Since the waste liquid containing nickel, chromium, aluminum and other metals in the process of aluminum profile processing is all made into mud after the process is produced, and the waste liquid containing metals to be recovered is made into sludge. After the sludge is formed, it is convenient to collect and transport, so the present invention uses sludge containing nickel, chromium and aluminum as the initial raw material of the process. Heavy metal ions in nickel-chromium-aluminum sludge exist in the form of hydroxide or carbonate. When the pH>2, the metal ions dissolve, so the dissolution process uses acid to dissolve the metal ions. Therefore, before the extraction, the sludge needs to be mixed and dissolved with hydrochloric acid + raffinate wastewater to adjust the slurry, and then the initial filtrate is obtained after pressure filtration, and then introduced into the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com