Porous material and method for producing the same

A manufacturing method and porosity technology, applied in the field of raw material composition for the synthesis of porous metal fluorides, can solve the problems of pore structure damage and unstable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Sodium silicate (Na 2 SiO 3 , 3g) was dissolved in 28% ammonia water (114ml), and was added into chromium trichloride aqueous solution (about 10% chromium content, 240g) while vigorously stirring. The pH after mixing is about 7. The precipitate was filtered and taken out, washed with deionized water, dried, and fired in a nitrogen atmosphere at 450° C. to obtain a chromium salt of a silicon-containing precursor. The specific surface area measured by BET method is 366m 2 / g.

Embodiment 2

[0060] The precursor prepared in Example 1 was treated with nitrogen-diluted hydrogen fluoride (hydrogen fluoride / nitrogen=1 / 3) at room temperature for 4 hours, then the temperature was raised, and finally, only hydrogen fluoride was used at 350°C to obtain a porous Chromium fluoride. The specific surface area measured by BET method is 176m 2 / g.

Embodiment 3

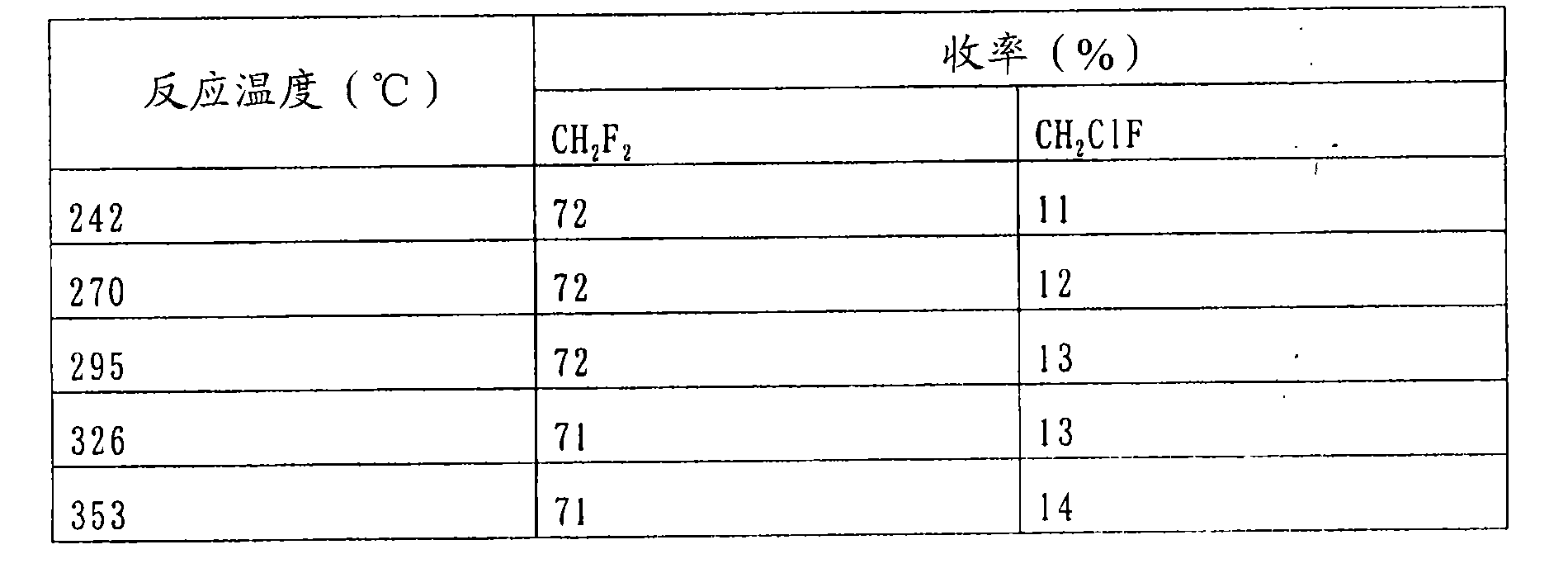

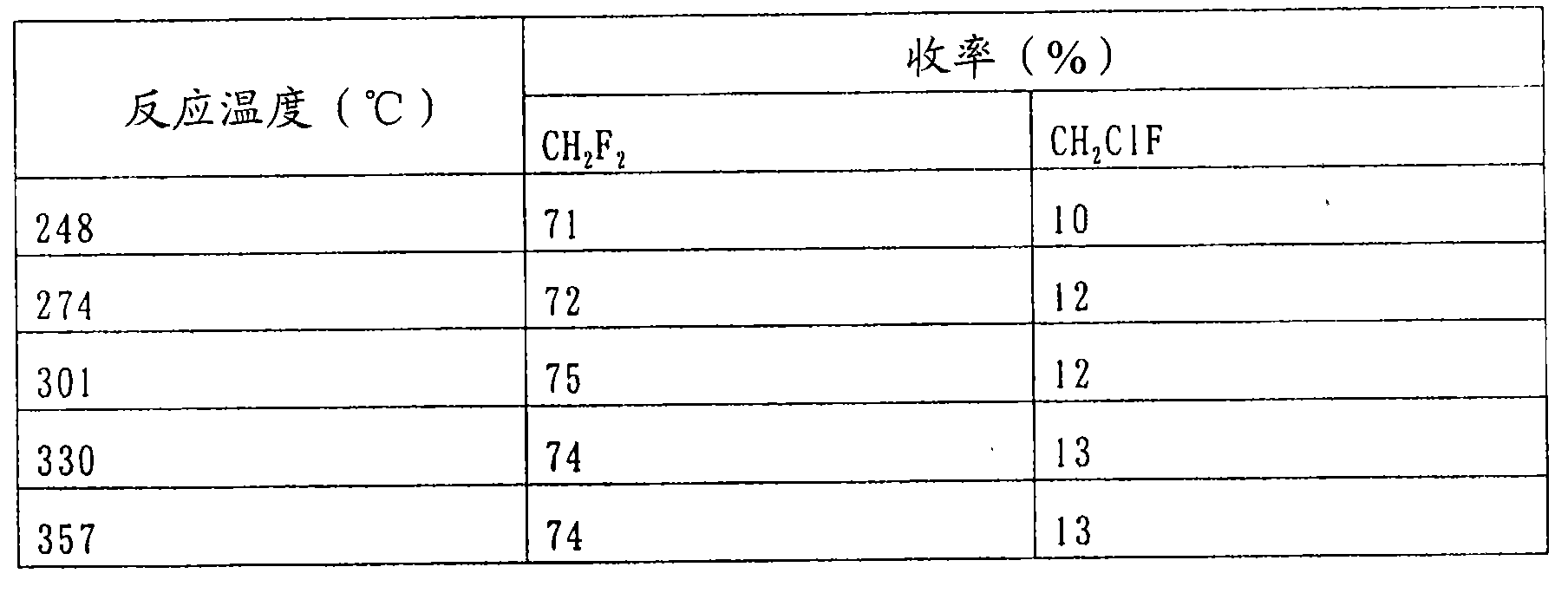

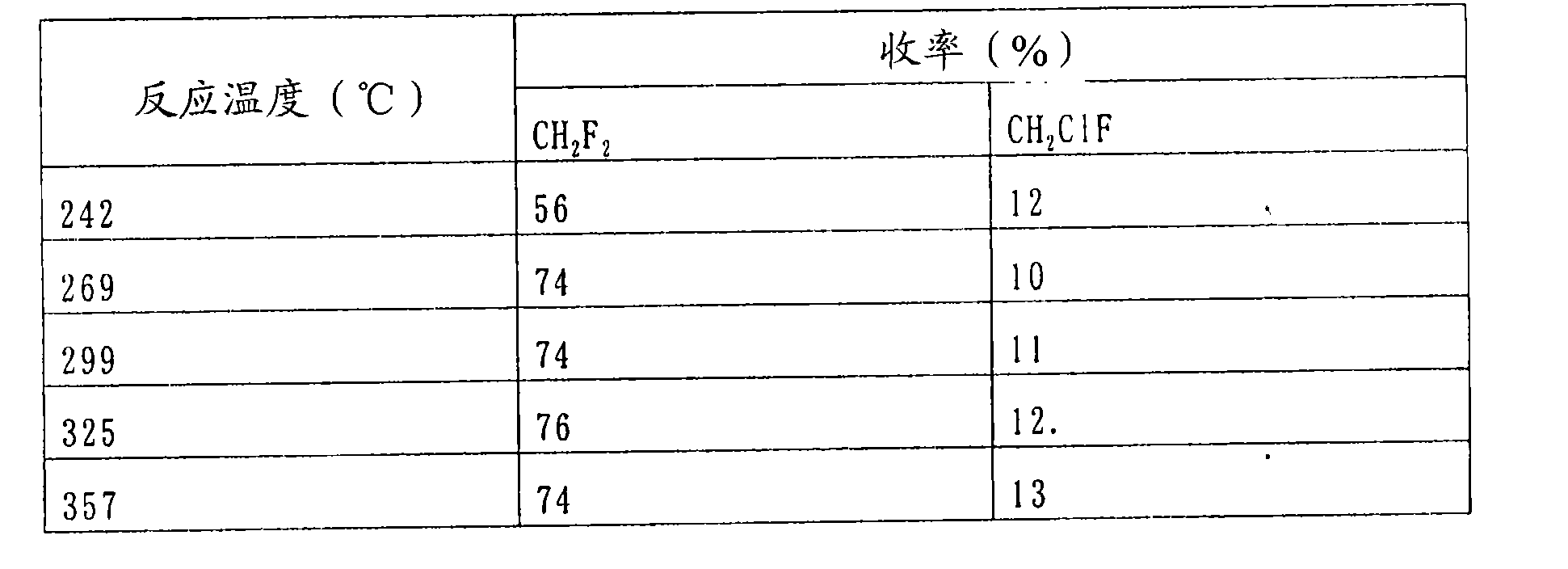

[0062] The porous chromium fluoride prepared in Example 2 was used as a catalyst for gas-phase fluorination of dichloromethane. Gasify dichloromethane (0.3g / min) and anhydrous hydrogen fluoride (300ml / min), react in the presence of a catalyst, wash the product with water, dry it with soda lime, and analyze it with gas chromatography. Difluoromethane (CH 2 f 2 ) and chlorofluoromethane (CH 2 The yield of CIF) is shown in Table 1.

[0063] 【Table 1】

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com