Purification process of mineral slag by chlorination process

A chlorination method, slag technology, applied in the direction of titanium tetrachloride, chemical instruments and methods, titanium halide, etc., can solve problems such as inability to directly stack, increase post-treatment costs, and unutilized vanadium, titanium and chromium resources. , to avoid dealing with problems and enrich the way of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0026] Any feature disclosed in this specification (including any appended claims, abstract and drawings), unless expressly stated otherwise, may be replaced by alternative features which are equivalent or serve a similar purpose. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

[0027] The specific implementation manners of the present invention will be described in detail below in conjunction with the drawings and embodiments.

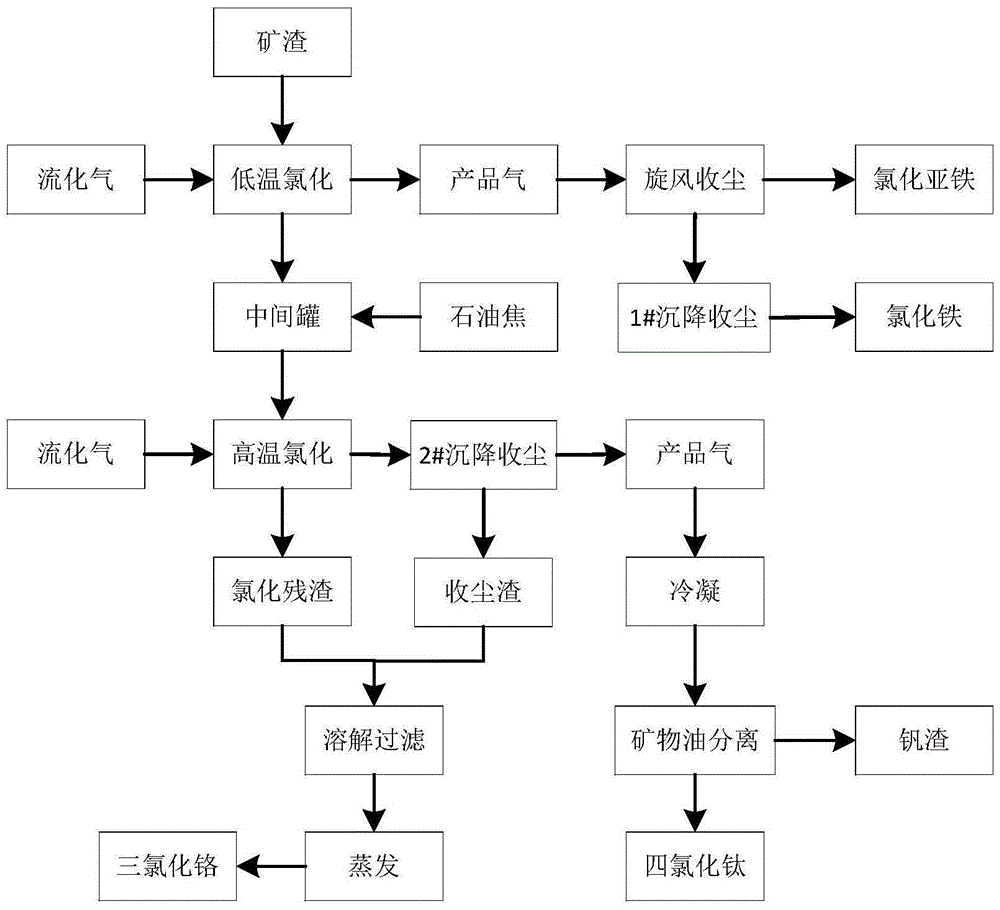

[0028] Such as figure 1 As shown, the chlorination purification process of slag in the embodiment of the present invention provides a chlorination production process to obtain vanadium, chromium, iron and titanium resources therein. The main objects of action are the Hongge ore veins in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com