Patents

Literature

34results about How to "Rich ways to use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

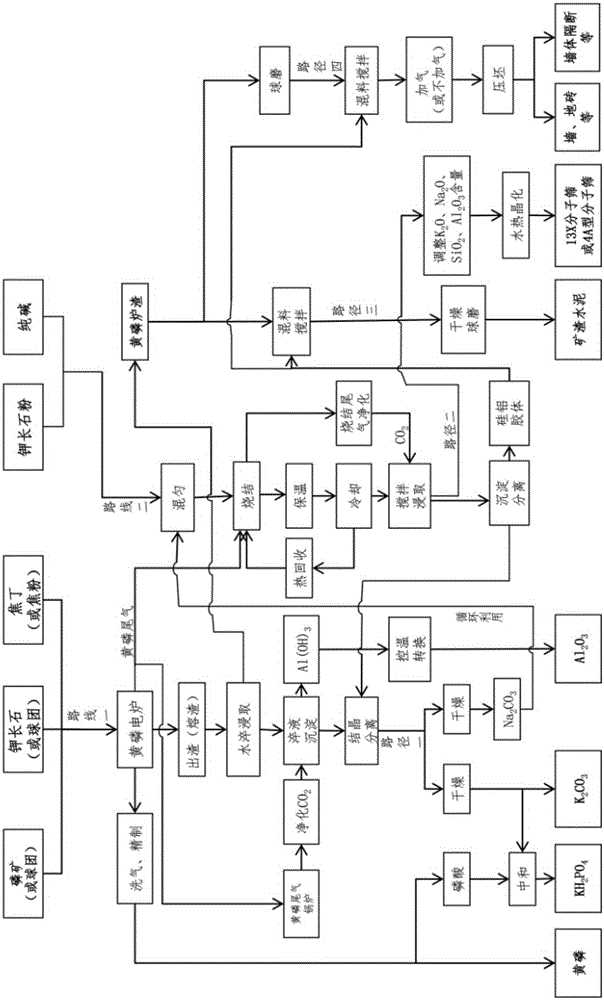

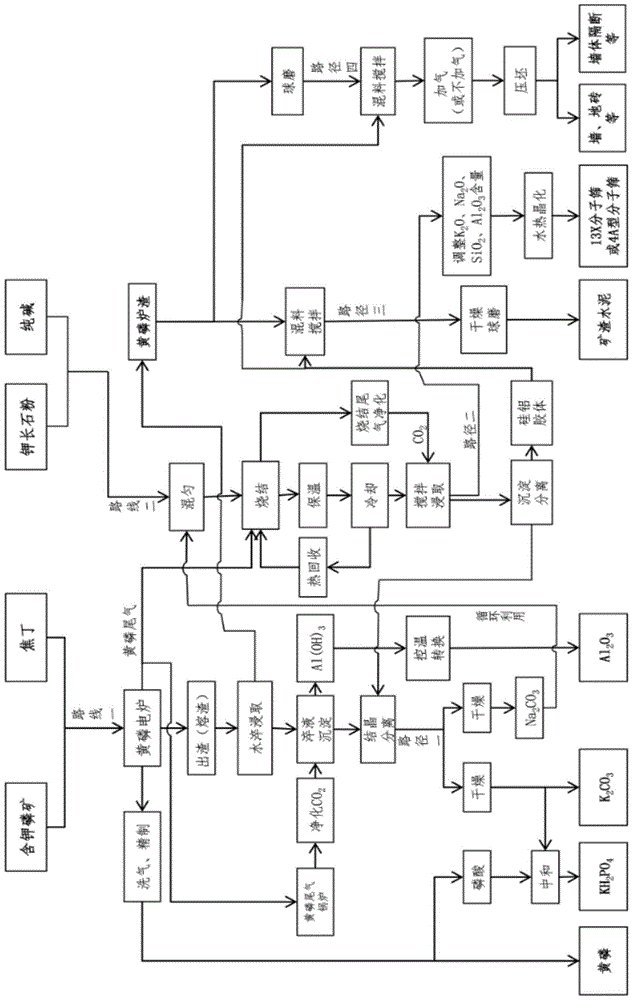

Circular clean production method for yellow phosphorus with co-production of potassium salt, aluminium oxide, molecular sieve, blast furnace slag cement and architectural profile

ActiveCN105217588AConsumption is not affectedReduce manufacturing costCement productionFaujasite aluminosilicate zeoliteSlagMaterials science

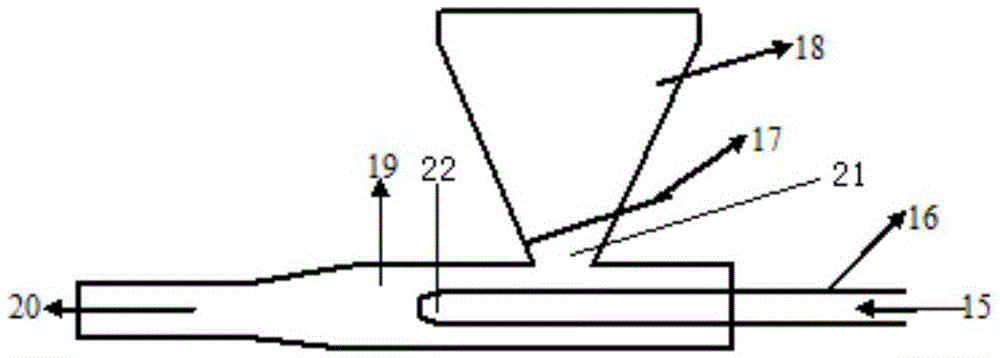

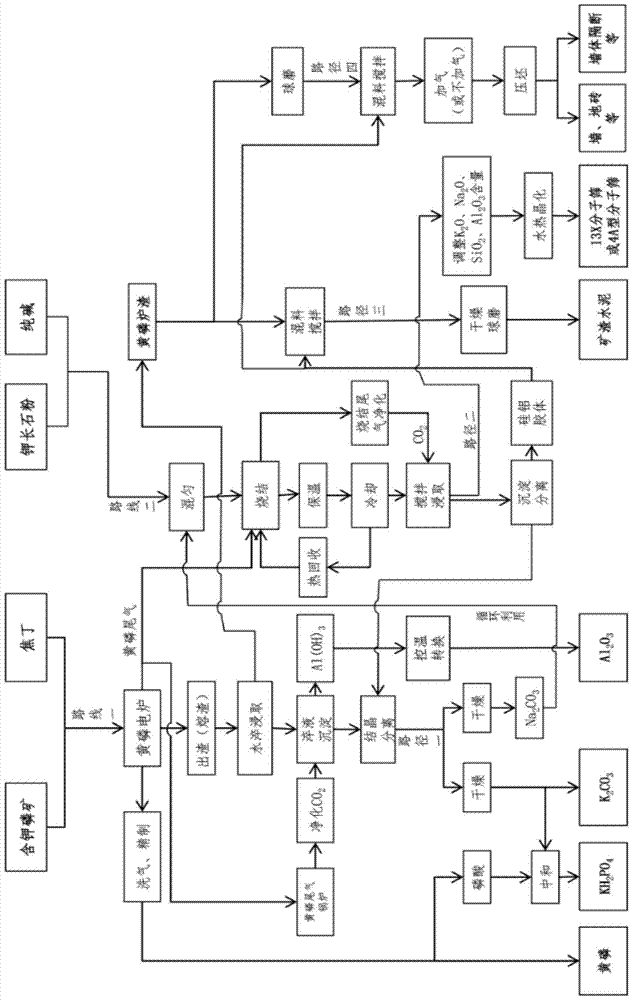

The invention relates to a circular clean production method for yellow phosphorus with co-production of potassium salt, aluminium oxide, a molecular sieve, blast furnace slag cement and an architectural profile. The method comprises two lines: 1, replacing externally added silica by potassium feldspar, and preparing high quality yellow phosphorus with phosphorite and coke nuts by virtue of an electric heating method; quenching yellow phosphorus slag, dissolving out KAlO2, filtering the mixture, introducing CO2, and precipitating Al(OH)3 and preparing a first filtrate; and carrying out temperature-controlled conversion on Al(OH)3 to obtain Al2O3. and 2, uniformly mixing potassium feldspar and Na2CO3, calcining the mixture with yellow phosphorus tail gas, and the leaching the mixture by water, introducing CO2, precipitating a silica-alumina gel body and preparing a second filtrate. then the line is divide into four using paths: (1) crystallizing the first and second filtrates in a centralized manner and drying the first and second filtrates to prepare K2CO3 and Na2CO3, returning Na2CO3 to a line 2 to be recycled, and continuously processing K2CO3 to potassium salt such as KH2PO4 and K2SO4 and the like; (2) carrying out hydrothermal crystallization on the unprecipitated silica-alumina gel body and the filtrate to prepare a molecular sieve; (3) preparing slag cement by the silica-alumina gel body and yellow phosphorus slag; and (4) preparing the architectural profile by the silica-alumina gel body and yellow phosphorus slag.

Owner:黄钰雪

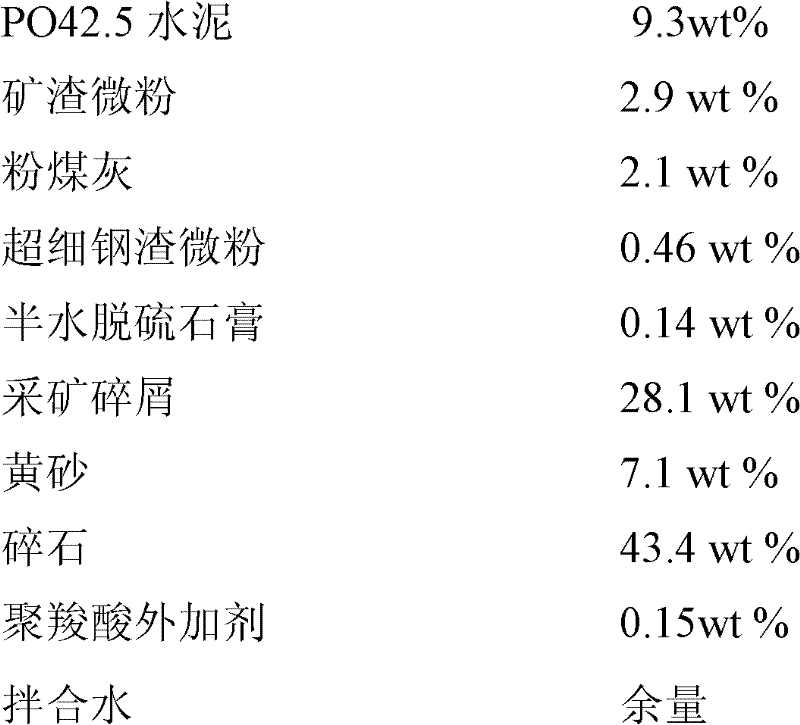

Concrete prepared from industrial solid waste materials

The invention discloses concrete prepared from industrial solid waste materials. The concrete provided by the invention comprises above 30% of industrial solid waste materials and has unit weight of 2335 to 2372kg / m<3>. The concrete provided by the invention is characterized by comprising 8 to 16 wt% of cement PO42.5, 2 to 4 wt% of slag micro-powder, 2 to 4 wt% of fly ash, 0.4 to 0.8 wt% of steel slag micro-powder, 0.1 to 0.2 wt% of semi-hydrated desulfurized gypsum, 27 to 29 wt% of mining scraps, 3 to 9 wt% of yellow sand, 43 to 45 wt% of crushed stones, and the balance mixing water and an additive. The concrete prepared from industrial solid waste materials has low production cost, greatly saves resource materials, has good workability, pumpability, strength and durability, provides a novel approach for solid waste comprehensive utilization, and has obvious social, economic and environmental benefits.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

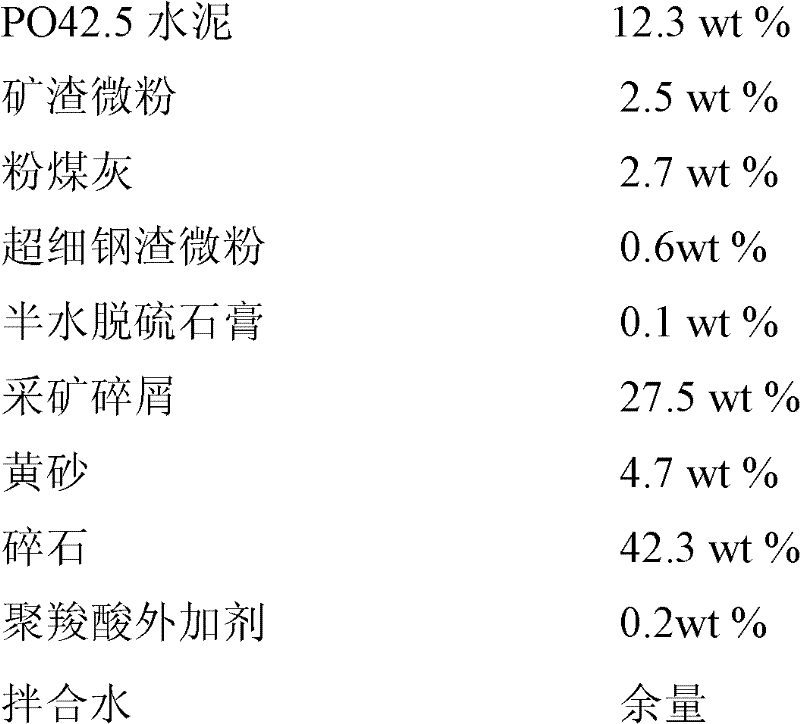

Method for dry-treating municipal sludge by biological dehydrating machinery

InactiveCN1775700AReduce moisture contentLow running costSludge treatment by de-watering/drying/thickeningBiological sludge treatmentSludgeSewage

The invention relates to a method for processing the mud in the city waste water processing factory, including the following steps of: a. mixing the dehydrated mud in the waste water processing factory (moisture content 78%) with mechanically dried mud particles with moisture content of 10% below to make the moisture content down to 50%-55%; b. adding biodehydrating bacterial strains into the biodehyrating tank; c. biochemical raising temperature and reacting for 8-10 days to make the moisture content down to below 35%; d. feeding the biodehydrated city mud with moisture content of below 35% into a mechanical drying system for drying to make the moisture content down to below 10%, returning a part of finished mud particles to mix with wet mud; e. the rest is the final product of the city mud processing and able to be used as fuel and soil modifying agent or is buried finally. The invention largely reduces operating expenses and applies to large scale mud processing and can make multichannel processing according to mud quality.

Owner:TIANJIN CAPITAL ENVIRONMENTAL PROTECTION GRP CO LTD

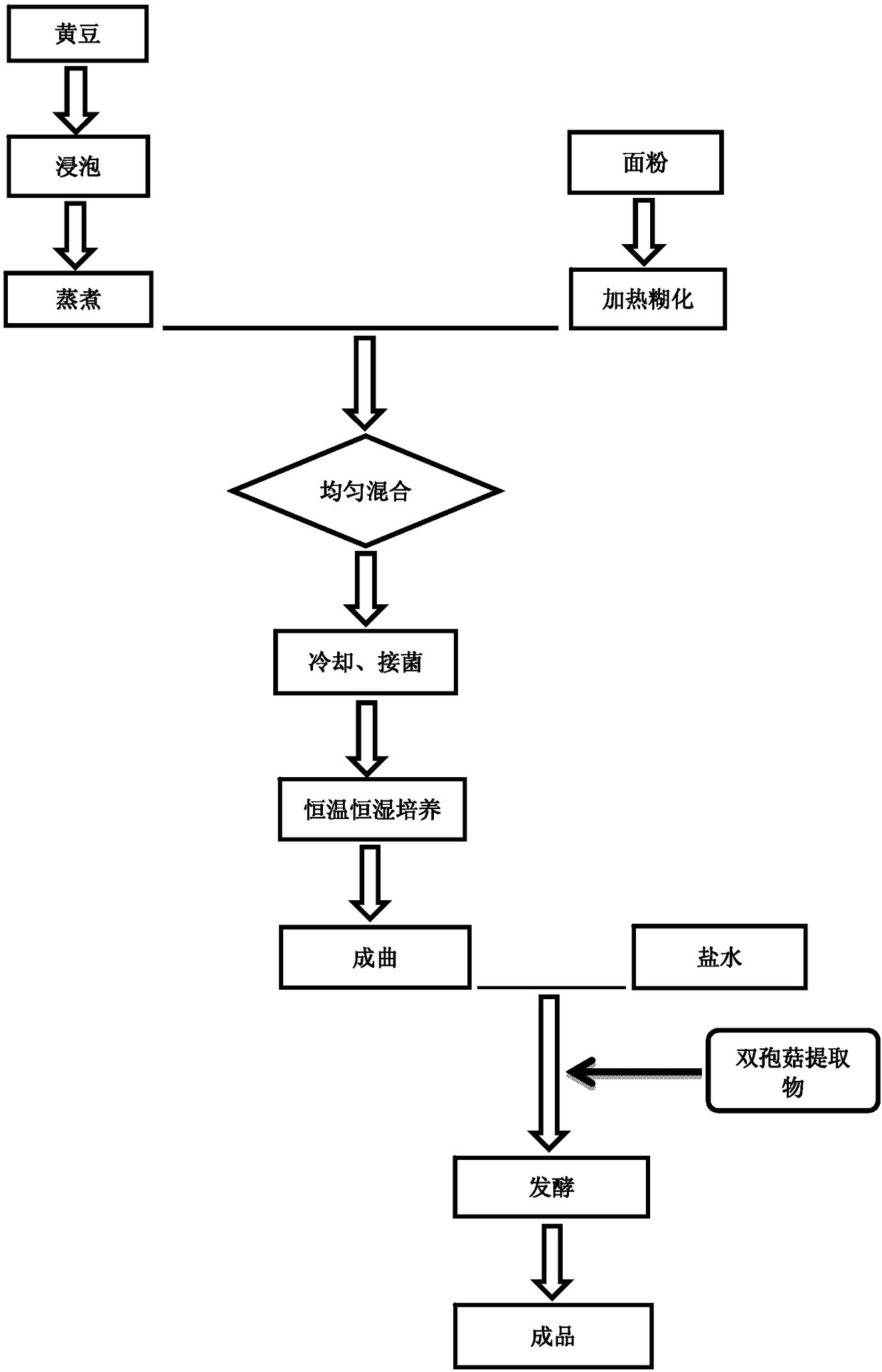

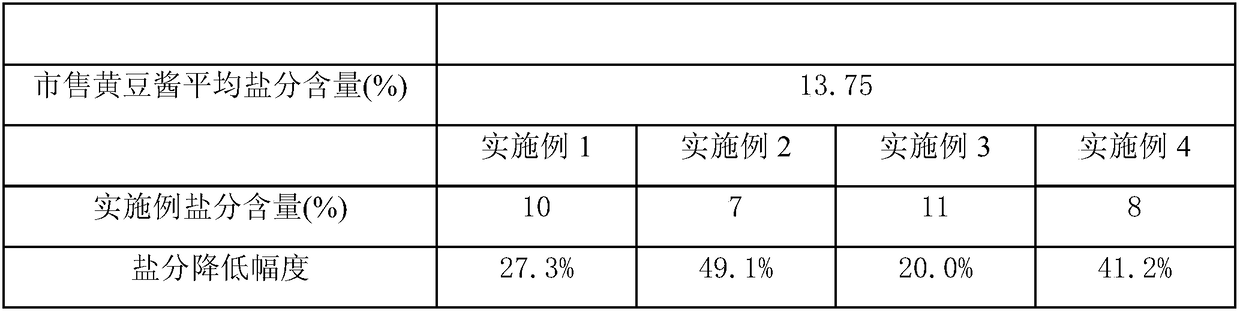

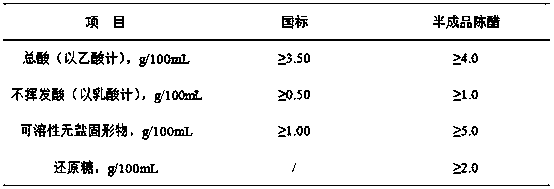

Preparation method of agaricus bisporus low-salt soybean sauce

InactiveCN108420000ALow costShorten the production cycleYeast food ingredientsFood ingredient functionsRoom temperatureAspergillus oryzae

The invention provides a preparation method of an agaricus bisporus low-salt soybean sauce. The preparation method comprises the following steps of putting soybeans after being subjected to cleaning and impurity removal into room-temperature water, performing soaking, and performing draining; cooking the drained soybeans until the soybeans are completely cooked; sufficiently and uniformly stirringheated flour with the cooked soybeans when the flour is hot to obtain mixed materials; after the mixed materials are cooled, performing inoculation with aspergillus oryzae mother starters, and performing culturing until starter materials are yellowgreen so as to obtain finished starters; and taking agaricus bisporus powder or an extraction solution thereof, mixing the taken agaricus bisporus powder or the extraction solution thereof with the finished starters to obtain a mixture, putting the mixture into a fermenter for fermentation, wherein the fermentation period is 7-10 days, then adding microzyme and lactic acid bacteria, setting the temperature to be 35-40 DEG C, and continuing performing fermentation for 5-7 days so as to obtain the agaricus bisporus low-salt soybean sauce. According to the preparation method disclosed by the invention, a low-salt solid state fermentation method is adopted, the fermentation time is short, the fermentation temperature is high, growth of infectious microbes is not facilitated, the agaricus bisporus low-salt soybean sauce is safe to eat, the soybean sauce produced by the method has the advantages of being healthy, environmentally-friendly, lowin cost and short in production cycle, besides, the soybean sauce inherits the advantages of the agaricus bisporus, and the soybean sauce obtains favor of consumers.

Owner:SHANGHAI INST OF TECH

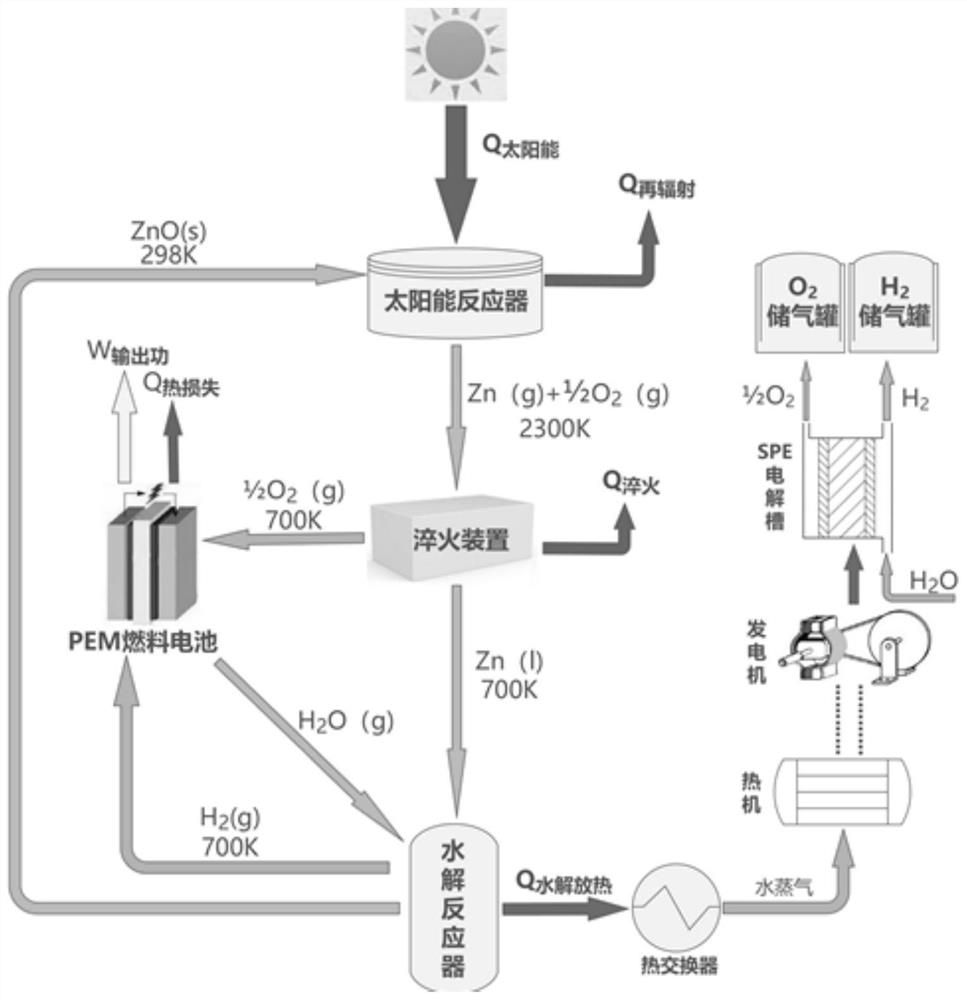

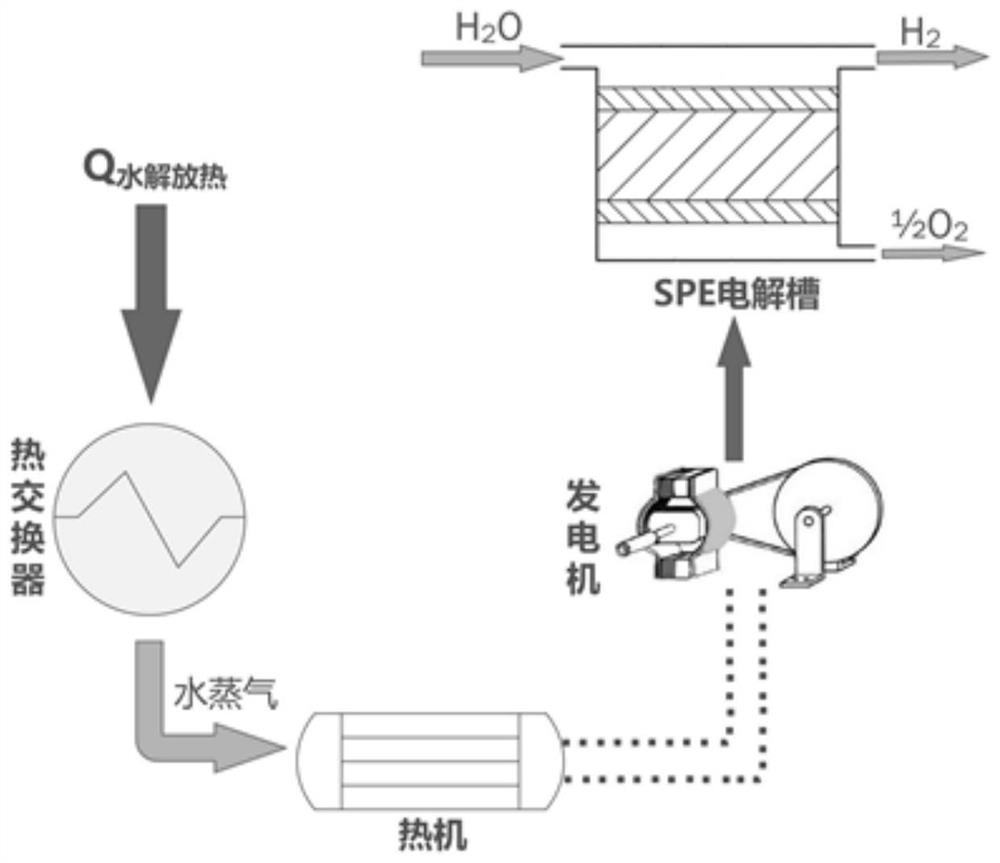

Method and system for hydrogen production and electricity production by two-step thermochemical cycle decomposition of water

InactiveCN112323092AAvoid emissionsReduce storage and transportation costsElectrolysis componentsEnergy inputChemistryThermo chemical

The invention belongs to the related technical field of new energy utilization, and discloses a method and a system for hydrogen production and electricity production by two-step thermochemical cycledecomposition of water. The method comprises the following steps: S1, carrying out a two-step thermochemical cycle water decomposition hydrogen production reaction which comprises two steps: 1, carrying out an endothermic reduction reaction on zinc oxide by using solar energy to obtain oxygen and zinc vapor, and 2, carrying out a water decomposition reaction by using zinc and water vapor to obtainhydrogen, zinc oxide and heat energy; and s2, enabling the oxygen in the first-step endothermic reduction reaction and the hydrogen obtained in the second-step hydrolysis reaction to be recycled andfed into a fuel cell for power generation, and therefore recycling of the oxygen and the hydrogen and conversion from solar energy to electric energy are achieved; and recycling the heat energy obtained in the hydrolysis reaction in the second step for electrolyzing water to generate hydrogen and oxygen, so as to realize the preparation of hydrogen. According to the invention, stable electric energy and high-purity hydrogen are obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

Drying treatment method for municipal sludge

InactiveCN106810032ALow running costMake products hygienicSludge treatment by de-watering/drying/thickeningBiological sludge treatmentFertilizerChemistry

The invention relates to a municipal sludge drying treatment method. Including the following steps: a. The dewatered sludge from the sewage plant is mixed with the dried granular sludge with a moisture content below 15% until the moisture content is 45%-50%; b. Add biological dehydration strains in the biological dehydration pool; c. After 10-15 days of biochemical heating reaction, the water content drops below 30%; d. Biologically dehydrated municipal sludge with a moisture content below 30% enters the drying system for drying until the moisture content is below 15%, and part of the finished particles is returned to be mixed with the wet sludge; e. The rest is the final product of municipal reform sludge disposal, which can be used as fuel, soil improver, etc. The beneficial effect of the present invention is that the operating cost is greatly reduced; it is suitable for large-scale sludge disposal, and the daily treatment of wet sludge can reach hundreds of tons; and there are various ways of utilization, such as fuel, fertilizer, soil conditioner, etc., It can be disposed according to the multi-channel disposal of sludge.

Owner:周子童

Recycling and clean production method for preparing yellow phosphorus, sylvite, aluminum oxide, molecular sieves, slag cement and architectural profiles through potassium-bearing phosphorite

ActiveCN105197902AReduce manufacturing costTake advantage ofSolid waste managementChemical industryFiltrationSlag

The invention relates to a recycling and clean production method for preparing yellow phosphorus, sylvite, aluminum oxide, molecular sieves, slag cement and architectural profiles through potassium-bearing phosphorite. The method utilizes two routes, for the first route, high quality yellow phosphorus is produced by the potassium-bearing phosphorite and coke nuts through an electrothermal method, water quenching is conducted on yellow phosphorus slags, KAlO2 is dissolved out, filtration is conducted, CO2 is introduced, Al(OH)3 is settled, first filtrate is obtained, and the Al(OH)3 is converted through temperature control to obtain Al2O3. For the second route, orthoclase power and Na2CO3 are evenly mixed, roasting is conducted through yellow phosphorus tail gas, water leaching is conducted through water, the CO2 is introduced to settle out silicon-aluminum colloid, and second filtrate is obtained. Crystallization and drying are conducted on the first filtrate and the second filtrate, and K2CO3 and Na2CO3 are obtained. The Na2CO3 returns to the second route to be recycled. The content of K2O, Na2O, SiO2 and Al2O3 is adjusted for partial silicon-aluminum colloid which is not subjected to sedimentation and the filtrate, hydrothermal crystallization reaction is conducted, and the molecular sieves are obtained; settled silicon-aluminum colloid is mixed with the yellow phosphorus slags to prepare the slag cement and / or the architectural profiles.

Owner:黄钰雪

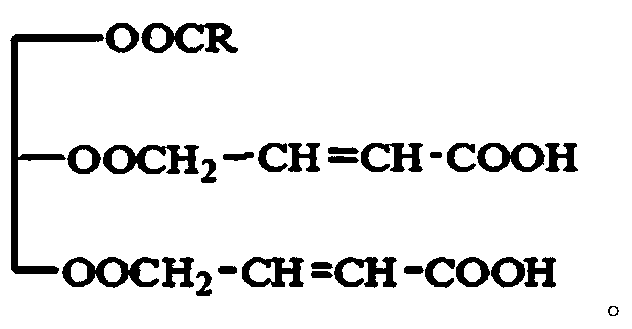

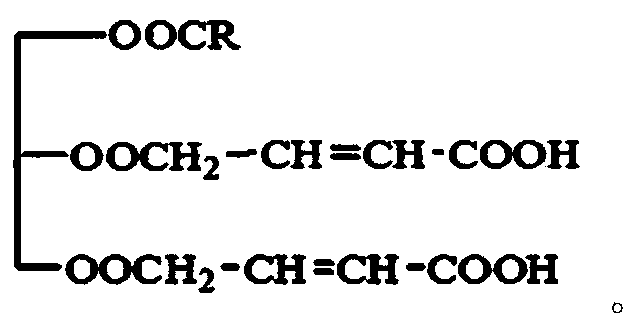

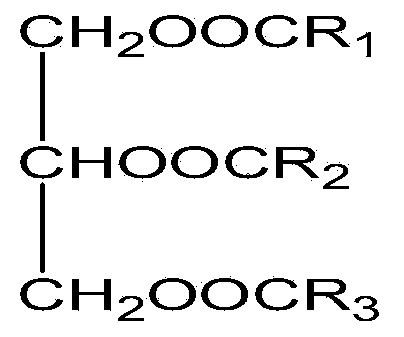

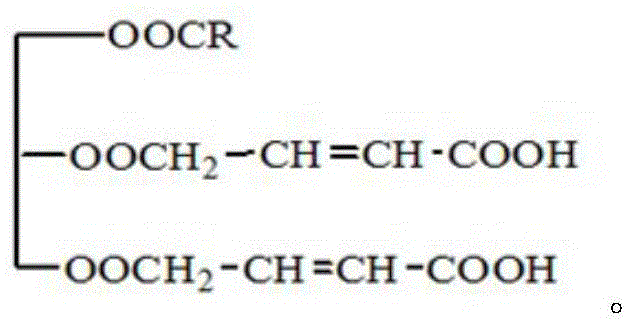

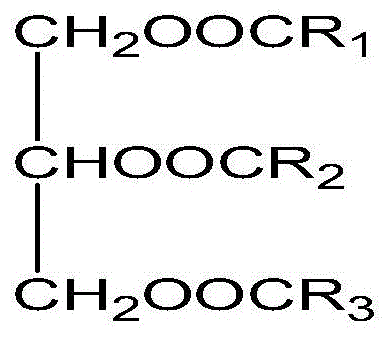

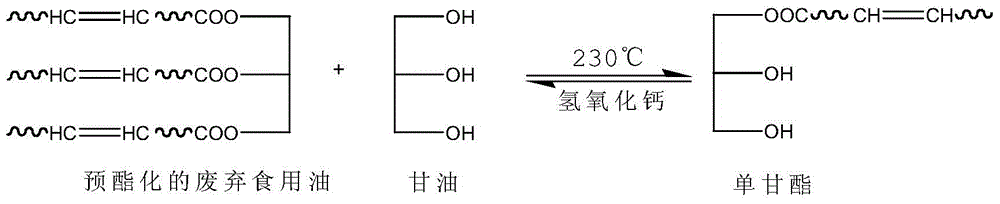

Preparation method of novel waste cooking oil based unsaturated polyester resin

The invention relates to a method for preparing novel unsaturated polyester resin from waste cooking oil. According to the preparation method, characteristics of waste cooking oil are fully utilized. Waste cooking oil which undergoes preliminary purification and glycerin are mixed in a high pressure reactor to carry out pre-esterification treatment so as to reduce acid value of waste cooking oil; the waste cooking oil which has undergone pre-esterification treatment reacts with glycerol to carry out an alcoholysis reaction so as to generate monoglyceride; monoglyceride reacts with maleic anhydride to generate monoglyceride maleic acid half ester; and finally monoglyceride maleic acid half ester is mixed with styrene to obtain the novel unsaturated polyester resin. The synthesized resin has advantages of unique structure, high rigidity, high hardness, high temperature resistance, nonflammability and good dimensional stability of a product. before curing, the resin is a viscous liquid with low molecular weight; and during molding process, the resin can flow, has plasticity, can be made into a certain shape and simultaneously undergoes a chemical reaction to be cross-linked and cured. The resin is suitable for various composite material molding technologies such as mould pressing, lamination, transfer molding, casting and the like.

Owner:WUHAN TEXTILE UNIV

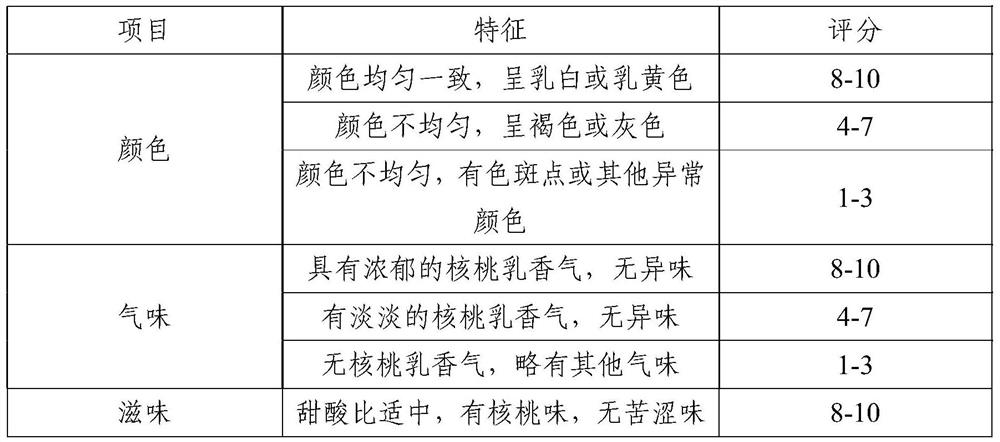

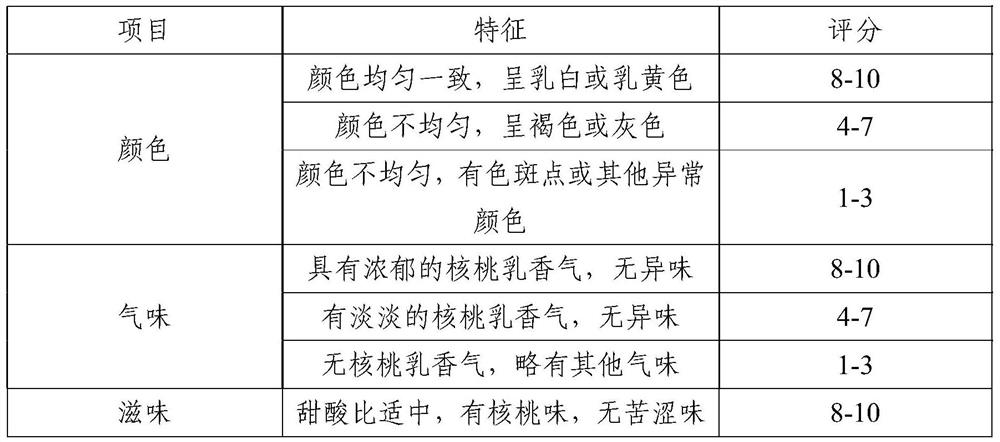

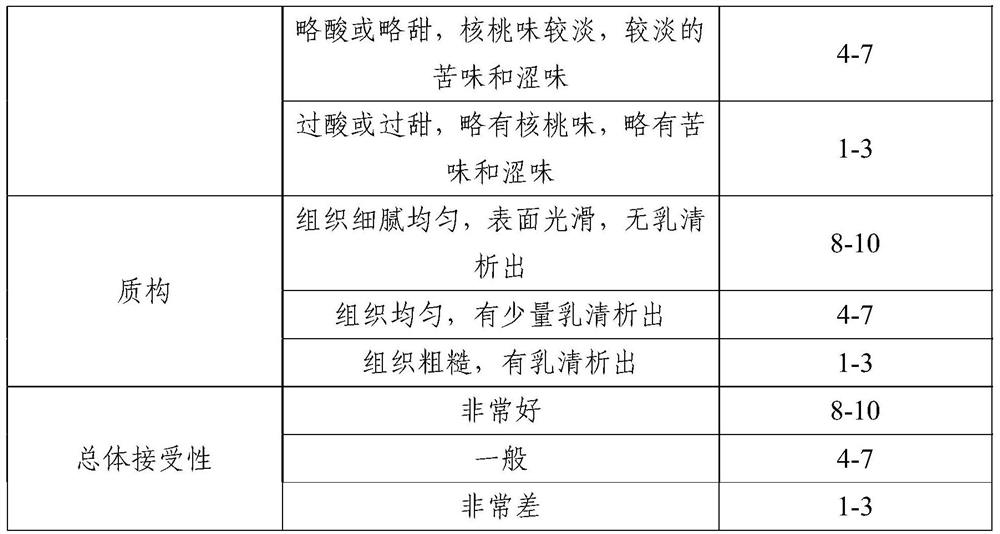

Walnut fermented milk and preparation method thereof

ActiveCN113207971AImprove sensory qualityTaking into account stabilityMilk substitutesWalnut NutNutritive values

The invention relates to the technical field of food processing, in particular to walnut fermented milk and a preparation method thereof. The method disclosed by the invention comprises the following steps: 1) baking peeled walnut kernels at 145-165 DEG C for 5-25 minutes; 2) deoiling the baked walnut kernels until the oil content is 20-50%, so as to obtain semi-degreased walnut kernels; 3) mixing the semi-skimmed walnut kernels with a stabilizer, a carbon source and water, and performing grinding to obtain walnut pulp; and 4) fully and uniformly mixing the walnut pulp, performing sterilizing, performing inoculating and performing fermenting. According to the method, the fragrance of the walnuts can be effectively improved after the walnuts are baked at a high temperature, on the basis, the ideal flavor of the system can be ensured after part of grease is removed, and the fermented milk which is stable in quality and rich in nutritional value can be obtained by removing the grease to the degree.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Technical method and schedule for preparation of foam carbon material used asphalt as raw material

The present invention belongs to the field of coal chemical technology, petrochemical technology and carbon material technology, and is preparation process of foamed carbon material with coal-base medium-temperature asphalt and petroleum-base intermediate-phase asphalt as material and through self reaction. The preparation process includes pulverizing and modifying asphalt material to form precursor; heating in reactor to form sticky fluid while releasing volatile gas to form foam; further raising temperature to solidify sticky fluid and settle foam; and final carbonizing at high temperature. The present invention has low production cost, high performance of the foamed carbon material, etc. and the product may be used in aeronautics, astronautics and other hi-tech fields.

Owner:DALIAN UNIV OF TECH

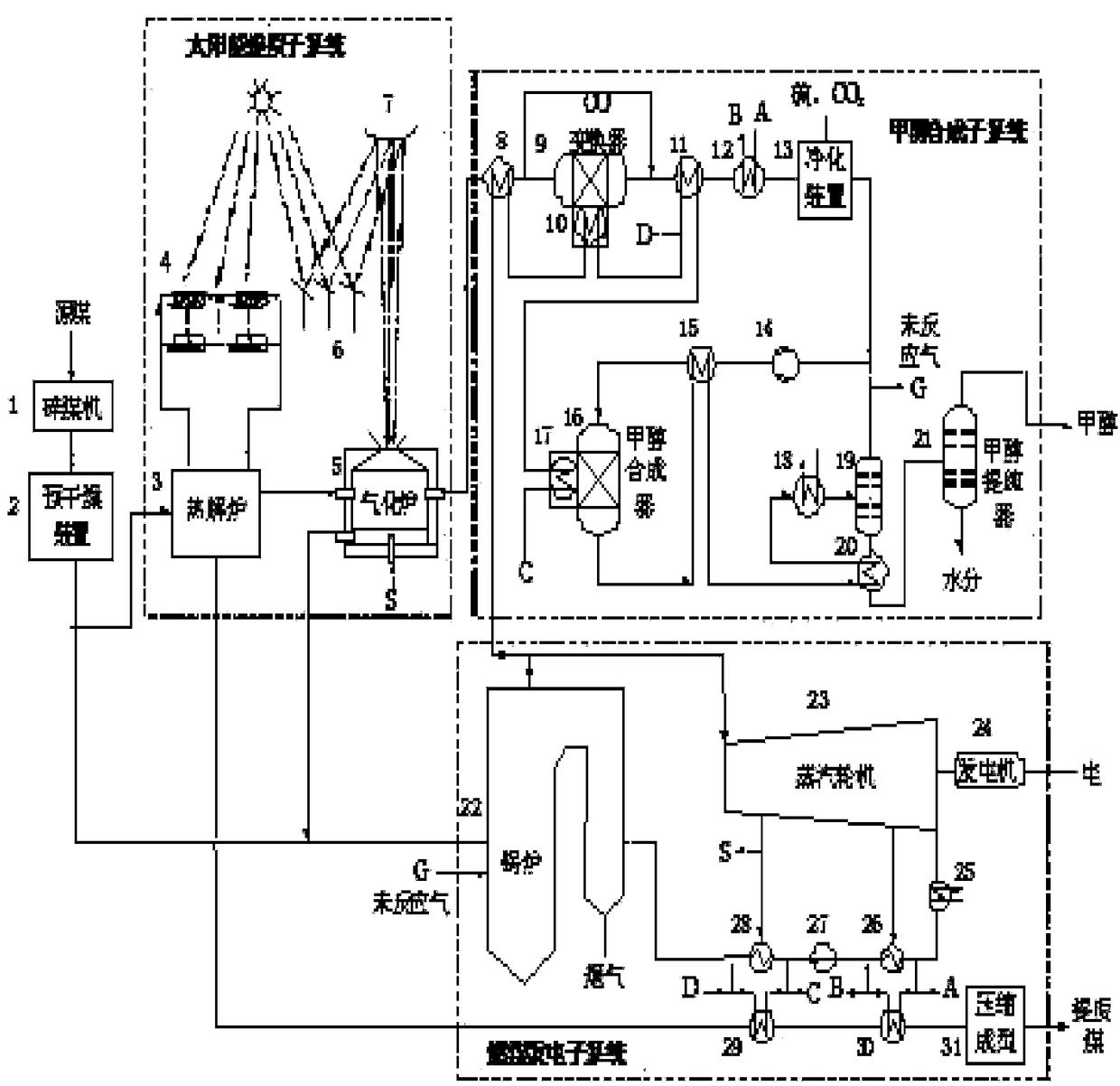

Solar-integrated coal based methanol synthesis and power generation co-production system

ActiveCN108442982AReduce consumptionImprove utilization efficiencyEnergy inputGasification processes detailsCouplingProcess engineering

The invention discloses a solar-integrated coal based methanol synthesis and power generation co-production system, belongs to the field of coal grading utilization. The system mainly comprises threesubsystems of solar mass extraction, methanol synthesis and fired coal power generation. In the system, solar-driven coal mass extraction, methanol synthesis and fired coal power generation are coupled; tank and tower solar energy provides heat for pyrolysis and gasification of coals; and waste heat and wastes in the mass extraction and methanol synthesis process realize gradient recycling througha boiler and a steam-water system of a fired coal generator set. The system widens the utilization path of solar energy and realize coal based poly-generation through efficient system integrated coupling, meanwhile, is hopeful to reduce the fossi energy consumption, and improves the energy comprehensive utilization efficiency.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Sand ginger and cordyceps militaris-containing sauce and preparation method thereof

The invention discloses a sand ginger and cordyceps militaris-containing sauce and a preparation method thereof. The sand ginger and cordyceps militaris-containing sauce is prepared by the method comprising the following steps: mixing residue powder extracted from sand ginger essential oil and residual mycoplasma powder obtained after collecting cultivated cordyceps militaris sporocarp so as to obtain a mixture, adding water according to the weight of 100-300% of the mixture, stirring uniformly and then sterilizing to obtain the sand ginger and cordyceps militaris-containing sauce, or adding a right amount of seasonings, stirring uniformly and then sterilizing to obtain the sand ginger and cordyceps militaris-containing sauce. The sand ginger and cordyceps militaris-containing sauce disclosed by the invention is nut-brown and uniform, is moderate in viscosity, has obvious fragrance of sand ginger and cordyceps militaris, does not have peculiar smell, has smooth taste, is spicy and delicious, and is rich in functional ingredients. The invention also discloses a preparation process of the sand ginger and cordyceps militaris-containing sauce, which is simple and feasible, easy to control in condition, and free of special expensive equipment. According to the invention, the comprehensive utilization of sand ginger and cordyceps militaris by-products is realized, and the deep development of medical and edible dual-purpose plants and fungi is better realized.

Owner:GUANGZHOU AOJIAN PERFUME

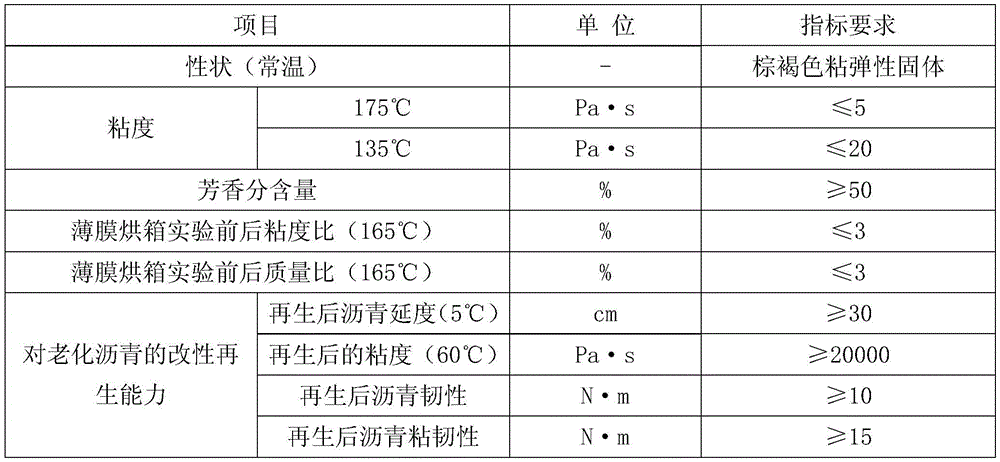

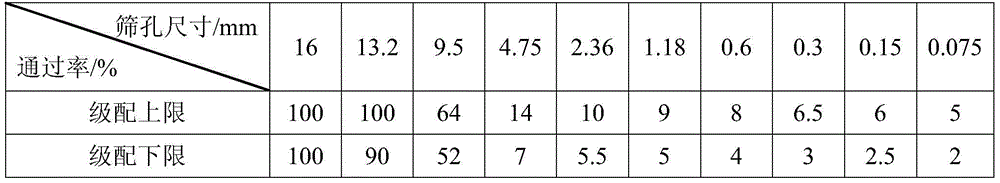

A kind of recycled semi-flexible pavement material and its preparation method

ActiveCN103450692BImprove carrying capacityAging resistantBuilding insulationsAging resistanceRoad surface

The invention relates to a regenerated semi-flexible pavement material obtained by efficiently utilizing waste asphalt concrete and a preparation method of the regenerated semi-flexible pavement material, and particularly relates to an aged asphalt modified regenerant and a preparation method thereof. The aged asphalt modified regenerant is characterized by comprising the following components in parts by mass: 100 parts of base oil, 20-50 parts of elasticizing components, 10-30 parts of tackifying components and 5-25 parts of permeability increasing components. The semi-flexible pavement material is prepared by utilizing the ageing asphalt modified regenerant, wherein the mass ratio of all the components is mineral materials: new asphalt: modified regenerant: cement mortar: fibers=100:(0.8-2.0):(5-12):(20-30):(0.25-0.5). The regenerated semi-flexible pavement material disclosed by the invention has the characteristics of ageing resistance and high bearing capacity and can solve the problems of insufficiency in durability and bearing capacity of dense-suspended type common regenerated asphalt concrete on a part of heavy-load traffic road segments and enlarge the application range of a regenerated asphalt pavement.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

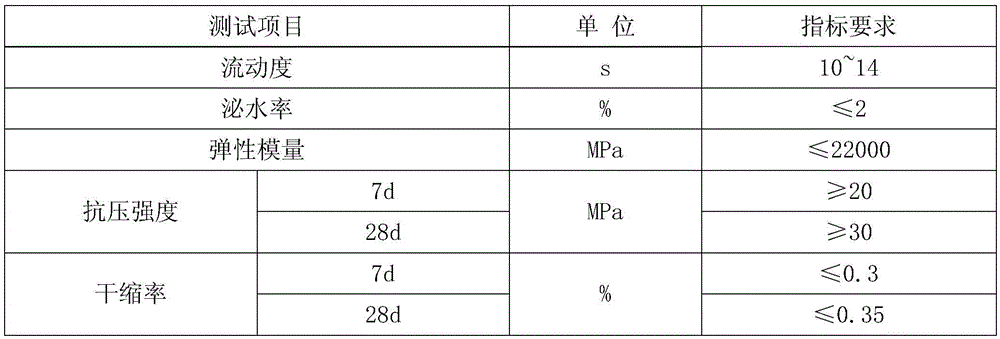

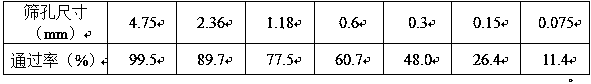

Recycled powder waste hydraulic pavement base material and preparation method

InactiveCN110963772AControl the number of cracksRich comprehensive utilizationRoad constructionWaste material

The invention discloses a recycled powder waste hydraulic pavement base material and a preparation method thereof. According to the novel pavement base material, a special stabilizer is adopted to modify and stabilize recycled powder produced by an asphalt mixing station, and a certain proportion of waste flash is made through doping, so that performance indexes such as mechanical properties of the material accord with those of a traditional pavement base material. According to the different mixing amounts of the stabilizer, the recycled powder and waste, the material can be selectively used for roads with different grades and different loads. The recycled powder is powdery waste generated by the production of an asphalt mixture mixing station, and about 40 kg of recycled powder can be generated when 1 ton of asphalt mixture is produced every time. At present, the road construction scale in China is huge, and traditional soil and gravel materials become scarce resources. The recycled powder and the waste are modified into the base material meeting engineering requirements by using the special stabilizer, so that the problem of sharp contradiction between supply and demand of traditional engineering materials is solved, and the waste can be recycled. Positive economic benefits, environmental protection benefits and social benefits can be generated for highway construction.

Owner:HENAN HIGHWAY ENG GROUP

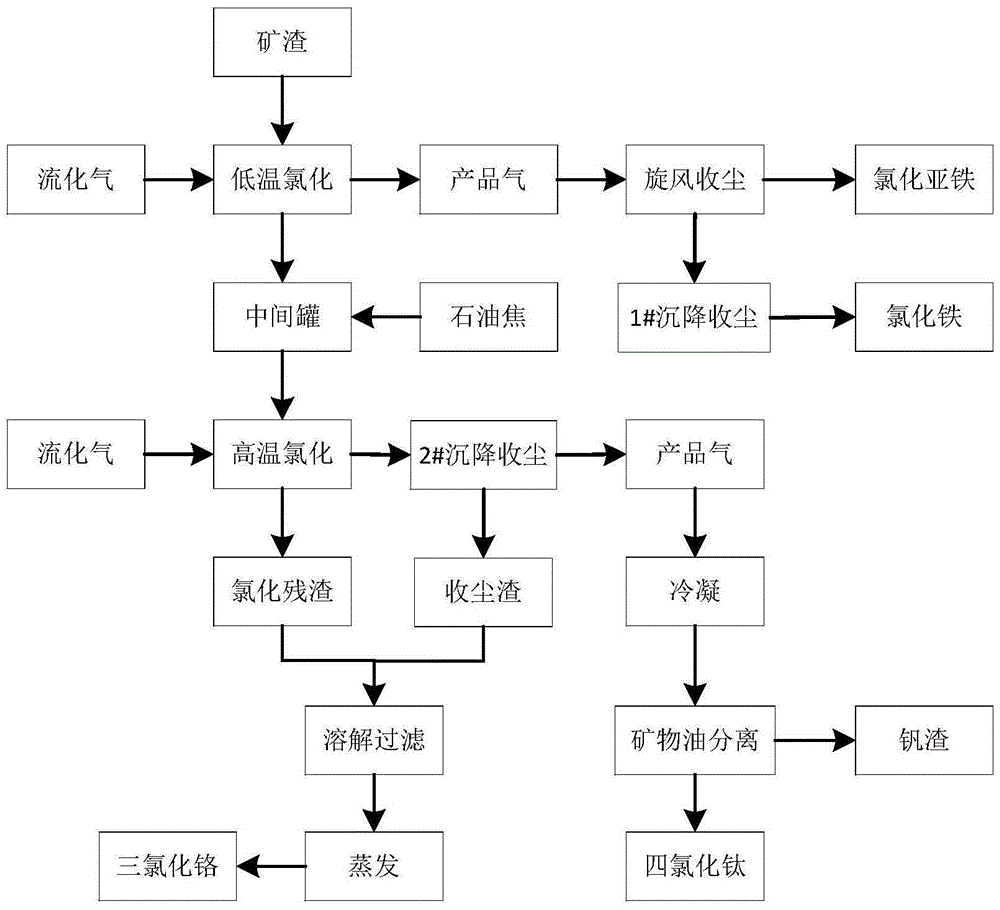

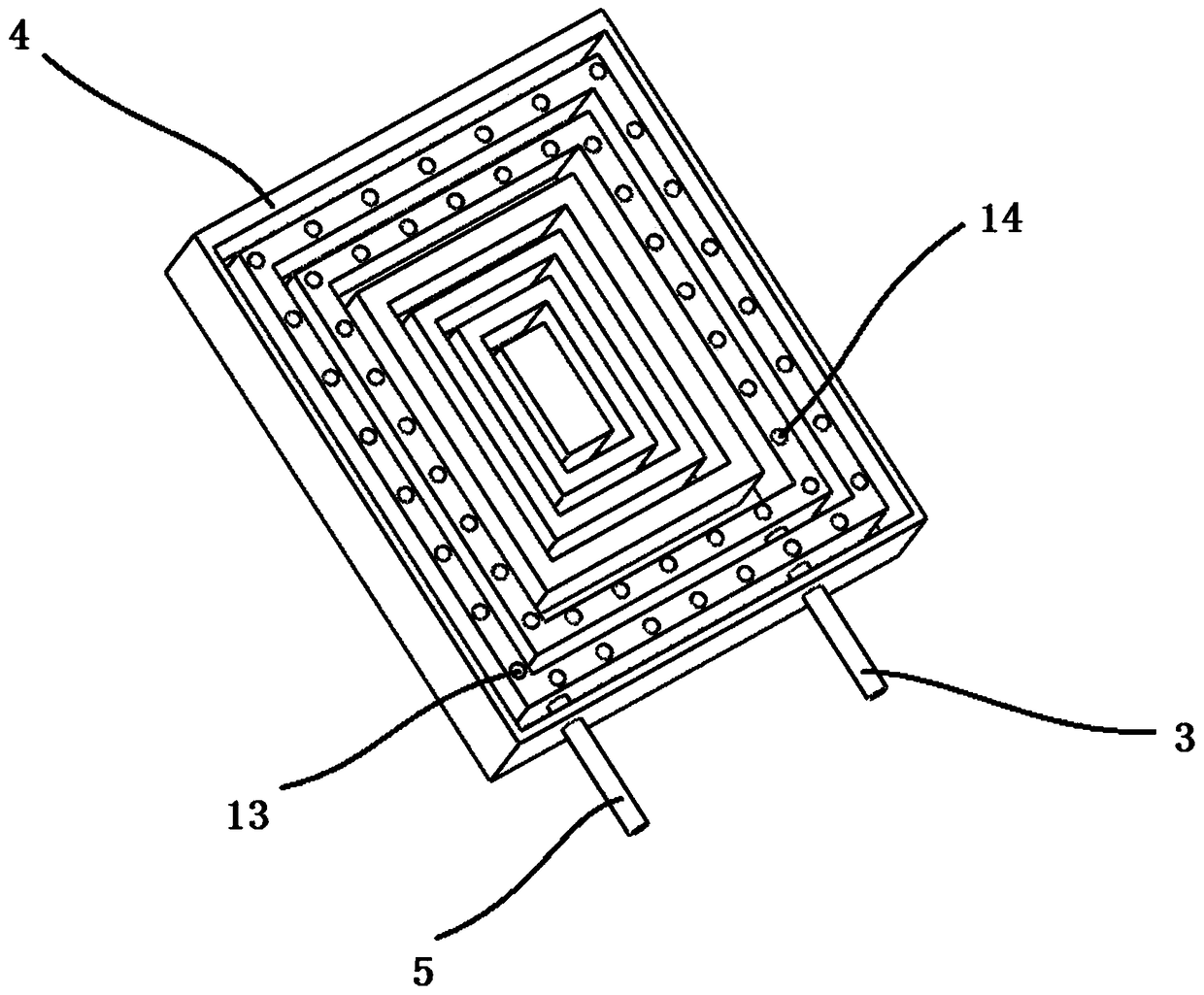

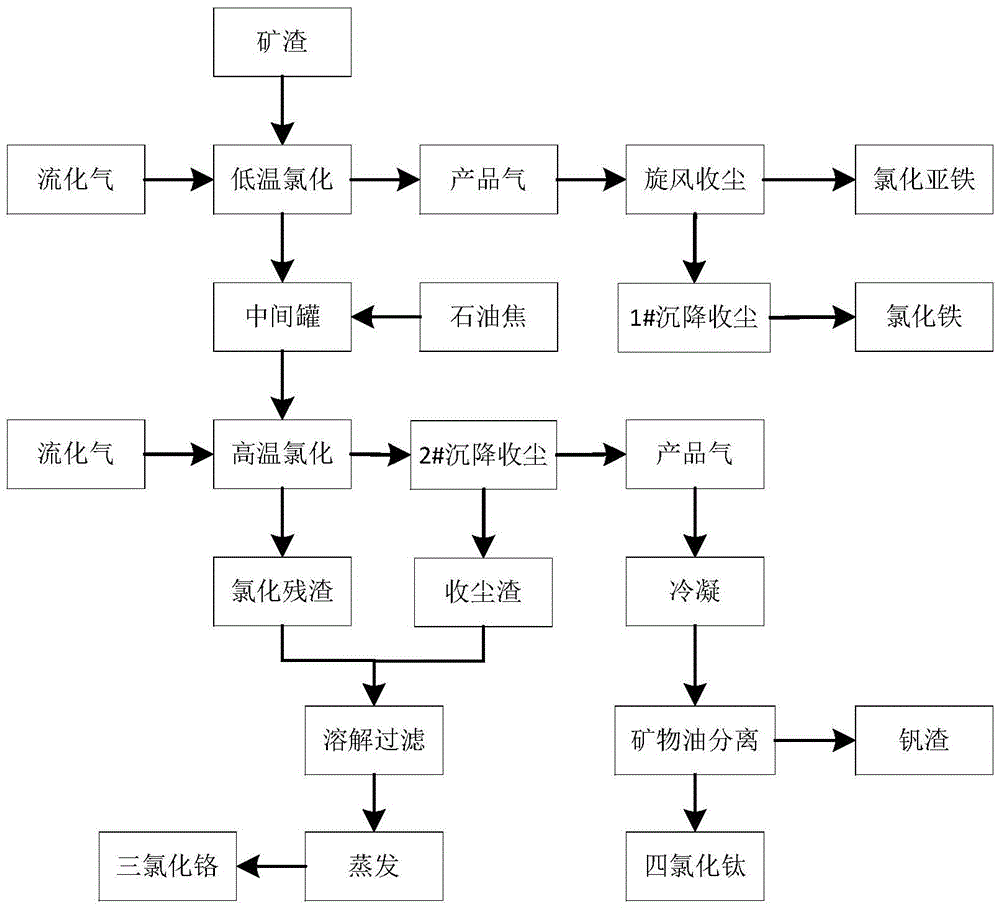

Purification process of mineral slag by chlorination process

ActiveCN105217682AEfficient separationRich ways to useTitanium tetrachlorideChromium halidesSlagMaterials science

The invention discloses a purification process of mineral slag by a chlorination process. The process comprises the following steps: carrying out low-temperature chlorination and recovering a solid product after reaction through a cyclone separation device; recovering a gaseous product through a first dust collector; carrying out high-temperature chlorination and recovering the gaseous product after reaction through a condenser; and settling the solid product after reaction through a second dust collector to form dust collecting slag. According to the process disclosed by the invention, elements in associated lean ores can be effectively separated to obtain a required corresponding product, so that the utilization mode of lean ore resources is enriched. According to the process disclosed by the invention, a chromium trichloride product of an industrial grade can be obtained, so that a problem of treating chromium slag after extraction of resources is avoided.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

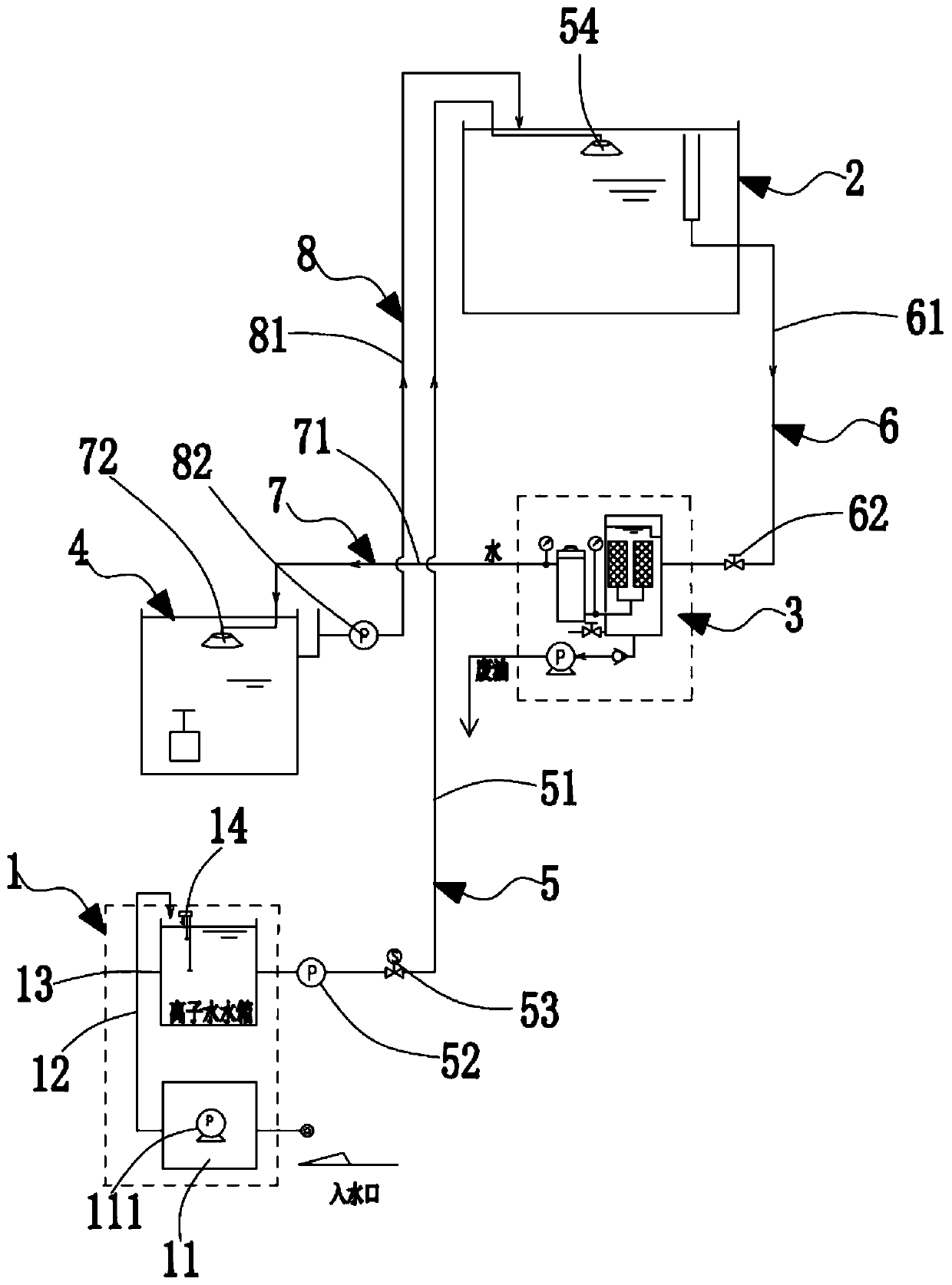

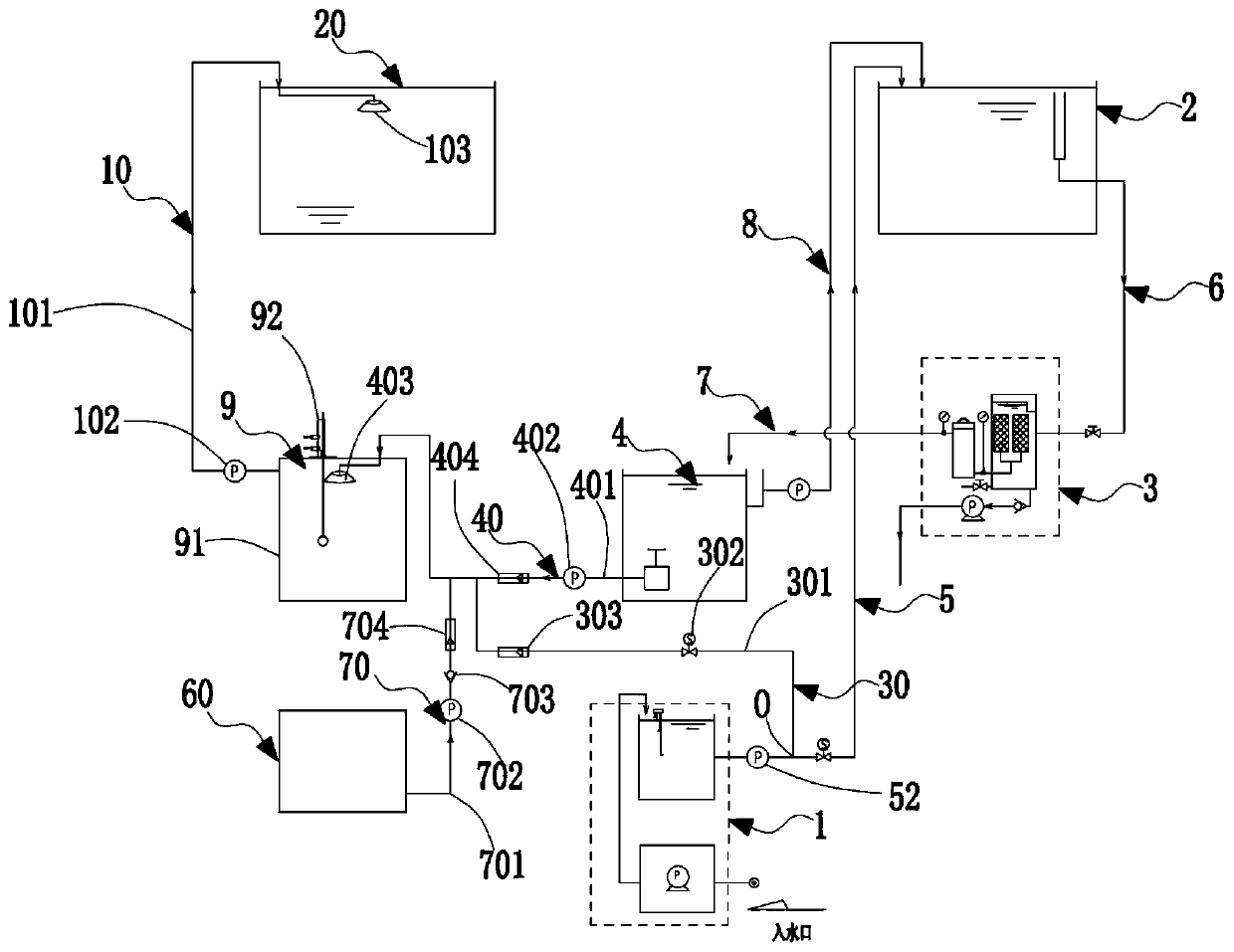

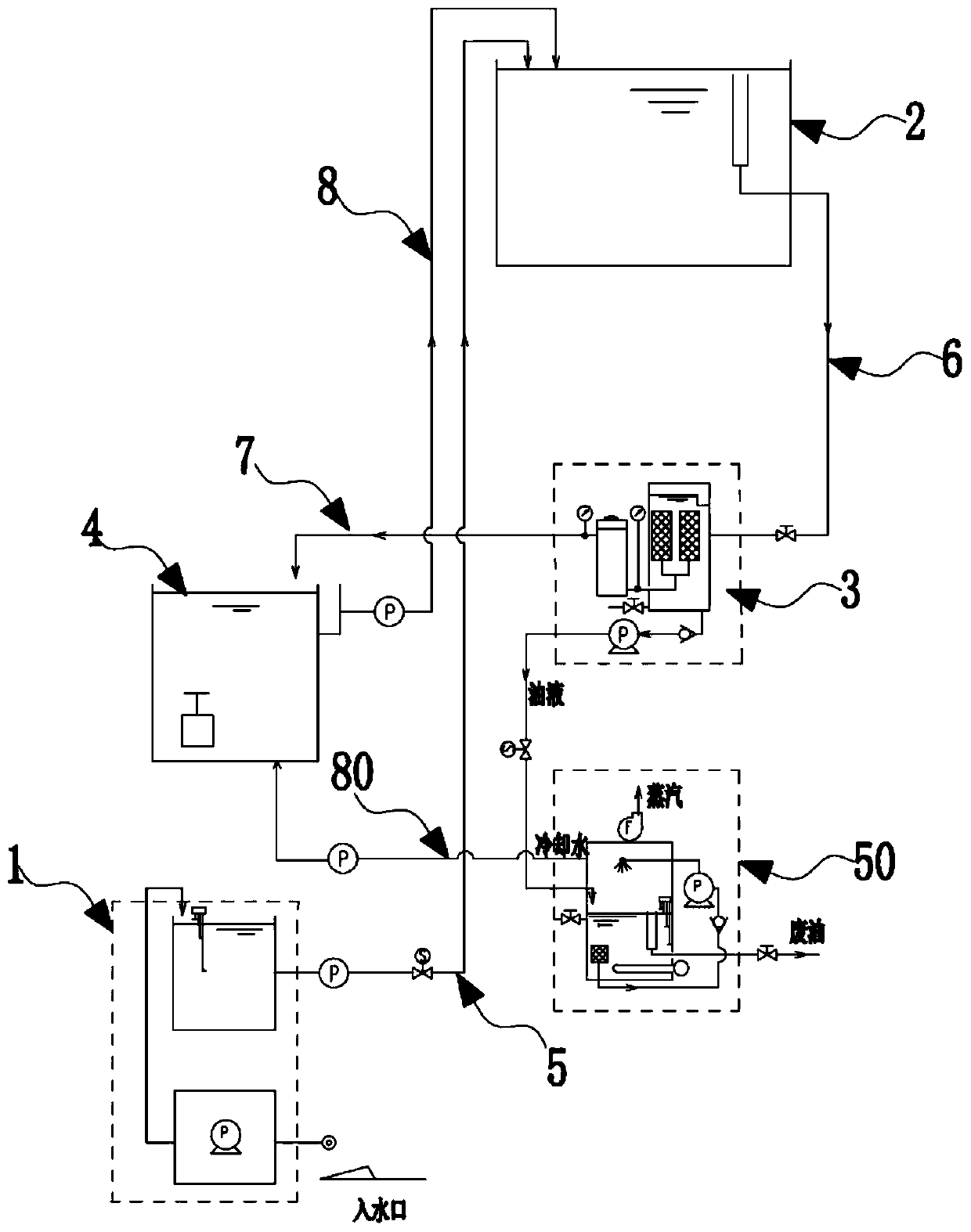

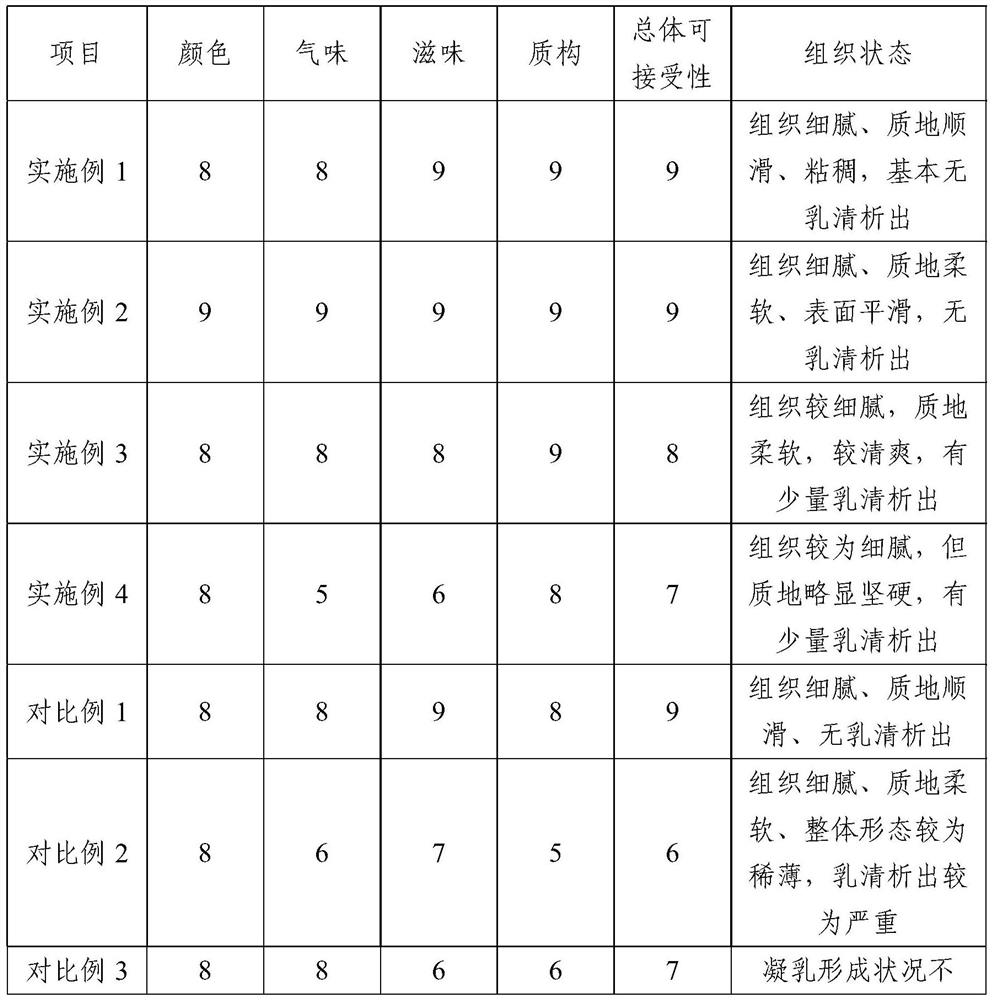

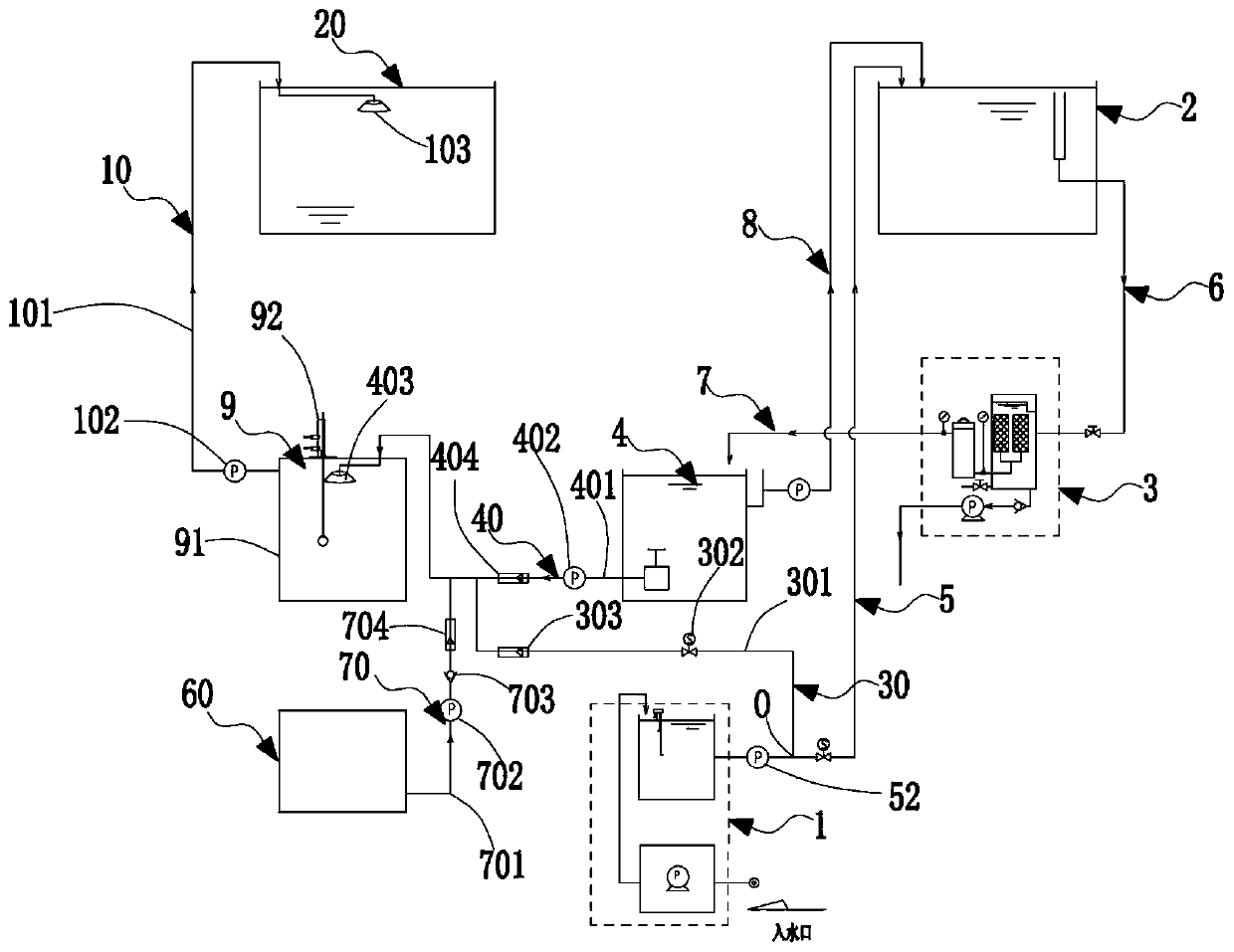

Energy-saving and emission-reducing cutting cooling liquid and cleaning liquid comprehensive utilizing system and using method of system

PendingCN109761429AReduce consumptionPrevent rust and corrosionWaste water treatment from metallurgical processMultistage water/sewage treatmentWastewaterChloride

The invention discloses an energy-saving and emission-reducing cutting cooling liquid and cleaning liquid comprehensive utilizing system and a using method of the system. The energy-saving and emission-reducing cutting cooling liquid and cleaning liquid comprehensive utilizing system comprises an alkaline ion water supplying device, a cleaning machine water tank, and a cleaning liquid treating device and a treatment liquid recovery water tank, wherein the alkaline ion water supplying device is connected with the cleaning machine water tank through a first water supplying pipeline; the cleaningmachine water tank is connected with the cleaning liquid treating device through a first water guide pipeline; water treated by the cleaning liquid treating device enters the treatment liquid recovery water tank through a second water guide pipeline; the treatment liquid recovery water tank is connected with the cleaning machine water tank through a second water supplying pipeline. In the scheme,alkaline ion water is adopted instead of ordinary tap water, so that the problems of rust and corrosion of workpieces easily caused by chloride ions in the tap water are solved effectively, and the workpiece quality is ensured; the used cleaning liquid can be recycled in combination with wastewater treatment, recycling and circulation pipelines, so that the water utilization rate is improved, theconsumption of the alkaline ion water is lowered, the wastewater discharge amount is reduced, the cleaning water cost is lowered, and the environmental friendliness is improved.

Owner:TAKAHASHI METAL MFG SUZHOU

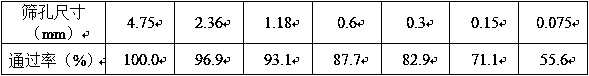

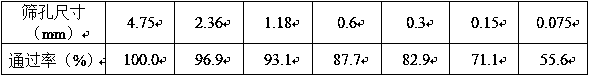

Iron tailing gravel hydraulic pavement base material and preparation method thereof

InactiveCN110655358AControl quantityGuaranteed StrengthIn situ pavingsCeramic shaping apparatusMining engineeringRoad surface

The invention discloses an iron tailing gravel hydraulic pavement base material and a preparation method thereof. According to the novel pavement base material, a special curing agent is adopted to modify and cure iron tailings produced by mining of iron ore enterprises, and a certain proportion of gravels with a certain specification are blended, so that performance indexes such as mechanical properties of the novel pavement base material accord with those of a traditional pavement base material. According to different mixing amounts of a curing agent and different gradations of the tailingsand gravels, the iron tailing gravel hydraulic pavement base material can be selectively used for roads with different grades and different loads. The iron tailings are industrial solid wastes and arelarge in stockpiling amount; at present, China is still in the capital construction peak period, the road construction scale is huge, and traditional soil and gravel materials become scarce resources. The iron tailings are modified into the base material meeting engineering requirements by using a special curing agent, so that the problem of sharp contradiction between supply and demand of traditional engineering materials is solved, a large amount of the iron tailings can be consumed, social, economic, environmental and safety pressure brought by a tailings bank is reduced, the ore enterprises are assisted in building tailings-free mines, and industrial pains of iron mine enterprises are solved.

Owner:安徽省东润新材料科技有限公司

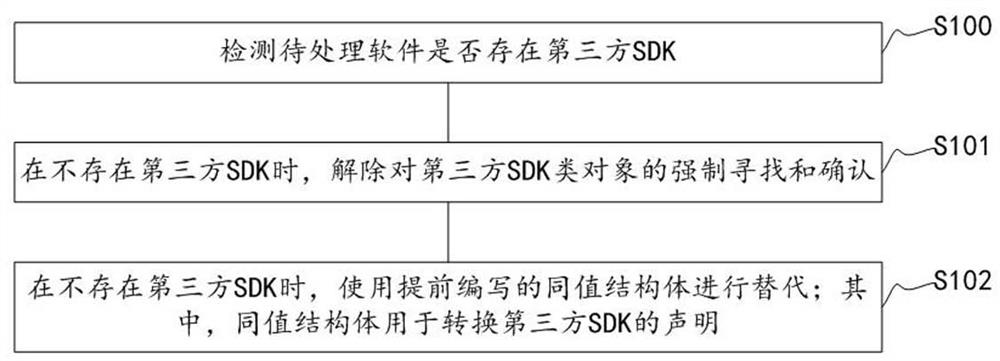

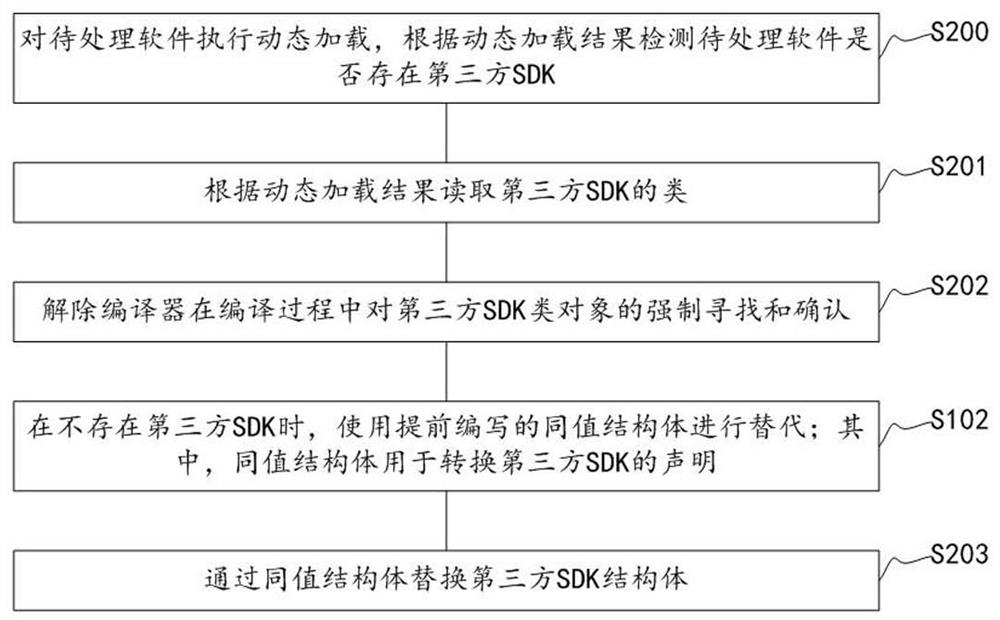

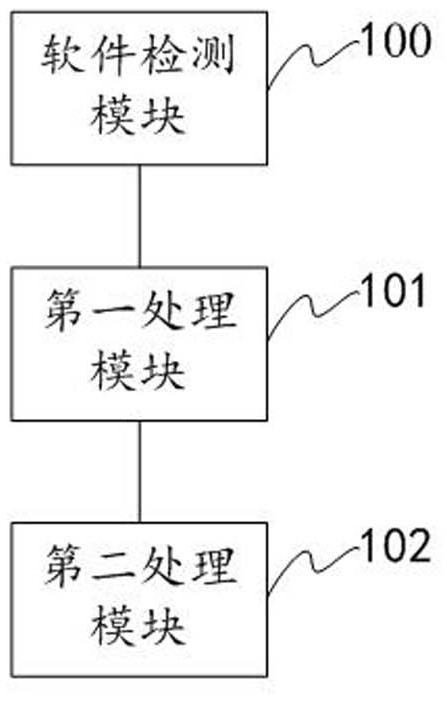

Method and device for solving forced dependence

InactiveCN114461226AIncreased flexibility of useRich ways to useCode compilationProgramming languageThird party

The invention relates to a method and device for solving mandatory dependency, and the method comprises the steps: detecting whether to-be-processed software has a third-party SDK or not, and when the third-party SDK does not exist, relieving the mandatory search and confirmation of a third-party SDK class object; meanwhile, when the third-party SDK does not exist, the same-value structural body written in advance is used for replacement; wherein the same-value structural body is used for converting the declaration of the third-party SDK. By releasing forced search and confirmation and compiling a same-value structural body, a module generating forced dependence in to-be-processed software weakens forced dependence of quotation and contact classes of a third-party SDK (Software Development Kit), and a'dynamic cutting 'effect is generated. Therefore, the use flexibility of the to-be-processed software is improved, the integration workload of a user is reduced, and the use modes of the to-be-processed software are enriched.

Owner:GUANGZHOU YIFANG INFORMATION TECH CO LTD

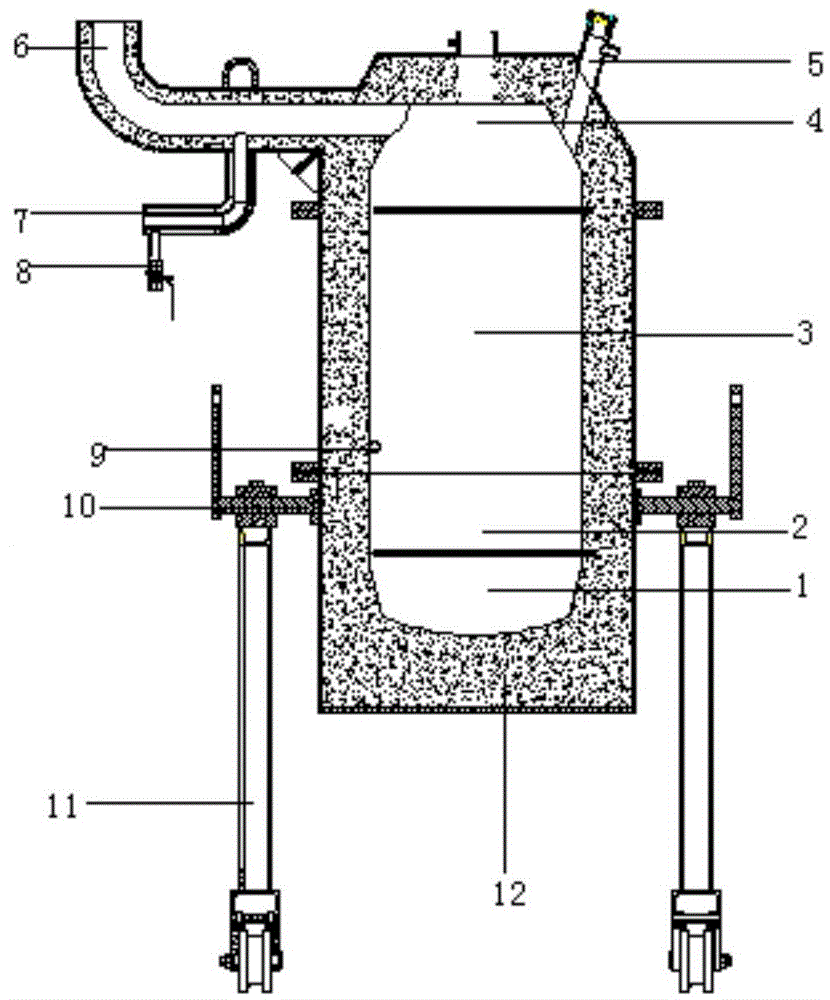

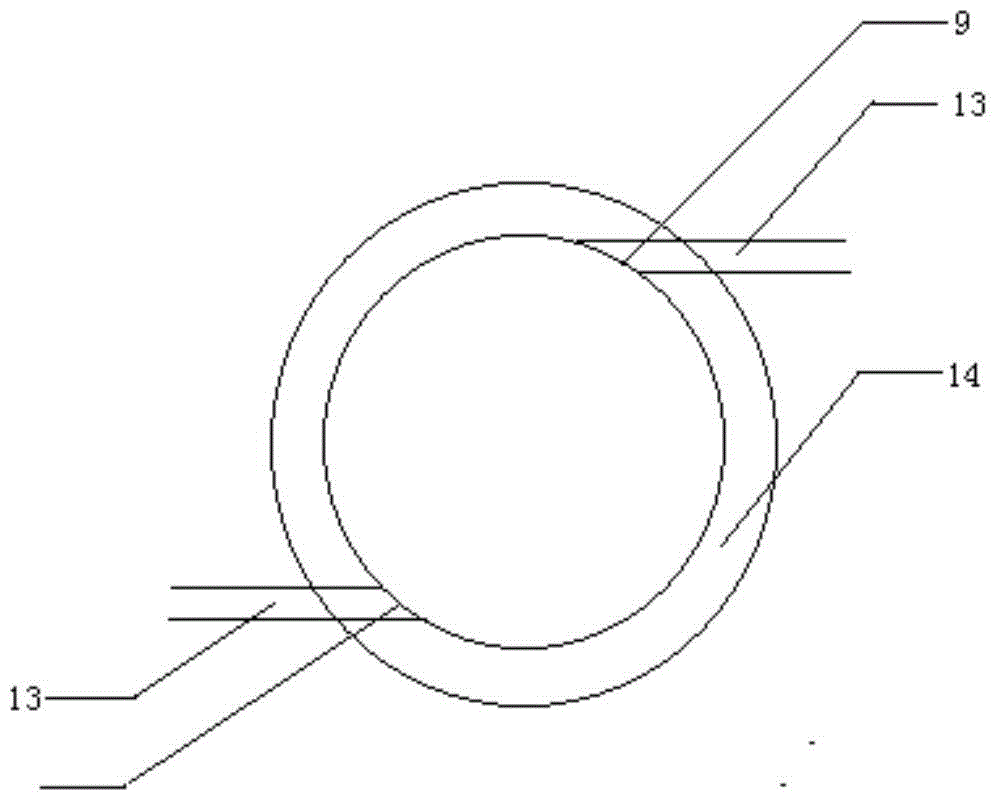

Improvement method and special equipment for iron-containing slag

ActiveCN104141019BRealize supplementary heatReduce pollutionRecycling and recovery technologiesLiquid stateEconomic benefits

The invention discloses a modification method of iron-containing slag and special equipment for the modification method. The method sequentially comprises the following steps: (1) spraying a mixture of a modifier and pulverized coal into a furnace hearth of a modification furnace so as to melt the modifier, and feeding the modifier in a high-temperature liquid state into the molten iron-containing slag; (2) adding a reducing agent into the slag and carrying out reduction on the slag so as to extract iron; (3) further spraying and blowing the mixture of the modifier and the pulverized coal into the furnace hearth of the modification furnace after the extraction of the iron and smelting the slag again. During the two modification processes, the mixture of the modifier and the pulverized coal is sprayed into the furnace hearth by virtue of two symmetric coal-fired vortex nozzles along a tangential direction of the furnace wall of the modification furnace, so that the modifier is molten in a heating manner and can be easily and evenly mixed with the molten slag; the modified slag can be directly used for preparing a high added-value product, so that the defects of the existing slag treatment and utilization mode which is simple, coarse, high in energy consumption and the like are avoided. The modification method disclosed by the invention has the characteristics of diversification of utilization mode, high utilization rate, good economic benefit, less environmental pollution and the like.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Sand ginger and cordyceps paste and its preparation method

The invention discloses a ginger and cordyceps paste and a preparation method thereof. The ginger and cordyceps paste is obtained by mixing the extract residue powder of ginger essential oil and the fungal substance powder remaining after harvesting the harvested fruit bodies of Cordyceps militaris to obtain a mixture, adding water according to 100-300% of the weight of the mixture, stirring evenly and then sterilizing, Or it can be obtained by adding appropriate amount of seasoning, stirring evenly, and then sterilizing. The ginger and cordyceps sauce of the present invention has a dark brown, uniform body, moderate viscosity, obvious aroma of ginger and cordyceps militaris, no peculiar smell, smooth taste, spicy and delicious, and rich in functional ingredients. The invention also discloses a preparation process of the sand ginger and cordyceps sauce, which is simple and feasible, the conditions are easy to control, and special expensive equipment is not needed. The invention realizes the comprehensive utilization of by-products of sand ginger and Cordyceps militaris, and better realizes the in-depth development of medicinal and edible plants and fungi.

Owner:GUANGZHOU AOJIAN PERFUME

Circular clean production method for preparing yellow phosphorus, potassium salt, alumina, molecular sieve, slag cement and building profiles from potassium-containing phosphate rock

ActiveCN105197902BReduce manufacturing costTake advantage ofSolid waste managementChemical industryFiltrationMolten slag

The invention relates to a recycling and clean production method for preparing yellow phosphorus, sylvite, aluminum oxide, molecular sieves, slag cement and architectural profiles through potassium-bearing phosphorite. The method utilizes two routes, for the first route, high quality yellow phosphorus is produced by the potassium-bearing phosphorite and coke nuts through an electrothermal method, water quenching is conducted on yellow phosphorus slags, KAlO2 is dissolved out, filtration is conducted, CO2 is introduced, Al(OH)3 is settled, first filtrate is obtained, and the Al(OH)3 is converted through temperature control to obtain Al2O3. For the second route, orthoclase power and Na2CO3 are evenly mixed, roasting is conducted through yellow phosphorus tail gas, water leaching is conducted through water, the CO2 is introduced to settle out silicon-aluminum colloid, and second filtrate is obtained. Crystallization and drying are conducted on the first filtrate and the second filtrate, and K2CO3 and Na2CO3 are obtained. The Na2CO3 returns to the second route to be recycled. The content of K2O, Na2O, SiO2 and Al2O3 is adjusted for partial silicon-aluminum colloid which is not subjected to sedimentation and the filtrate, hydrothermal crystallization reaction is conducted, and the molecular sieves are obtained; settled silicon-aluminum colloid is mixed with the yellow phosphorus slags to prepare the slag cement and / or the architectural profiles.

Owner:黄钰雪

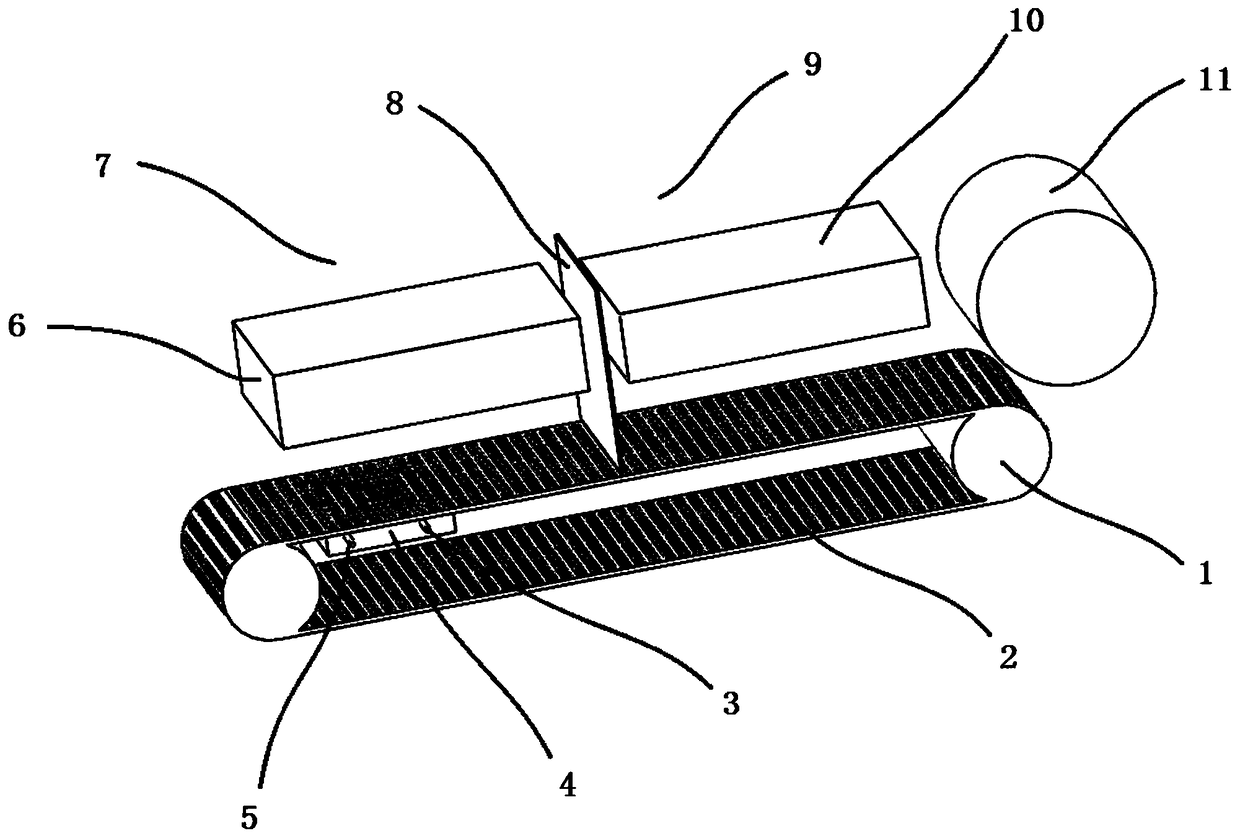

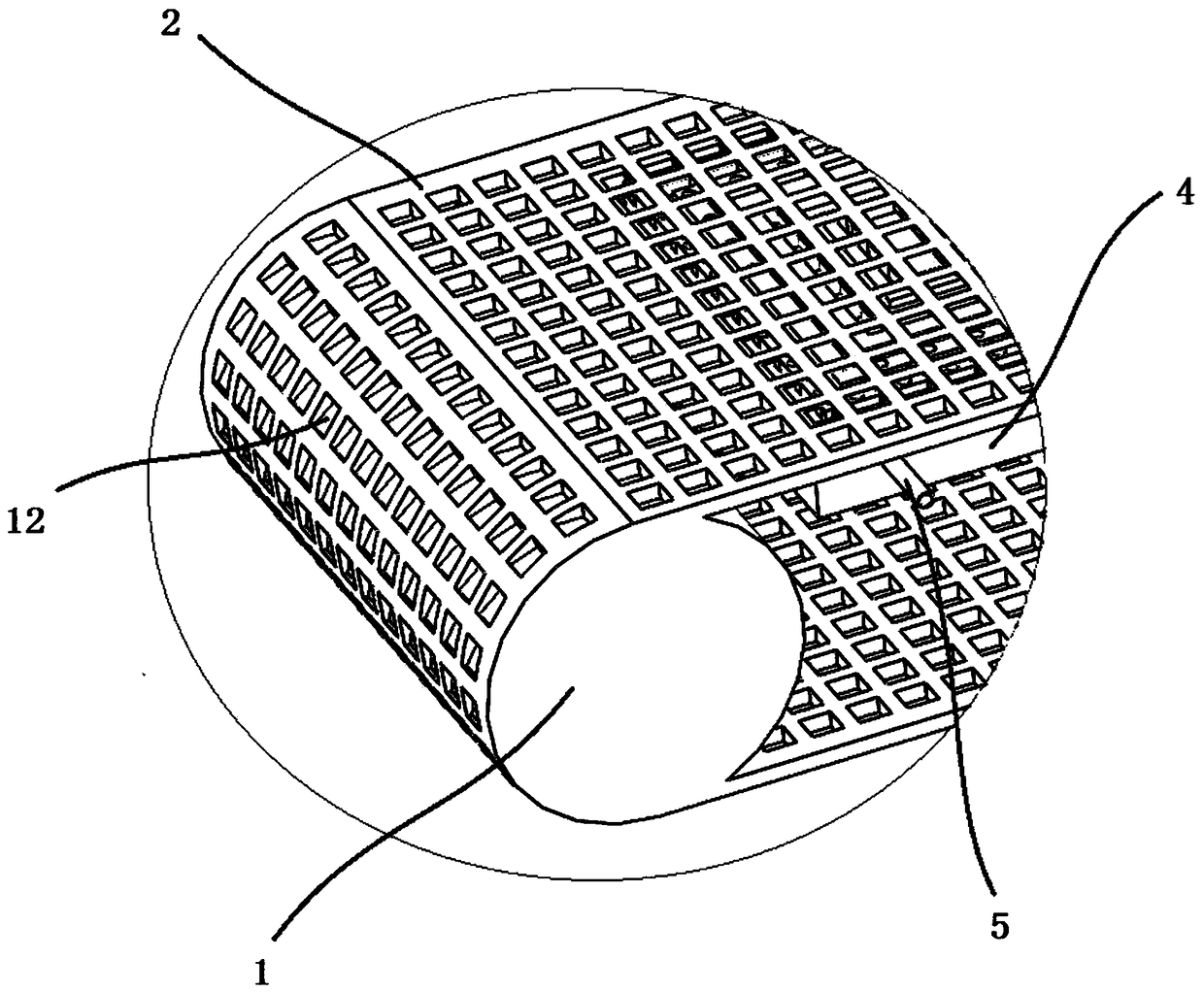

Surface antibacterial non-woven fabric processing device

InactiveCN109371735ASimple and flexible processingImprove fiber utilizationMachine wet endWoven fabricSlurry flow

The invention discloses a surface antibacterial non-woven fabric processing device. The device comprises a collecting belt, the collecting belt is of an annular structure, a plurality of through holesare formed in the collecting belt at intervals, the two ends of the inner side of the collecting belt are rotated through the roller driving, an upper area of the collecting belt is divided into a first area and a second area, a first slurry tank is disposed in the first area, a second slurry tank is disposed in the second area, liquid outlets are formed in the bottoms of the first slurry tank and the second slurry tank, the slurry flowing out through the liquid outlets is dropped on the collecting belt to form a non-woven fabric, the collecting belt is provided with a winding roller at an oblique upper portion of one end, the winding roller collects the non-woven fabric, and the device is flexible to use.

Owner:长沙云聚汇科技有限公司

Chlorination purification process of slag

ActiveCN105217682BEfficient separationRich ways to useTitanium tetrachlorideChromium halidesSlagCyclonic separation

The invention discloses a purification process of mineral slag by a chlorination process. The process comprises the following steps: carrying out low-temperature chlorination and recovering a solid product after reaction through a cyclone separation device; recovering a gaseous product through a first dust collector; carrying out high-temperature chlorination and recovering the gaseous product after reaction through a condenser; and settling the solid product after reaction through a second dust collector to form dust collecting slag. According to the process disclosed by the invention, elements in associated lean ores can be effectively separated to obtain a required corresponding product, so that the utilization mode of lean ore resources is enriched. According to the process disclosed by the invention, a chromium trichloride product of an industrial grade can be obtained, so that a problem of treating chromium slag after extraction of resources is avoided.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

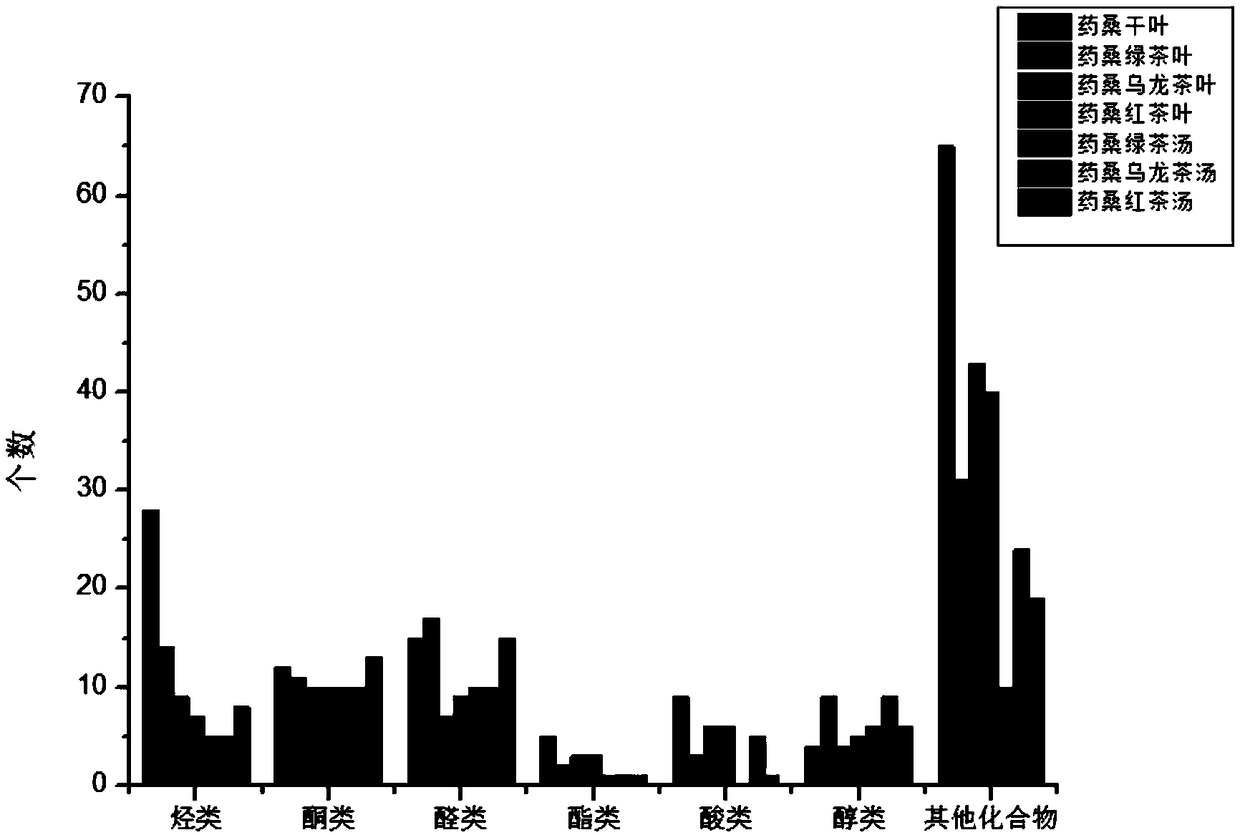

Sinkiang medicinal folium mori tea and making method thereof

InactiveCN109123017AGrowth inhibitionWith blood pressure loweringTea substituesAdditive ingredientBlack tea

The invention relates to Sinkiang medicinal folium mori tea which is made of Sinkiang medicinal folium mori leaves and comprises medicinal folium mori green tea, medicinal folium mori Wulong tea and medicinal folium mori black tea. By adopting the medicinal folium mori tea provided by the invention, the problem that conventional medicinal folium mori leaves are inconvenient to use and preserve issolved, most active substances and medicinal components in the medicinal folium mori leaves can be maintained, the medicinal folium mori tea is convenient to preserve and use and has taste and flavorsimilar to those of conventional tea, and utilization ways of the Sinkiang medicinal folium mori tea are enriched. The invention further provides a making method of the Sinkiang medicinal folium moritea.

Owner:TARIM UNIV

A kind of walnut fermented milk and preparation method thereof

ActiveCN113207971BImprove sensory qualityTaking into account stabilityMilk substitutesWalnut NutNutritive values

The invention relates to the technical field of food processing, in particular to walnut fermented milk and a preparation method thereof. The method of the present invention comprises the following steps: 1) baking the uncoated walnut kernels at 145-165° C. for 5-25 minutes; 2) deoiling the baked walnut kernels until the oil content is 20-50% , to obtain semi-skimmed walnut kernels; 3) mixing the semi-skimmed walnut kernels with a stabilizer, carbon source and water to obtain walnut slurry; 4) fully mixing the walnut slurry to sterilize, inoculate, and ferment . In the present invention, the aroma of walnuts can be effectively improved after being baked at high temperature. On this basis, the ideal flavor of the system can be guaranteed after removing part of the oil, and the quality is stable and nutritious can be obtained by removing the oil to the above level. Rich fermented milk.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

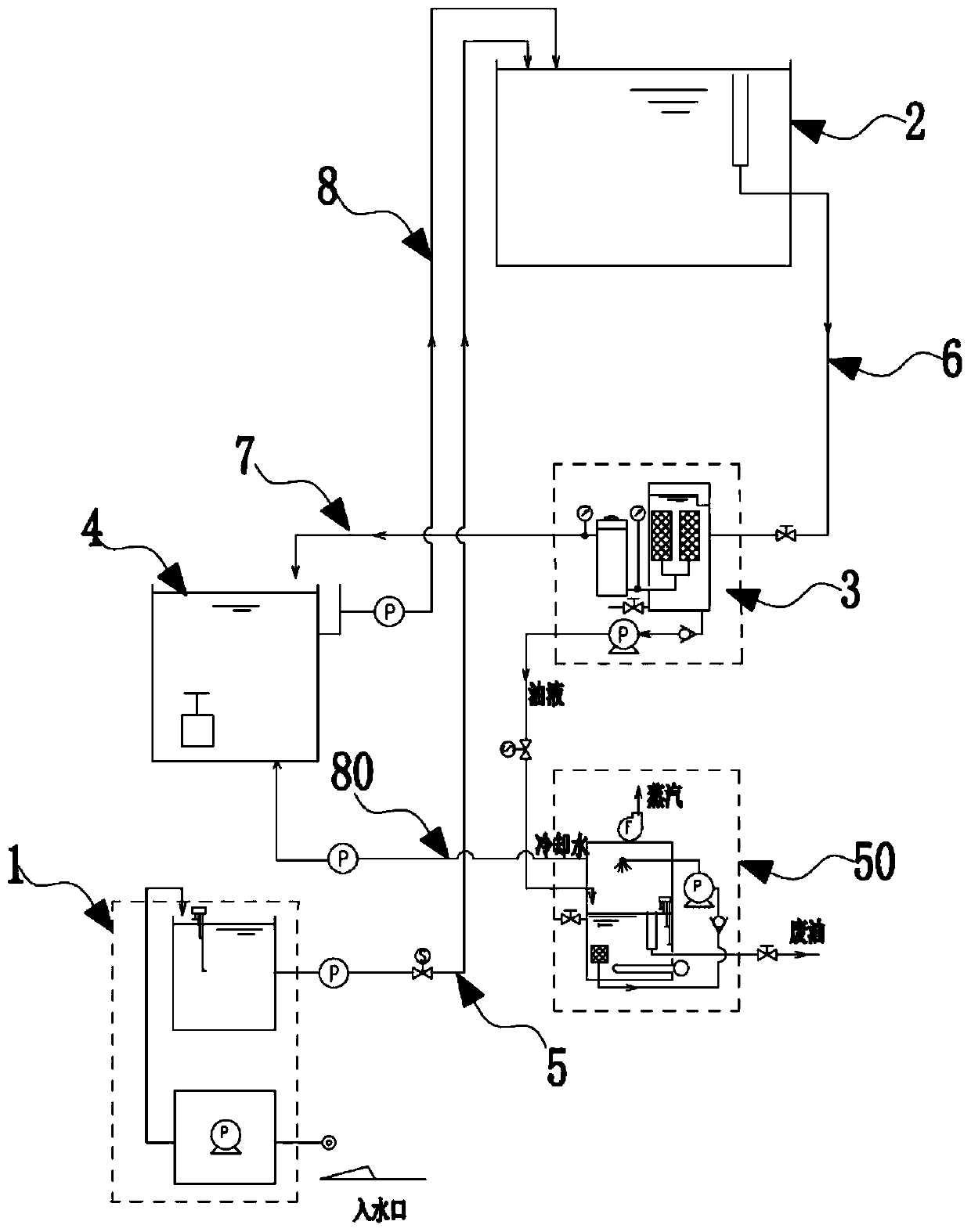

Liquid volume reduction device and energy saving and emission reduction type machining water treatment system

PendingCN109748348AReduce the amount of waterSmall volumeWater/sewage treatmentMultistage water/sewage treatmentWater treatment systemEnvironmental engineering

The invention discloses a liquid volume reduction device and an energy saving and emission reduction type machining water treatment system, wherein the liquid volume reduction device comprises a liquid feed pipeline, the liquid feed pipeline is connected with a heating tank, the heating tank heats a liquid in the heating tank through a heater, the heating tank is further provided with a water pumping pipeline connected with a nozzle in an atomizing chamber, the atomizing chamber is connected with an exhaust fan, an air outlet of the exhaust fan is connected with the atmosphere. The scheme usesthe characteristic that liquids of different densities are layered, the waste liquid is heated, then the different substances are layered, the heated water on the lower layer is atomized and discharged, so that the quantity of water in the waste liquid is reduced, the volume of the waste liquid is efficiently reduced, the discharged vapor is directly blended into the atmosphere, no pollution is caused, meanwhile, not like discharging water directly, no extra pipeline needs to be configured to transport, the environmentally friendliness is good, the whole equipment is compact in structure andlow in energy consumption, and the effective implementation means is provided for the volume reduction of the liquid.

Owner:TAKAHASHI METAL MFG SUZHOU

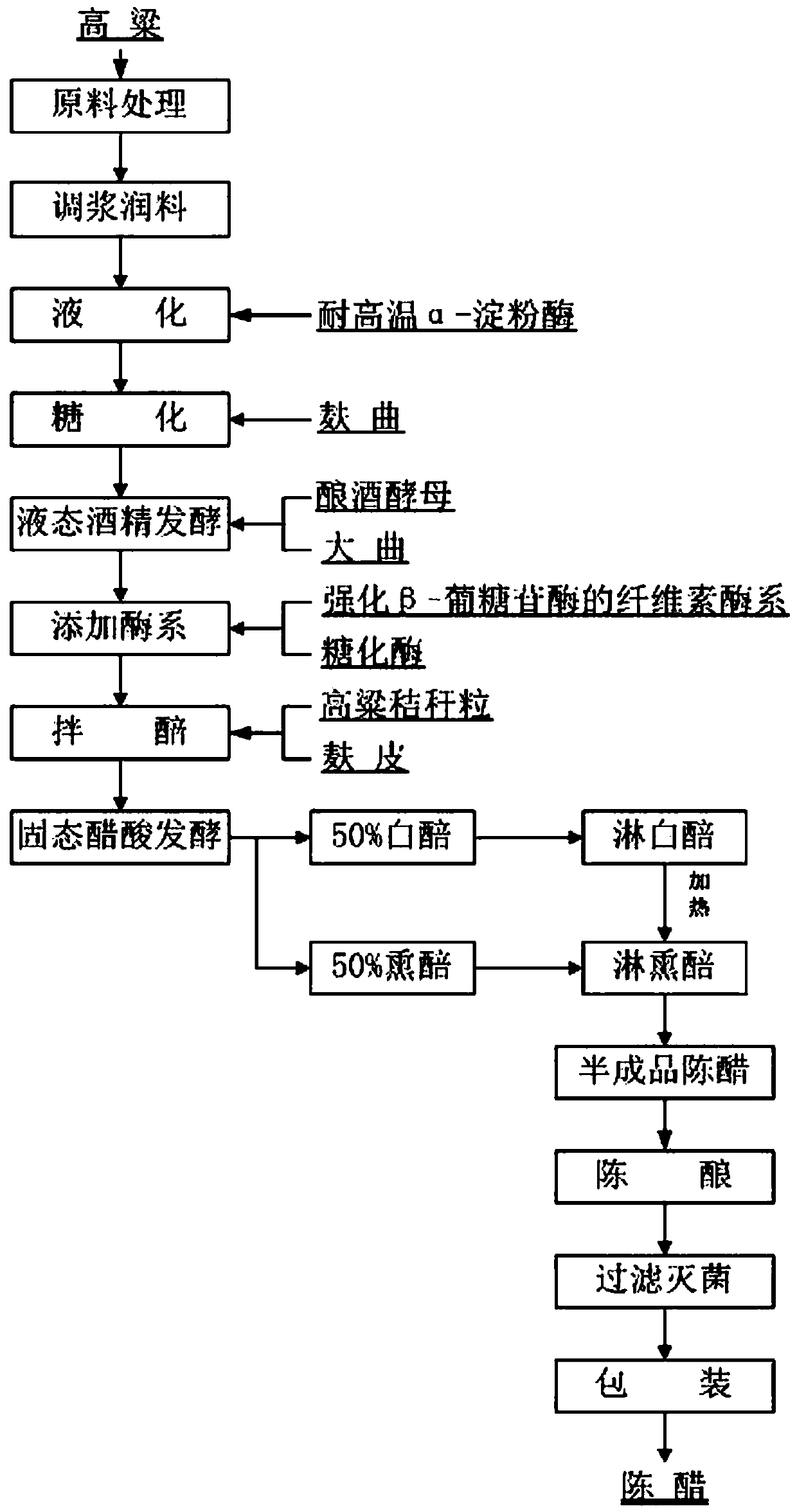

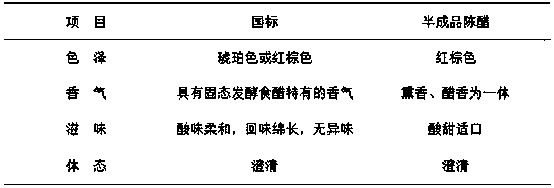

Method for brewing mature vinegar by using cellulase system to decompose sorghum straw instead of auxiliary materials

ActiveCN106754229BEvenly distributedImprove degradation rateVinegar preparationBiotechnologyEngineering

The invention discloses a method for brewing mature vinegar by utilizing cellulase system decomposed sorghum straw for replacing an auxiliary material. Sorghum is used as a raw material, and is subjected to liquid thick-mash alcoholic fermentation; afterwards, a proper amount of cellulase system for intensifying beta-glucosidase and a saccharifying enzyme are added into wine mash; meanwhile, the particle of sorghum straw is uniformly mixed with bran according to a certain proportion; an obtained first mixture is used as the auxiliary material; afterwards, the wine mash is uniformly mixed with the auxiliary material; an obtained second mixture is used as acetic fermenting grains; solid-state acetic fermentation is started; afterwards, a mature vinegar finished product is obtained through grain smoking, vinegar spraying and aging. The method is a novel way for the high-efficiency utilization of the sorghum straw; the production process is simple; not only is the variety of the mature vinegar enriched and is the production cost greatly decreased at the same time by using the sorghum straw for replacing auxiliary materials of rice bran, rice husk and the like, but also the pressure brought to an environment due to the incineration of the sorghum straw is reduced; the utilization rate of a resource is effectively improved.

Owner:SHANXI ZILIN VINEGAR

A kind of preparation method of waste edible oil-based unsaturated polyester resin

The invention relates to a method for preparing novel unsaturated polyester resin from waste cooking oil. According to the preparation method, characteristics of waste cooking oil are fully utilized. Waste cooking oil which undergoes preliminary purification and glycerin are mixed in a high pressure reactor to carry out pre-esterification treatment so as to reduce acid value of waste cooking oil; the waste cooking oil which has undergone pre-esterification treatment reacts with glycerol to carry out an alcoholysis reaction so as to generate monoglyceride; monoglyceride reacts with maleic anhydride to generate monoglyceride maleic acid half ester; and finally monoglyceride maleic acid half ester is mixed with styrene to obtain the novel unsaturated polyester resin. The synthesized resin has advantages of unique structure, high rigidity, high hardness, high temperature resistance, nonflammability and good dimensional stability of a product. before curing, the resin is a viscous liquid with low molecular weight; and during molding process, the resin can flow, has plasticity, can be made into a certain shape and simultaneously undergoes a chemical reaction to be cross-linked and cured. The resin is suitable for various composite material molding technologies such as mould pressing, lamination, transfer molding, casting and the like.

Owner:WUHAN TEXTILE UNIV

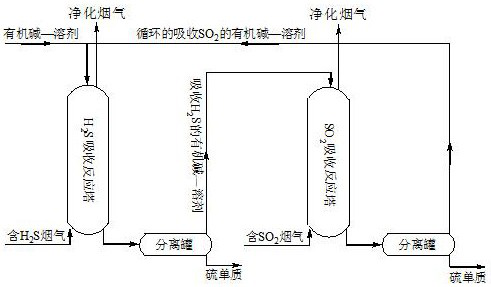

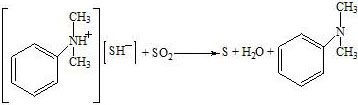

A cycle to remove h 2 s and so 2 And the method of recovering sulfur

ActiveCN109772134BAvoid desorption regeneration processRich ways to useDispersed particle separationSulfur preparation/purificationFluid phaseOrganic base

The invention discloses a cyclic removal of H 2 S and SO 2 And the method for recovering sulfur belongs to the fields of energy saving, emission reduction and gas purification. The method of the present invention will H 2 S or SO 2 with the absorbed SO into the column 2 or H 2 The organic base-solvent reaction of S will also be absorbed by the regenerated organic base and the unused organic base in the process, and the regenerated organic base and unused organic base will absorb H 2 S or SO 2 After solid-liquid separation in the separation tower, it can directly enter the next reaction absorption tower for use. The invention enables the traditional high-temperature gas phase Claus process to be realized under the condition of mild liquid phase, which not only breaks through the heat balance limitation of high temperature on the Claus reaction, thereby improving the conversion rate; 2 S and SO 2 There is the problem of high desorption energy consumption and serious loss of absorbent; secondly, this method performs absorption and reaction in a single device, which is more in line with the concept of green chemistry.

Owner:KUNMING UNIV OF SCI & TECH

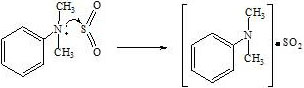

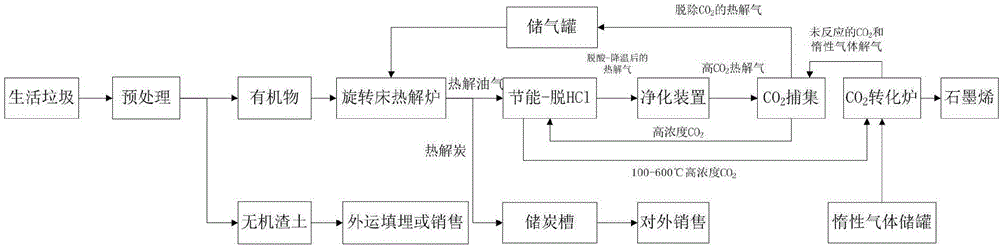

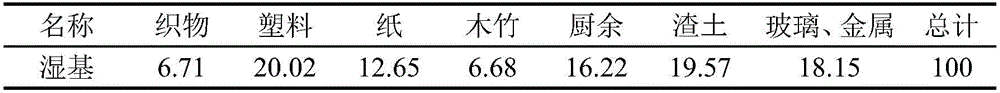

CO2 resource utilization system and CO2 resource utilization method in household garbage treatment

PendingCN106544049AHigh calorific valueRich ways to useChemical industryGrapheneProcess engineeringHigh concentration

The invention discloses a CO2 resource utilization system and a CO2 resource utilization method in household garbage treatment. The system comprises a pyrolysis unit, an energy-saving deacidifying unit, a gas purifying unit and a CO2 trapping unit, wherein the pyrolysis unit comprises a pyrolysis unit garbage inlet, a CO2-free pyrolysis gas inlet, a pyrolysis carbon outlet and a pyrolysis oil gas outlet; the energy-saving deacidifying unit comprises a pyrolysis oil gas inlet and a deacidified oil gas outlet; the pyrolysis oil gas inlet is connected with the pyrolysis oil gas outlet; the gas purifying unit comprises a deacidified oil gas inlet and a high-CO2 pyrolysis gas outlet; the CO2 trapping unit comprises a high-CO2 pyrolysis gas inlet and a CO2-free pyrolysis gas outlet; the CO2-free pyrolysis gas outlet is connected with the CO2-free pyrolysis gas inlet; and the high-CO2 pyrolysis gas inlet is connected with the high-CO2 pyrolysis gas outlet. According to the CO2 resource utilization system and the CO2 resource utilization method, high-concentration CO2 is separated from the raw material pyrolysis gas, graphene is prepared by a CO2 converter at certain temperature and under certain pressure, the heat value of the pyrolysis gas is increased, and the CO2 resource utilization is realized.

Owner:SHENWU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com