A cycle to remove h 2 s and so 2 And the method of recovering sulfur

A SO2, sulfur recovery technology, applied in chemical instruments and methods, separation methods, sulfur preparation/purification, etc., can solve the problems of long process, low conversion rate, high energy consumption, and achieve a large degree of reaction, high utilization efficiency, The effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

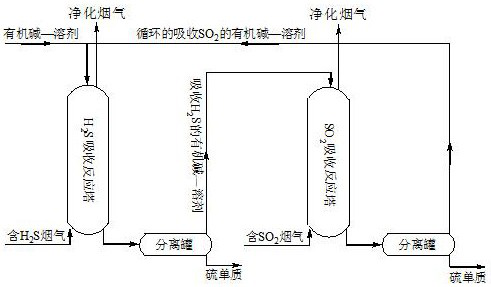

[0033] An energy-saving, efficient and recyclable H2 removal method using liquid-phase Claus 2 S and SO 2 The technical method of reclaiming sulfur, concrete process is as follows:

[0034] (1) H containing 1% atm 2 S exhaust gas from H 2 The bottom of the S absorption reaction tower is passed into, the liquid phase composed of organic base-solvent and the absorbed SO from the subsequent process cycle 2 The organic base-solvent liquid phase from H 2 The top of the S absorption reaction tower flows in, and the SO is absorbed circularly 2 The organic base-solvent will react with H 2 S undergoes a liquid-phase Claus reaction to produce sulfur and regenerates the organic base absorbent, while the unused organic base-solvent and the organic base regenerated by the liquid-phase Claus reaction also absorb the incoming H 2 S, the treated waste gas is discharged from the top of the tower; then absorbed H 2 S and the organic base-solvent solid-liquid two-phase system containing s...

Embodiment 2

[0038] An energy-saving, efficient and recyclable H2 removal method using liquid-phase Claus 2 S and SO 2 The technical method of reclaiming sulfur, concrete process is as follows:

[0039] (1) H containing 5% atm 2 S exhaust gas from H 2 The bottom of the S absorption reaction tower is passed into, the liquid phase composed of organic base-solvent and the absorbed SO from the subsequent process cycle 2 The organic base-solvent liquid phase flows in from the top of the tower, and the SO 2 The organic base-solvent will react with H 2 S undergoes a liquid-phase Claus reaction to produce sulfur and regenerates the organic base absorbent, while the unused organic base-solvent and the organic base regenerated by the liquid-phase Claus reaction also absorb the incoming H 2 S, the treated waste gas is discharged from the top of the tower. then absorbed H 2 S and the organic base-solvent solid-liquid two-phase system containing sulfur element from H 2 The bottom of the S absor...

Embodiment 3

[0043] An energy-saving, efficient and recyclable H2 removal method using liquid-phase Claus 2 S and SO 2 The technical method of reclaiming sulfur, concrete process is as follows:

[0044] (1) H containing 1% atm 2 S exhaust gas from H 2 The bottom of the S absorption reaction tower is passed into, the liquid phase composed of organic base-solvent and the absorbed SO from the subsequent process cycle 2 The organic base-solvent liquid phase flows in from the top of the tower, and the SO 2 The organic base-solvent will react with H 2 S undergoes a liquid-phase Claus reaction to produce sulfur and regenerates the organic base absorbent, while the unused organic base-solvent and the organic base regenerated by the liquid-phase Claus reaction also absorb the incoming H 2 S, the treated waste gas is discharged from the top of the tower. then absorbed H 2 S and the organic base-solvent solid-liquid two-phase system containing sulfur element from H 2 The bottom of the S absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com