A kind of preparation method of waste edible oil-based unsaturated polyester resin

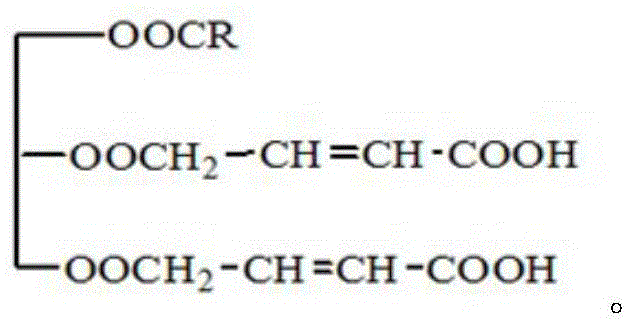

A technology of waste cooking oil and polyester resin, which is applied in the field of preparation of new unsaturated polyester resin from renewable waste cooking oil, which can solve the problems of limited reuse of waste cooking oil and limited production scale, and achieve dimensional stability of products Good, high temperature resistance, rich utilization methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

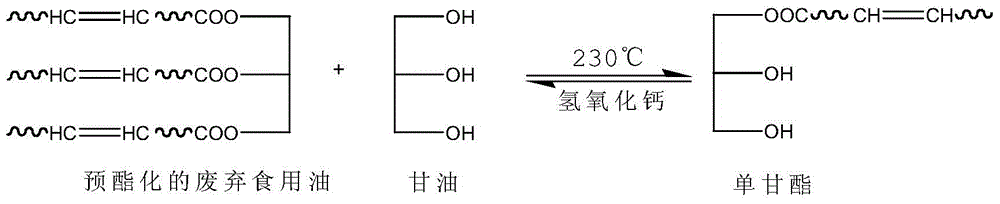

[0034] Preparation of B monoglycerides

[0035] The waste edible oil and glycerol with an acid value of less than 1mgKOH / g are put into the reactor at a ratio of 2.5:1 to 3:1, and N is fed into the reactor. 2 , in N 2 Under the protection, add 0.1-0.3% catalyst Ca(OH) of waste edible oil with a relative acid value of less than 1mg KOH / g and glycerol to the reaction kettle 2 , the temperature of the reactor was raised to 210-250°C, and the catalyst Ca(OH) 2 Under the action, alcoholysis reaction is carried out on waste edible oil whose acid value is less than 1mgKOH / g, and the reaction time is 3-5h, and then the temperature is lowered to below 15 DEG C to obtain monoglyceride, which is ready for use.

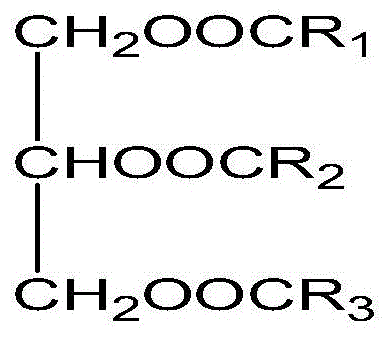

[0036] The waste edible oil with an acid value of less than 1mgKOH / g and glycerol are subjected to alcoholysis reaction to obtain monoglycerides, and the general reaction formula is as follows:

[0037]

[0038]The synthesis principle of this step is: the redistribution of ...

Embodiment 1

[0050] Embodiment 1, by above-mentioned preparation method:

[0051] A Pre-esterification treatment of waste edible oil

[0052] Put the preliminarily purified 70% waste edible oil and 30% glycerin into an autoclave, react at a high temperature of 200°C for 6 hours, and pre-esterify the preliminarily purified waste edible oil. The acid value of the waste edible oil was 0.8 mgKOH / g.

[0053] Preparation of B monoglycerides

[0054] The waste edible oil and glycerol with an acid value of 0.8mgKOH / g are put into the reactor at a ratio of 2.5:1, and N is fed into the reactor. 2 , in N 2 Under the protection, a catalyst Ca(OH) with a relative acid value of 0.8mgKOH / g and 0.1% of the total amount of waste edible oil and glycerol was added to the reactor. 2 , the reactor was heated to 210°C, and the catalyst Ca(OH) 2 Under the action, alcoholysis reaction is performed on waste edible oil with an acid value of 0.8 mgKOH / g, the reaction time is 3 h, and then the temperature is low...

Embodiment 2

[0059] Embodiment 2, by above-mentioned preparation method:

[0060] A Pre-esterification treatment of waste edible oil

[0061] Put the preliminarily purified 80% waste edible oil and 20% glycerin into the autoclave, react at a high temperature of 215 ° C for 8 hours, pre-esterify the preliminarily purified waste edible oil, and after the pre-esterification The acid value of the waste edible oil was 0.7 mgKOH / g.

[0062] Preparation of B monoglycerides

[0063] The waste edible oil and glycerol with an acid value of 0.7mgKOH / g are put into the reactor at a ratio of 2.7:1, and N is fed into the reactor. 2 , in N 2 Under the protection, 0.2% catalyst Ca(OH) with a relative acid value of 0.7mgKOH / g waste edible oil and glycerol was added to the reactor. 2 , the reaction kettle was heated to 230 ° C, and the catalyst Ca(OH) 2 Under the action, alcoholysis reaction is carried out on waste edible oil with an acid value of 0.7 mgKOH / g, the reaction time is 4 h, and then the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com