A kind of walnut fermented milk and preparation method thereof

A technology for fermented milk and walnuts, applied in dairy products, milk substitutes, milk preparations, etc., can solve the problem that nutrition and health are not as good as pure fermented yogurt, it is difficult to ferment and prepare pure fermented yogurt, and fermented milk is unstable, etc. problems, to achieve the effect of enriching utilization channels, improving sensory quality, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

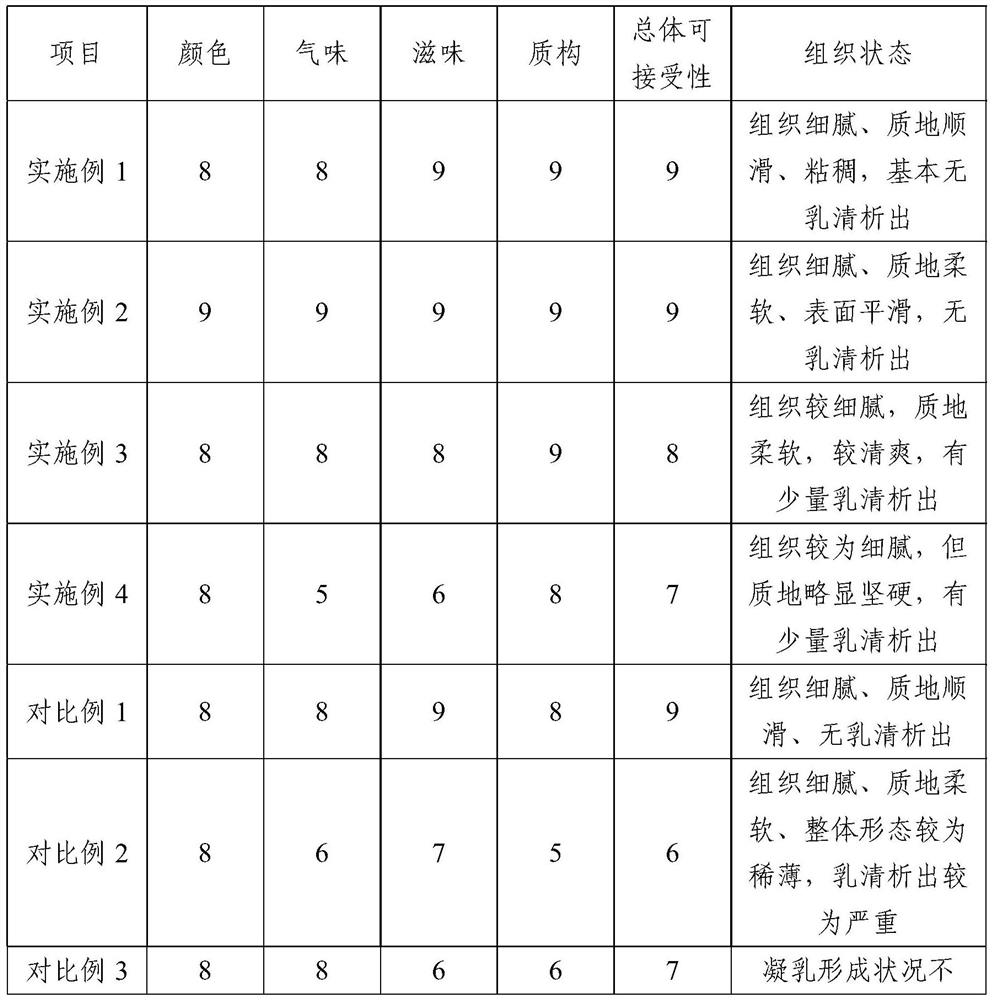

Embodiment 1

[0034] The present embodiment relates to a preparation method of walnut fermented milk, comprising the following steps:

[0035] (1) Bake the undressed walnut kernels at 160°C for 15min, and cool to room temperature for subsequent use;

[0036] (2) squeezing the roasted walnut kernels at 6MPa for 15min to obtain semi-skimmed roasted walnuts with a fat content of 49.61%;

[0037] (3) the semi-skimmed roasted walnut obtained in step (2) is mixed with auxiliary materials, carbon source and water and then refined to obtain a walnut slurry, in which the mass ratio of the semi-skimmed roasted walnut to water is 1:13 The percentage of the adjuvant added in the mass of the walnut slurry is: diacetyl tartaric acid mono-diglyceride 0.05wt%, hydroxypropyl distarch phosphate 0.08wt%, pectin 0.3wt%; the carbon source is sucrose 8wt% ; the water is pure water; the refining speed is 36000r / min; the refining temperature is 40°C;

[0038] (4) add the hot-pressed walnut oil after heating to 1...

Embodiment 2

[0045]The present embodiment relates to a preparation method of walnut fermented milk, comprising the following steps:

[0046] (1) Bake the undressed walnut kernels at 145°C for 20min, and cool to room temperature for subsequent use;

[0047] (2) squeezing the roasted walnut kernels at 8MPa for 40min to obtain semi-skimmed roasted walnuts with a fat content of 40%;

[0048] (3) the semi-skimmed roasted walnut obtained in step (2) is mixed with auxiliary materials, carbon source and water and then refined to obtain walnut slurry, and the mass ratio of semi-skimmed and water in the walnut slurry is 1:10; the described The percentage of the adjuvant added in the mass of the walnut slurry is: 1.5wt% of hydroxypropyl distarch phosphate, 0.3wt% of sodium carboxymethyl cellulose, and 0.1wt% of agar; the carbon source is 5wt% of glucose; the The water is pure water; the refining speed is 30000r / min; the refining temperature is 50°C;

[0049] (4) add the hot-pressed walnut oil after...

Embodiment 3

[0055] The present embodiment relates to a preparation method of walnut fermented milk, comprising the following steps:

[0056] (1) Bake the undressed walnut kernels at 165°C for 5min, and cool to room temperature for subsequent use;

[0057] (2) squeezing the roasted walnut kernels at 22 MPa for 30 min to obtain semi-skimmed roasted walnuts with a fat content of 21%;

[0058] (3) mixing the semi-skimmed roasted walnut obtained in step (2) with auxiliary materials, carbon source and water and then refining to obtain a walnut slurry, and the mass ratio of semi-skimmed and water in the walnut slurry is 1:10; the described The percentage of the adjuvant added in the mass of the walnut slurry is: pectin 0.15wt%, gellan gum 0.3wt%; the carbon source is sucrose 7wt%; the water is pure water; the grinding speed is 36000r / min; The refining temperature is 65°C;

[0059] (4) add the hot-pressed walnut oil after heating to 150 DEG C of cooling by 2% of the quality of the walnut slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com