A kind of recycled semi-flexible pavement material and its preparation method

A semi-flexible pavement and regeneration agent technology, applied in building insulation materials, building components, buildings, etc., can solve the problems of waste asphalt concrete such as poor anti-aging performance, difficult to use, insufficient bearing capacity, etc., to overcome cracking problems, good adhesion Polymerization ability and excellent viscoelastic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

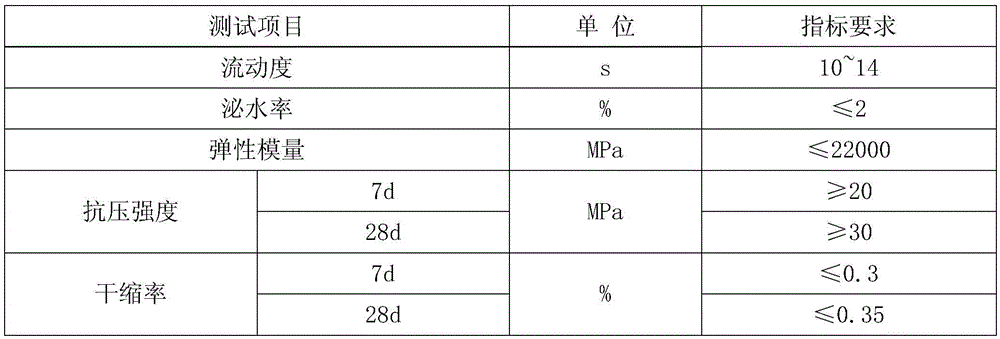

Examples

Embodiment 1

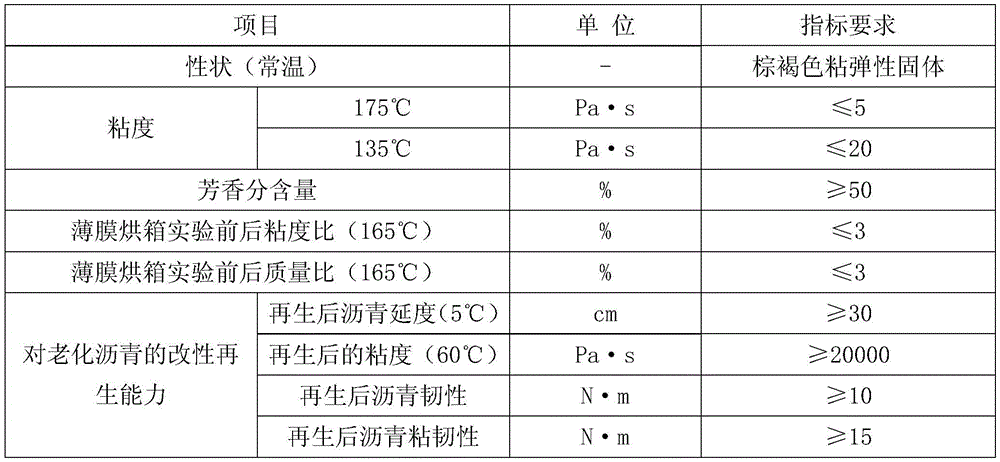

[0045] Preparation of aged asphalt modified regenerant:

[0046] According to the mass ratio, the second-line extraction oil: styrene-butadiene-styrene block copolymer: C9 petroleum resin: carboxylated polyethylene wax = 100:20:15:5 ingredients, first base oil (minus the second-line extraction oil) to 165°C, start the high-speed shearing machine at a speed of 3500r / min, add styrene-butadiene-styrene block copolymer, C9 petroleum resin and carboxylated polyethylene wax components in sequence, and continue shearing for 30min , and then placed in an oven at 155°C for 40 minutes to develop, and after taking it out, let it stand at room temperature for 60 minutes to obtain an aged asphalt modified regenerant, which will be used after heating.

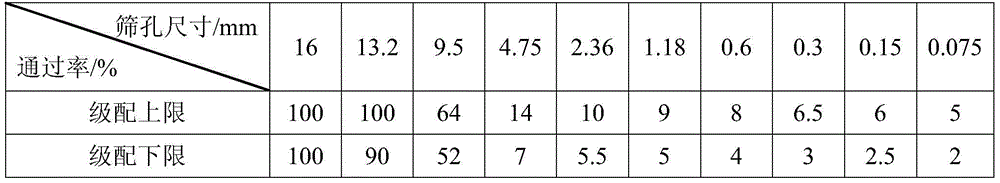

[0047] The composition of mineral materials:

[0048] According to the mass ratio, the sieve part of the waste asphalt coarse aggregate of 2.36 mm, basalt (size 5-10 mm, 10-15 mm), limestone powder = 100: 120: 3 ingredients. The waste asph...

Embodiment 2

[0057] Preparation of aged asphalt modified regenerant:

[0058] According to the mass ratio, the three-line extraction oil: styrene-butadiene-styrene block copolymer: C9 petroleum resin: carboxylated polyethylene wax = 100:30:10:10 ingredients, first heat the base oil to 170 ° C , start the high-speed shearing machine at a speed of 4500r / min, add styrene-butadiene-styrene block copolymer, C9 petroleum resin and carboxylated polyethylene wax components in sequence, continue shearing for 50min, and then place it at 160°C Develop in an oven for 60 minutes, take it out and let it stand at room temperature for 60 minutes to obtain the aged asphalt modified regenerant, which will be used after heating.

[0059] The composition of mineral materials:

[0060] According to the mass ratio, the sieve part of the waste asphalt coarse aggregate of 2.36 mm, basalt (5-10 mm, 10-15 mm in size), and finely ground mineral powder in the strong basic rock in the magmatic rock = 100: 140: 3.5 in...

Embodiment 3

[0069] Preparation of aged asphalt modified regenerant:

[0070] According to the mass ratio, the second-line extraction oil: styrene-butadiene-styrene block copolymer: terpene resin: carboxylated polyethylene wax = 100:30:15:18 ingredients, first heat the base oil to 170 ° C , start the high-speed shearing machine at a speed of 5000r / min, add styrene-butadiene-styrene block copolymer, terpene resin and carboxylated polyethylene wax components in sequence, continue shearing for 50min, and then place it at 155°C Develop in an oven for 60 minutes, take it out and let it stand at room temperature for 90 minutes to obtain the aged asphalt modified regenerant, which will be used after heating.

[0071] The composition of mineral materials:

[0072] According to the mass ratio, the above-sieve part of the waste asphalt coarse aggregate of 2.36 mm, limestone (size 5-10 mm, 10-15 mm), and strong basic rock in the magmatic rock are finely ground ore powder = 100: 160: 5.5 ingredients ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com