Improvement method and special equipment for iron-containing slag

A special equipment and upgrading technology, which is applied in the utilization field of metallurgical slag, can solve the problems of inability to achieve quenching and tempering, poor economic benefits, high cost, etc., and achieve the effects of diversified utilization methods, less environmental pollution and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific embodiments, and the advantages and characteristics of the present invention will become clearer along with the description. However, these embodiments are only exemplary and do not constitute any limitation to the scope of the present invention. It should be understood by those skilled in the art that the details and forms of the present invention can be modified or replaced without departing from the spirit and scope of the present invention, but these modifications and replacements all fall within the protection scope of the present invention.

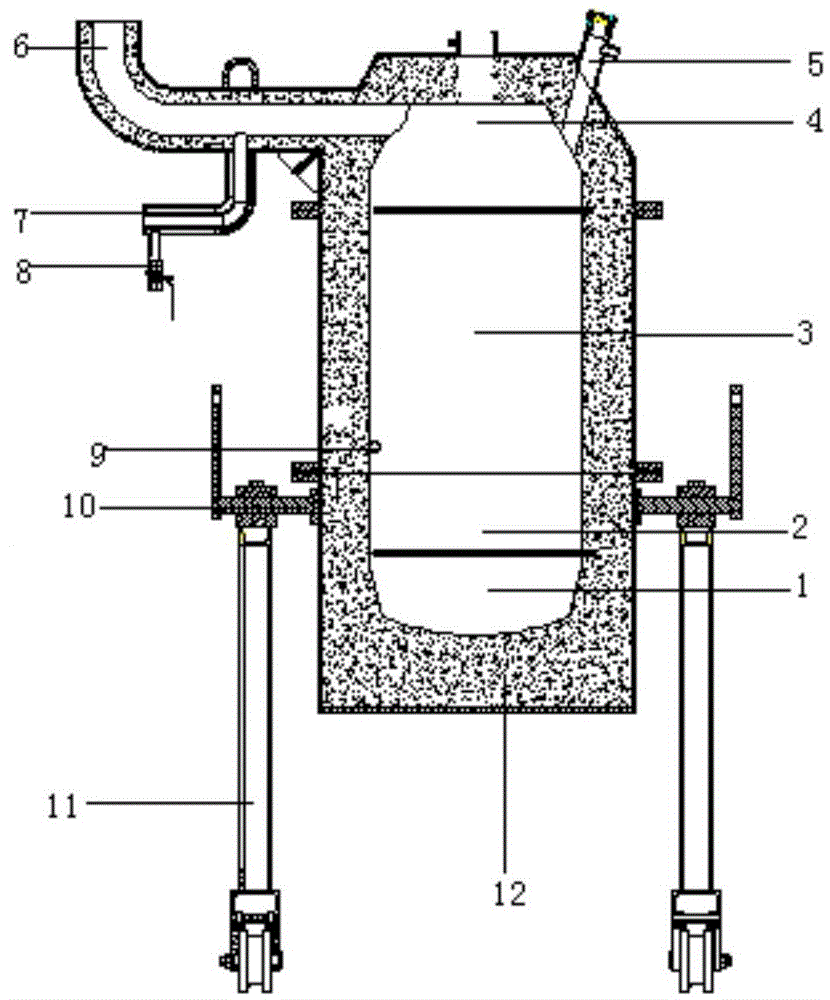

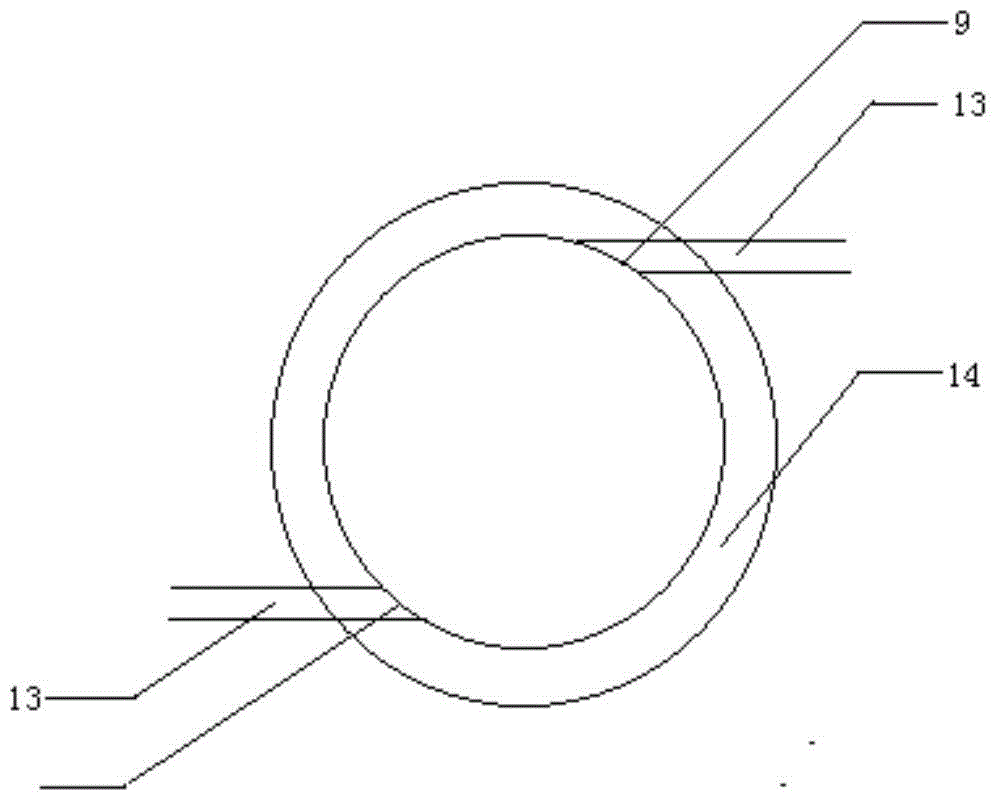

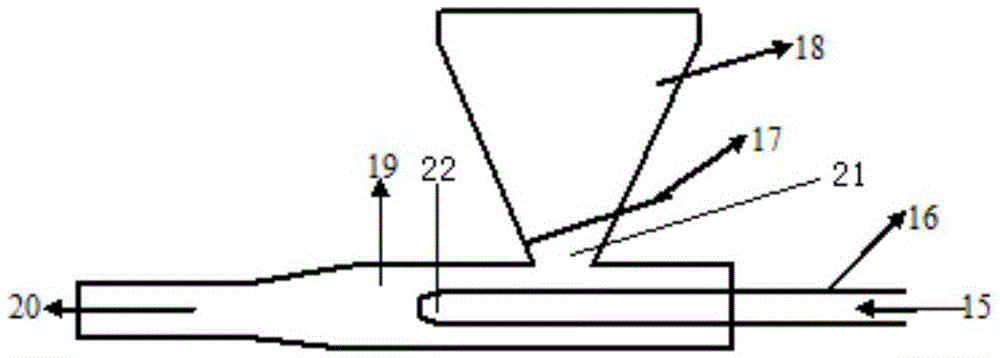

[0032] Taking the use of fly ash as a modifying agent to modify molten steel slag into glass-ceramic raw materials as an example, the embodiment of the present invention will be further described. There are two processes of crystal glass modification. Iron upgrading is to firstly adjust the binary alkalinity of steel slag to the optimal iron al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com