Bottom-top composite injection smelting reduction furnace for treating molten copper slag

A technology for melting copper and reduction furnaces, which is applied in electric furnaces, crucible furnaces, rotary drum furnaces, etc. It can solve the problems of low heat utilization rate and long reduction time, and achieve the effects of reducing labor intensity, reducing energy consumption, and stabilizing heat balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

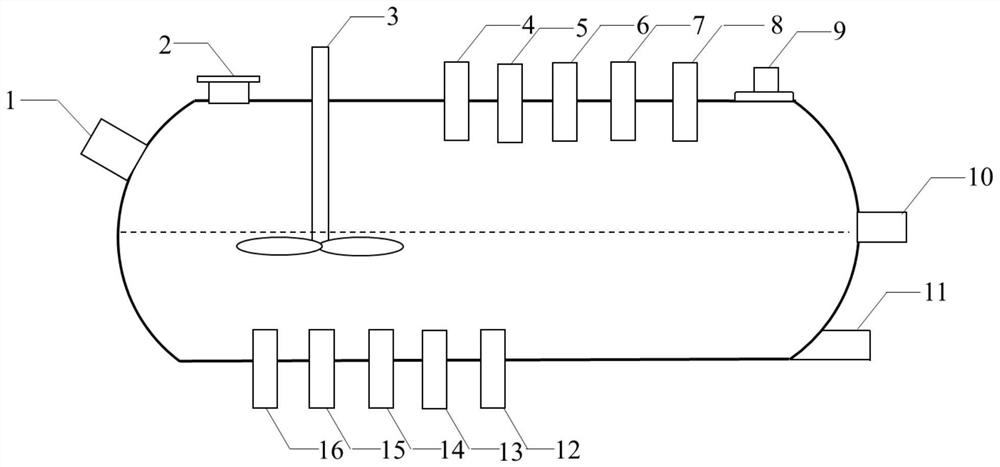

[0042] The structure of the bottom-top compound injection smelting reduction furnace for processing molten copper slag is as follows: figure 1 As shown, it includes a horizontal furnace body, molten copper slag inlet 1, feeding port 2, exhaust port 9, slag discharge port 10, iron discharge port 11, stirring device 3, first top blowing lance 4, second top blowing lance 5. The third top blowing spray gun 6, the fourth top blowing spray gun 7, the fifth top blowing spray gun 8, the first bottom blowing spray gun 16, the second bottom blowing spray gun 15, the third bottom blowing spray gun 14, the fourth bottom blowing spray gun 13 and the fifth bottom blowing lance 12;

[0043] The horizontal furnace body is composed of a horizontally placed cylinder and the heads at both ends;

[0044]The charging port 2 is located at the top of one side of the horizontal furnace body, and the exhaust port 9 is located at the top of the other side of the horizontal furnace body; Among them, t...

Embodiment 2

[0057] The structure of the bottom-top compound injection smelting reduction furnace for processing molten copper slag is the same as in Example 1;

[0058] Method is with embodiment 1, and difference is:

[0059] (1) Inject gas reducing agent into the horizontal furnace body through the bottom blowing lance;

[0060] (2) The amount of slagging agent is based on the binary basicity (CaO / SiO 2 ) is added at 1.2; the consumption of reducing agent is added by 1.3 times of the total amount required to complete the reduction reaction;

[0061] (3) Heating and controlling the molten pool to a temperature of 1500°C; the average residence time of the molten copper slag in the horizontal furnace body is 45 minutes;

[0062] (4) The copper-containing molten iron contains 0.84% Cu by mass percentage.

Embodiment 3

[0064] The structure of the bottom-top compound injection smelting reduction furnace for processing molten copper slag is the same as in Example 1;

[0065] Method is with embodiment 1, and difference is:

[0066] (1) Inject gas reducing agent into the horizontal furnace body through the bottom blowing lance;

[0067] (2) The amount of slagging agent is based on the binary basicity (CaO / SiO 2 ) is added at 1.4; the consumption of reducing agent is added by 1.5 times of the total amount required to complete the reduction reaction;

[0068] (3) Heating and controlling the molten pool to a temperature of 1480°C; the average residence time of the molten copper slag in the horizontal furnace body is 50 minutes;

[0069] (4) The copper-containing molten iron contains 0.81% Cu by mass percentage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com