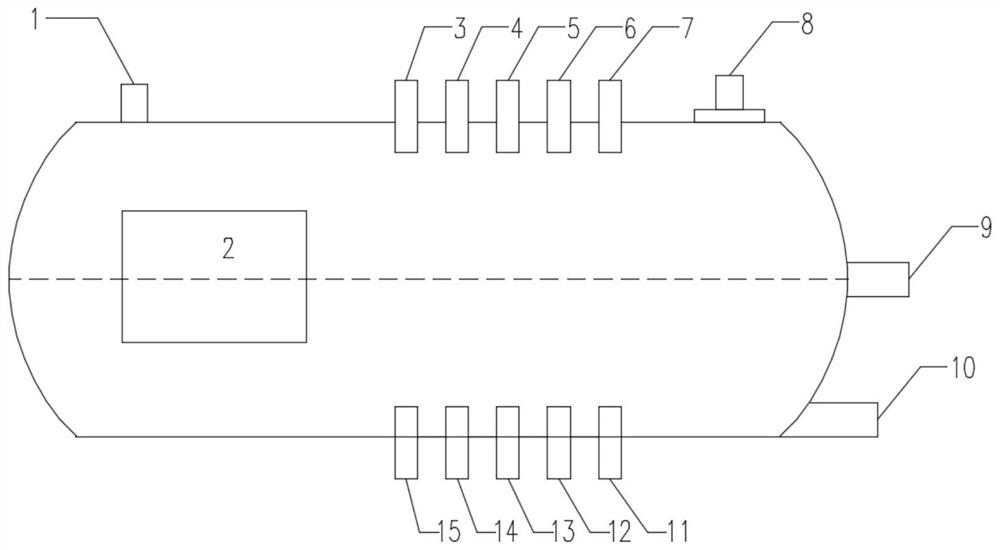

Bottom-top composite injection smelting reduction furnace for treating high-iron red mud

A technology of high-speed iron red mud and reduction furnace, which is applied in the direction of reducing gas emission, can solve the problems of low heat utilization rate and long equipment reduction time, and achieve the effects of improving reduction rate, strengthening melting reduction efficiency and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The reducing agent is coke, and the molar ratio of the carbon in the reducing agent to the iron oxide in the high-iron red mud is 1.5:1; the ratio of the calcium oxide in the added lime to the sum of the mass of silica and alumina in the high-iron red mud is 1.5:1 ; The added amount of fluorite is 8% of the added amount of calcium oxide. The reduction process temperature is 1650°C, and the reduction time is 20 minutes. After reduction, the iron reduction rate is 96.5%, and about 70% of the sodium oxide in the red mud is enriched in the flue gas for recovery.

Embodiment 2

[0038]The reducing agent is spent cathode carbon block, and the molar ratio of the carbon in the reducing agent to the iron oxide in the high-iron red mud is 6.5:1; 0.8:1; the added amount of fluorite is 15% of the added amount of calcium oxide. The reduction process temperature is 1350°C, and the reduction time is 120min. After reduction, the reduction rate of iron is 95.0%, and about 30% of the sodium oxide in the red mud is enriched in the flue gas for recovery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com