Iron tailing gravel hydraulic pavement base material and preparation method thereof

A technology of pavement base materials and iron tailings, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems that cannot meet the road strength requirements, easily cause shrinkage cracks, and low concrete strength, and achieve rich and comprehensive Utilization methods, improvement of comprehensive utilization rate, and effect of saving sand and gravel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The iron tailing gravel hydraulic pavement base material of the present embodiment includes the following components by mass: 60 parts of iron tailings, 20 parts of crushed stones of 5-10mm, 20 parts of crushed stones of 15-30mm, and 6 parts of curing agent , 7.1 parts of water;

[0035] The curing agent of this embodiment includes the following components in mass percentage: CaO content 50%, Al 2 o 3 Content 12%, MgO content 3%, SiO2 content 35%;

[0036] The particle size specifications of iron tailings in this embodiment are: 0.3mm sieve hole pass rate is 85.4%, 0.075mm sieve hole pass rate is 54.8%; coarse sand particle size specification is: 0.3mm sieve hole pass rate is 47.4%, 0.075 mm sieve pass rate is greater than 11%.

[0037] The bearing ratio CBR of iron tailings is 38.

[0038] The preparation method of the iron tailing gravel hydraulic pavement base material of the present embodiment comprises the following steps:

[0039] Step 1. Take the iron tailin...

Embodiment 2

[0048] The iron tailing gravel hydraulic pavement base material of the present embodiment comprises the following components by mass: 51 parts of iron tailings, 9 parts of coarse sand, 20 parts of crushed stones of 5-10mm, and 20 parts of crushed stones of 15-30mm , 6 parts of curing agent, 6.5 parts of water;

[0049] The curing agent of this embodiment includes the following components in mass percentage: CaO content 50%, Al 2 o 3 Content 12%, MgO content 3%, SiO2 content 35%;

[0050] The particle size specifications of the iron tailings in this embodiment are: the pass rate of 0.3mm sieve hole is 87.3%, and the pass rate of 0.075mm sieve hole is 56.4%.

[0051] The bearing ratio CBR of iron tailings is 39.

[0052] The preparation method of the iron tailing gravel hydraulic pavement base material of the present embodiment comprises the following steps:

[0053] Step 1. Take the iron tailings with the above-mentioned particle size specifications for subsequent use, and ...

Embodiment 3

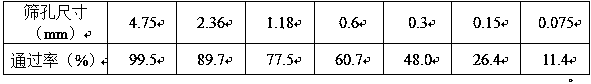

[0060] In this embodiment, the curing agent is the same as in Embodiment 1, the bearing ratio CBR of the iron tailings is 41, and the gradation particle size distribution of the iron tailings is:

[0061]

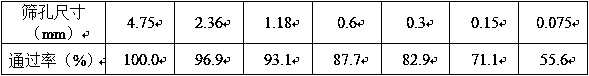

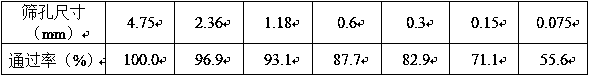

[0062] The particle size distribution of coarse sand gradation is:

[0063]

[0064] .

[0065] The preparation method of the iron tailing gravel hydraulic pavement base material of the present embodiment comprises the following steps:

[0066] Step 1, preparing the above curing agent for subsequent use;

[0067] Step 2: Take 42 parts of screened iron tailings, 18 parts of coarse sand, 20 parts of 5-10mm crushed stones, 20 parts of 15-30mm crushed stones and 6 parts of curing agent by quality and put them into the stabilized soil mixer. Mix evenly, then add 6.1 parts of water and stir evenly for 18 seconds;

[0068] Step 3: Extrude the mixed material stirred in step 2 with a press, and maintain the extruded mixed material for 7 days to obtain the iron tailing sand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com