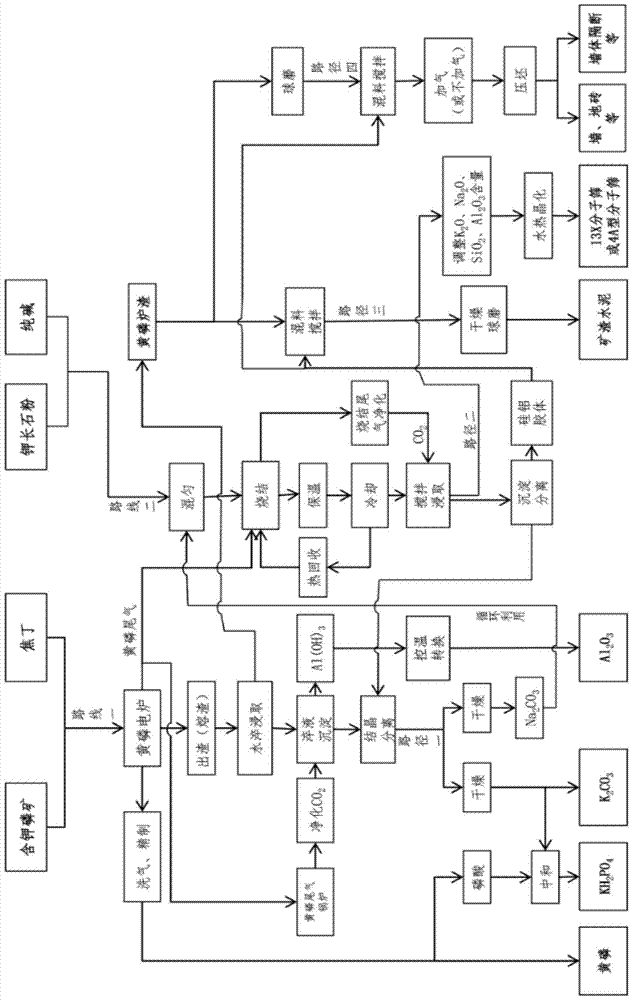

Circular clean production method for preparing yellow phosphorus, potassium salt, alumina, molecular sieve, slag cement and building profiles from potassium-containing phosphate rock

A technology of slag cement and molecular sieve, which is applied in the field of phosphorus chemical industry, can solve the problems of non-compliance with yellow phosphorus enterprises, insufficient use of heat, and reduction of production energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] A potassium-containing phosphate mining enterprise has 5 sets of yellow phosphorus electric furnaces with a capacity of 5×20000KVA. Its potassium phosphate rock P 2 o 5 content of 17%, SiO 2 content of 28%, CaO content of 35%, CO 2 The content is 3.9%, K 2 O content is 5%, Na 2 O content is trace. P obtained after beneficiation 2 o 5 content of 23%, SiO 2 content of 12%, CaO content of 32%, CO 2 The content is 3.9%, K 2 O content is 2.9%, Na 2 Potassium-containing phosphate ore concentrate with a small amount of O content.

[0075] According to the method of the invention, the potassium-containing phosphate ore concentrate is used to form pellets, and the yellow phosphorus tail gas is used to dry, consolidate into pellets and coke to produce yellow phosphorus. The ratio of the yellow phosphorus electric furnace is potassium-containing phosphate ore concentrate pellets: coke diced = 1000:145. The slag is quenched with water to remove the slag, and the filtra...

Embodiment 2

[0079] A factory has 1 yellow phosphorus electric furnace with a capacity of 1×20000KVA.

[0080] According to the method of the present invention, with P 2 o 5 content of 20.5%, SiO 2 content of 22.2%, CaO content of 33.0%, K 2 O content is 1.89%, Na 2 O content is 0.44%, CO 2 Potassium-containing phosphate rock (15-25mm) with a content of 4.0% and coke (3-25mm) with a fixed carbon content of 80% are added to the yellow phosphorus electric furnace according to the ratio of potassium-containing phosphate rock: coke diced = 1000:131.5. The slag is quenched with water to remove the slag, and the filtrate is used for later use. Potassium feldspar concentrate K selected from potassium-containing phosphate rock 2 O content is 14.5%, Na 2 O content is a trace amount of potassium feldspar powder and Na 2 CO 3 Mixed according to 1:0.92, after 5 seconds high-temperature rapid calcination, calcination temperature 830 ℃, 800 ℃ constant temperature 2h, after leaching, into CO 2 ...

Embodiment 3

[0084] A company has 2 yellow phosphorus electric furnaces with a capacity of 2×20000KVA.

[0085] According to the method of the present invention, with P 2 o 5 content of 19.5%, SiO 2 content of 22.2%, CaO content of 33.0%, K 2 O content is 2.2%, Na 2 O content is 0.10%, CO 2 Potassium-containing phosphate rock (15-25mm) with a content of 4.0% and coke (3-25mm) with a fixed carbon content of 80% are added to the yellow phosphorus electric furnace according to the ratio of potassium-containing phosphate rock: coke diced = 1000:125.6. The slag is quenched with water to remove the slag, and the filtrate is used for later use. Potassium feldspar concentrate K selected from potassium-containing phosphate rock 2 O content is 15%, Na 2 Potassium feldspar powder with 1% O content and Na 2 CO 3 Mixed according to 1:0.92, after 5 seconds high-temperature rapid calcination, calcination temperature 830 ℃, 800 ℃ constant temperature 2h, after leaching, into CO 2 , to precipitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com