Method and system for hydrogen production and electricity production by two-step thermochemical cycle decomposition of water

A thermochemical cycle and water splitting technology, applied in chemical instruments and methods, hydrogen production, inorganic chemistry, etc., can solve the problem of low energy utilization and hydrogen production efficiency, which do not meet the requirements of global sustainable development and strategic requirements, Exacerbate problems such as global energy exhaustion, achieve the effect of improving energy utilization, saving storage and transportation costs, and avoiding emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

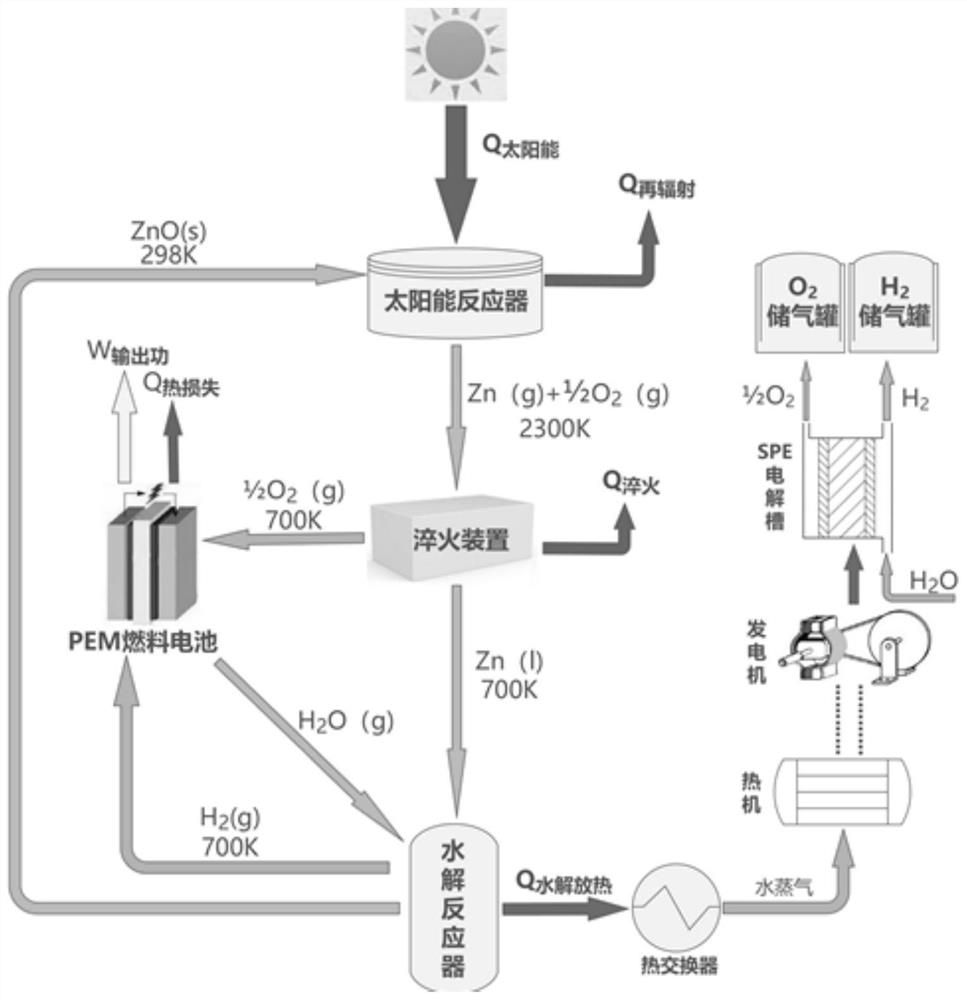

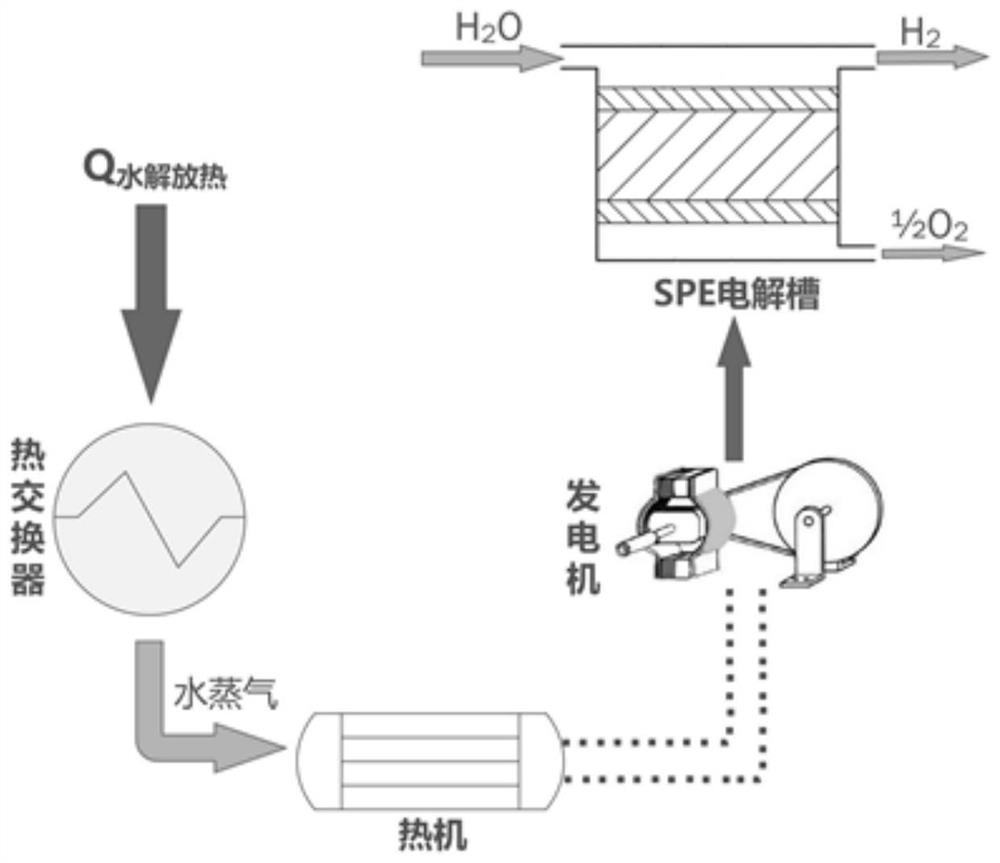

[0040] Under the conditions of solar flux C=5000 and constant pressure of 1bar, solid zinc oxide enters the solar reactor at a molar rate of 1mol / s. The solar reactor is a window rotating cavity receiver that absorbs concentrated solar energy and works The temperature is 2300K, and the solid zinc oxide is thermally decomposed into oxygen and zinc vapor in the reactor.

[0041] The inert gas is passed into the solar reactor, the molar ratio of the inert gas and the zinc vapor is kept below 10, and the gaseous product oxygen and zinc vapor are swept out of the reactor by the continuous flow of the inert gas and enter the quenching device.

[0042] The quenching device is a water-cooled condenser, in which 2300K oxygen and zinc vapor are rapidly cooled to 700K oxygen and zinc liquid, and oxygen and zinc liquid can be separated naturally.

[0043] Put the separated zinc liquid and water vapor with a molar rate of 1mol / s into the hydrolysis reactor, and at a temperature of 700K, hy...

Embodiment 2

[0048] Under the conditions of solar flux C=10000 and constant pressure of 1bar, solid zinc oxide enters the solar reactor at a molar rate of 1mol / s. The solar reactor is a window rotating cavity receiver that absorbs concentrated solar energy and works The temperature is 2300K, and the solid zinc oxide is thermally decomposed into oxygen and zinc vapor in the reactor.

[0049] The inert gas is passed into the solar reactor, the molar ratio of the inert gas and the zinc vapor is kept below 10, and the gaseous product oxygen and zinc vapor are swept out of the reactor by the continuous flow of the inert gas and enter the quenching device.

[0050] The quenching device is a water-cooled condenser, in which 2300K oxygen and zinc vapor are rapidly cooled to 700K oxygen and zinc liquid, and oxygen and zinc liquid can be separated naturally.

[0051] Put the separated zinc liquid and water vapor with a molar rate of 1mol / s into the hydrolysis reactor, and at a temperature of 700K, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com