Solar-integrated coal based methanol synthesis and power generation co-production system

A technology of methanol synthesis and solar energy, applied in energy input, steam generation, machines/engines, etc., can solve problems such as poor waste heat utilization efficiency, reduce fossil energy consumption, reduce carbon dioxide and pollutant emissions, and reduce investment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

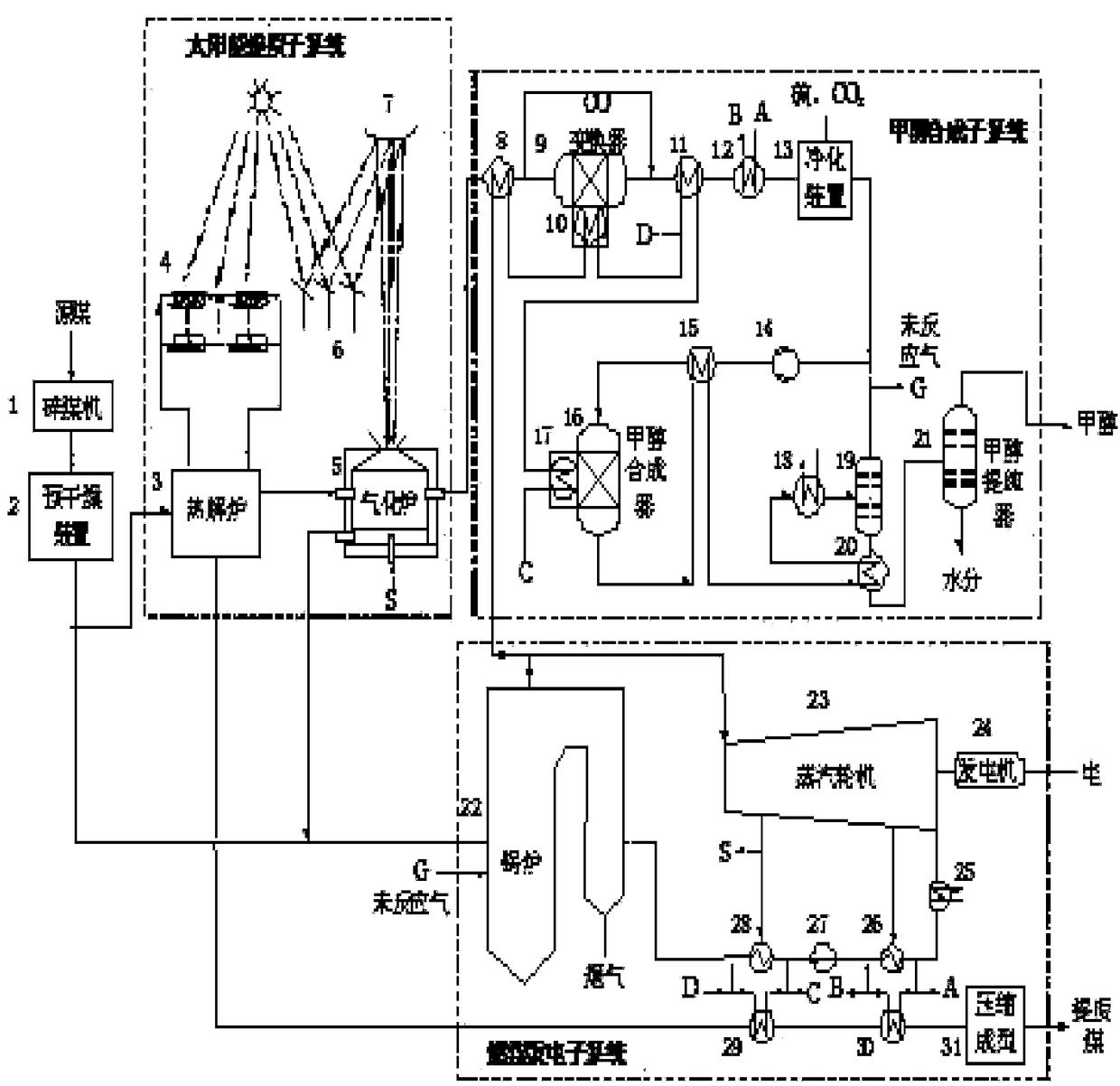

[0017] The present invention proposes a coal-based methanol synthesis and power generation co-production system integrating solar energy, which will be described below with reference to the accompanying drawings.

[0018] like figure 1The shown integrated solar energy coal-based methanol synthesis and power generation co-generation system includes three main parts: a solar energy upgrading subsystem, a methanol synthesis subsystem, and a coal-fired power generation subsystem; wherein, the coal crusher 1 is connected to the pre-drying device 2, The pre-drying device 2 is respectively connected to the boiler 22 and the pyrolysis furnace 3, and the pyrolysis furnace 3 is respectively connected to the solar collector 4, the gasifier 5 and the high temperature coal cooler 29, the high temperature coal cooler 29 and the low temperature coal cooler 30 , the compression molding device 31 is connected in series; the high-temperature coal cooler 29 is respectively connected with the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com