Concrete prepared from industrial solid waste materials

A technology of industrial solid waste and concrete, which is applied in the field of concrete, can solve the problems of a large amount of yellow sand and cannot meet the cost requirements, and achieve good workability, reduce production costs, and save resource materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

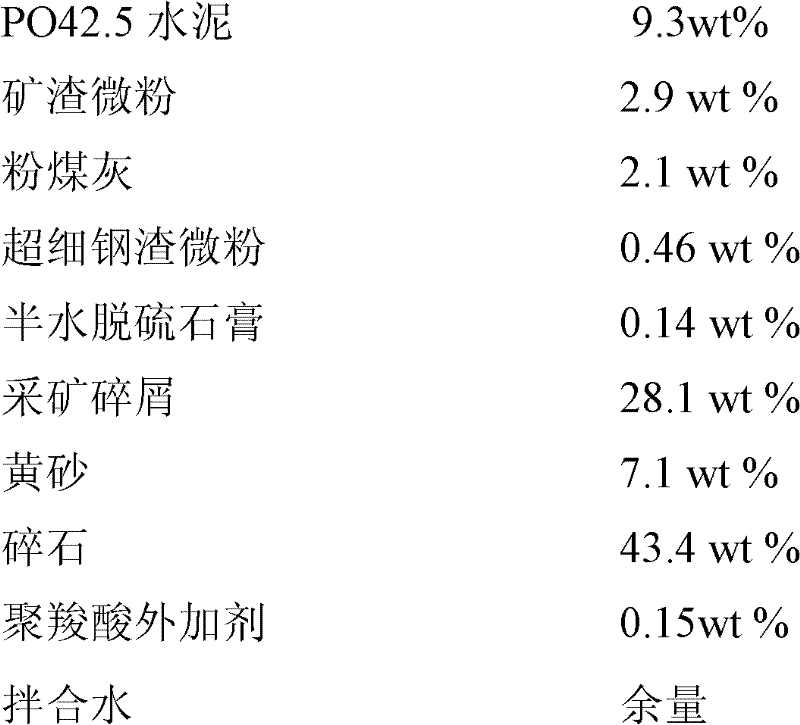

[0020] The concrete that adopts the industrial solid waste material preparation of the present embodiment, its composition and the weight percentage of each composition are as follows:

[0021]

[0022] The sum of the weight percentages of the above compositions is 100%.

[0023] The specific preparation process is as follows: First, mix cement, fly ash, modified mineral powder mixed with ultra-fine steel slag powder and hemihydrate desulfurization gypsum, yellow sand, mining debris, crushed stone, admixtures, etc. to prepare various raw materials for concrete. Carry out performance testing according to the standard; send the inspected and accepted raw materials into the corresponding silos; input the mix ratio after design verification into the production automatic control system; The feeding sequence of mineral powder) - mixing water - admixtures is sequentially fed, and the mixing is performed for 40 to 50 seconds, and the concrete slump is controlled to 120 to 160 mm. ...

Embodiment 2

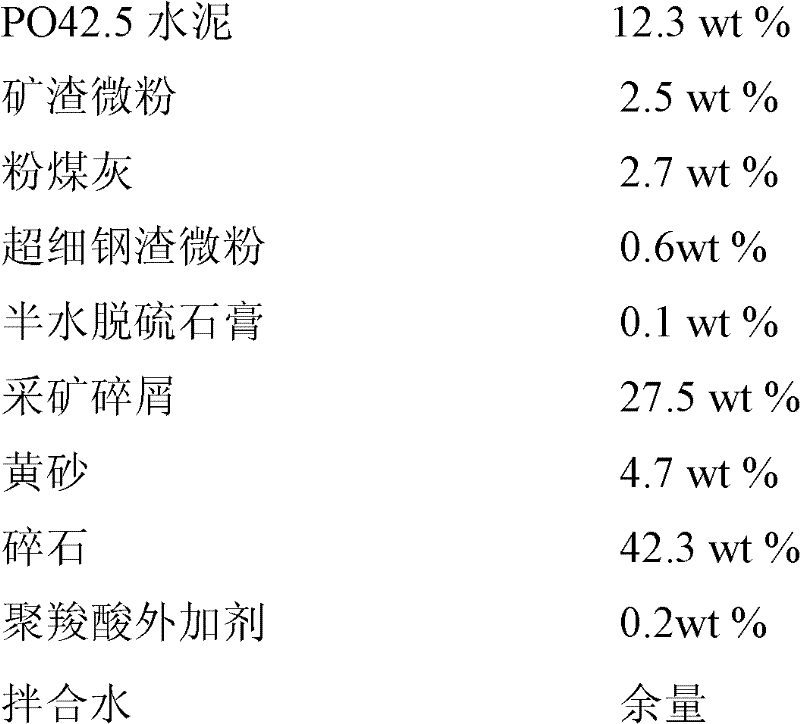

[0027] The concrete that adopts the industrial solid waste material preparation of the present embodiment, its composition and the weight percentage of each composition are as follows:

[0028]

[0029] The sum of the weight percentages of the above compositions is 100%.

[0030] The specific preparation process is as follows: First, mix cement, fly ash, modified mineral powder mixed with ultra-fine steel slag powder and hemihydrate desulfurization gypsum, yellow sand, mining debris, crushed stone, admixtures, etc. to prepare various raw materials for concrete. Carry out performance testing according to the standard; send the inspected and accepted raw materials into the corresponding silos; adjust and optimize the concrete mix ratio and input it into the automatic production control system; according to coarse aggregate - mining debris - yellow sand - cementitious materials (cement, fly ash, Mineral powder)-mixing water-admixture feeding sequence in turn, mix for 30-40 sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com