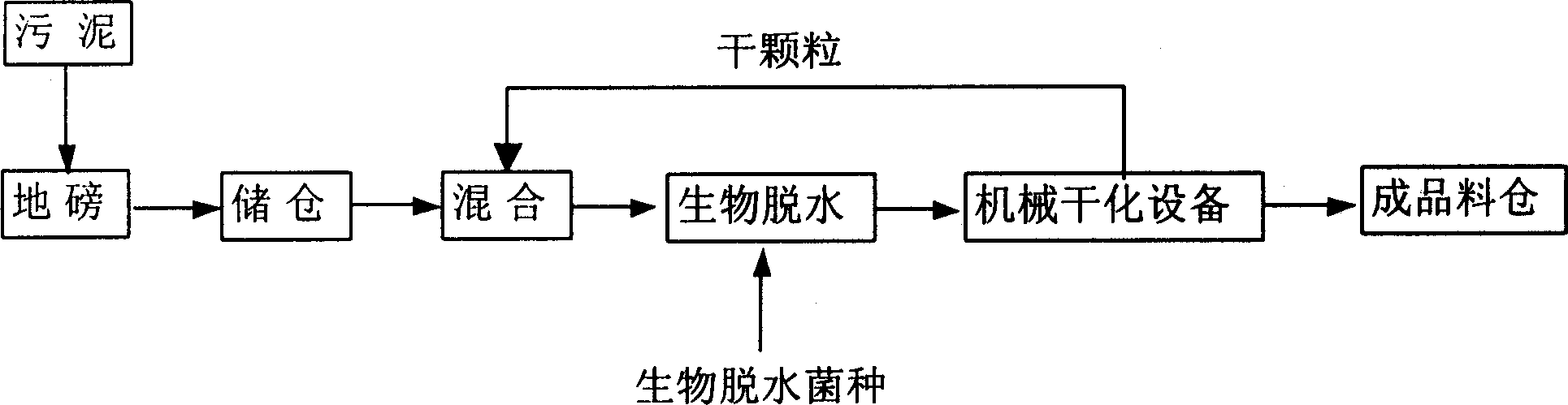

Method for dry-treating municipal sludge by biological dehydrating machinery

A technology for municipal sludge and dewatered sludge, applied in biological sludge treatment, dehydration/drying/concentrated sludge treatment, etc. problems, to achieve the effect of product sanitation, high degree of mechanization, and reduction of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The dewatered sludge with a moisture content of 78% and the dried sludge particles with a moisture content of 8% are uniformly mixed in a mass ratio of 1:0.67 to reduce the moisture content to 50%. At the same time, biological dehydration strains are added. The mixture is stacked in the forced ventilation strip groove, the thickness of the stack is 1.2-1.5m, the width is 3-6m, and the length can be adjusted according to the total amount of materials. There is an automatic turning machine on the trough. Control the ventilation volume to 0.1m 3 / (min·m 3 ), the turning frequency is once a day in the first 3 days, and once in the next 5-6 days, during which it can be monitored according to the temperature. In the initial stage of dehydration, the temperature rises rapidly, and when the temperature is greater than 65 degrees Celsius, it is necessary to turn over the pile. According to the weather conditions, the moisture content of the stockpiles can be reduced to below...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com