Technical method and schedule for preparation of foam carbon material used asphalt as raw material

A technology of foamed carbon and asphalt, which is applied in the field of self-reactive foaming to prepare foamed carbon materials, can solve the problems of complex foamed carbon technology, and achieve the effects of abundant utilization, easy production, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]Coal-based medium-temperature pitch was used as raw material to prepare foamed carbon. The softening point of the coal-based medium-temperature pitch used was 80°C. It was pulverized by a rapid grinder and passed through a 80-mesh sieve for use. The modification process is to take about 2g of the above-mentioned raw materials, put them into a high-alumina porcelain mold, place them in a high-pressure reactor, and put the reactor into a crucible furnace; open the inflation valve, fill in argon gas under a pressure of 1MPa, and observe When the pressure gauge on the reaction kettle shows the same pressure as the pressure reducing valve, close the inflation valve, open the vent valve, release the gas in the reaction kettle, close the vent valve, and repeat the above operation once to drain the kettle Then increase the pressure of the pressure relief valve to 3MPa (cold pressure), fill it into the reactor, and close the inflation valve and pressure relief valve. Start the te...

Embodiment 2

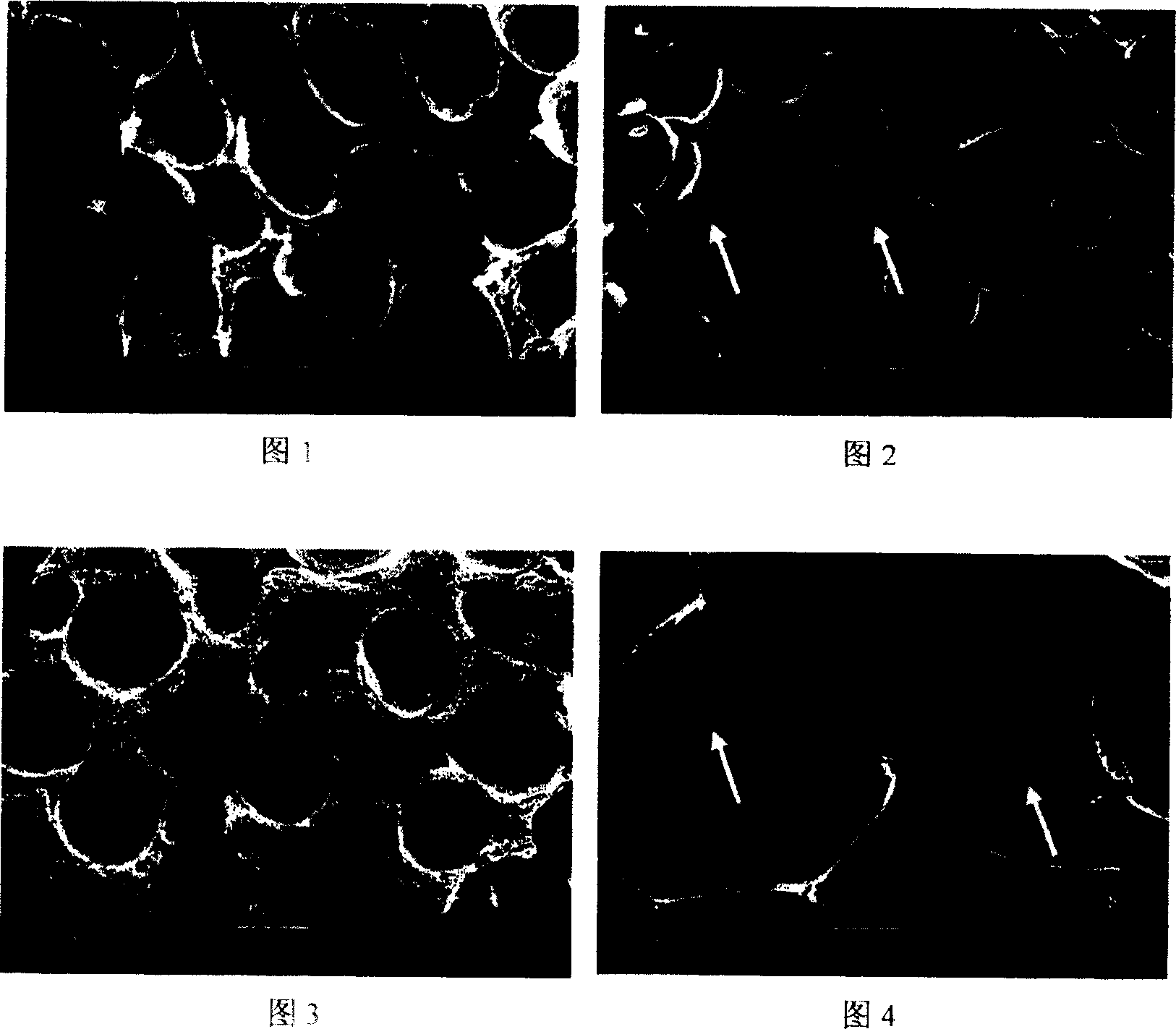

[0031] Foam carbon was prepared by using petroleum-based mesophase pitch as raw material. The softening point of the petroleum-based mesophase pitch used was 220°C. It was pulverized by a rapid grinder and passed through an 80-mesh sieve for use. Take 10 g of the above raw materials, mix them evenly with ferric nitrate at a ratio of 10:1, keep the temperature in an oven at 100°C for 1 hour, and cool down for later use. Take 2 g of the above-mentioned raw materials, and increase the pressure of the reactor to 4 MPa (cold pressure) completely according to the method of Example 1, and the heating rate of the foaming process and the carbonization process is exactly the same as that of Example 1. In order to investigate the influence of pressure on the cell structure, the pressure during foaming is controlled in the range of 0.5-4MPa (cold press), and foam carbon with different cell structures can be obtained. The samples were characterized and analyzed by scanning electron microsc...

Embodiment 3

[0033] Coal-based medium-temperature pitch was used as raw material to prepare glassy carbon foam with a network structure. The medium-temperature pitch used and its modification process were exactly the same as in Example 1. The modified medium-temperature pitch was taken out without grinding and directly put into the tubular The temperature is programmed in the carbonization furnace for carbonization, and the entire carbonization process is carried out under nitrogen conditions. The heating rate of the carbonization process is 2°C / min to 400°C, constant temperature for 30 minutes, 8-10°C / min to 1000°C, constant temperature for 3 hours, and natural cooling to room temperature. The samples were characterized and analyzed by scanning electron microscope (SEM) and X-ray diffractometer (XRD), and the density, porosity, mechanical properties and thermal properties were analyzed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com