Patents

Literature

76results about "Lithium nitrates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

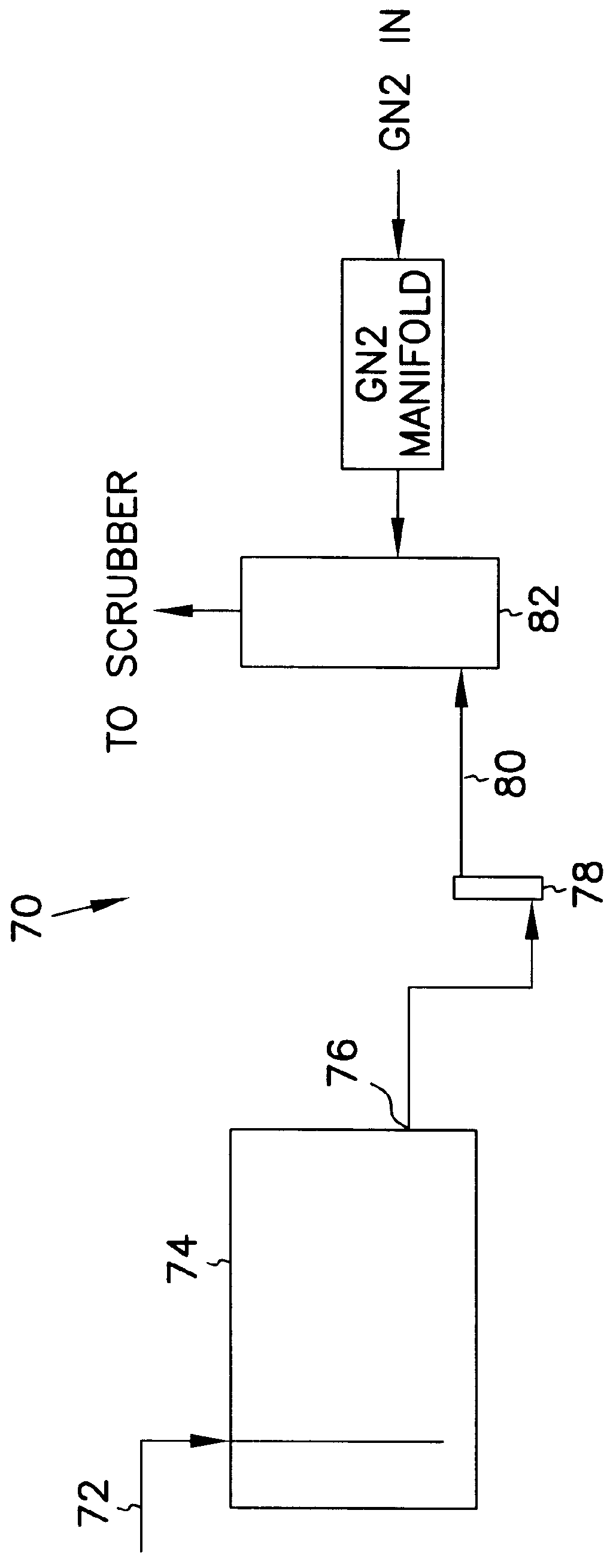

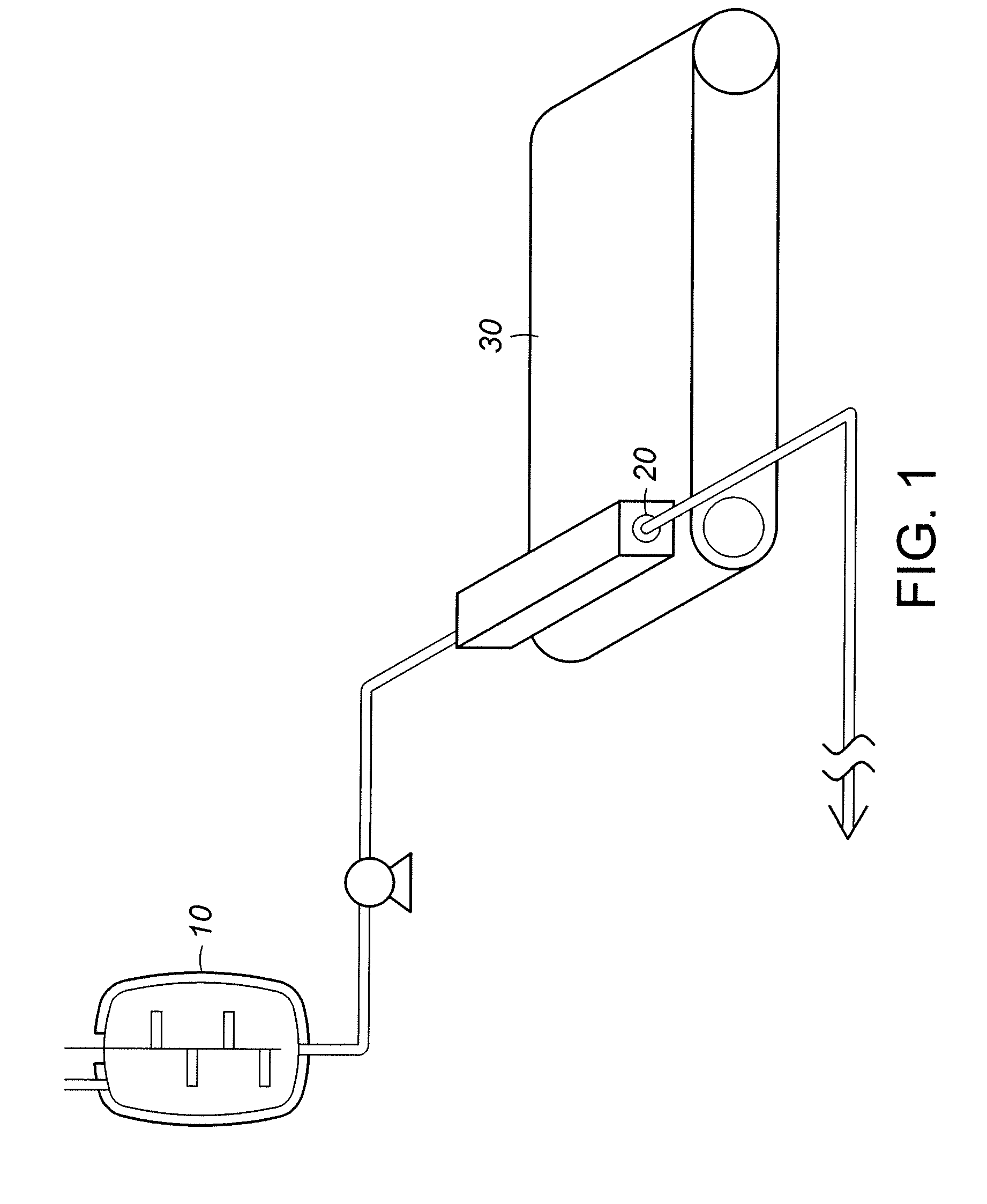

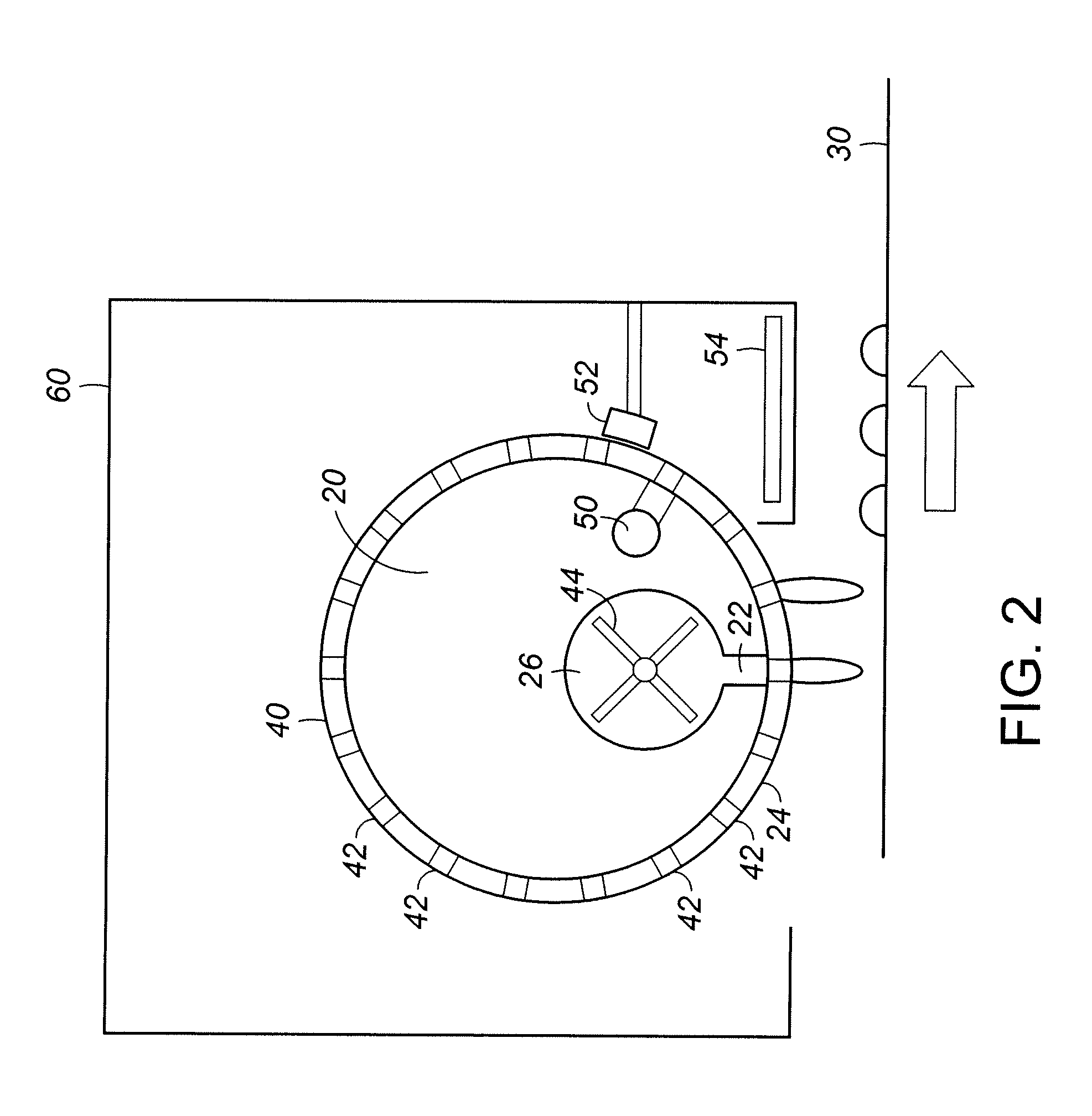

Process and equipment for nitrogen oxide waste conversion to fertilizer

The present invention describes a process for converting vapor streams from sources containing at least one nitrogen-containing oxidizing agent therein to a liquid fertilizer composition comprising the steps of: a) directing a vapor stream containing at least one nitrogen-containing oxidizing agent to a first contact zone, b) contacting said vapor stream with water to form nitrogen oxide(s) from said at least one nitrogen-containing oxidizing agent, c) directing said acid(s) as a second stream to a second contact zone, d) exposing said second stream to hydrogen peroxide which is present within said second contact zone in a relative amount of at least 0.1% by weight of said second stream within said second contact zone to convert at least some of any nitrogen oxide species or ions other than in the nitrate form present within said second stream to nitrate ion, e) sampling said stream within said second contact zone to determine the relative amount of hydrogen peroxide within said second contact zone, f) adding hydrogen peroxide to said second contact zone when a level of hydrogen peroxide less than 0.1 % by weight in said second stream is determined by said sampling, g) adding a solution comprising potassium hydroxide to said second stream to maintain a pH between 6.0 and 11.0 within said second stream within said second contact zone to form a solution of potassium nitrate, and h) removing said solution of potassium nitrate from said second contact zone.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION U S GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR

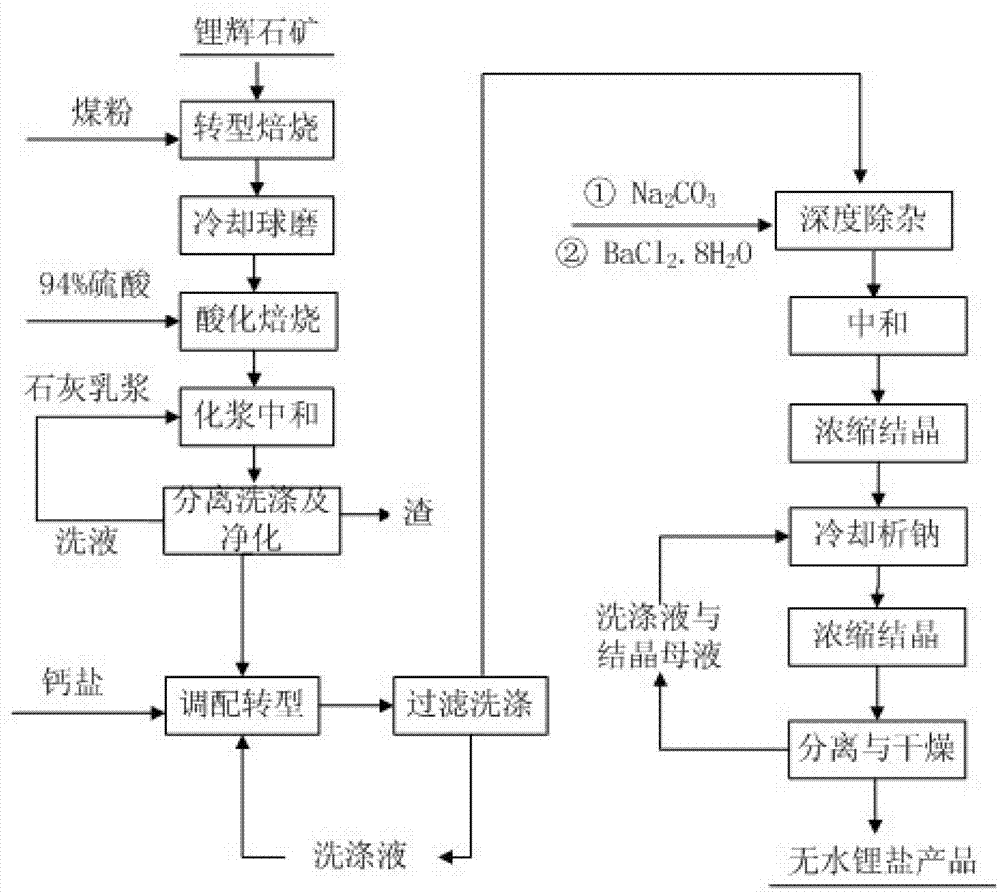

Method for preparing lithium salts from lithium extracted from spodumene

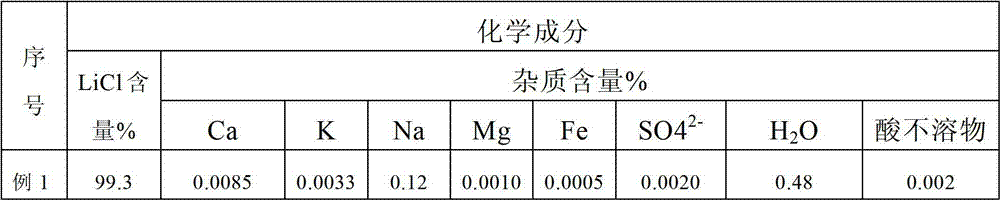

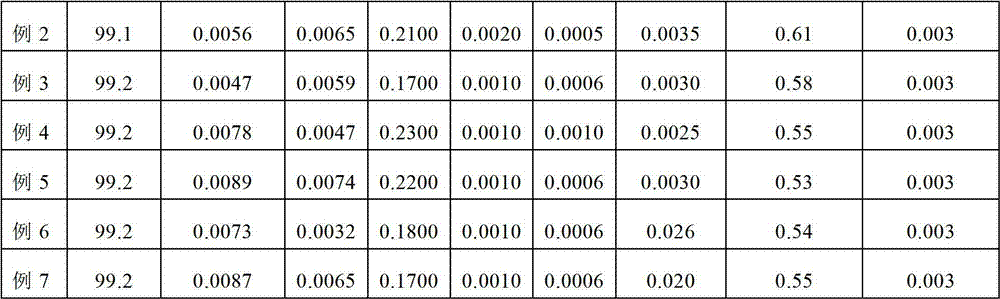

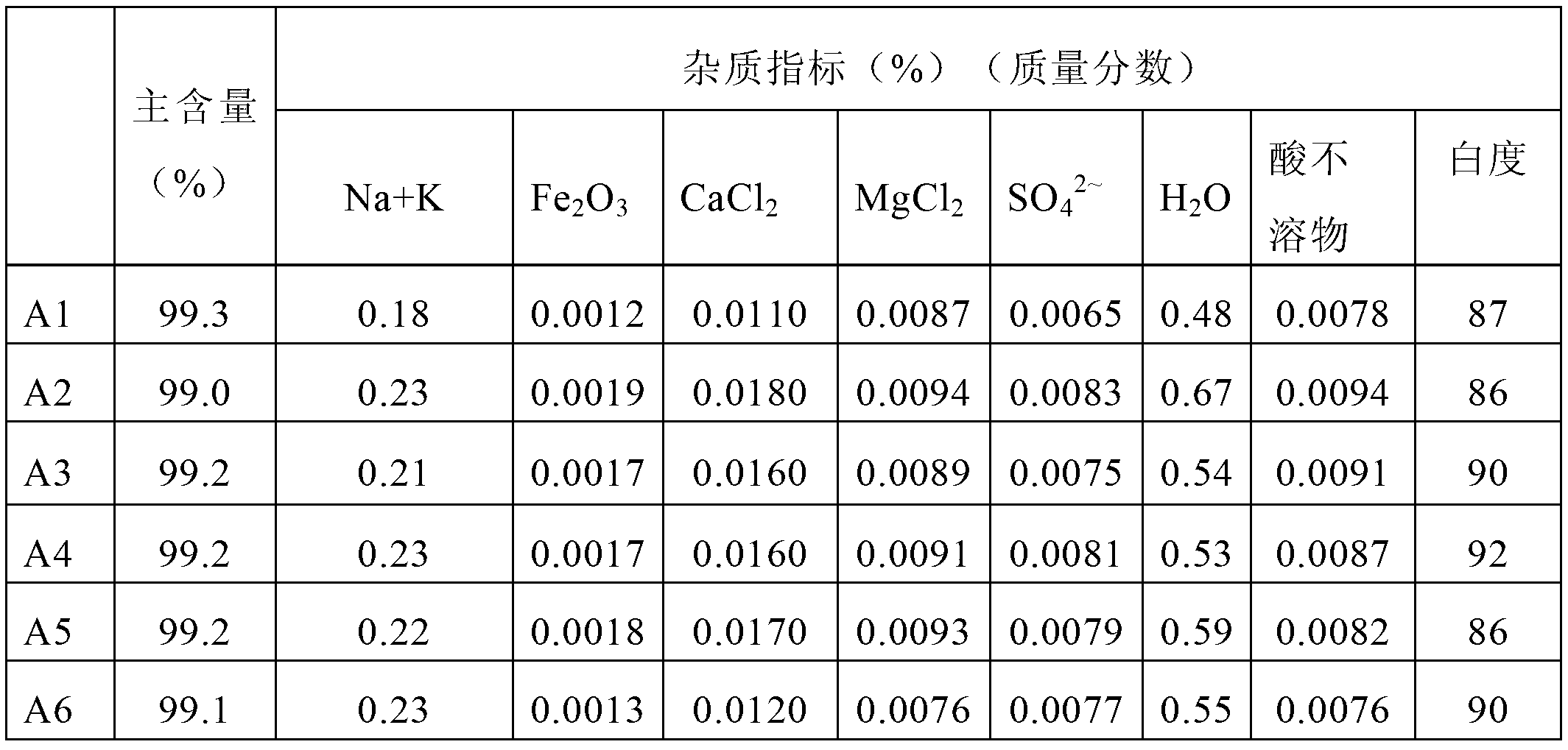

InactiveCN102765734AShort processEasy to operateLithium halidesLithium nitratesResource utilizationImpurity

The invention discloses a method for preparing lithium salts from lithium extracted from spodumene, which comprises the following steps: a. transforming and roasting; b. cooling and ball milling; c. acidifying and roasting; d. slurrying and neutralizing; e. separating, washing and purifying; f. blending and transforming; g. filtering and washing; h. deep impurity removing; i. neutralizing; j. concentrating and crystallizing; k. cooling to precipitate sodium; l. concentrating and crystallizing; and m. separating and drying. The method disclosed by the invention has the advantages of short technical process, low energy consumption, simple operation steps, low production cost and high resource utilization ratio.

Owner:GANFENG LITHIUM CO LTD

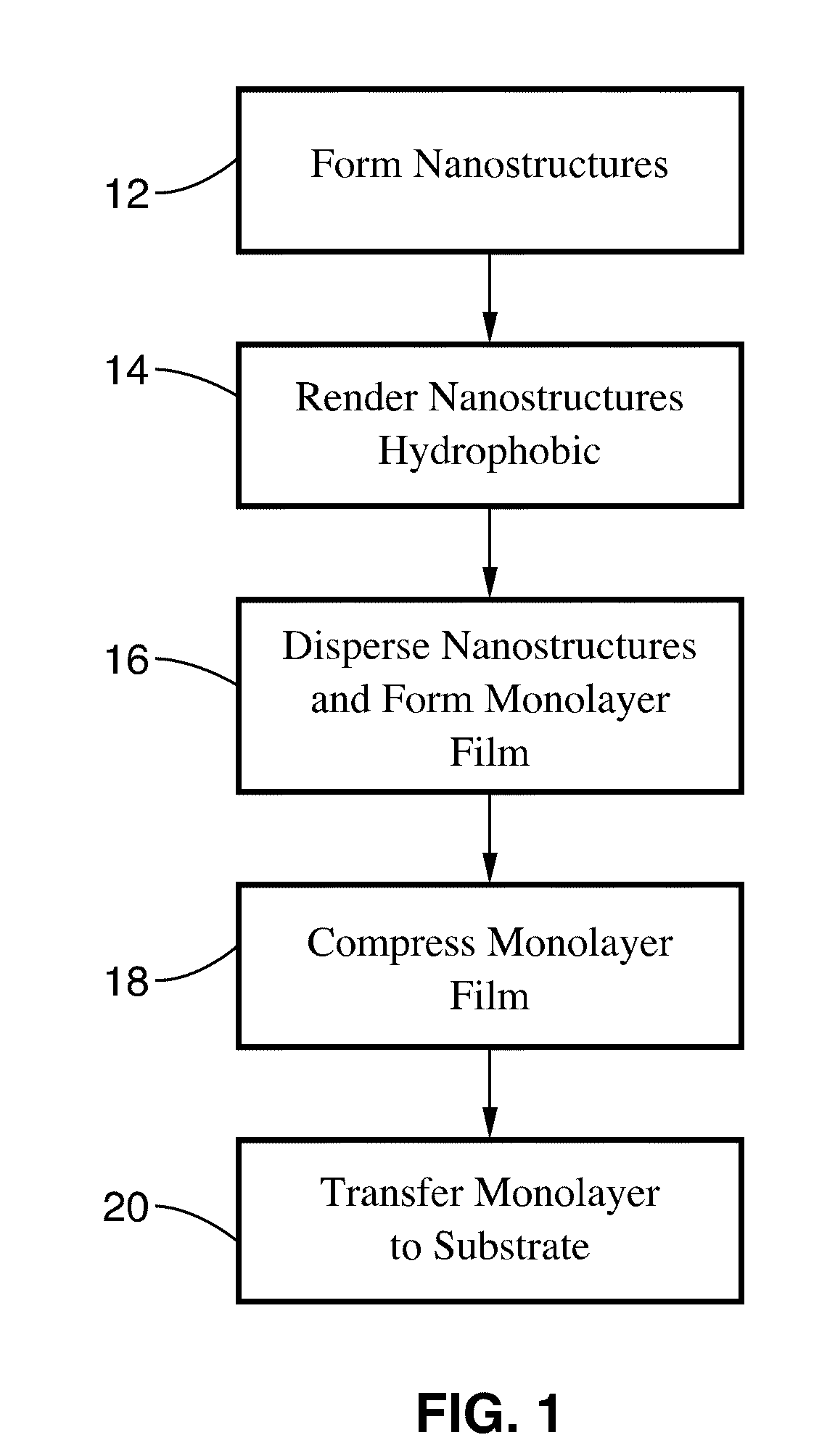

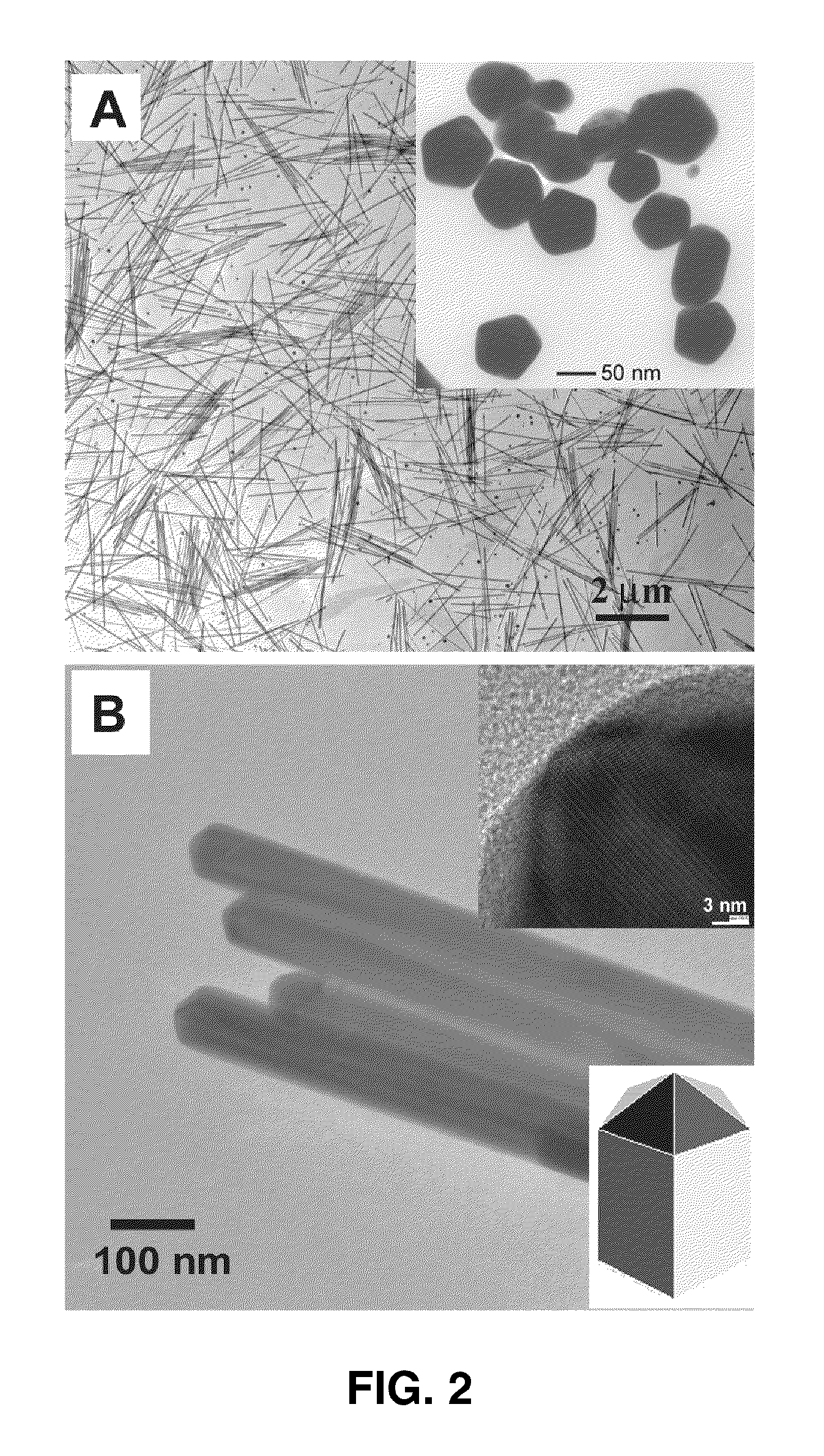

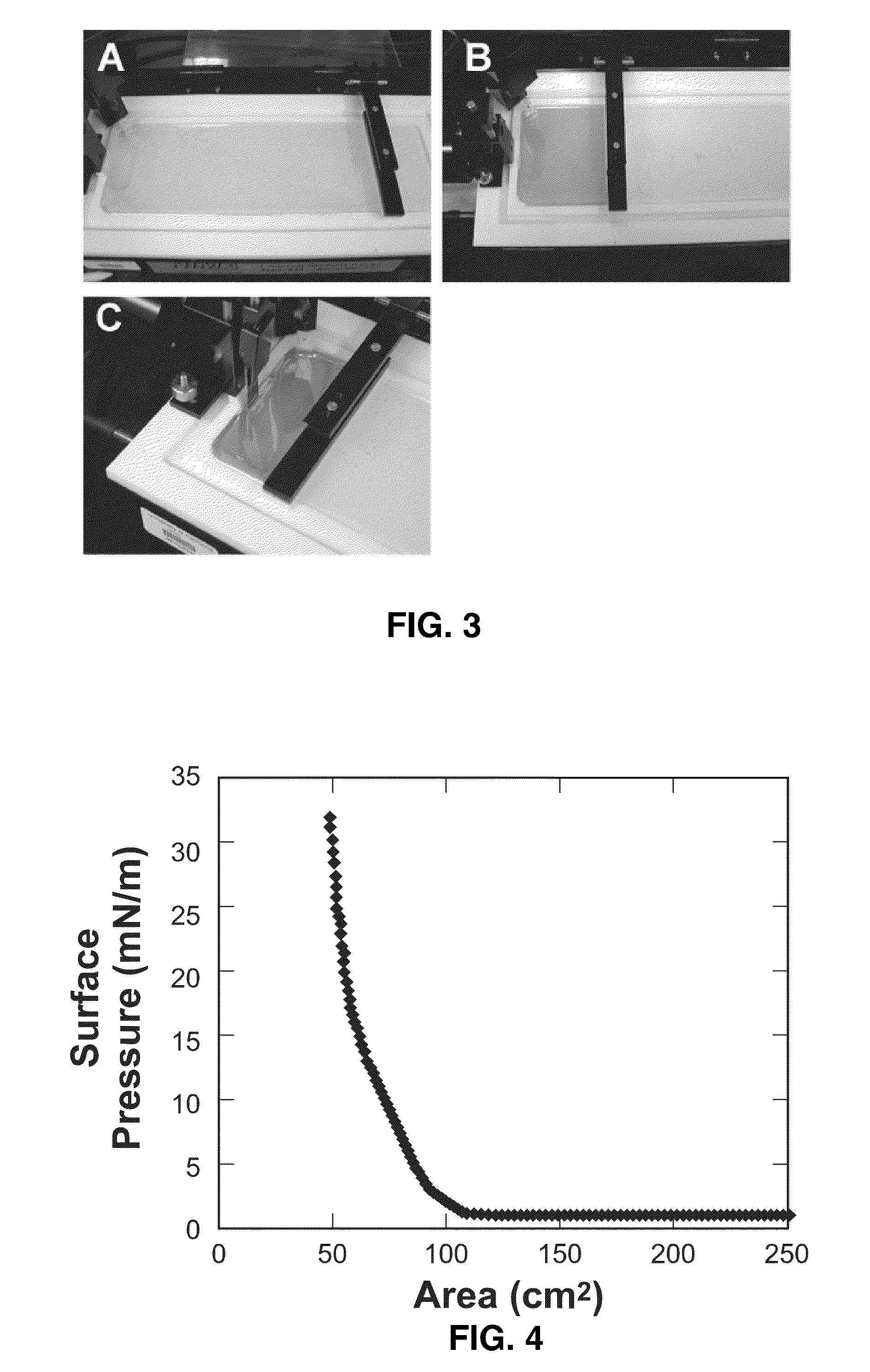

Langmuir-blodgett nanostructure monolayers

InactiveUS20090169807A1Easy to useLarge field enhancementLiquid surface applicatorsNanostructure manufactureNanoparticleEngineering

Methods for assembly of monolayers of nanoparticles using the Langmuir-Blodgett technique, as well as monolayers, assemblies, and devices are described. The surface properties of these monolayers are highly reproducible and well-defined as compared to other systems. These monolayers can readily be used for molecular detection in either an air-borne or a solution environment, and sensors using the monolayer could have significant implications in chemical and biological warfare detection, national and global security, as well as in medical detection applications.

Owner:RGT UNIV OF CALIFORNIA

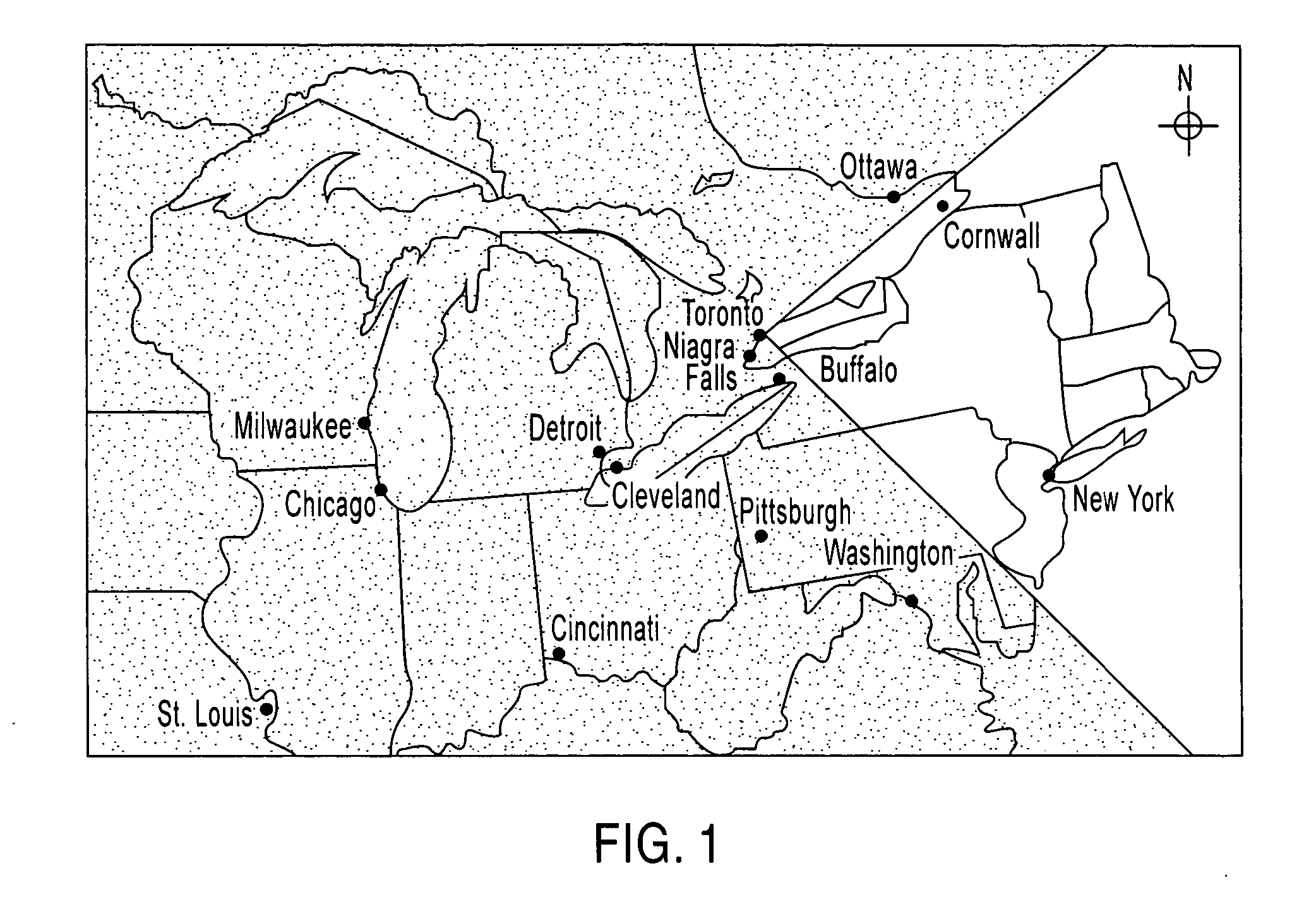

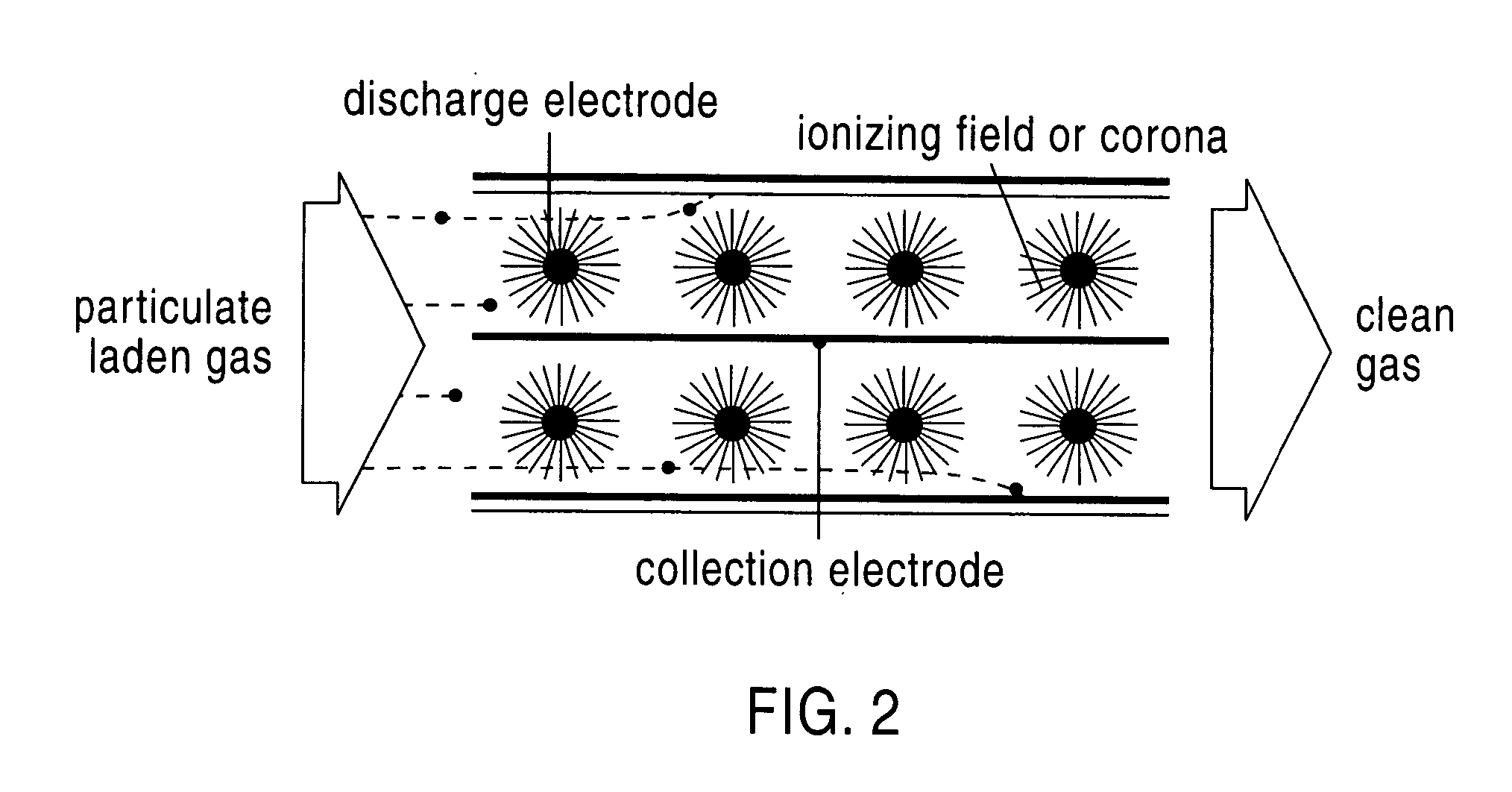

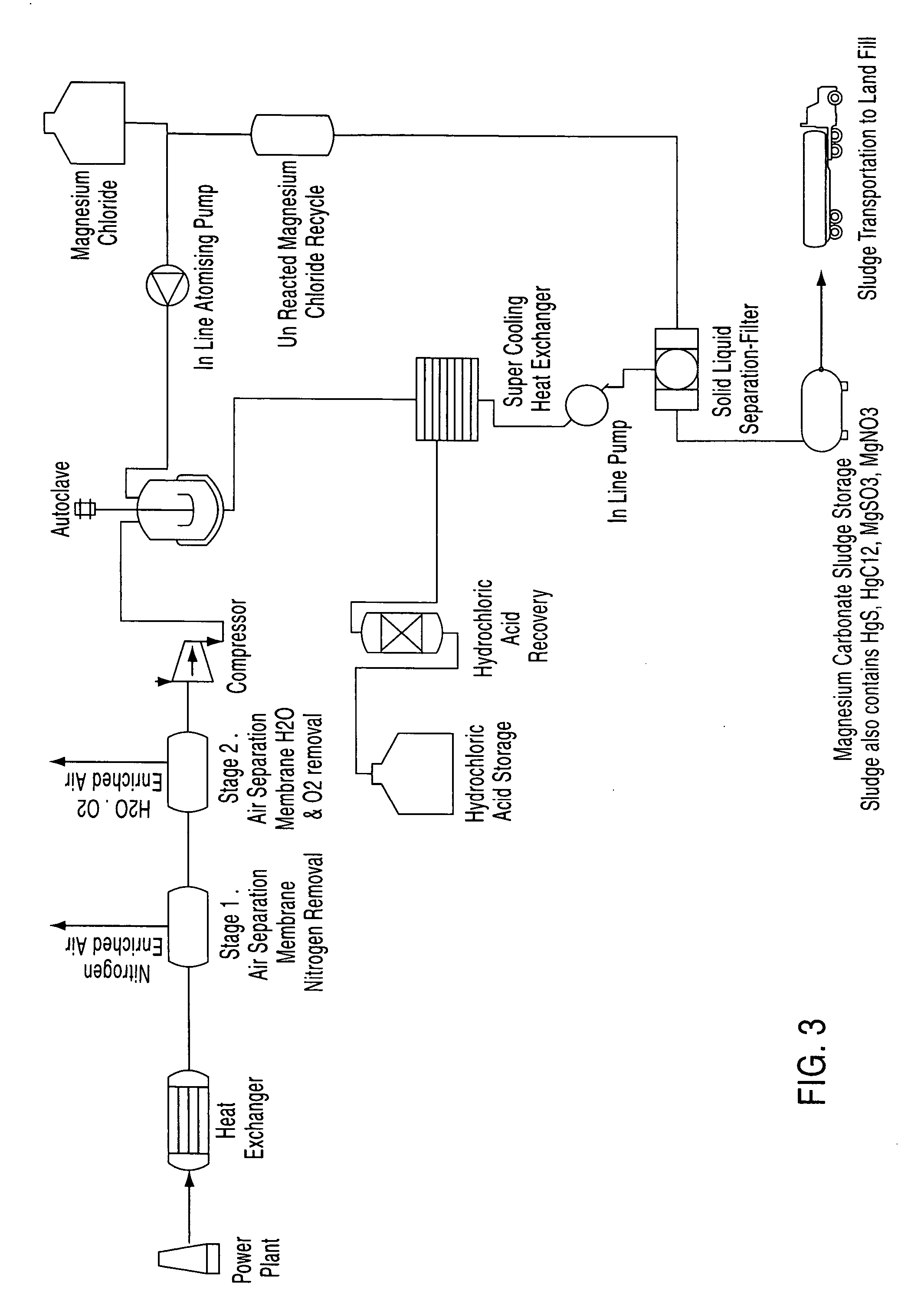

Process for removal of pollutants

A process for the removal of pollutants from a combustion process and, more particularly, a process for removing pollutants such as carbon dioxide, mercury, sulphur dioxide, nitrogen compounds and oxygen compounds from a combustion process. The process includes the removal of pollutants from a combustion process that produces an emission comprising: cooling the emission to a temperature of about 200° C.; removing nitrogen, water and oxygen from the emission to produce a gas containing a concentration of pollutants; contacting the gas with an aqueous magnesium chloride solution, wherein a slurry mixture is formed; and cooling the gas and the slurry mixture, wherein hydrochloric acid vapour and a sludge are formed.

Owner:CLEAN WORLD STRATEGIES CORP

Lithium ion battery and positive electrode material thereof

InactiveCN108075111AReduce residual lithium on the surfaceLarge specific surface areaSecondary cellsPositive electrodesPhysical chemistryLithium-ion battery

The invention discloses a lithium ion battery and a positive electrode material thereof. The general chemical formula of the positive electrode material of the lithium ion battery is LiNixM[1-x]O2, wherein x is greater than or equal to 0.5 but smaller than 1; the M is one or more of Co, Mn, Al, Mg, Ti and Zr; the specific surface area of the positive electrode material of the lithium ion battery is 0.2 to 0.6m<2> / g; the surface lithium residue quantity is 200 to 1000 ppm. Compared with the prior art, the positive electrode material of the lithium ion battery is prepared through solid phase reaction; the surface lithium residue quantity of the material can be obviously reduced; the specific surface area increase of the positive electrode material of the lithium ion battery in the reaction process can also be avoided. The circulation stability of the positive electrode material of the lithium ion battery is good; the preparation method is simple; the implementation is easy; the production cost is low; good application prospects are realized. The invention also discloses the lithium ion battery.

Owner:CONTEMPORARY AMPEREX TECH CO

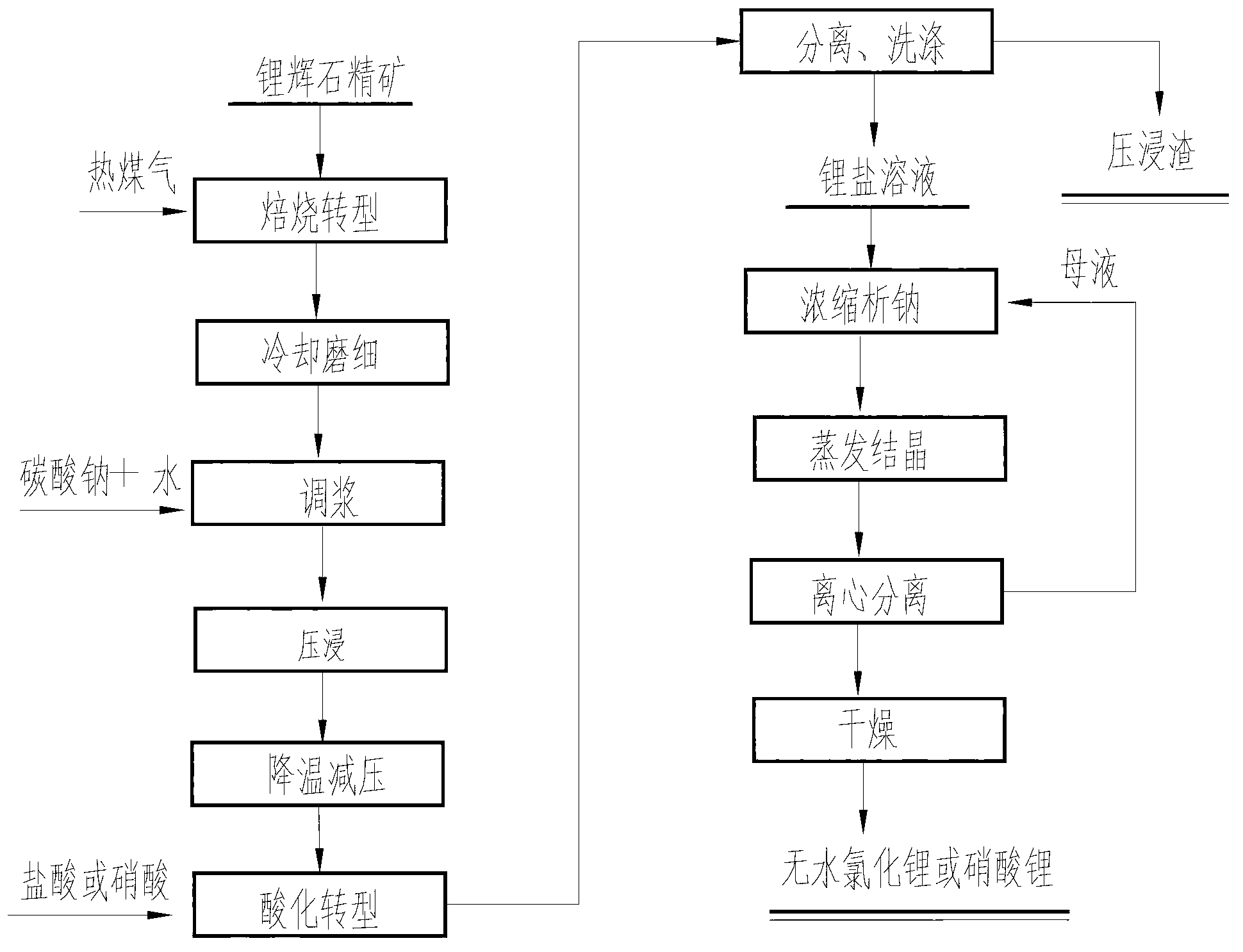

Method for extracting lithium salt from spodumene by soda ash pressure leach method

ActiveCN103183366AImprove resource utilizationSimple processProcess efficiency improvementLithium halidesResource utilizationChemistry

The invention discloses a method for extracting lithium salt from spodumene by a soda ash pressure leach method. The method comprises the following technological process: (1) roasting and transforming; (2) cooling and grinding; (3) size mixing; (4) pressure leaching; and (5) cooling and decompressing. The method is characterized by further comprising the following technological process: (6) pressure filtering and separating; (7) acidifying and transforming; (8) separating and washing; (9) condensing and separating out sodium; (10) evaporating and crystallizing; (11) centrifugal separation; and (12) drying. The method for extracting lithium salt from spodumene by the soda ash pressure leach method provided by the invention is simple in process, low in cost and high in resource utilization rate.

Owner:GANFENG LITHIUM CO LTD +1

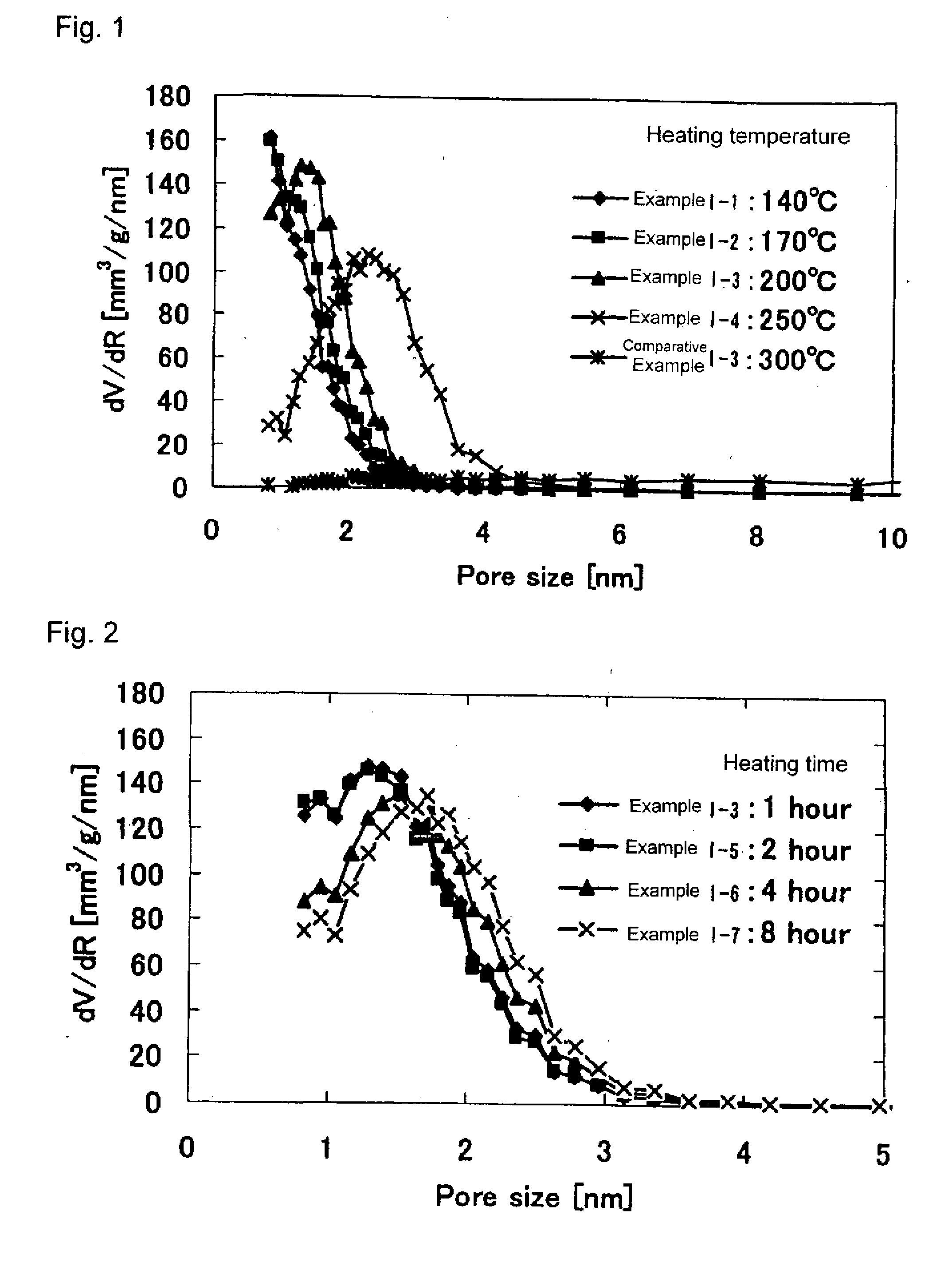

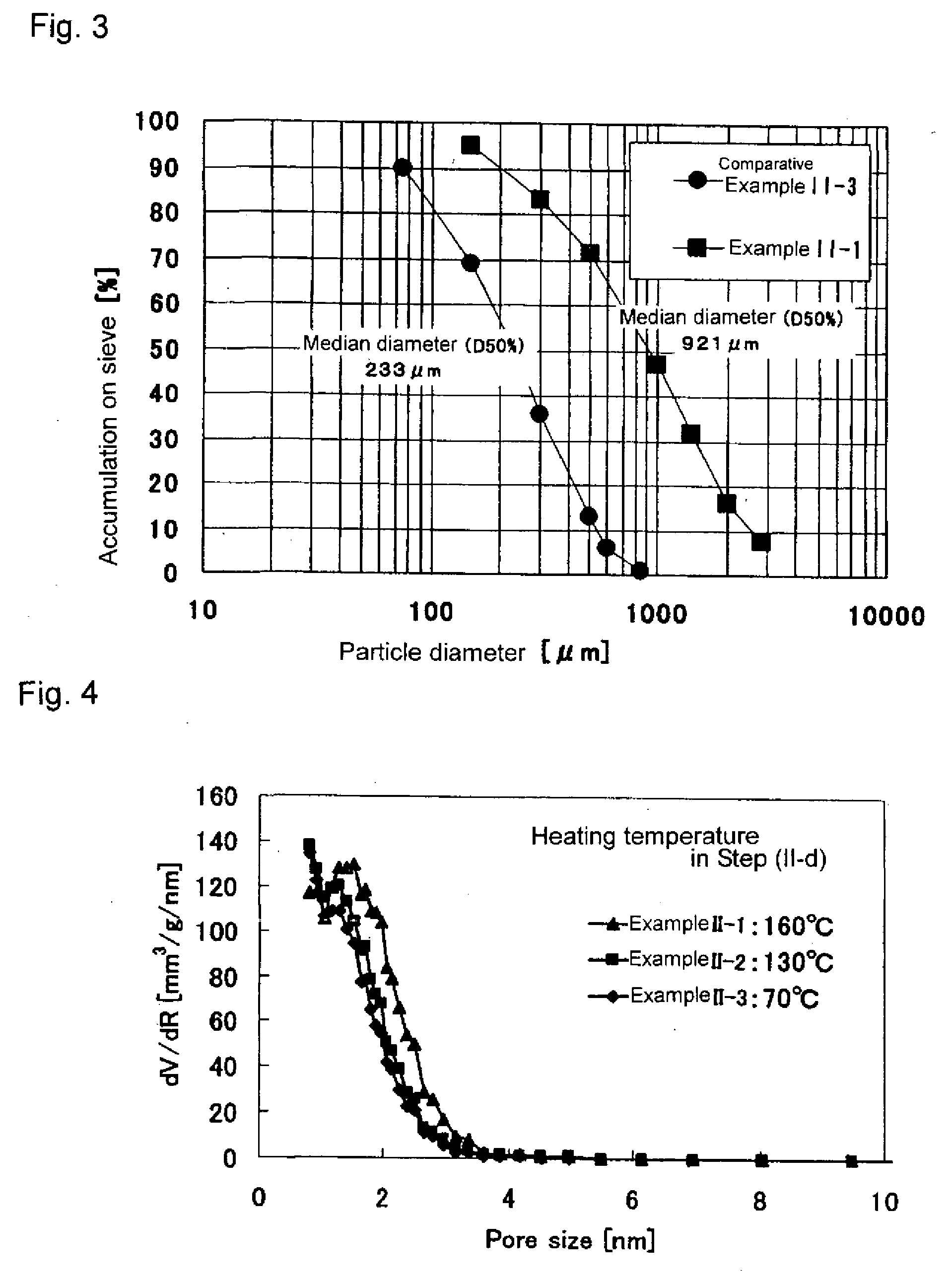

Method for producing iron oxyhydroxide and adsorbing material comprising iron oxyhydroxide

InactiveUS20090028770A1Improve adsorption capacityEfficient productionPhosphorus oxidesNitrogen compoundsIndustrial effluentHazardous substance

The present invention provides a method for advantageously producing an iron oxyhydroxide exhibiting excellent capability of adsorbing harmful substances, such as a phosphrous components and endocrine disrupting chemicals, which are contained in industrial wastewater, exhaust gases, etc., and an adsorbent material comprising the iron oxyhydroxide produced by the method as a main component. Specifically, the present invention provides an adsorbent material produced by a method comprising the steps of:(a) adding a base to an aqueous iron ion-containing solution, adjusting the pH of the resultant mixture to 9 or less, to form a precipitate that contains an iron oxyhydroxide;(b) drying the precipitate at a temperature of 100° C. or lower to obtain an iron oxyhydroxide;(c) contacting the resultant iron oxyhydroxide with water; and(d) subjecting the resultant iron oxyhydroxide to a heat treatment under a gas atmosphere having an inert gas concentration of 80% or greater at a temperature of 100 to 280° C.

Owner:JAPAN SCI & TECH CORP +2

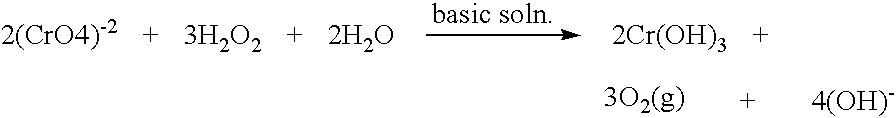

Aqueous solution of chromium salt and method for producing same

InactiveUS20070086938A1Overcome disadvantagesPigmenting treatmentNitrogen compoundsOXALIC ACID DIHYDRATEChloride

Disclosed is an aqueous solution of a chromium salt, in which the oxalic acid content is 8% by weight or less relative to chromium. In the aqueous solution of the chromium salt, the total organic carbon content is 4% by weight or less relative to chromium. The chromium salt is preferably a chromium chloride, a chromium phosphate, or a chromium nitrate. The chromium chloride preferably contains a basic chromium chloride represented by the composition formula Cr(OH)xCly (wherein 0<x≦2, 1≦y<3, and x+y=3). The chromium phosphate is preferably one represented by the composition formula Cr(H3−3 / nPO4)n (wherein n is a number satisfying 2≦n≦3). The chromium nitrate is preferably a basic chromium nitrate represented by the composition formula Cr(OH)x(NO3)y (wherein 0<x≦2, 1≦y<3, and x+y=3).

Owner:NIPPON CHECMICAL IND CO LTD

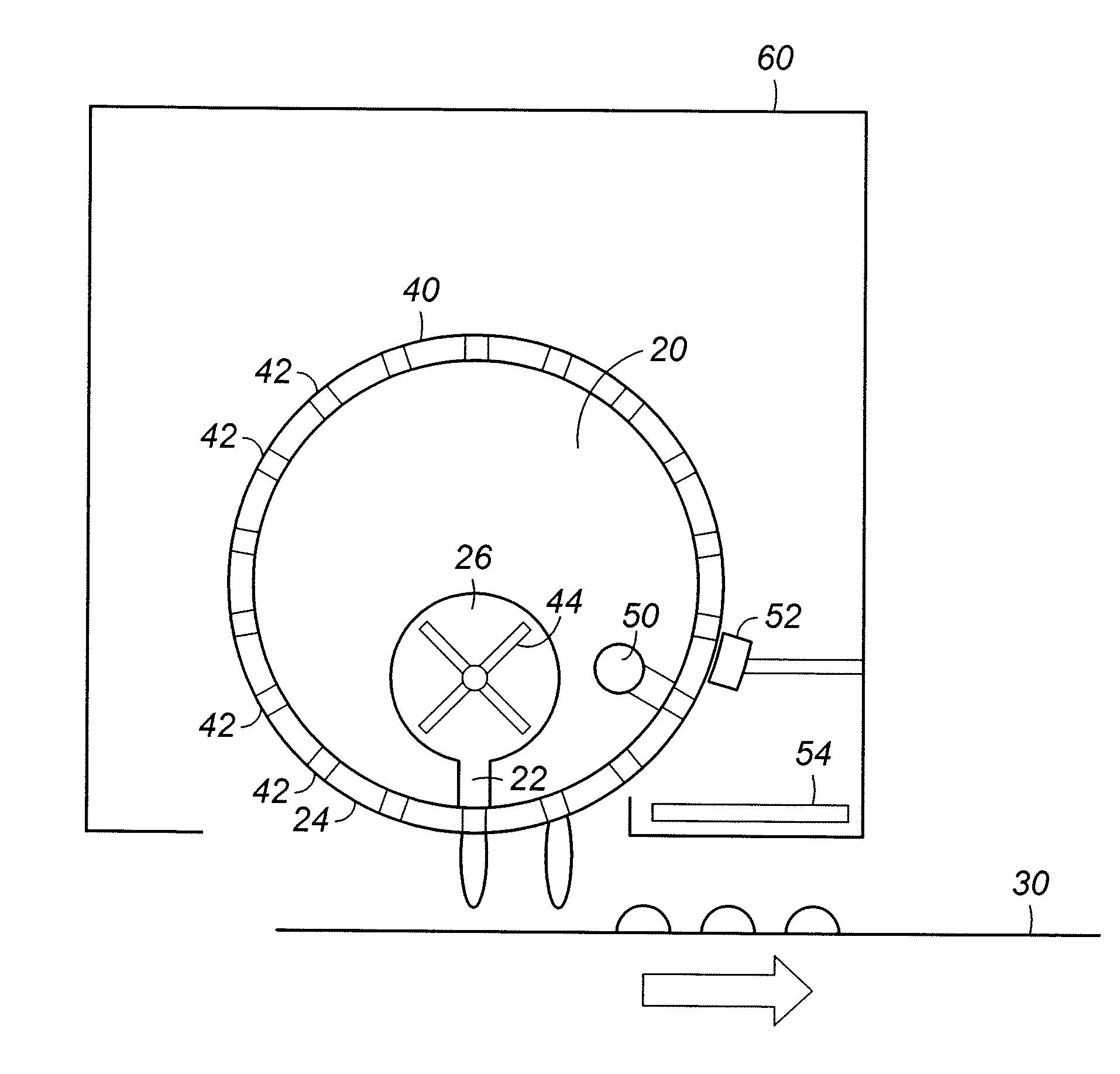

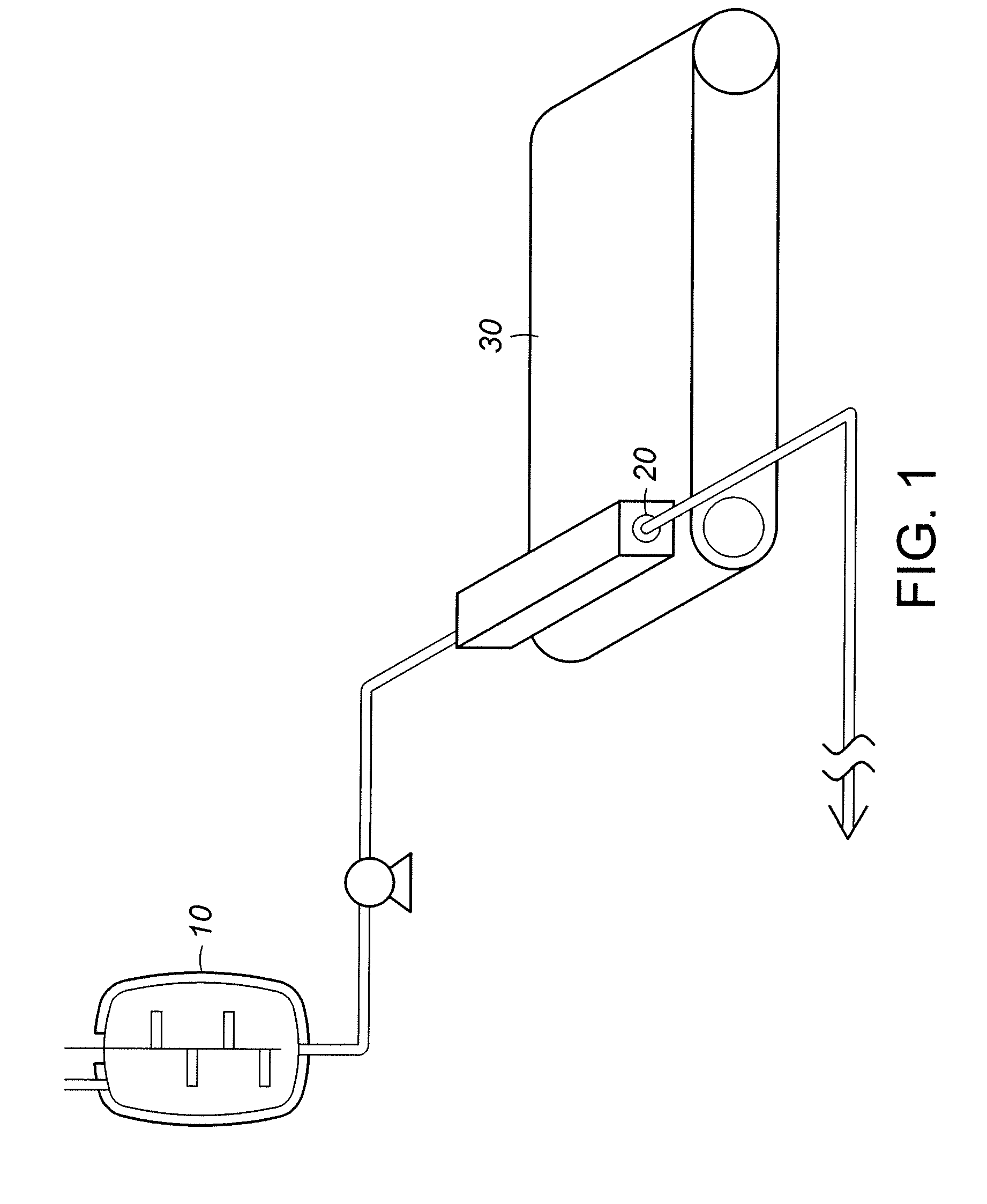

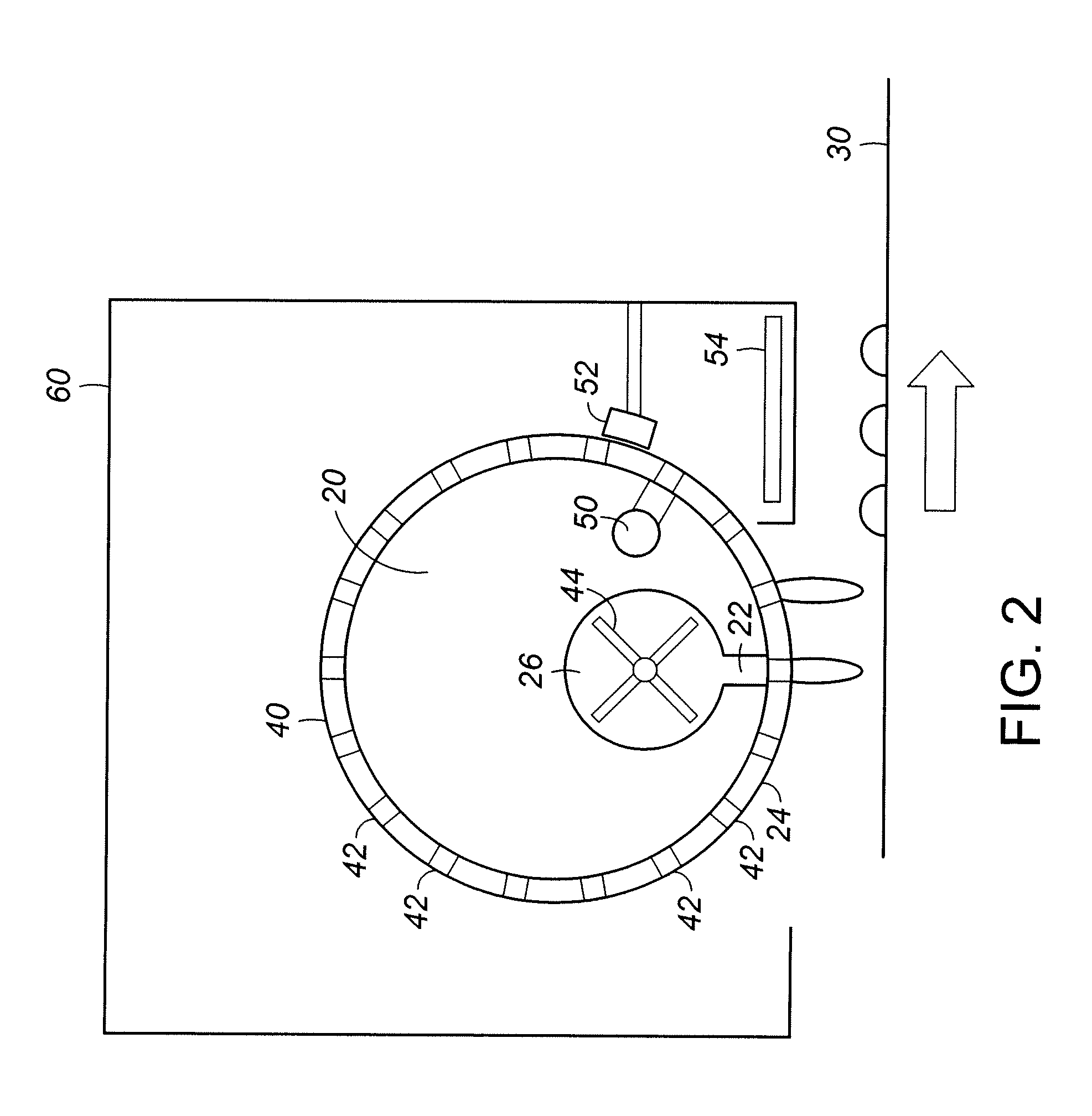

Pastillation of Ammonium Sulfate Nitrate

A process is presented for the production of ammonium sulfate nitrate. The process provides for producing a highly uniform product and having a substantially uniform size. The process includes reacting ammonium sulfate and ammonium nitrate to form an FASN slurry melt. The slurry melt is continuously stirred and heated to keep the slurry melt under a shear thinned condition and at a uniform temperature until the slurry melt is extruded, cooled and solidified.

Owner:ADVANSIX RESINS & CHEM LLC

Methods of making cesium salts and other alkali metal salts

A method of making a cesium salt is described and involves reacting a cesium sulfate containing solution with lime to form 1) a solution containing at least cesium hydroxide and 2) a residue comprising calcium sulfate. The method further involves removing the residue from the solution and converting the cesium hydroxide that is present in the solution to at least one type of cesium salt. The present invention further relates to uses of the cesium salt as well as methods of making cesium hydroxide using lime. Also, methods of making alkali metal salts and alkali metal hydroxides are also described.

Owner:CABOT SPECIALTY FLUIDS

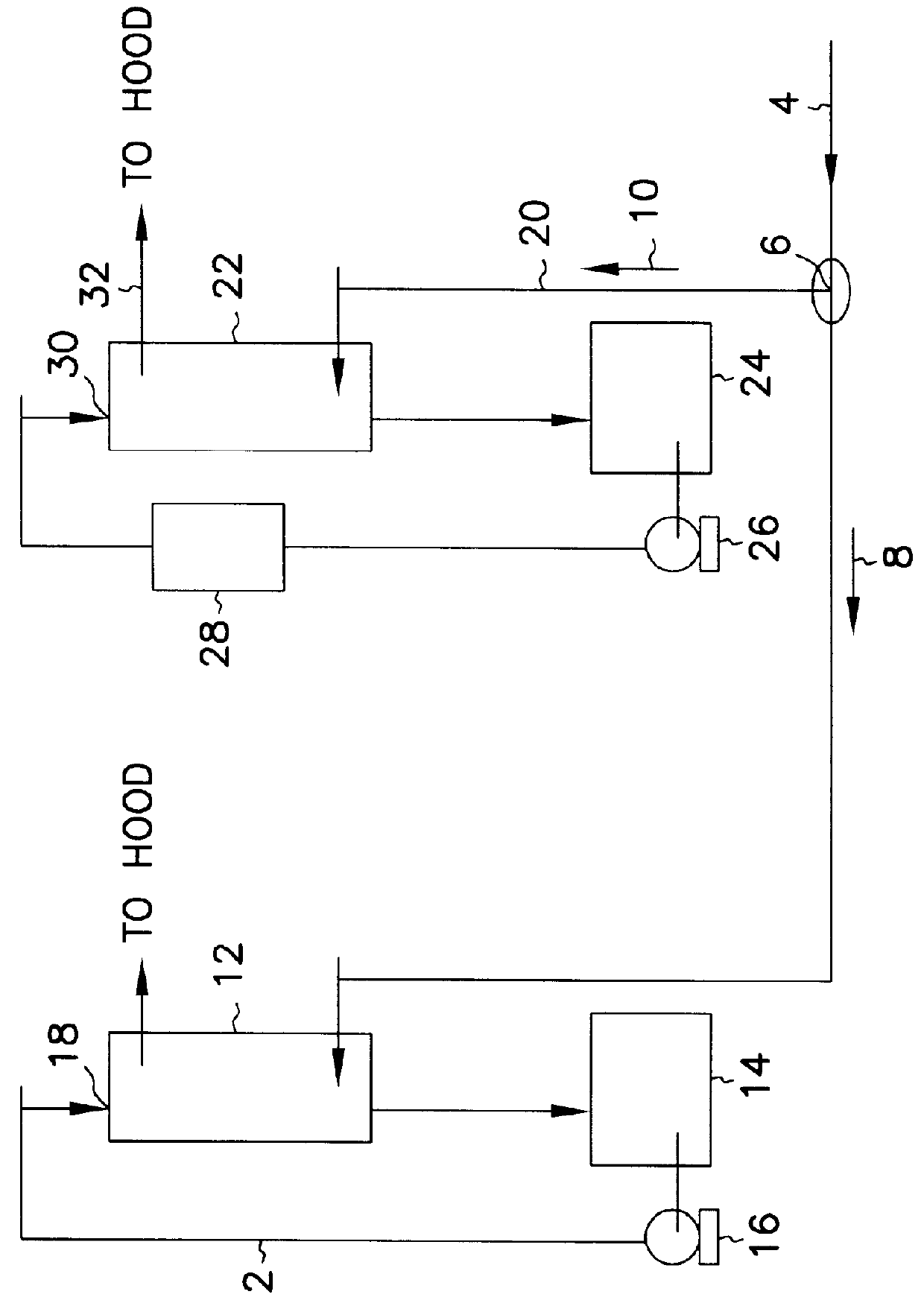

Recovery of Li values from sodium saturate brine

InactiveUS8309043B2Efficient and high throughputOther chemical processesCrystallization separationHydrated aluminaAqueous solution

The present invention provides a process for recovering Li values from a sodium saturated brine. The process includes recovering Li values from a sodium saturated brine which contains LiX. The process includes concentrating the sodium saturated brine to at least 9000 mg / l LiX, passing the concentrated brine through a bed of polycrystalline hydrated alumina pellets until the pellets are loaded with LiX from the concentrated brine, displacing brine held-up in the bed by using concentrated NaX, unloading LiX from the pellets by flowing through the bed an aqueous solution of LiX which is not saturated, displacing the LiX from the bed using concentrated NaX, and repeating the steps at least one additional time to provide the Li values.

Owner:FMC CORP

Recovery of li values from sodium saturate brine

InactiveUS20120141342A1Efficient and high throughput processEfficient and high throughputOther chemical processesEvaporator accessoriesHydrated aluminaAqueous solution

The present invention provides a process for recovering Li values from a sodium saturated brine. The process includes recovering Li values from a sodium saturated brine which contains LiX. The process includes concentrating the sodium saturated brine to at least 9000 mg / l LiX, passing the concentrated brine through a bed of polycrystalline hydrated alumina pellets until the pellets are loaded with LiX from the concentrated brine, displacing brine held-up in the bed by using concentrated NaX, unloading LiX from the pellets by flowing through the bed an aqueous solution of LiX which is not saturated, displacing the LiX from the bed using concentrated NaX, and repeating the steps at least one additional time to provide the Li values.

Owner:FMC CORP

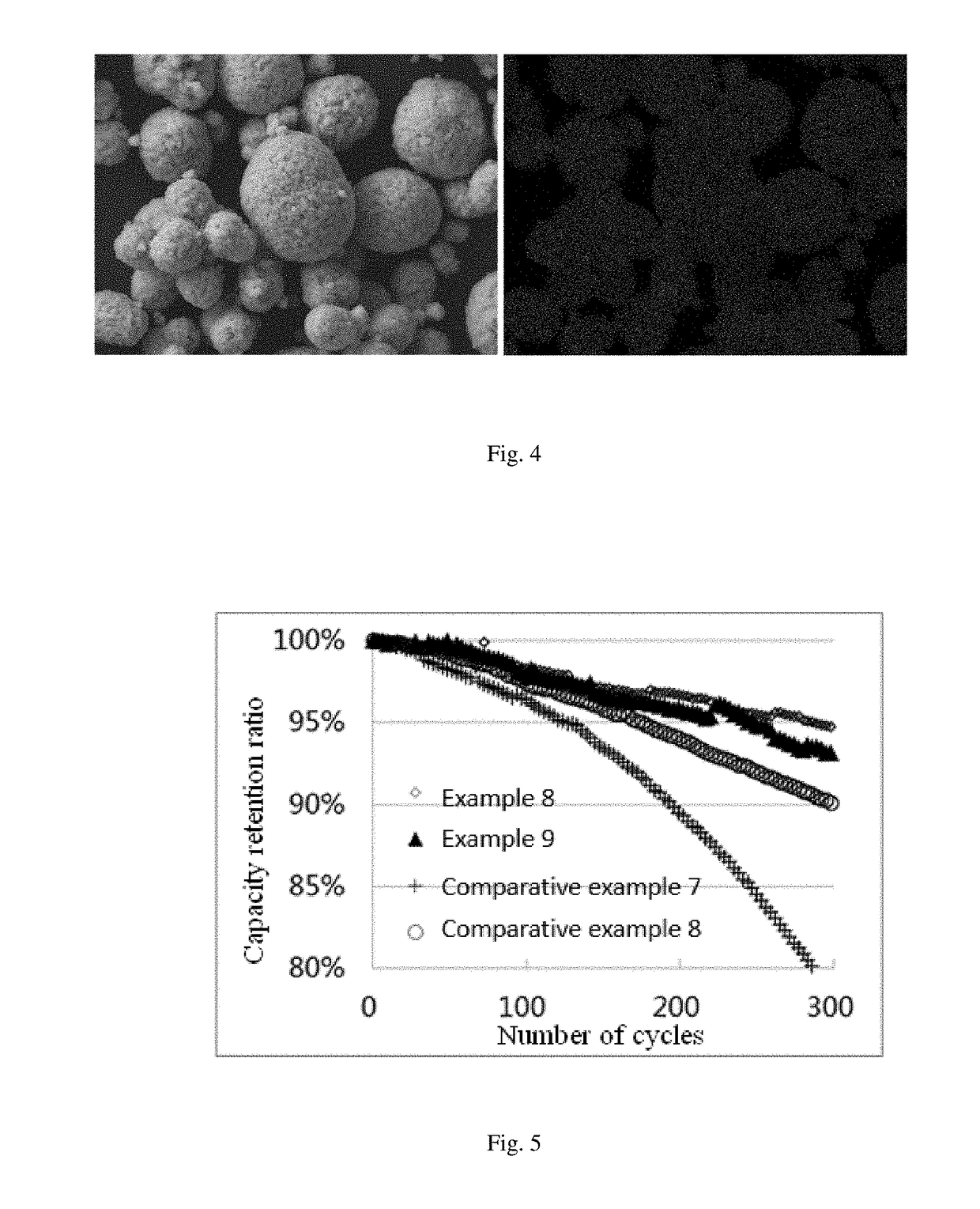

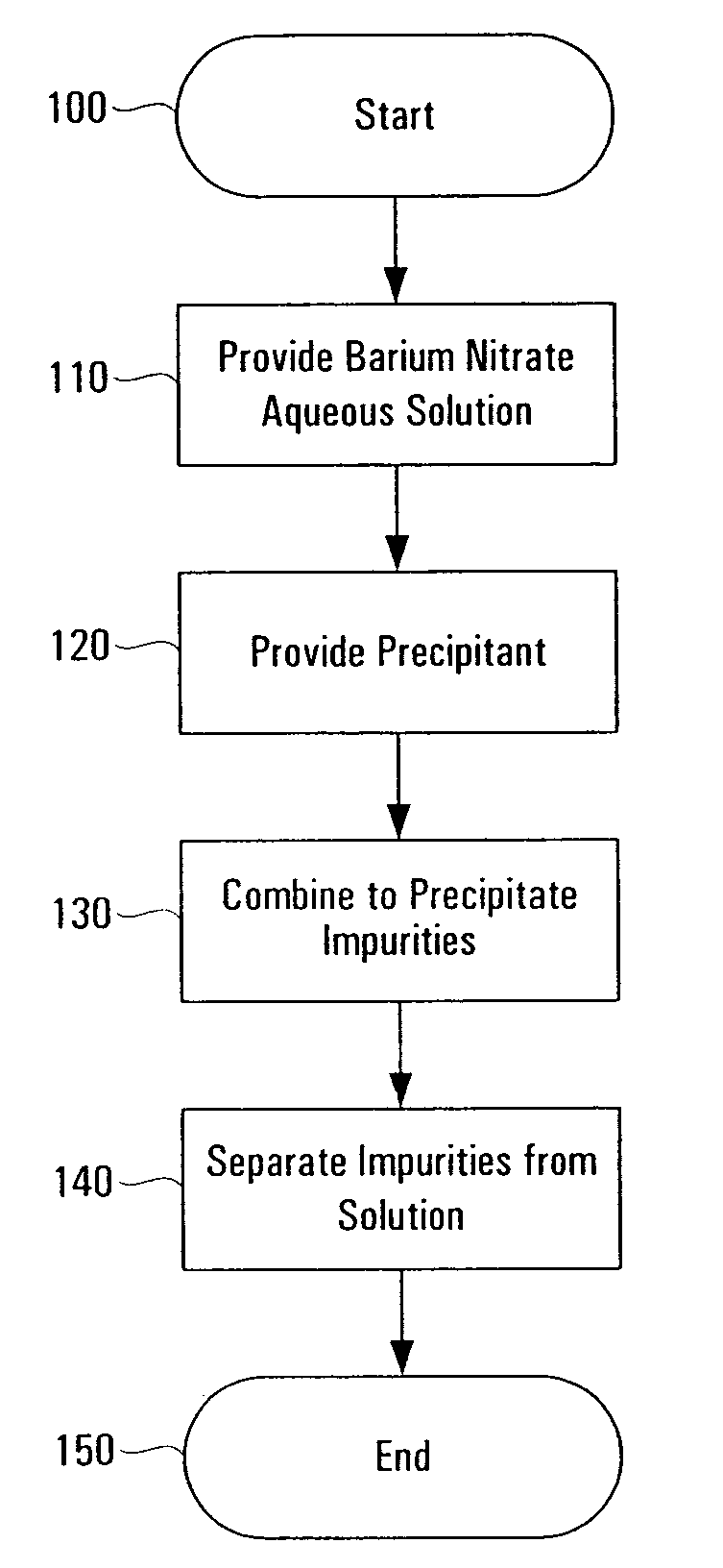

Lithium ion battery and positive electrode material thereof

InactiveUS20180145324A1Avoid increase of specific surface areaSlow capacity fading rateSecondary cellsPositive electrodesLithium-ion batteryBattery cell

The present invention provides a lithium ion battery and positive electrode material thereof. The positive electrode material includes a high nickel material having a chemical formula of LiNixM1-xO2 and a coating layer, wherein 0.5≤X<1, M is selected from at least one of Co, Mn, Al, Mg, Ti and Zr, a specific surface area of the positive electrode material is 0.2 to 0.6 m2 / g, and a residual lithium content on a surface of the positive electrode material is 200 to 1000 ppm. Compared with the prior art, the positive electrode material for lithium ion battery of the present invention is prepared by solid phase reaction, which not only can significantly reduce the residual lithium content on the surface of the positive electrode material, but also can avoid increase of the specific surface area of the positive electrode material for lithium ion battery.

Owner:CONTEMPORARY AMPEREX TECH CO

Methods of making cesium salts and other alkali metal salts

A method of making a cesium salt is described and involves reacting a cesium sulfate containing solution with lime to form 1) a solution containing at least cesium hydroxide and 2) a residue comprising calcium sulfate. The method further involves removing the residue from the solution and converting the cesium hydroxide that is present in the solution to at least one type of cesium salt. The present invention further relates to uses of the cesium salt as well as methods of making cesium hydroxide using lime. Also, methods of making alkali metal salts and alkali metal hydroxides are also described.

Owner:CABOT SPECIALTY FLUIDS

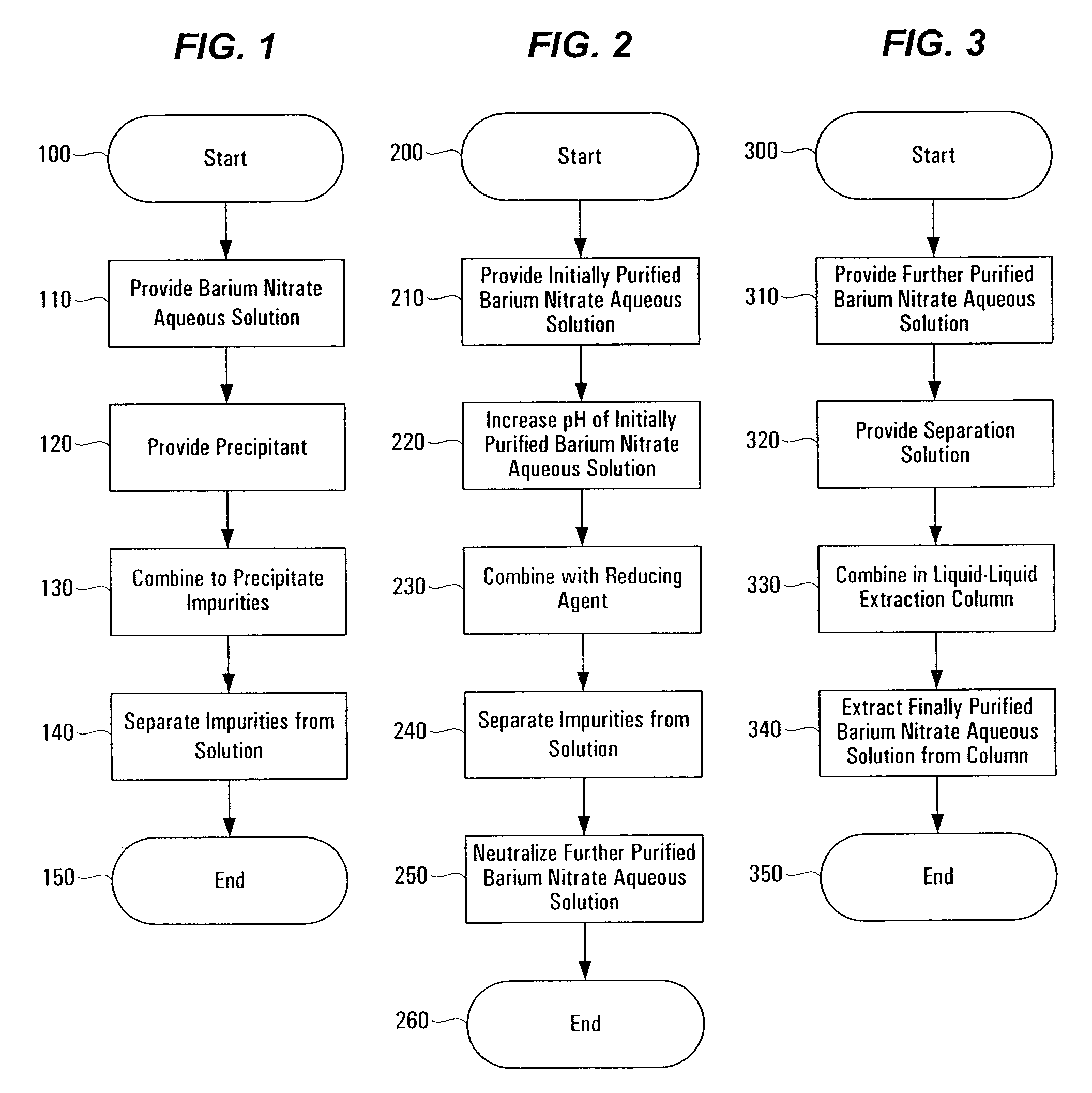

Method of purifying barium nitrate aqueous solution

InactiveUS7648687B1Solid sorbent liquid separationLiquid solutions solvent extractionBarium nitrateOxidation state

Purification techniques have been developed for ceramic powder precursors, e.g., barium nitrate. These techniques can be performed using one or more of the following operations: (1) removal of impurities by precipitation or coprecipitation and separation using a nonmetallic-ion-containing strong base, e.g., tetraalkylammonium hydroxides; (2) reduction of higher oxidation-state-number oxymetal ions and subsequent precipitation as hydroxides that are separated from the solution; and (3) use of liquid-liquid exchange extraction procedures to separate certain impurities.

Owner:EESTOR

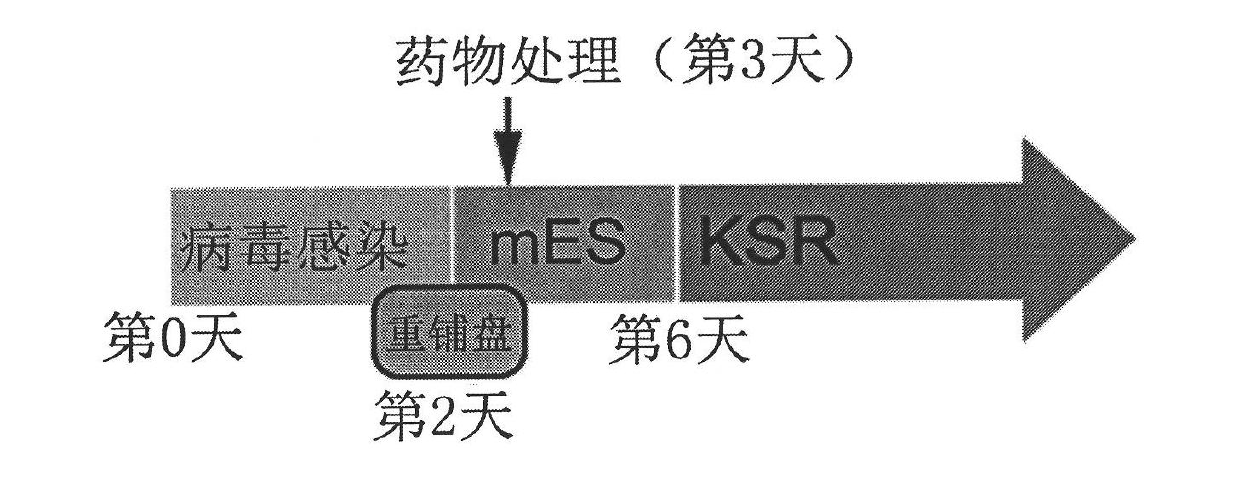

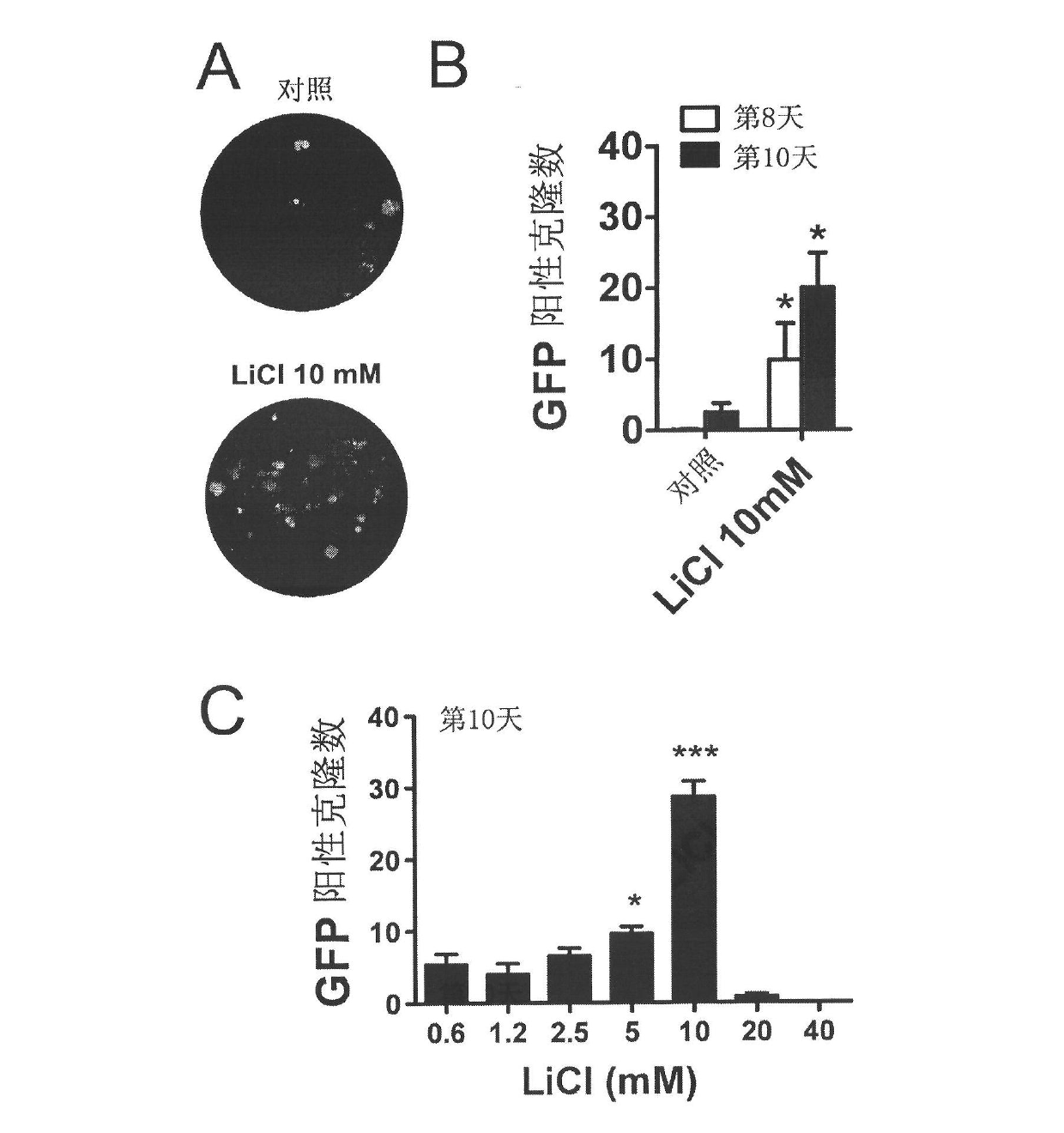

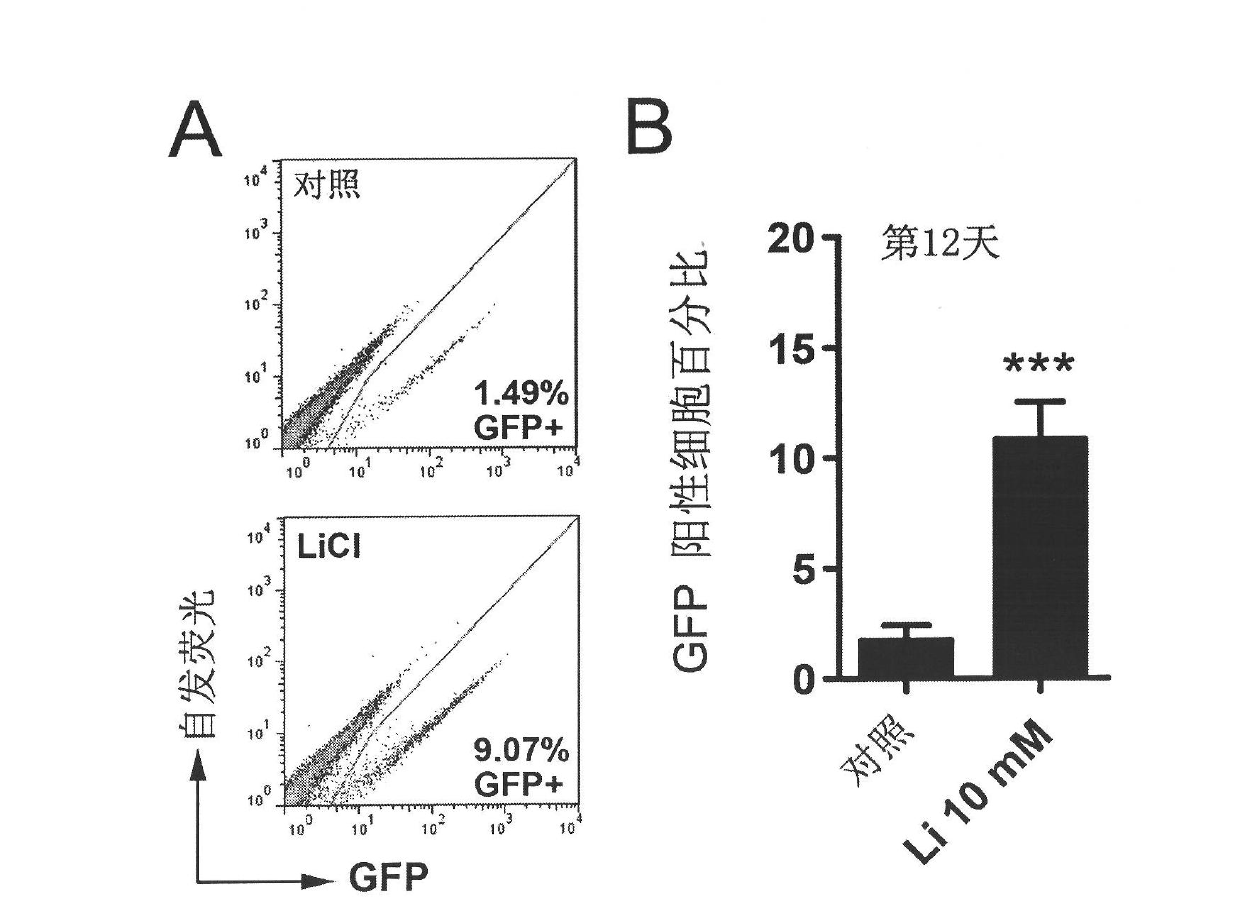

Preparing method of iPS cell and medium for preparing iPS cell

InactiveCN102559587AImprove versatilityAchieve germline transmissionGenetically modified cellsCulture processLithiumSex factors

The invention provides a preparing method of an iPS cell, which includes the following steps: step 1, introducing one or many stem cell pluripotent sex factors into a somatic cell; step 2, adopting the medium added with lithium to cultivate the somatic cell introduced with the stem cell pluripotent sex factors in the step 1; and step 3, identifying the cloning of the iPS cell. Furthermore, the invention also provides a medium for preparing the iPS cell, wherein the cell further includes lithium. The lithium-contained medium is applied to efficiently generating the iPS cell. In the invention, the lithium can improve the generation efficiency of the mouse iPS cell to be 5 to 60 times. The efficient iPS cell inducing method is highly significant in improving the iPS technical safety and applying the iPS cell to the field of regeneration medicine.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

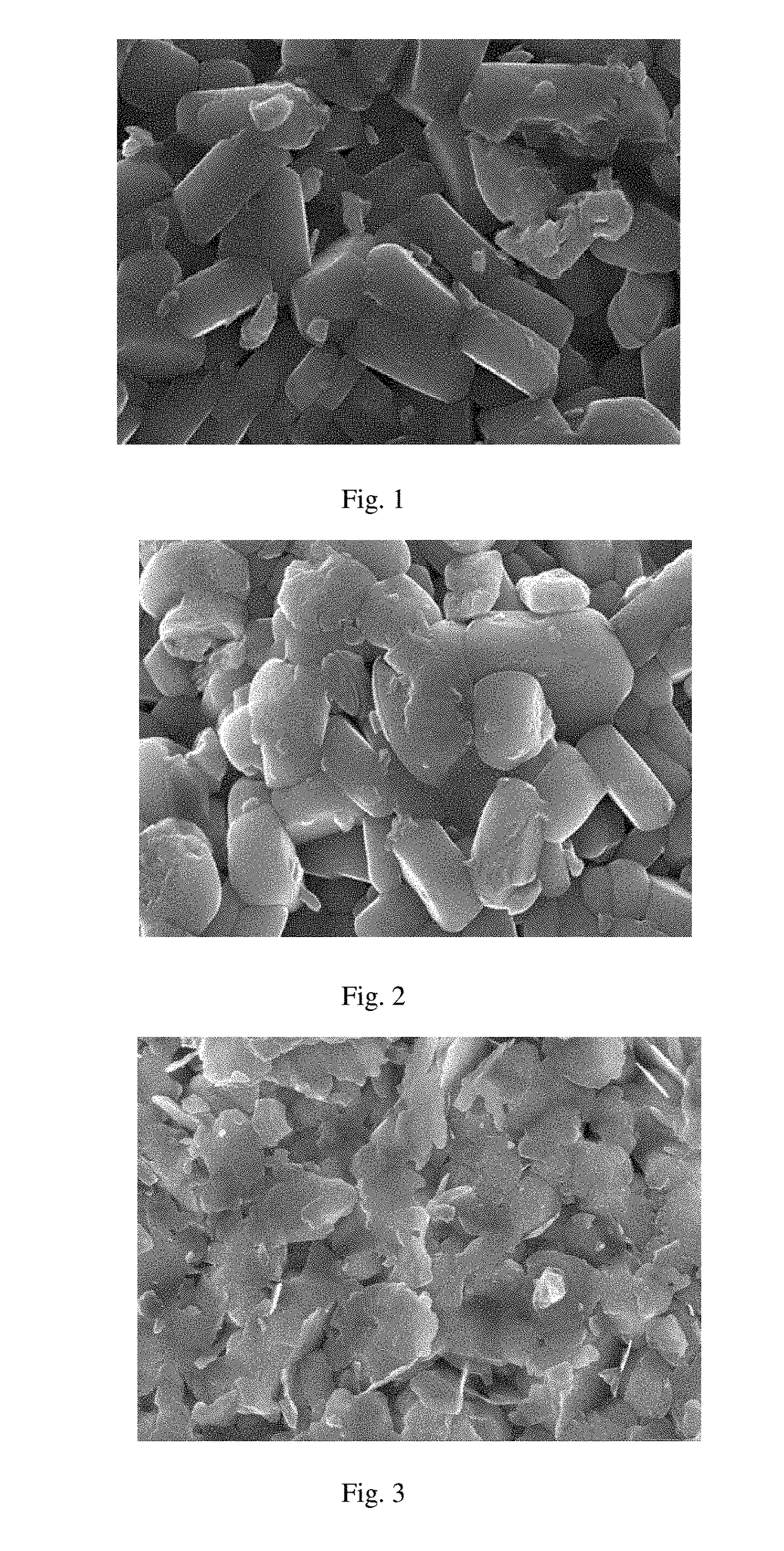

Strontium nitrate and method for manufacturing same

Low-cost, high-purity strontium nitrate that is low in Ba, Na, Ca, Cr, and other impurities and that is suitable for use in airbags or the like is provided. High-purity strontium nitrate having a Ba content of 0.01 wt % or lower, an Na content of 0.005 wt % or lower, a Ca content of 0.01 wt % or lower, a Cr content of less than 0.001 wt %, and a purity of 99.5 wt % or higher is produced by a manufacturing method comprising a first step for performing crystallization by adding nitric acid to an aqueous solution obtained by dissolving a strontium compound as a starting material, a second step for separating the resulting crystals, a third step for crystallizing the resulting separated solution, and a fourth step for separating the resulting crystals.

Owner:DOWA METALS & MINING CO LTD +1

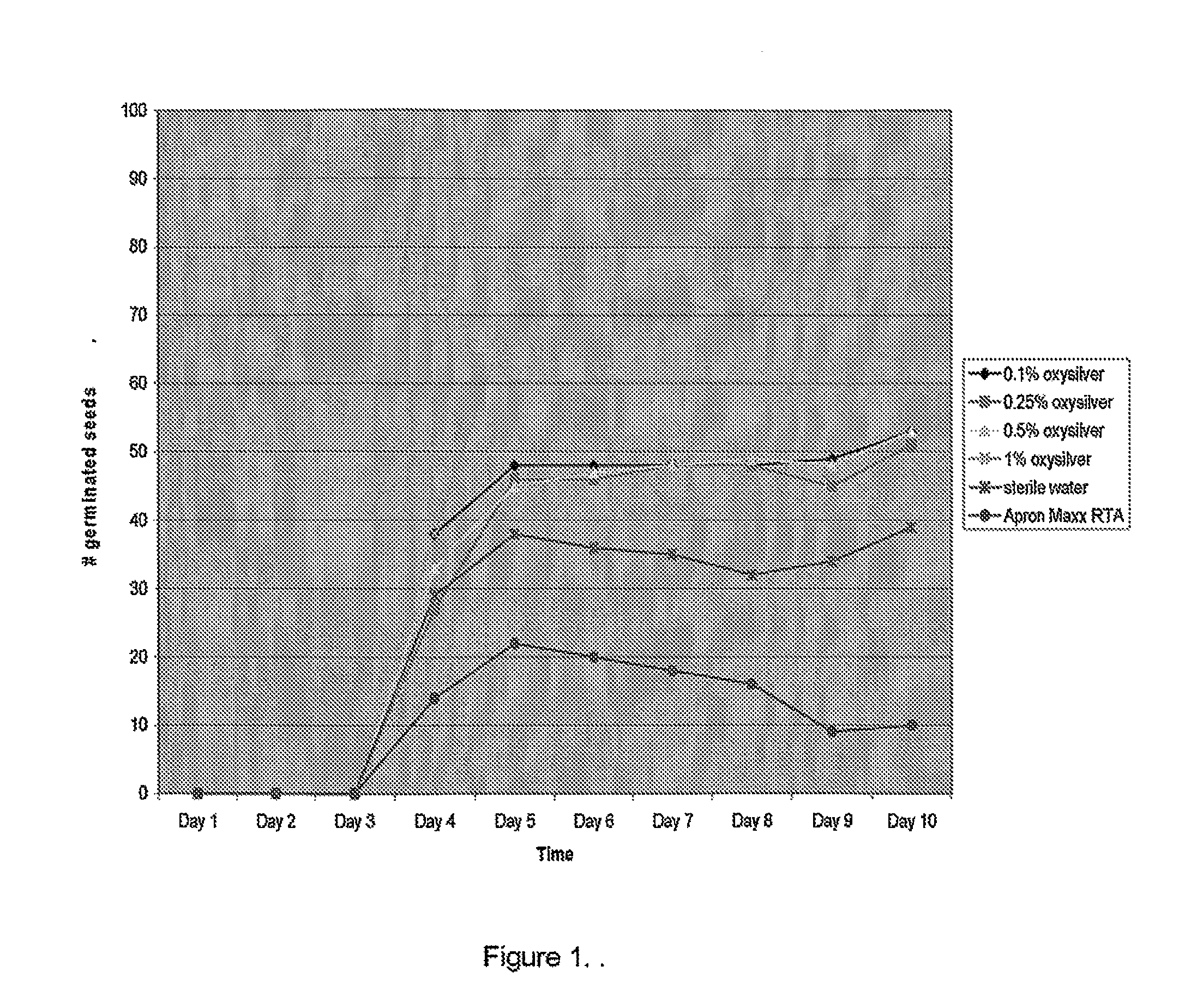

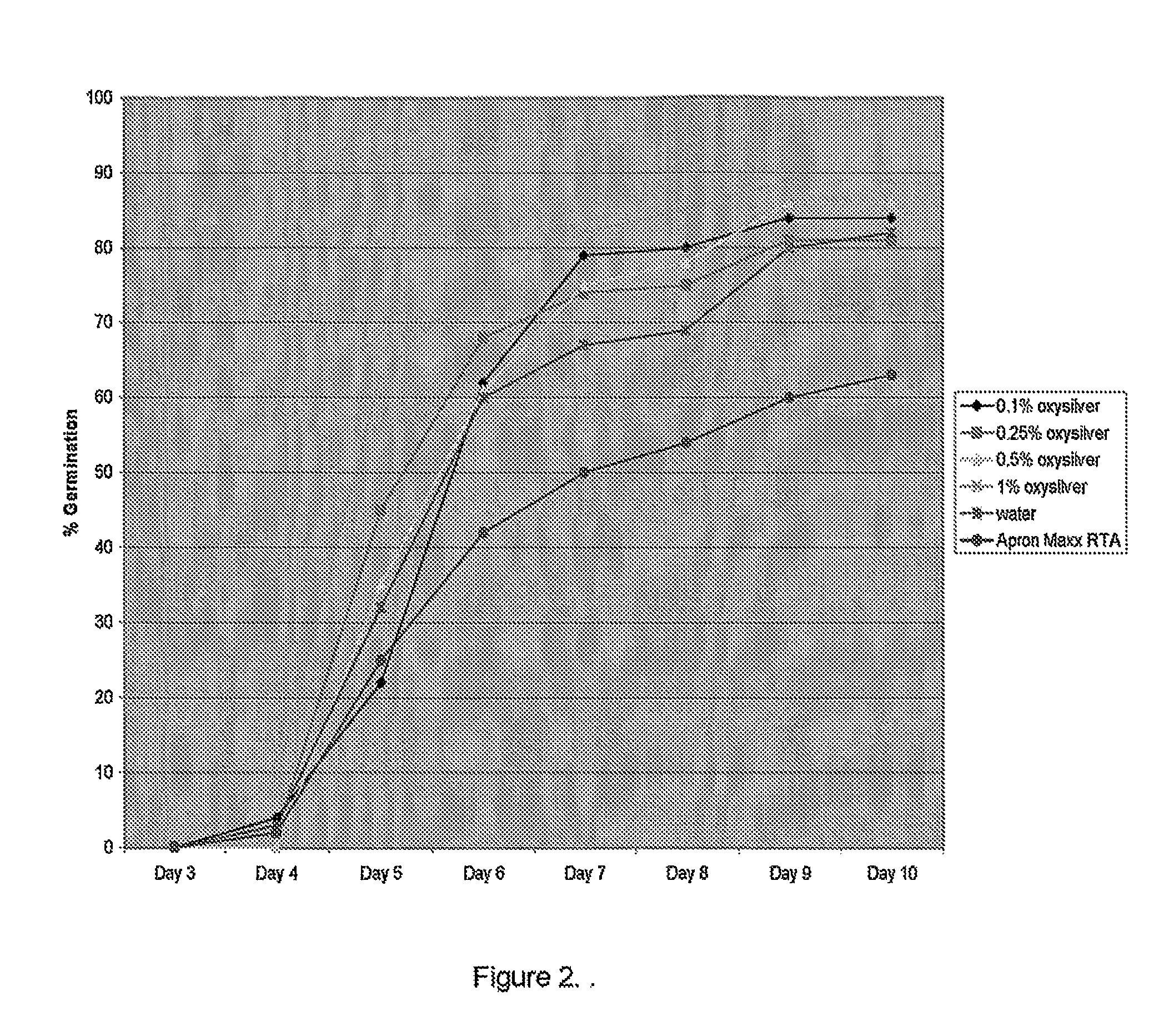

Compositions and Methods Comprising High Valency Silver for Increasing Seed Germination

InactiveUS20110275518A1Promote seed germinationImproved and efficient active agent delivery systemBiocideNitrogen compoundsBiofilmGermination

The present invention is compositions and methods for improving seed germination rates or speed using a composition comprising at least one high valency silver ion. The compositions and methods of the present invention are effective in treating biofilms.

Owner:MARQUES LYRIAM L +2

Pastillation of ammonium sulfate nitrate

A process is presented for the production of ammonium sulfate nitrate. The process provides for producing a highly uniform product and having a substantially uniform size. The process includes reacting ammonium sulfate and ammonium nitrate to form an FASN slurry melt. The slurry melt is continuously stirred and heated to keep the slurry melt under a shear thinned condition and at a uniform temperature until the slurry melt is extruded, cooled and solidified.

Owner:ADVANSIX RESINS & CHEM LLC

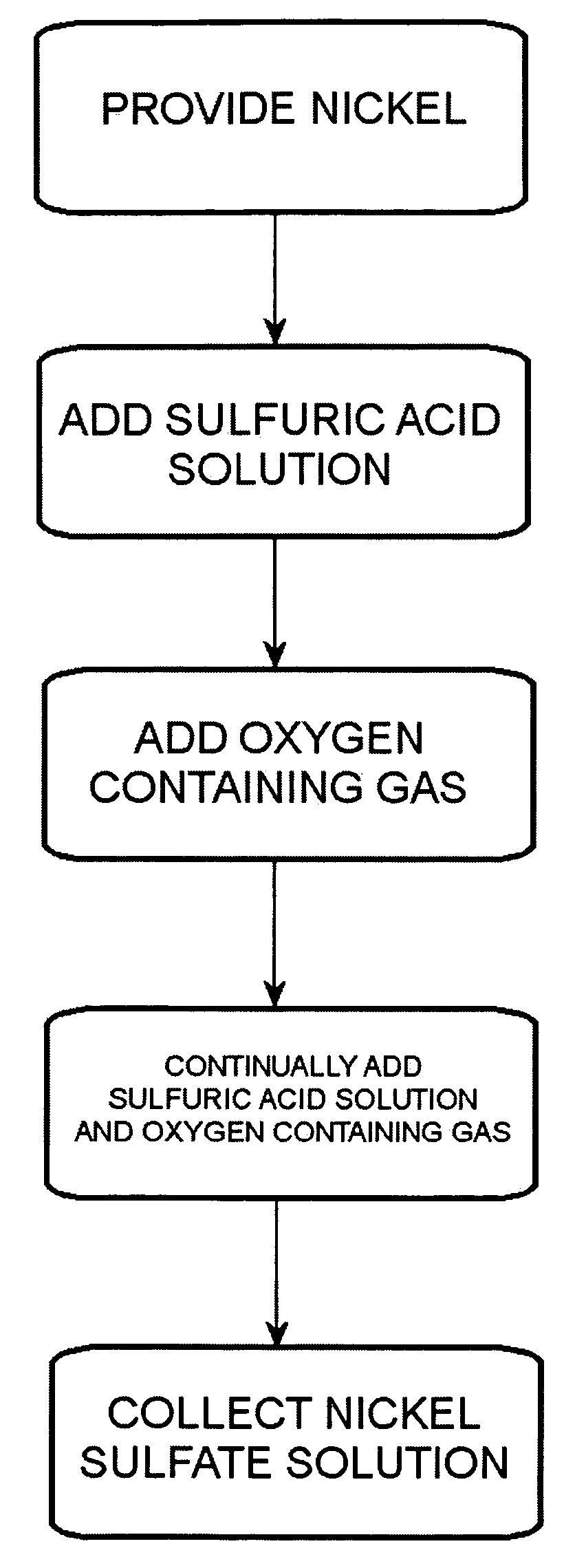

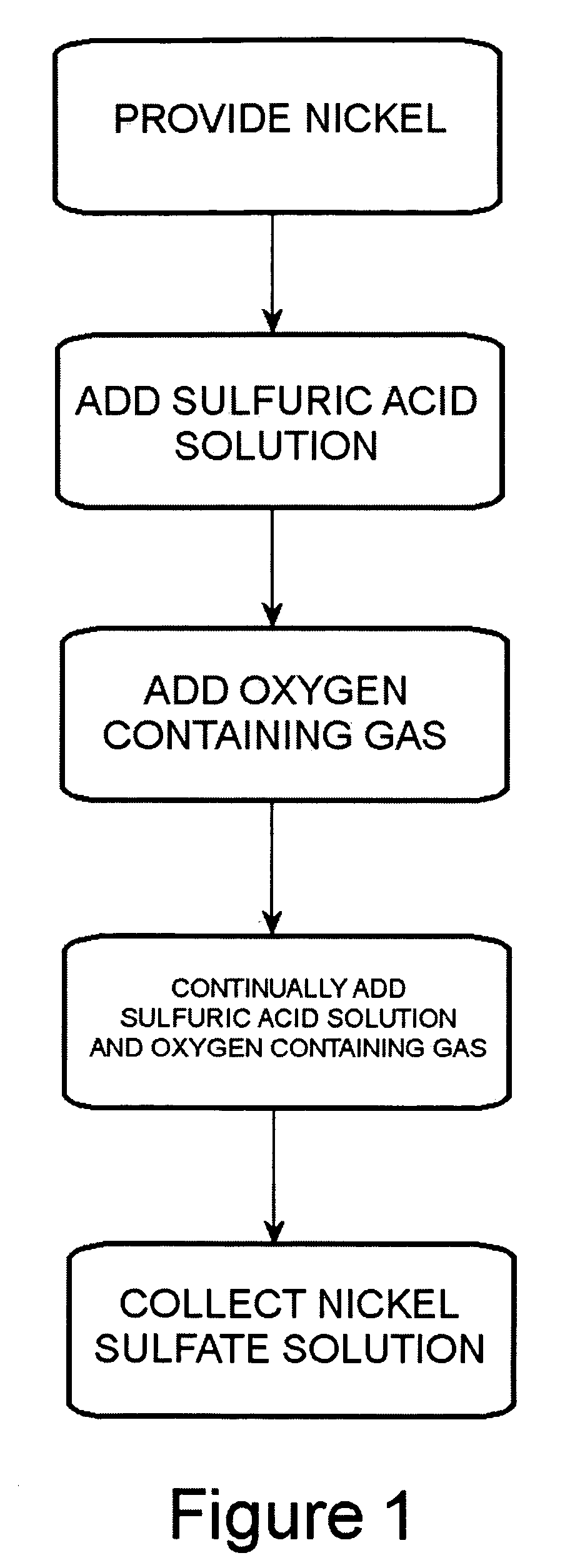

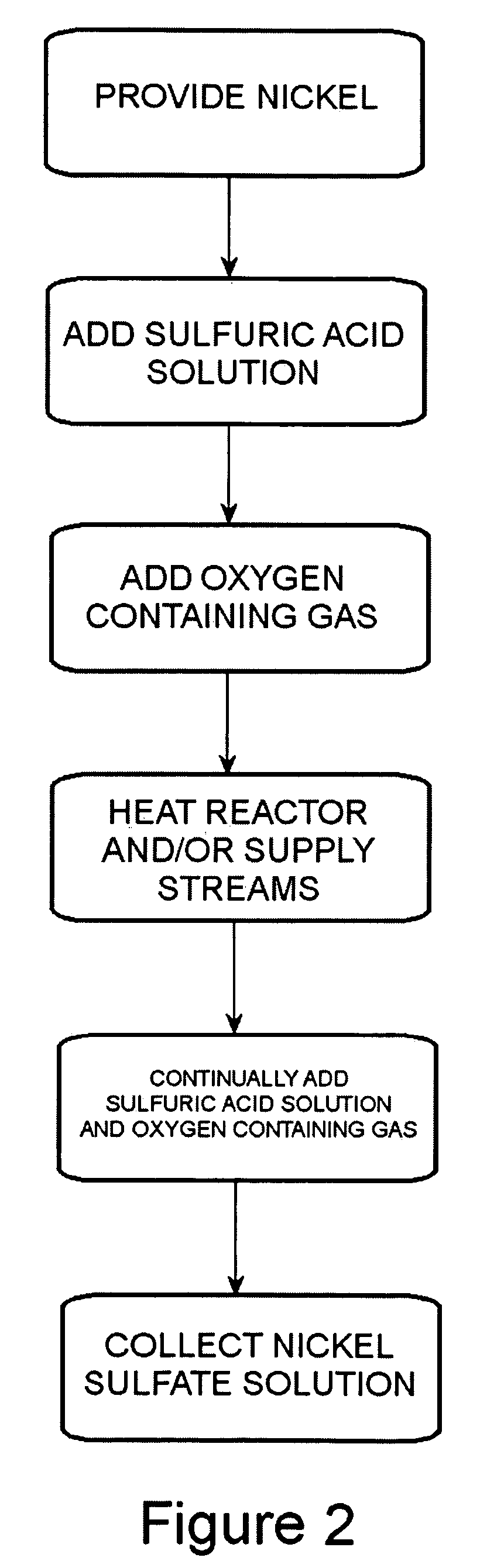

Method of producing a nickel salt solution

A method for converting nickel into a nickel salt solution. Nickel is dissolved and reacted in an oxygen-enriched acidic solution to produce a nickel salt solution as illustrated in the following chemical equation, wherein X is a conjugate base: Ni+H2X+½O2->NiX+H2O.

Owner:CHEVRON TEXACO TECH VENTURES

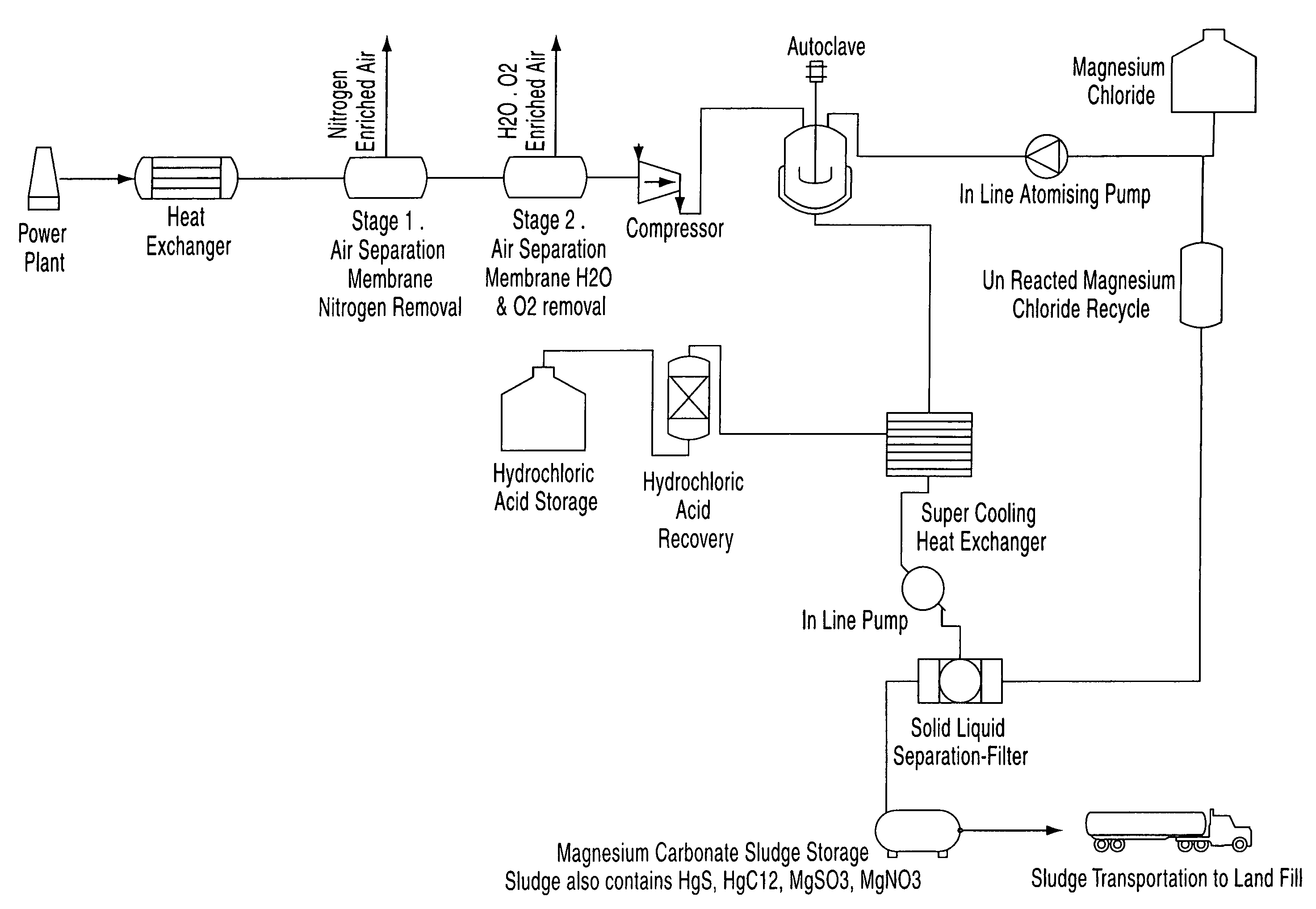

Process for removal of pollutants

A process for the removal of pollutants from a combustion process and, more particularly, a process for removing pollutants such as carbon dioxide, mercury, sulphur dioxide, nitrogen compounds and oxygen compounds from a combustion process. The process includes the removal of pollutants from a combustion process that produces an emission comprising: cooling the emission to a temperature of about 200° C.; removing nitrogen, water and oxygen from the emission to produce a gas containing a concentration of pollutants; contacting the gas with an aqueous magnesium chloride solution, wherein a slurry mixture is formed; and cooling the gas and the slurry mixture, wherein hydrochloric acid vapour and a sludge are formed.

Owner:CLEAN WORLD STRATEGIES CORP

Method for lithium salts from high-magnesium lithium-containing brine

InactiveCN105645443AStable recoveryRealize cyclic applicationLithium halidesLithium sulfates/sulfitesLithiumHigh magnesium

The invention discloses a method for lithium salts from high-magnesium lithium-containing brine. The method comprises the following steps: extraction: mixing a tributyl phosphate extraction system with high-magnesium lithium-containing brine and an alkaline solution, and carrying out lithium extraction to obtain a lithium-carried extraction system and an extracted water phase; exchange: mixing a lithium salt water solution with the lithium-carried extraction system to remove impurities in the lithium-carried extraction system, thereby obtaining a high-purity-lithium-carried extraction system and an exchanged water phase: and back extraction: carrying out back extraction on the high-purity-lithium-carried extraction system with an acid solution to obtain a lithium-salt-containing water phase, and drying the water phase by distillation to obtain the lithium salts. The alkaline solution can be mixed with the extraction phase in the back extraction step and the extracted water phase in the extraction step, and the obtained regenerated extraction system can be recycled. The alkali solution is added in the extraction technique, thereby solving the problem of uncontrollable extraction process and unstable regeneration of the extraction system in the prior art.

Owner:上海颐润科技有限公司 +1

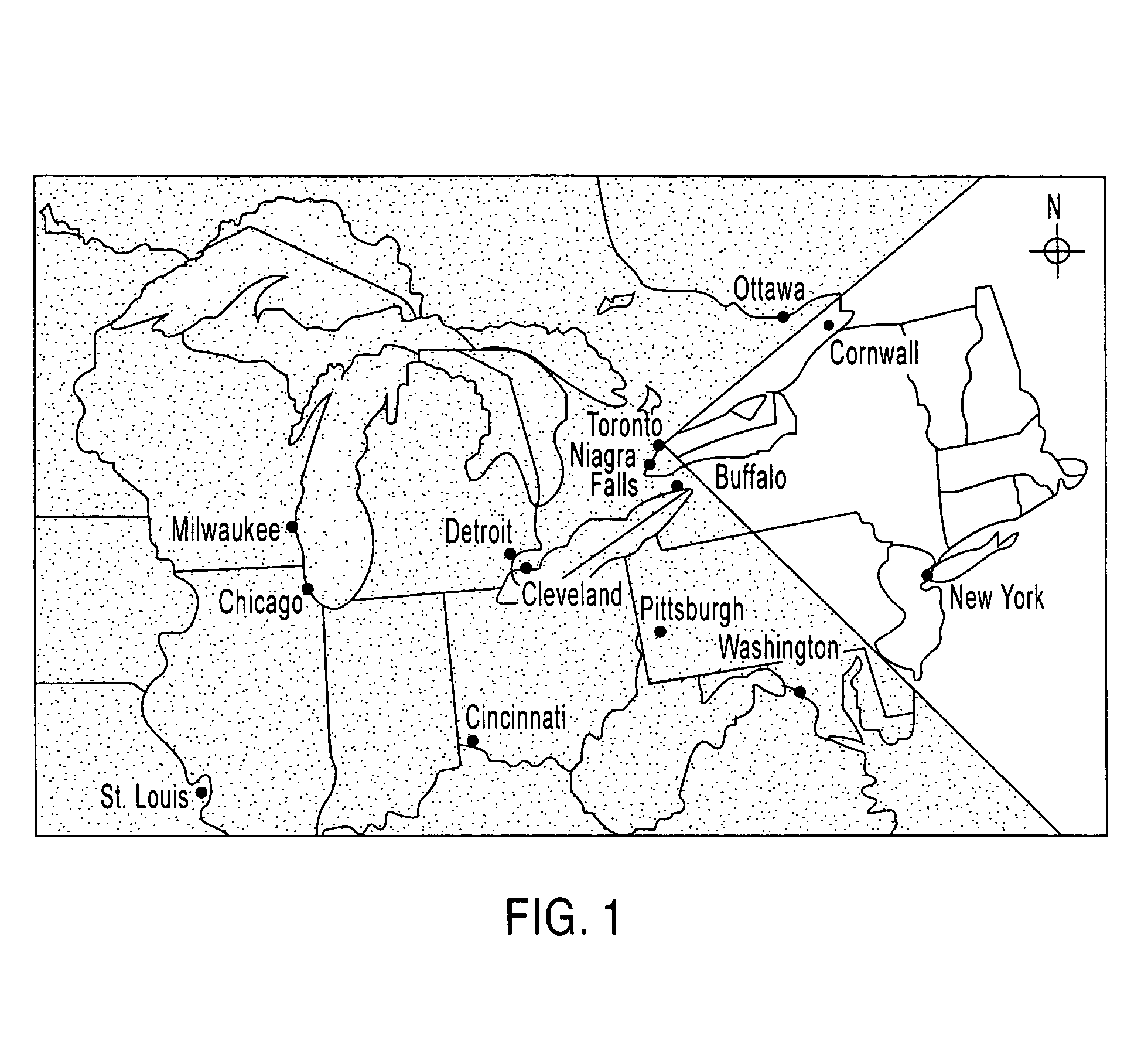

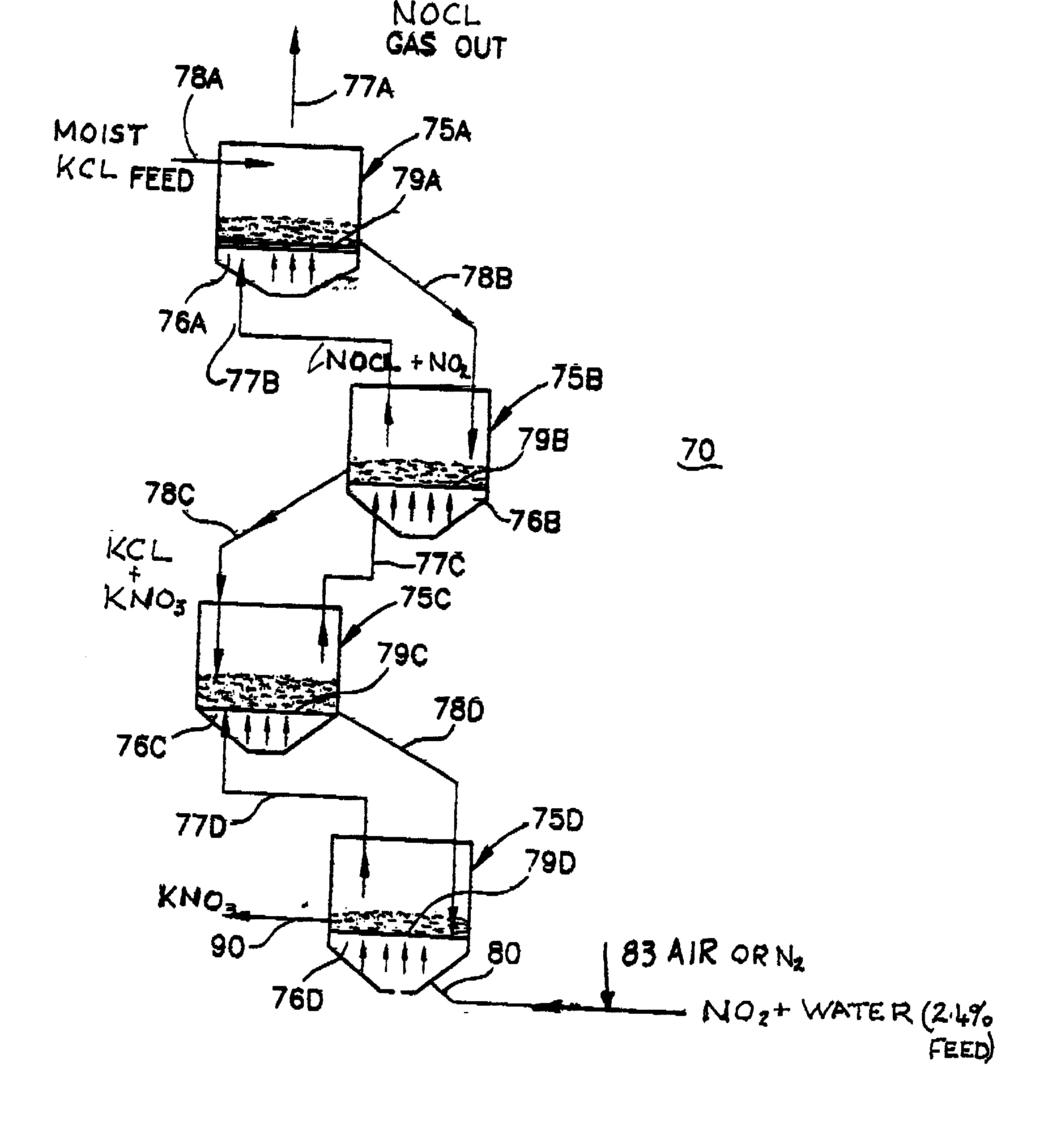

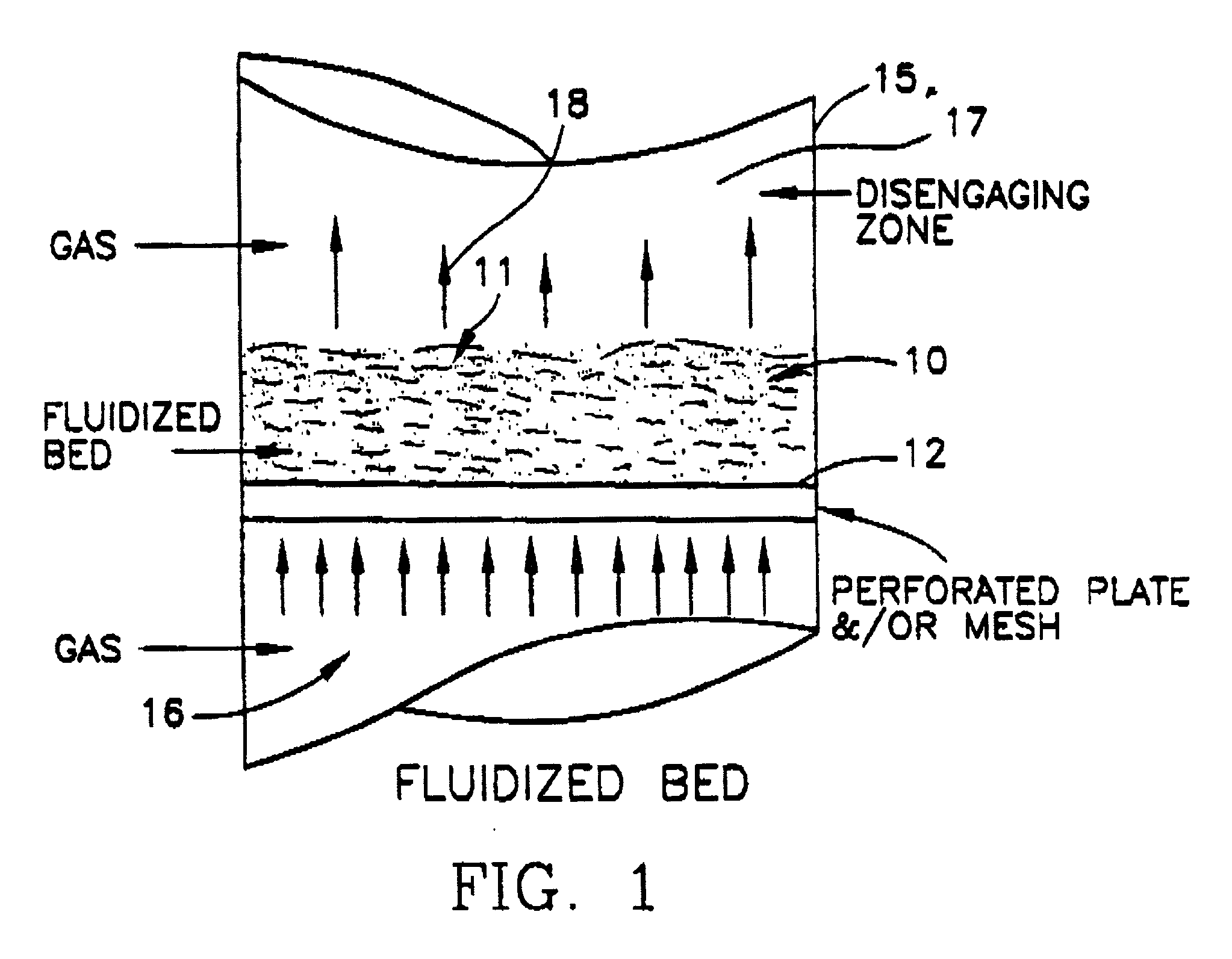

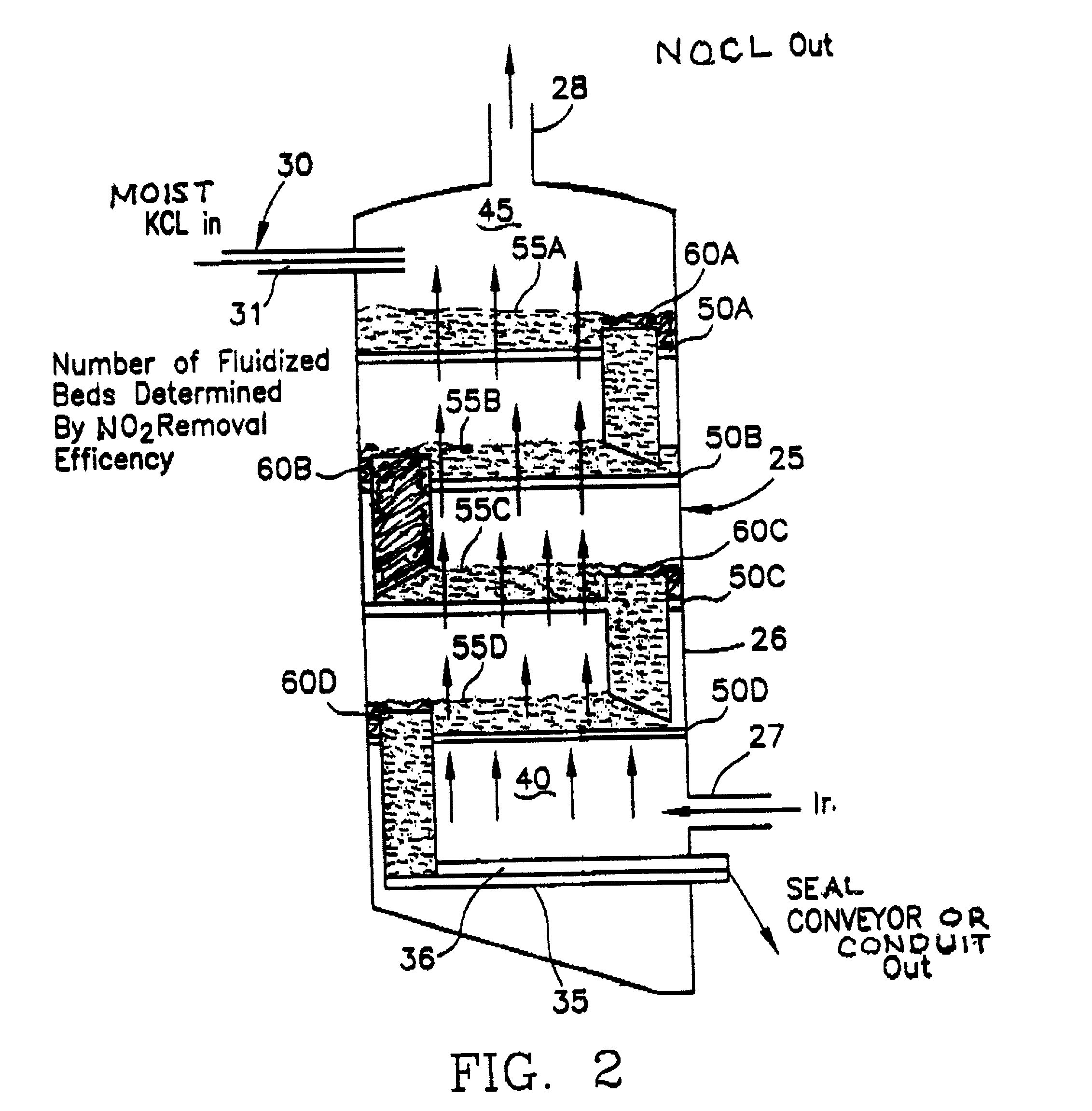

Process for manufacturing potassium nitrate fertilizer and other metal nitrates

InactiveUS20020110512A1Cost effectiveEfficient executionCalcareous fertilisersCobalt ammonia complexesWater vaporCounter current

A process for producing potassium nitrate and other metal nitrates from the chlorides, sulfates, oxides of these metals. The process uses nitrogen dioxide as a true fluidizing medium in shallow beds of the aforementioned solids at moderately elevated temperatures in a continuous counter current process to convert the metal chlorides, sulfates, and oxides, into metal nitrates and effluent gas and water vapor. The process may be carried out in a series of true fluidized beds arranged in a vertical configuration so that the solids flow downward due to the fluidized process and the nitrogen dioxide gas flows counter currently in an upward direction producing pure metal nitrates at the bottom and nitrosyl chloride gas and / or water vapor at the top.

Owner:RIGBY WILLIAM J

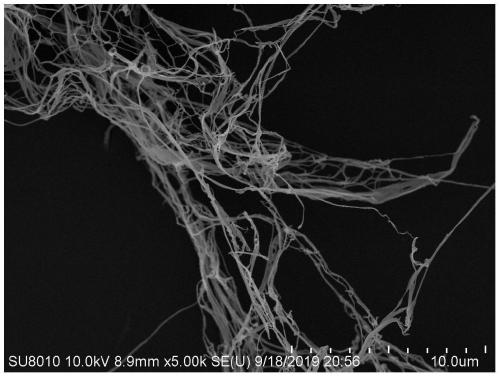

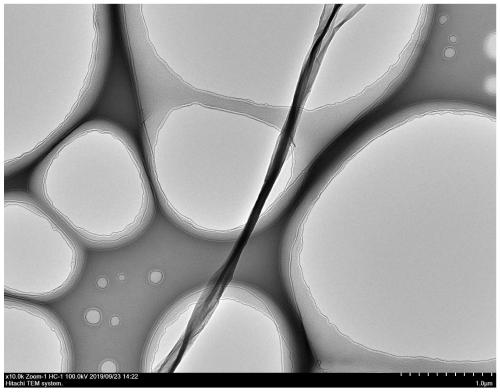

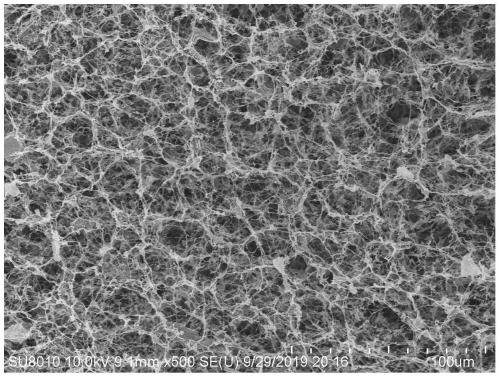

Preparation method of graphene oxide nano roll and composite material thereof

ActiveCN111252760AFast conductionImprove conductivityZinc halidesMaterial nanotechnologyFluid phaseNetwork structure

The invention discloses a preparation method of a graphene oxide nano roll and a composite material thereof, which belong to the field of preparation of carbon nano materials. According to the invention, the defects of complex process, low efficiency, high energy consumption, complex process, single product and the like of the existing preparation method of the carbon nano roll and the composite material are overcome. The method comprises the following steps: ultrasonically dispersing graphene oxide sponge prepared by adopting a liquid phase stripping method and freeze-drying in deionized water; dissolving graphene oxide in water, dropwise adding to a clean substrate, horizontally placing in equipment connected with a vacuum pump, and vacuumizing at normal temperature to quickly evaporatewater, thereby obtaining the graphene oxide nano roll; and obtaining a one-dimensional or three-dimensional network structure by controlling the concentration of the graphene oxide; preparing the GO-carbon tube nanoscroll or the GO-carbon tube-metal salt nanoscroll composite material by selectively adding acidified carbon nanotubes and various metal salts. The method is low in cost, easy to operate, high in safety and convenient for large-scale preparation, popularization and application of various products.

Owner:HARBIN INST OF TECH

Thermocatalytically active coating, substrate having the thermocatalytically active coating at least in parts, and process for producing same

InactiveUS8008225B2Reduce the temperatureNitrogen compoundsSulfate/bisulfate preparationLithiumReflective layer

A substrate, such as a glass, glass ceramic, ceramic or metal substrate, is provided with a thermocatalytically active coating on at least a part of the substrate surface. The thermocatalytic coating contains an inorganic lithium salt or organic lithium-containing compound in an amount that is equivalent to not less than 2 wt. % of lithium ions, based on total coating weight. The thermocatalytic coating has a glass, glass solder or sol-gel matrix in which the lithium salt or organic lithium-containing compound is introduced. Optional barrier and IR-reflecting layers are arranged between the substrate surface and the thermocatalytically active coating.

Owner:SCHOTT AG

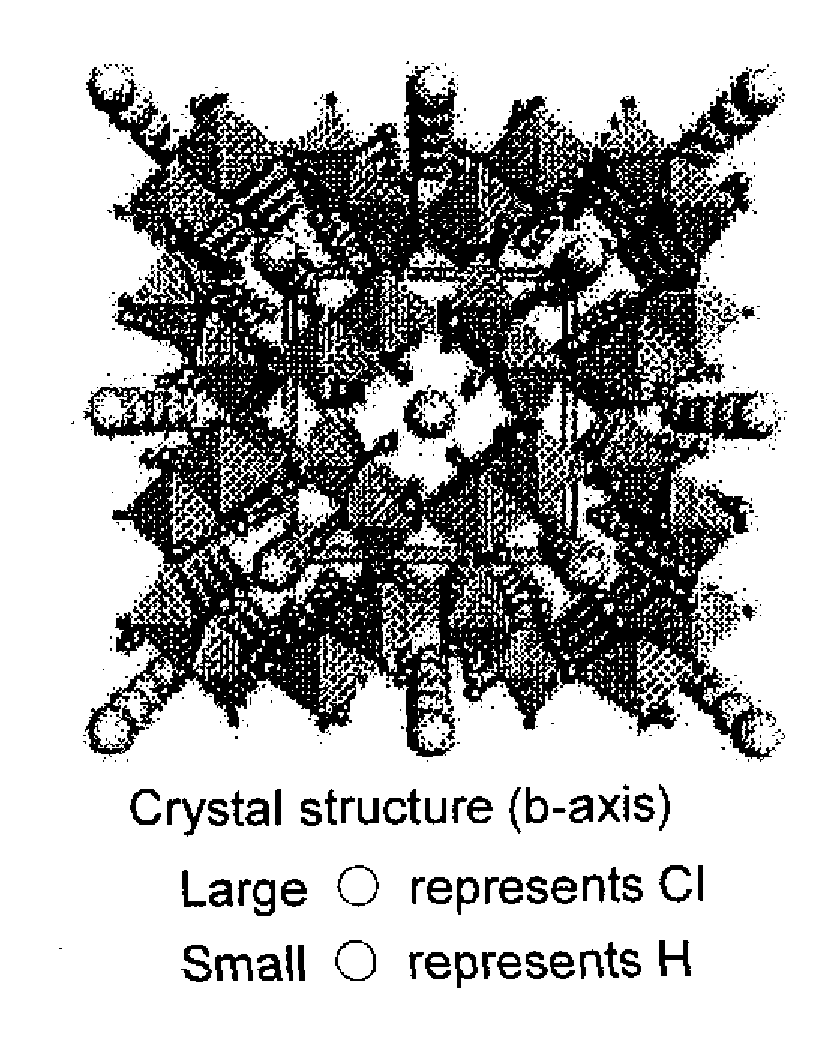

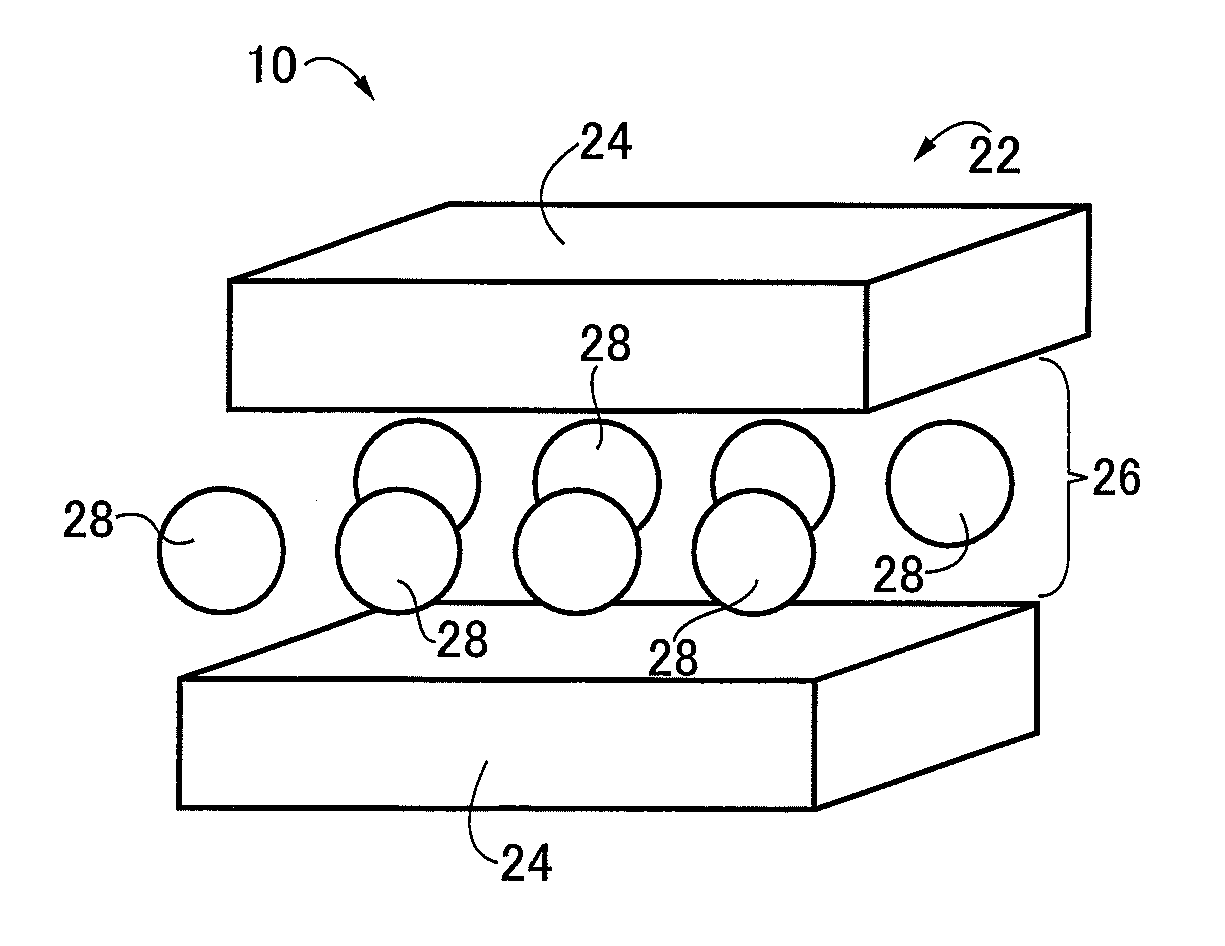

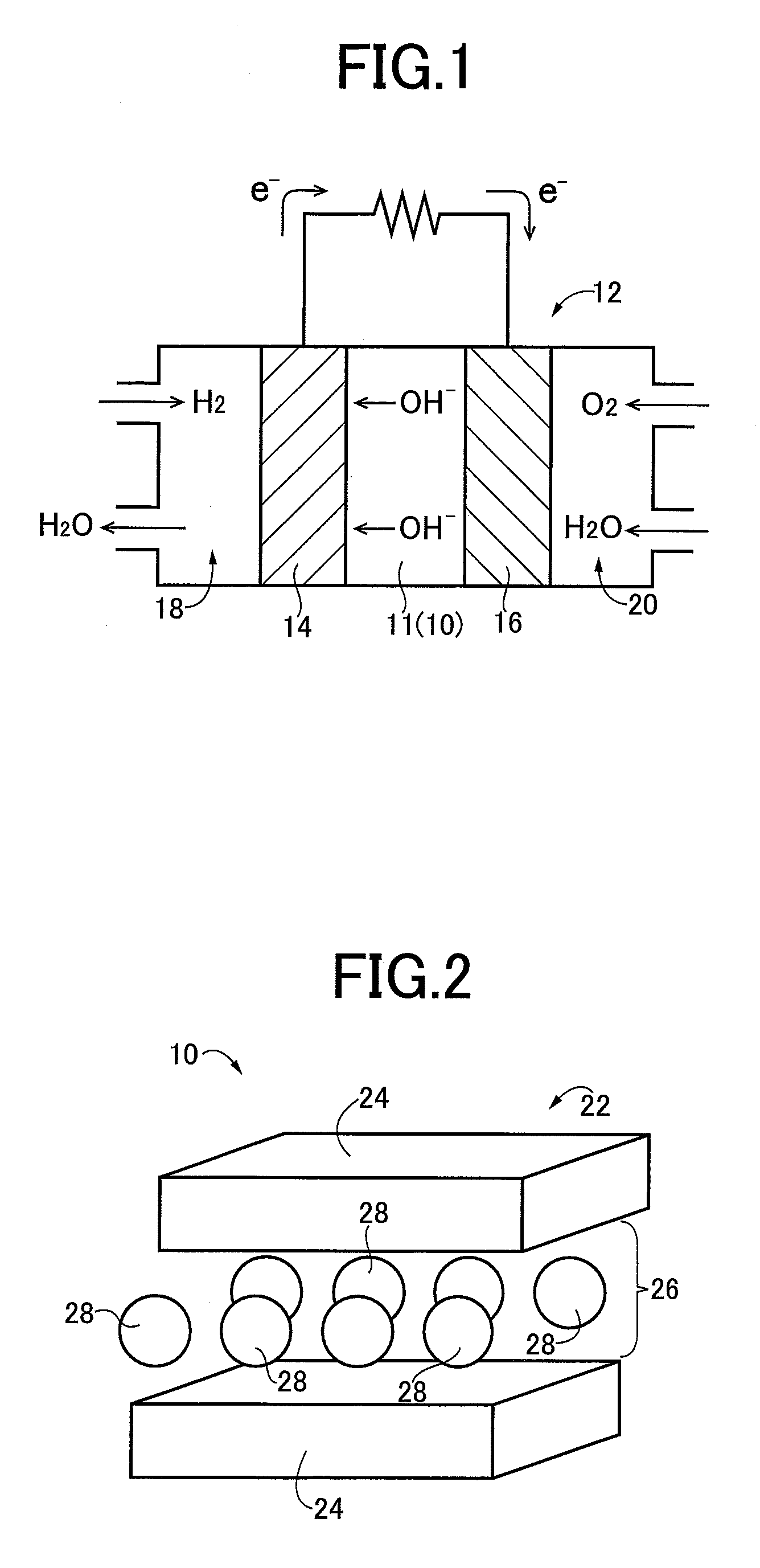

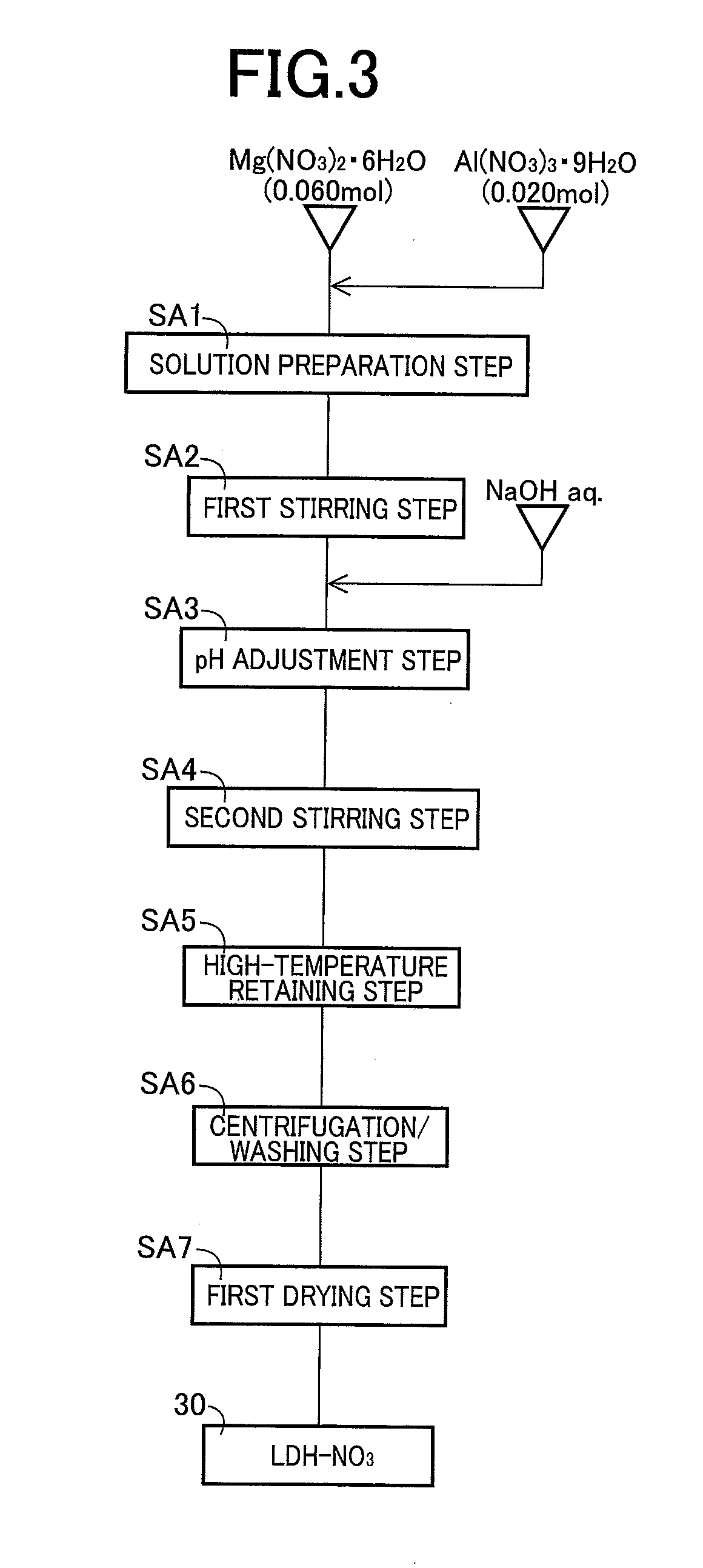

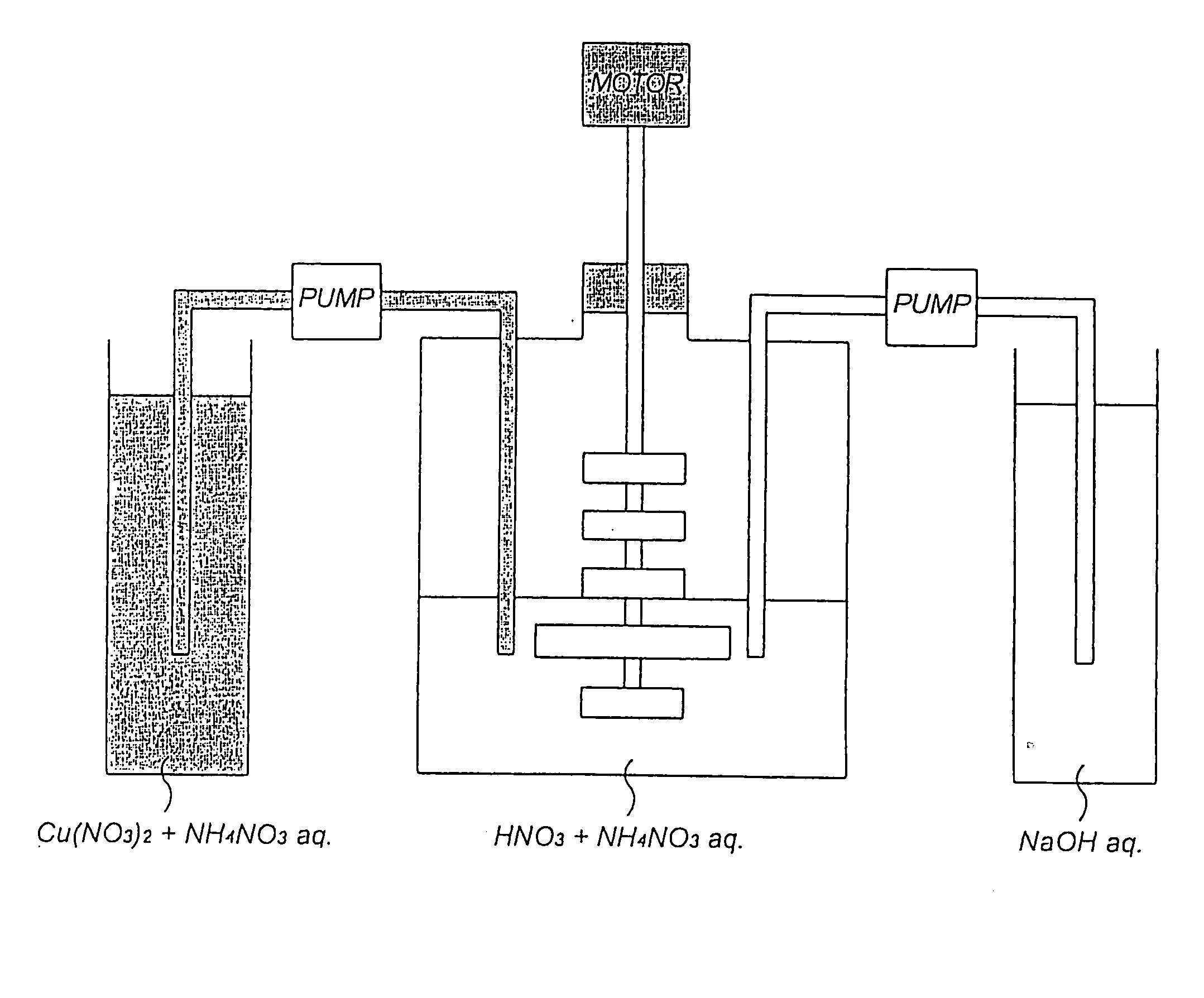

Anion-conducting material and method for manufacturing same

InactiveUS20160159659A1Reduction in ion conductivity is preventedImprove ionic conductivityNitrogen compoundsCell electrodesConductive materialsPolymer chemistry

An anion conductive material consists of a low-regularity layered double hydroxide having ion conductivity enhanced by delamination of a layer structure of a regular layered double hydroxide.

Owner:NORITAKE CO LTD

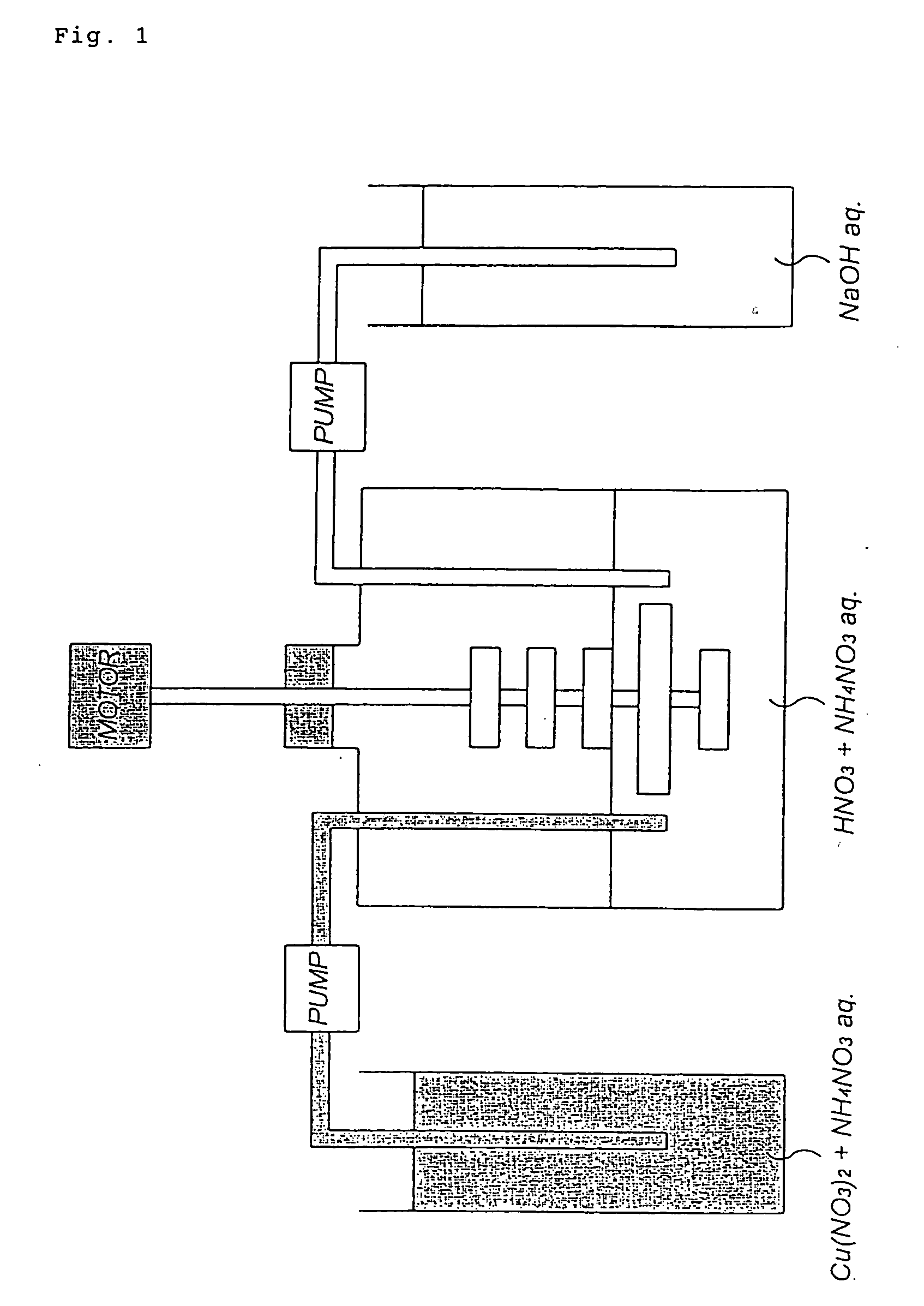

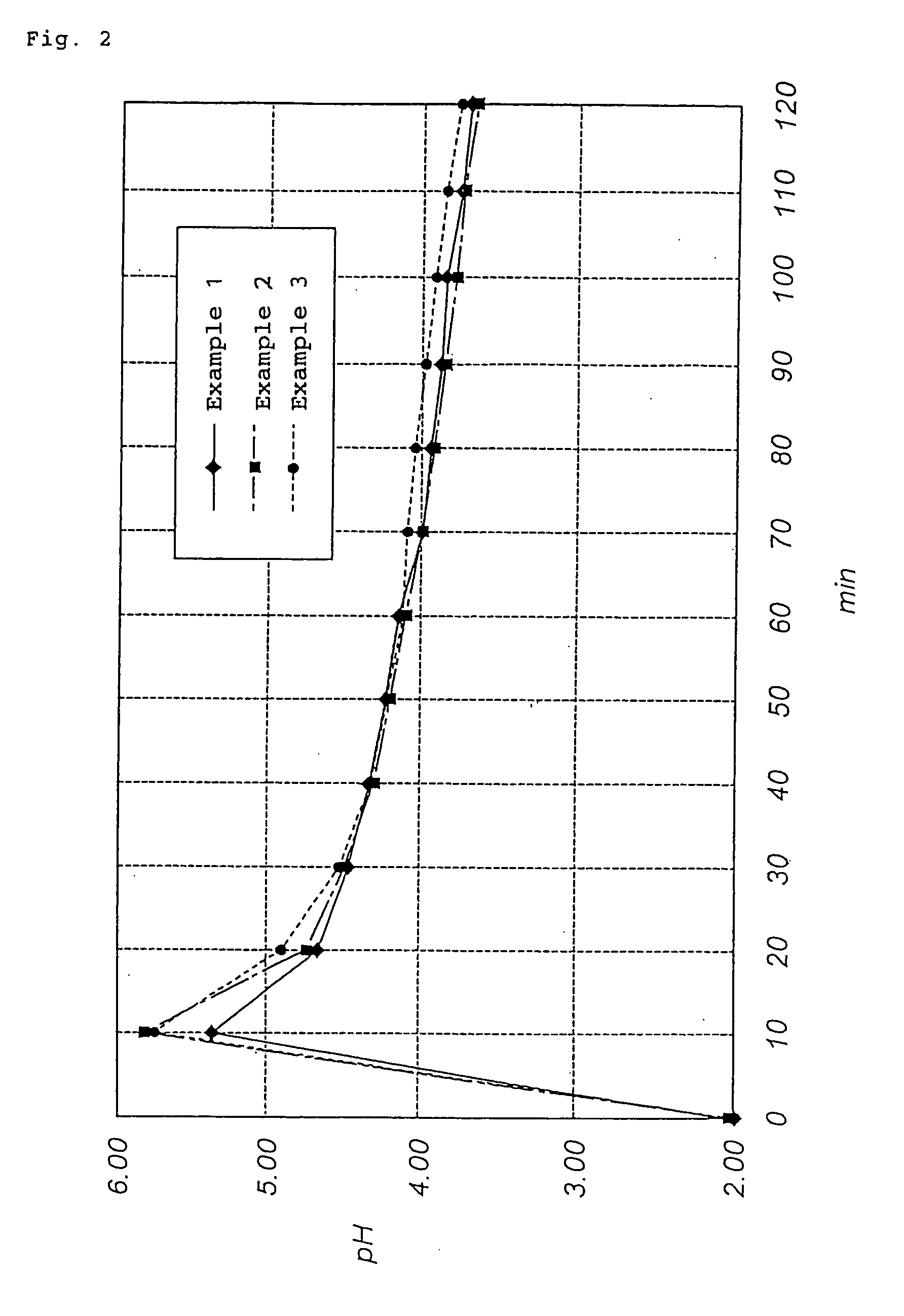

Method for producing basic metal nitrate

A process in which a basic metal nitrate is obtained in a high yield is provided. A process for producing a basic metal nitrate, which comprises adding an aqueous solution of a metal nitrate or an aqueous solution of a mixture of a metal nitrate and a water-soluble additive and an alkali solution to a reaction vessel in which a reaction solvent whose pH at 20° C. is adjusted to 6 or less is present, and conducting the reaction with stirring.

Owner:DAICEL CHEM IND LTD

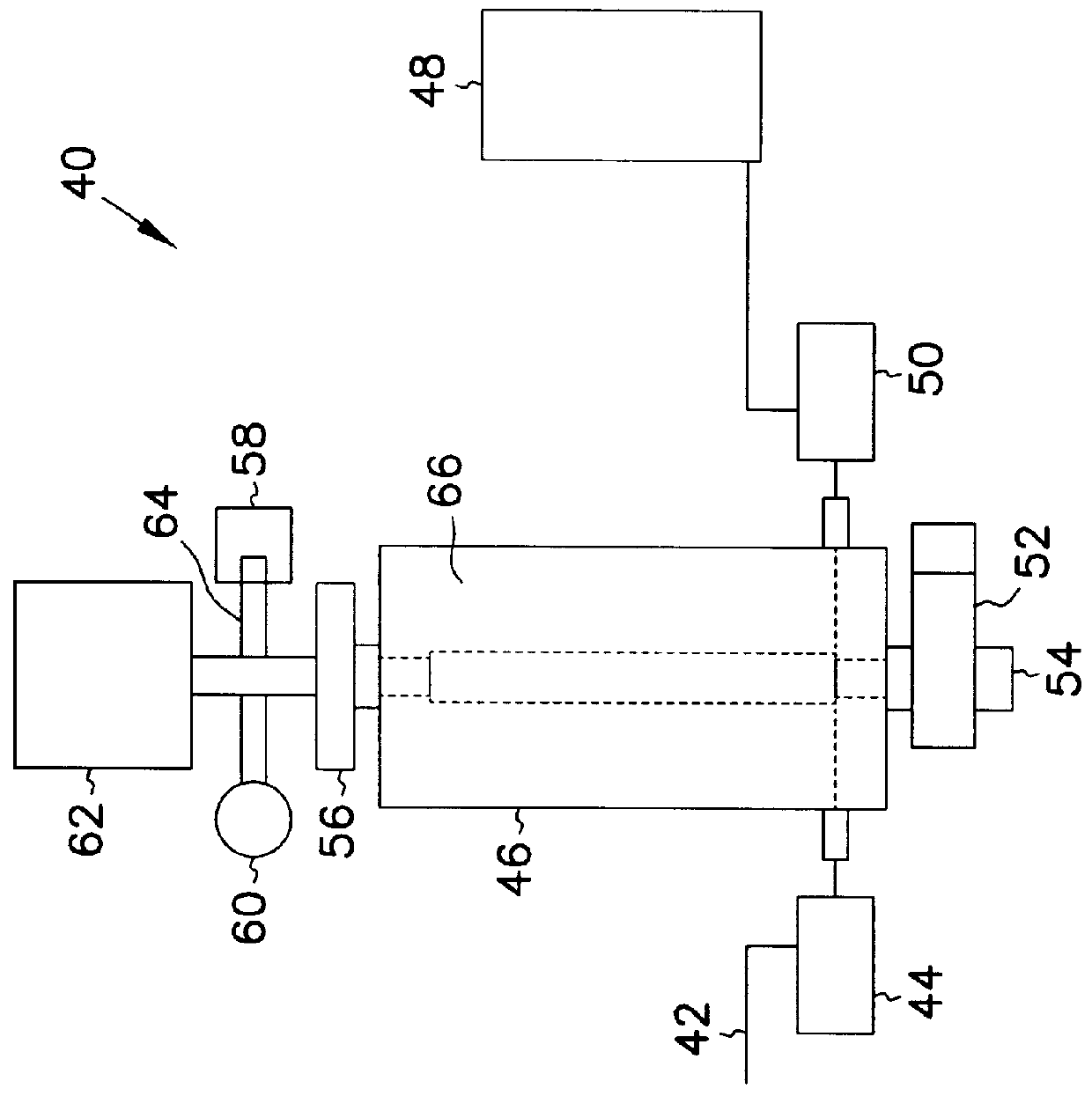

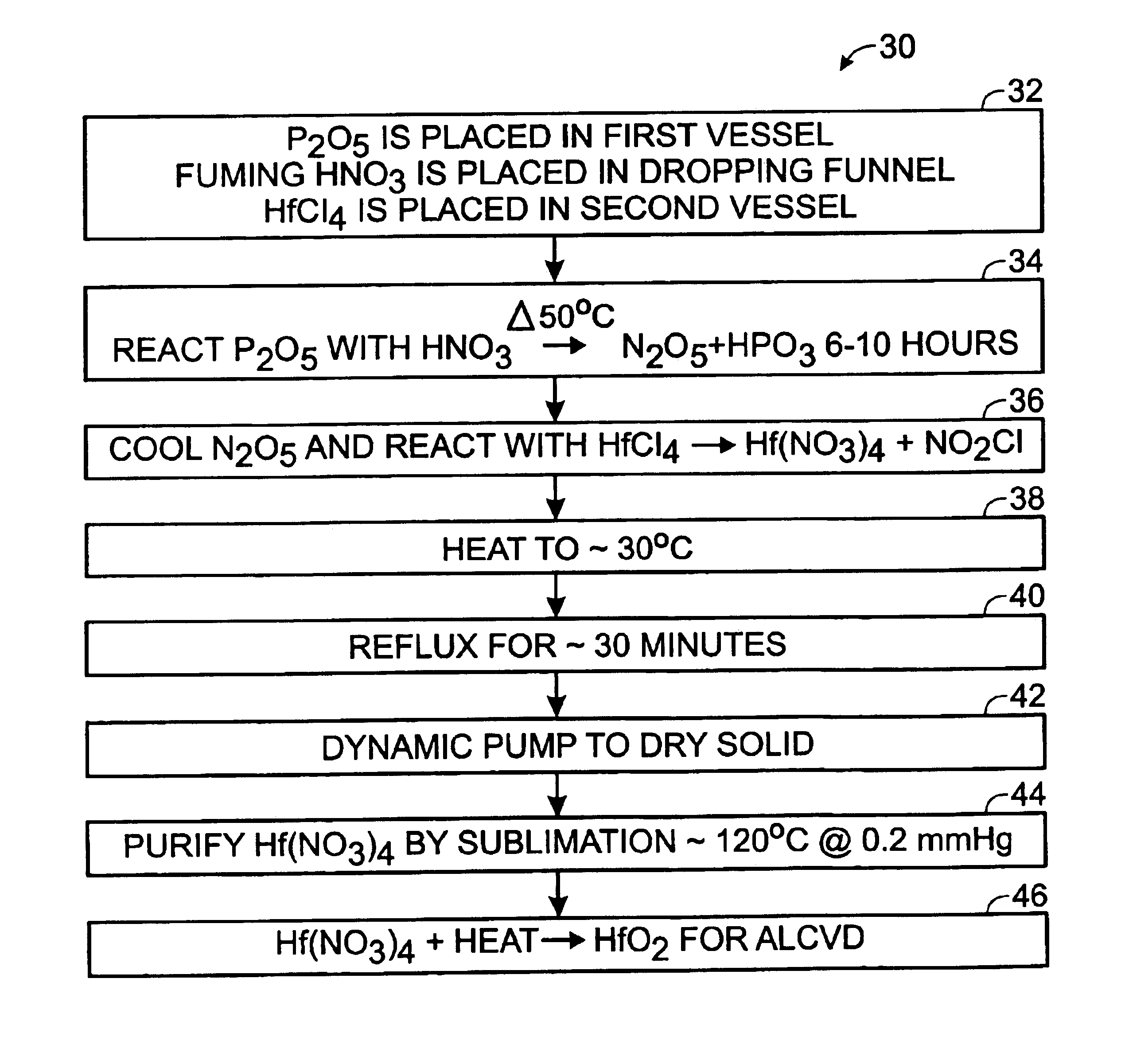

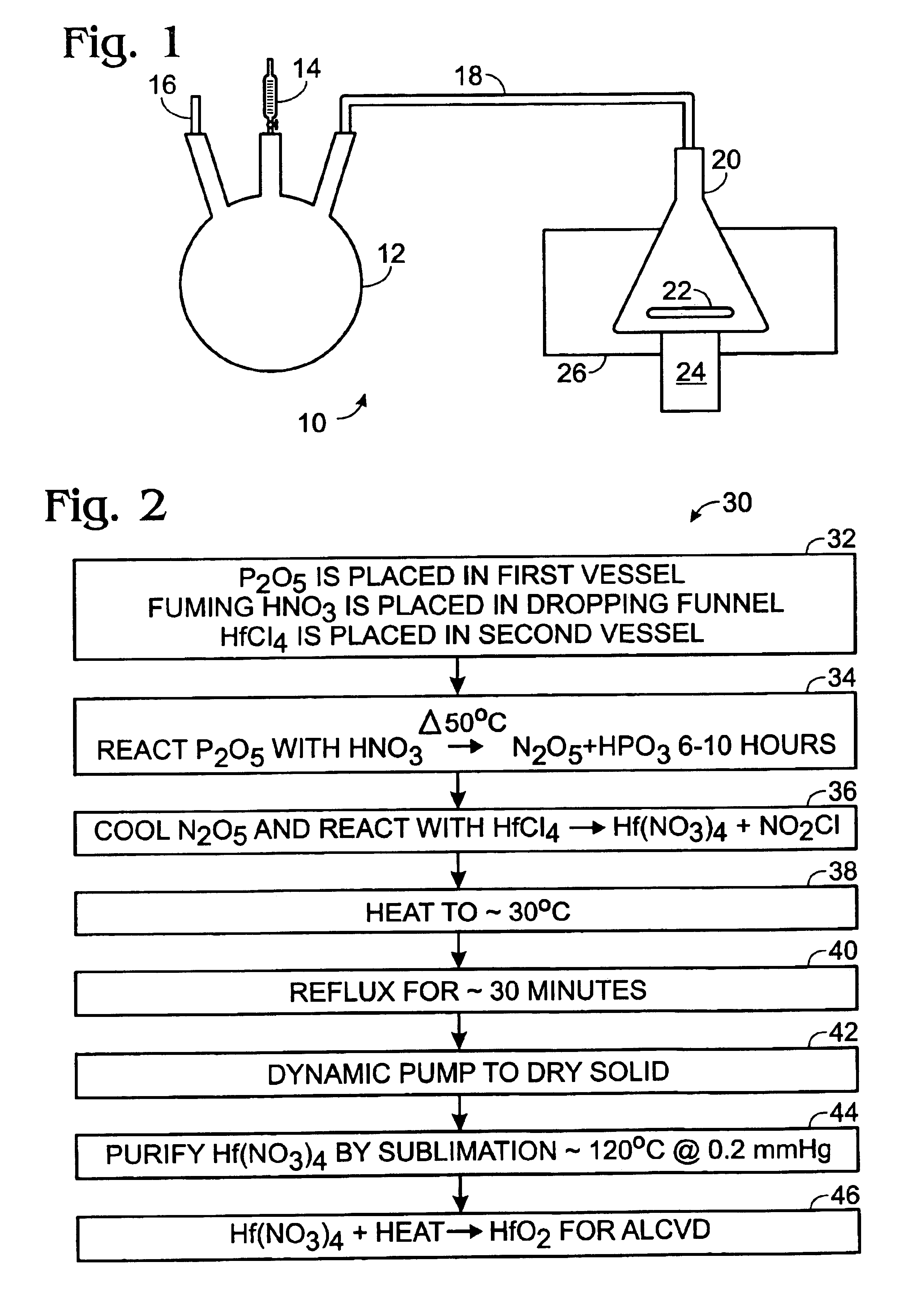

Method of synthesis of hafnium nitrate for HfO2 thin film deposition via ALCVD process

A method of preparing a hafnium nitrate thin film includes placing phosphorus pentoxide in a first vessel; connecting the first vessel to a second vessel containing hafnium tetrachloride; cooling the second vessel with liquid nitrogen; dropping fuming nitric acid into the first vessel producing N2O5 gas; allowing the N2O5 gas to enter the second vessel; heating the first vessel until the reaction is substantially complete; disconnecting the two vessels; removing the second vessel from the liquid nitrogen bath; heating the second vessel; refluxing the contents of the second vessel; drying the compound in the second vessel by dynamic pumping; purifying the compound in the second vessel by sublimation to form Hf(NO3)4, and heating the Hf(NO3)4 to produce HfO2 for use in an ALCVD process.

Owner:SHARP LAB OF AMERICA INC

Nitrates

InactiveUS20090189117A1Solution rate in fasterAmmonium nitratesNitrogen compoundsNitrate saltsNuclear chemistry

A method of producing anhydrous calcium nitrate, anhydrous magnesium nitrate or mixture thereof involves removing water from a solution of calcium nitrate, magnesium nitrate or mixture thereof in a pulse combustion drier. The invention also provides a mixture of anhydrous calcium nitrate, anhydrous magnesium nitrate and the individual anhydrous nitrate salts in a sealed container.

Owner:FORSYTH ALASTAIR JAMES

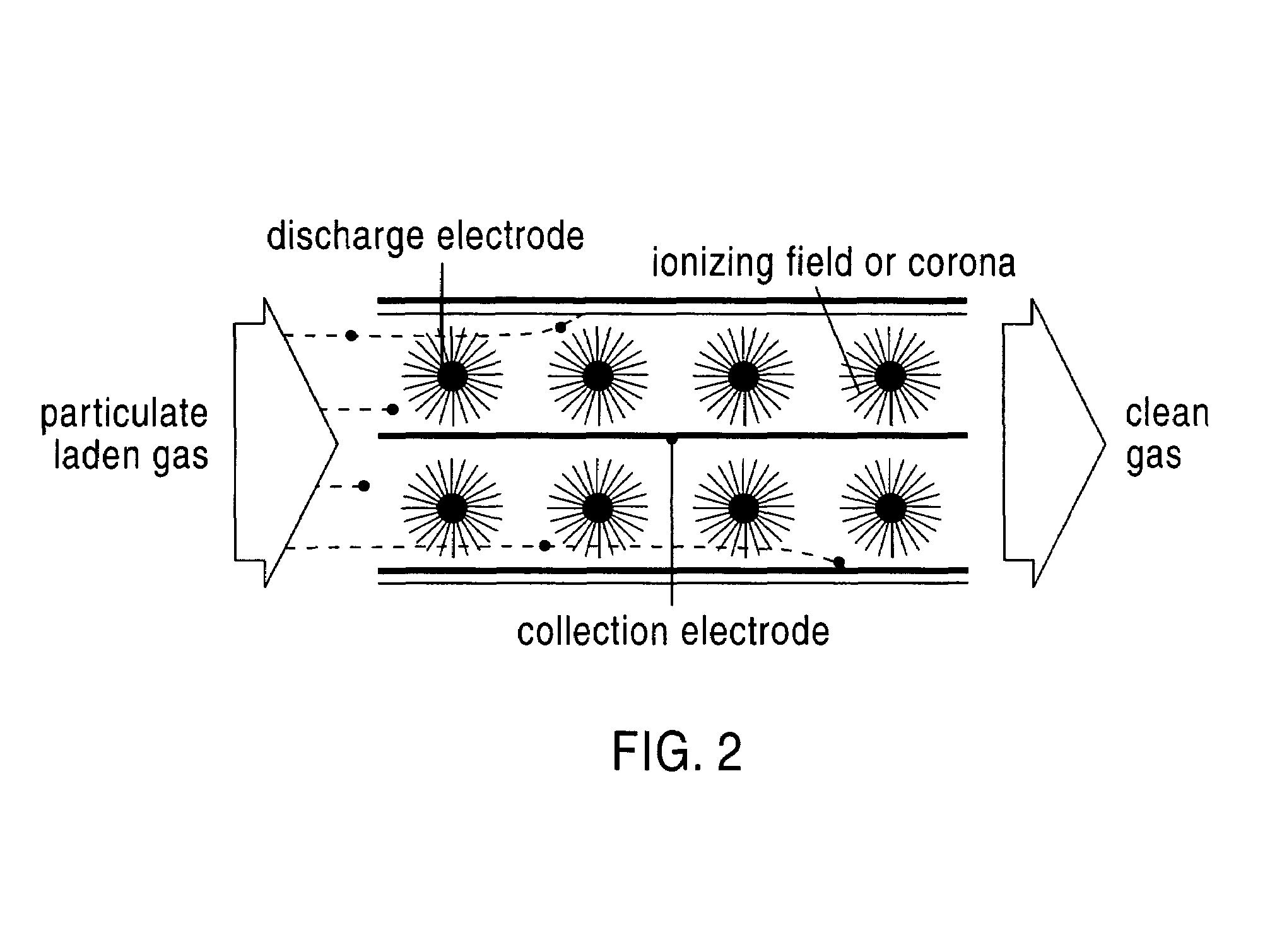

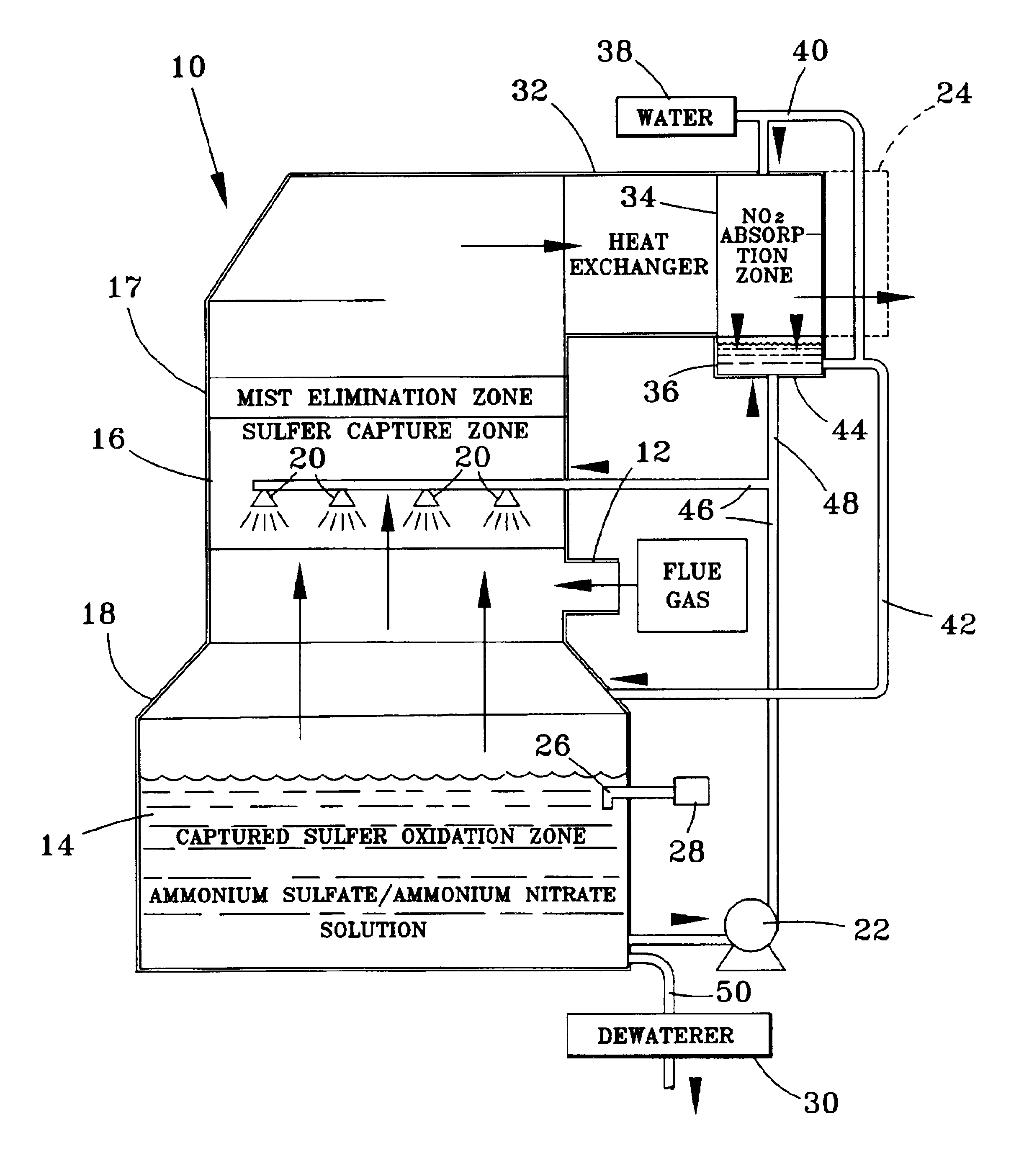

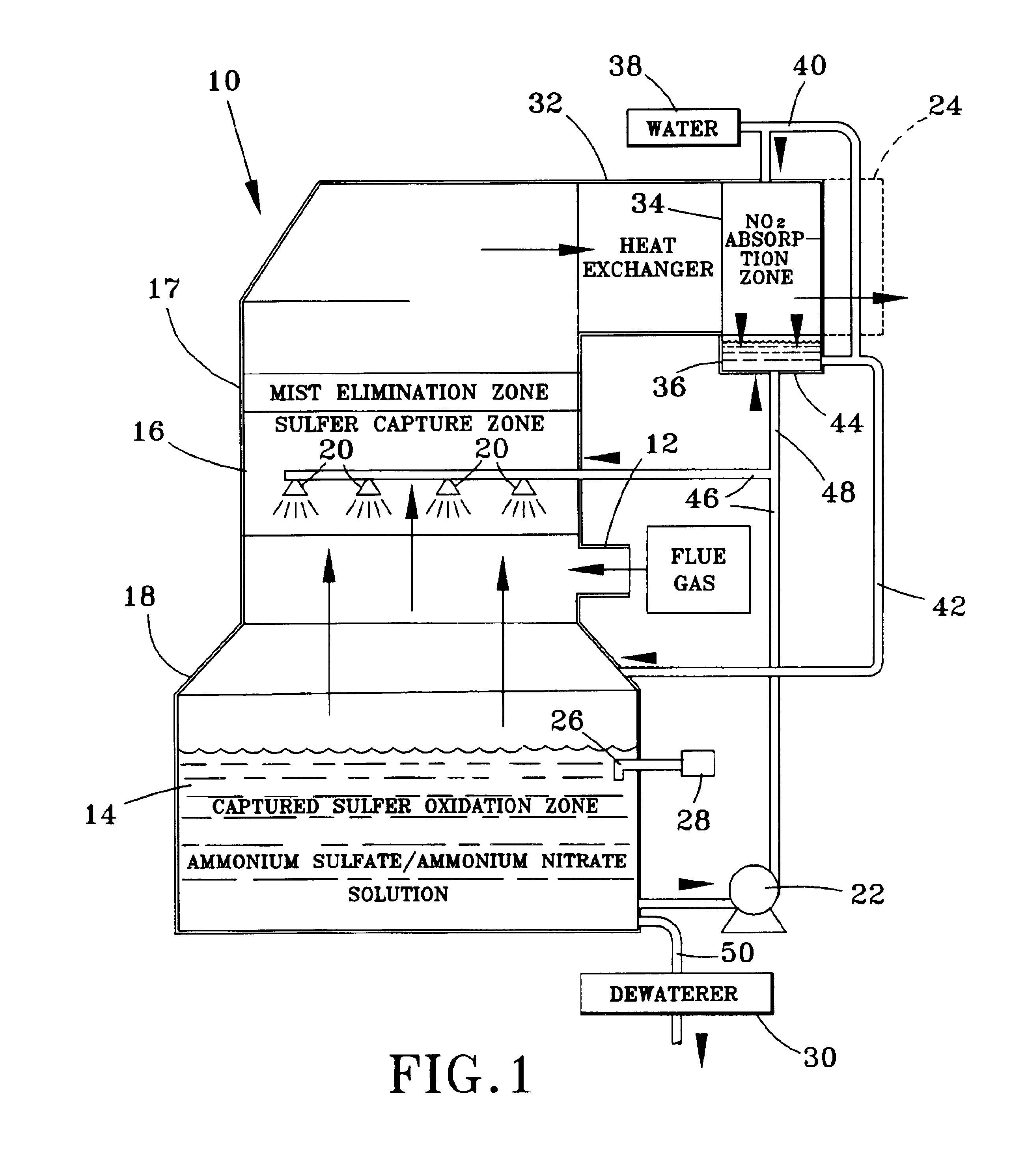

Flue gas desulfurization process and apparatus for removing nitrogen oxides

InactiveUS6958133B2Reduce the temperatureCombination devicesAmmonium nitratesNitrogen oxidesFlue gas

An apparatus and process for removing acidic gases and NOx from flue gases produced by utility and industrial plants. The process and apparatus convert NOx, and particularly nitric oxide, to nitrogen dioxide, which is then reacted to form a valuable byproduct. The process generally entails contacting a flue gas with a scrubbing medium to absorb acidic gases from flue gas and produce an intermediate flue gas. The intermediate flue gas is then cooled to cause nitric oxide present therein to be oxidized to form nitrogen dioxide, which is then absorbed from the flue gases to produce a nitrogen dioxide-containing solution and a scrubbed flue gas. The nitrogen dioxide in the nitrogen dioxide-containing solution is then reacted with ammonium hydroxide to form ammonium nitrate as a valuable byproduct.

Owner:BANK OF MONTREAL AS ADMINISTATIVE AGENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com