Preparation method of graphene oxide nano roll and composite material thereof

A composite material and graphene technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of cumbersome process, complex process, low efficiency, etc., and achieve the effect of avoiding freeze-drying and accelerating gasification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the preparation method of one-dimensional pure graphene oxide nanovolume in the present embodiment is carried out according to the following steps:

[0035] Step 1: Graphene oxide was prepared by liquid phase exfoliation method (Hummers), centrifugally washed until the pH value of the solution was neutral, and then freeze-dried at -10°C to obtain a graphene oxide sponge, which was added to deionized water and ultrasonically dispersed for 60 minutes , to obtain a 0.01mg / mL graphene oxide dispersion;

[0036] Step 2. Then take 1 ml and drop it on a clean 3cm×3cm silicon wafer, and then place it horizontally in a device connected to a vacuum pump. Under normal temperature conditions, vacuumize to a vacuum of 10Pa, and process at a vacuum of 10Pa. After 10 minutes, the graphene oxide nano-volumes are obtained, and the curls are uniform.

[0037] In this embodiment, graphene oxide is prepared by using the existing liquid phase exfoliation method (Hummers), spe...

Embodiment 2

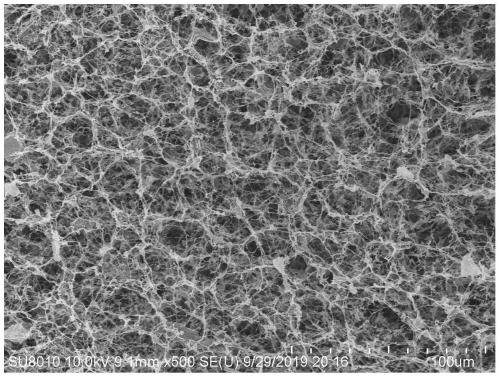

[0040] Embodiment 2: the preparation method of three-dimensional pure graphene oxide nanovolume in the present embodiment is carried out according to the following steps:

[0041] Step 1: Graphene oxide was prepared by liquid phase exfoliation method (Hummers), centrifugally washed until the pH value of the solution was neutral, and then freeze-dried at -10°C to obtain a graphene oxide sponge, which was added to deionized water and ultrasonically dispersed for 60 minutes , to obtain a 2mg / mL graphene oxide dispersion;

[0042] Step 2. Then take 1 ml and drop it on a clean 3cm×3cm glass, and then place it horizontally in a device connected to a vacuum pump. Under normal temperature, evacuate to a vacuum of 10Pa, and treat it for 10min at a vacuum of 10Pa. , that is, graphene oxide nanovolumes are obtained, which are uniformly curled and can form a three-dimensional network structure.

[0043] Graphene oxide is prepared according to the method in Example 1 in this example.

[00...

Embodiment 3

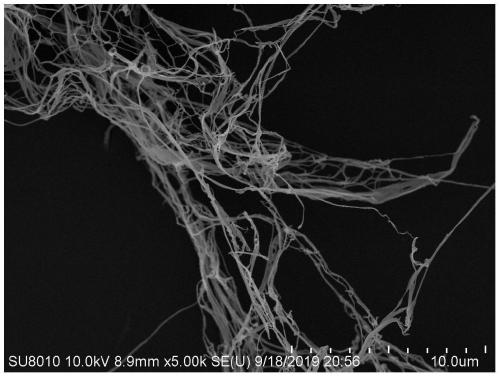

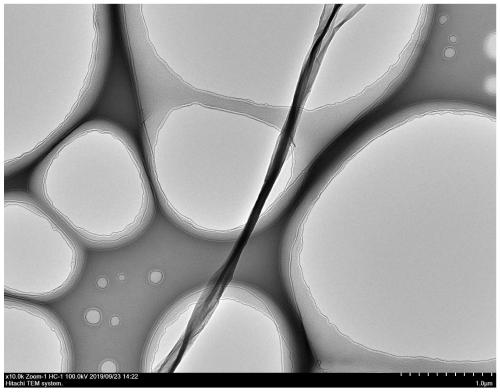

[0045] Embodiment 3: the preparation method of a kind of graphene oxide-carbon nanotube nano volume composite material in the present embodiment is to carry out according to the following steps:

[0046] Step 1. Prepare graphene oxide by liquid phase exfoliation (Hummers), centrifuge and wash until the pH of the solution is neutral, then freeze-dry at -10°C to obtain graphene oxide sponge, add deionized water, and ultrasonically disperse for 30 minutes , to obtain a 1mg / mL graphene oxide dispersion;

[0047] Step 2. Add 150mL of concentrated sulfuric acid and 50mL of concentrated nitric acid into 2g of carbon nanotubes, condense and reflux at 55°C for 3h, wash with deionized water until the pH is neutral, and freeze at -10°C Dry, add deionized water, and ultrasonically disperse for 30 minutes to obtain a 0.5 mg / mL carbon nanotube dispersion;

[0048] Step 3, after mixing 5mL of the graphene oxide dispersion obtained in step 1 with 2mL of the carbon nanotube dispersion obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com