Method for preparing lithium salts from lithium extracted from spodumene

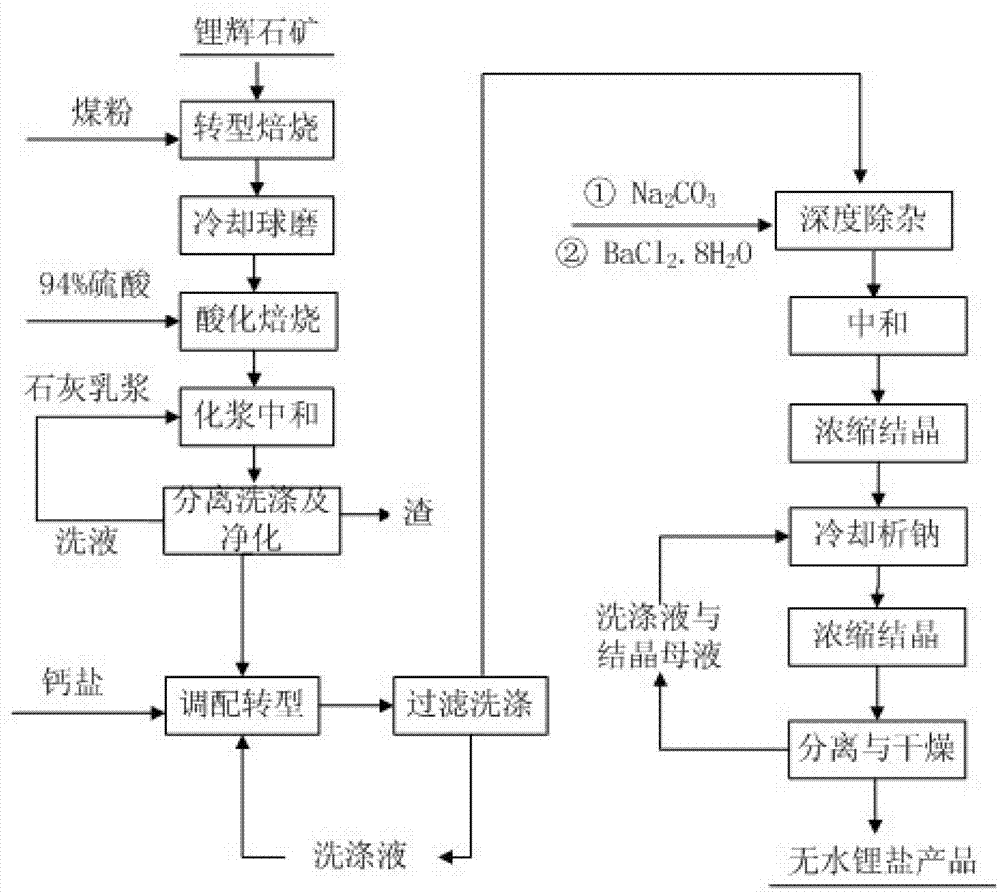

A spodumene and lithium extraction technology, applied in chemical instruments and methods, lithium halide, lithium nitrate and other directions, can solve the problems of long process flow and high production cost, and achieve the advantages of shortening the process flow, low production cost and simplifying operation steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

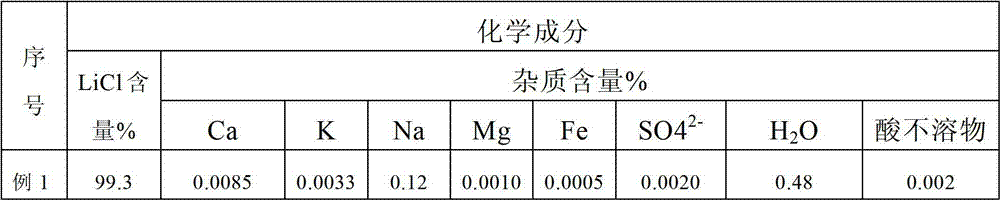

Embodiment 1

[0065] a. Transformation roasting: 1000Kg spodumene ore (Li 2 O·Al 2 o 3 4SiO2 2 ) is placed in an internally heated rotary furnace, and undergoes transformation roasting under high temperature conditions, and the roasting temperature is controlled at 1250°C to make it transform from α type to β type;

[0066] B, cooling ball milling: the raw material after the roasting of step a is cooled to normal temperature, then it is ball milled to 325 orders, obtains 999Kg lithium stone ore, analyzes Li in the spodumene after ball milling 2 O content is 6.1%;

[0067] c. Acidification and roasting: Blend concentrated sulfuric acid with a mass concentration of 95% and spodumene ground into step b to form a slurry, with an excess of 20% concentrated sulfuric acid (that is, the material-acid ratio is 4.01), and then place it in a rotary kiln for roasting , the roasting temperature is controlled at 280°C, and the roasting time is 60 minutes;

[0068] d. Slurry neutralization: Add the w...

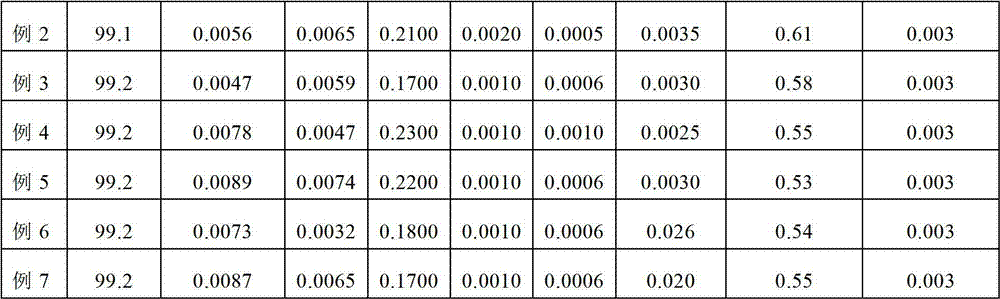

Embodiment 2

[0079] a. Transformation roasting: 1000Kg spodumene ore (Li 2 O·Al 2 o 3 4SiO2 2 ) is placed in an internal heating rotary furnace, and undergoes transformation roasting under high temperature conditions, and the roasting temperature is controlled at 1150°C to make it transform from α type to β type;

[0080] B, cooling ball milling: the raw material after the roasting of step a is cooled to normal temperature, then it is ball milled to 50 orders, obtains 999Kg lithium stone ore, analyzes Li in the spodumene after ball milling 2 O content is 5.56%;

[0081]c. Acidification roasting: blend concentrated sulfuric acid with a mass concentration of 98% and finely ground spodumene in step b to form a slurry, with an excess of 40% concentrated sulfuric acid (that is, the material-acid ratio is 3.89), and then place it in a rotary kiln for roasting , the roasting temperature is controlled at 250°C, and the roasting time is 30 minutes;

[0082] d. Slurry neutralization: Add the wa...

Embodiment 3

[0093] a. Transformation roasting: 1000Kg spodumene ore (Li 2 O·Al 2 o 3 4SiO2 2 ) is placed in an internally heated rotary furnace, and undergoes transformation roasting under high temperature conditions, and the roasting temperature is controlled at 1200°C to make it transform from α type to β type;

[0094] B, cooling ball milling: the raw material after the roasting of step a is cooled to normal temperature, then it is ball milled to 200 orders, obtains 999Kg lithium stone ore, analyzes Li in the spodumene after ball milling 2 O content is 6.07%;

[0095] c. Acidification and roasting: blend concentrated sulfuric acid with a mass concentration of 97% and spodumene ground into step b to form a slurry, with an excess of 25% concentrated sulfuric acid (that is, the ratio of material to acid is 3.95), and then place it in a rotary kiln for roasting , the roasting temperature is controlled at 265°C, and the roasting time is 45 minutes;

[0096] d. Slurry neutralization: Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com