Single-layer CrI3 sheet prepared based on chemical vapor transport and method

A chemical vapor phase, single-layer technology, applied in chromium halide and other directions, can solve the problems of high preparation environment requirements, high experimental cost, small size, etc., and achieve the effects of easy control of reaction conditions, simple operation, and few materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A kind of preparation of monolayer CrI based on chemical vapor transport 3 The method of flakes includes the following steps:

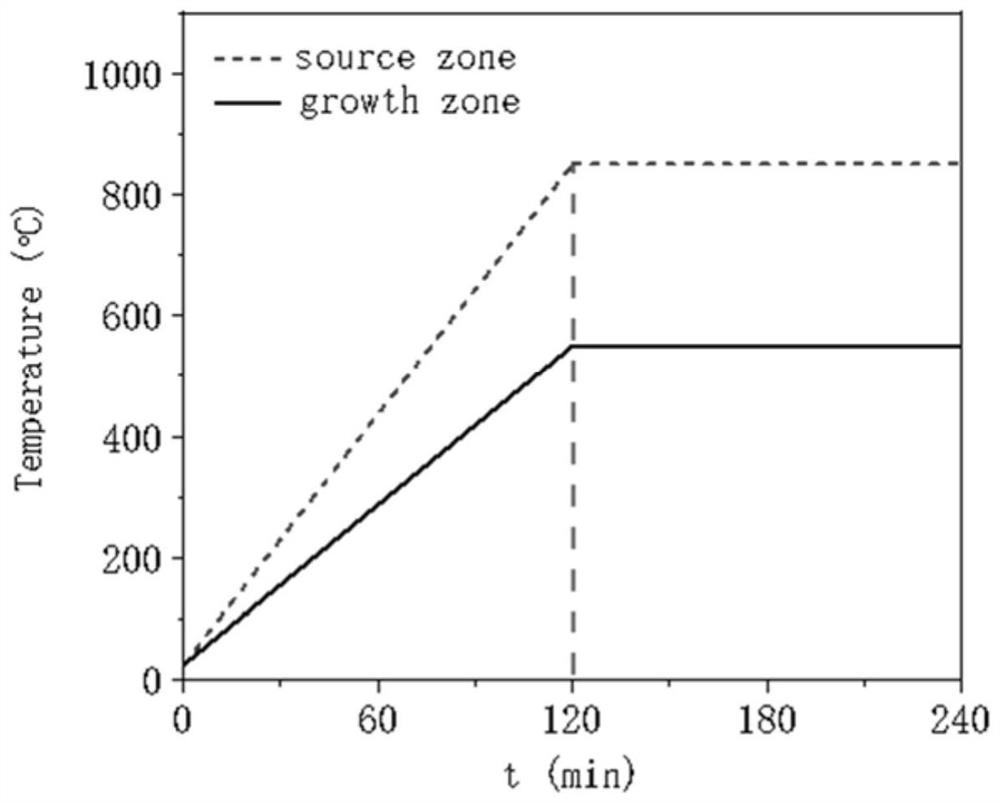

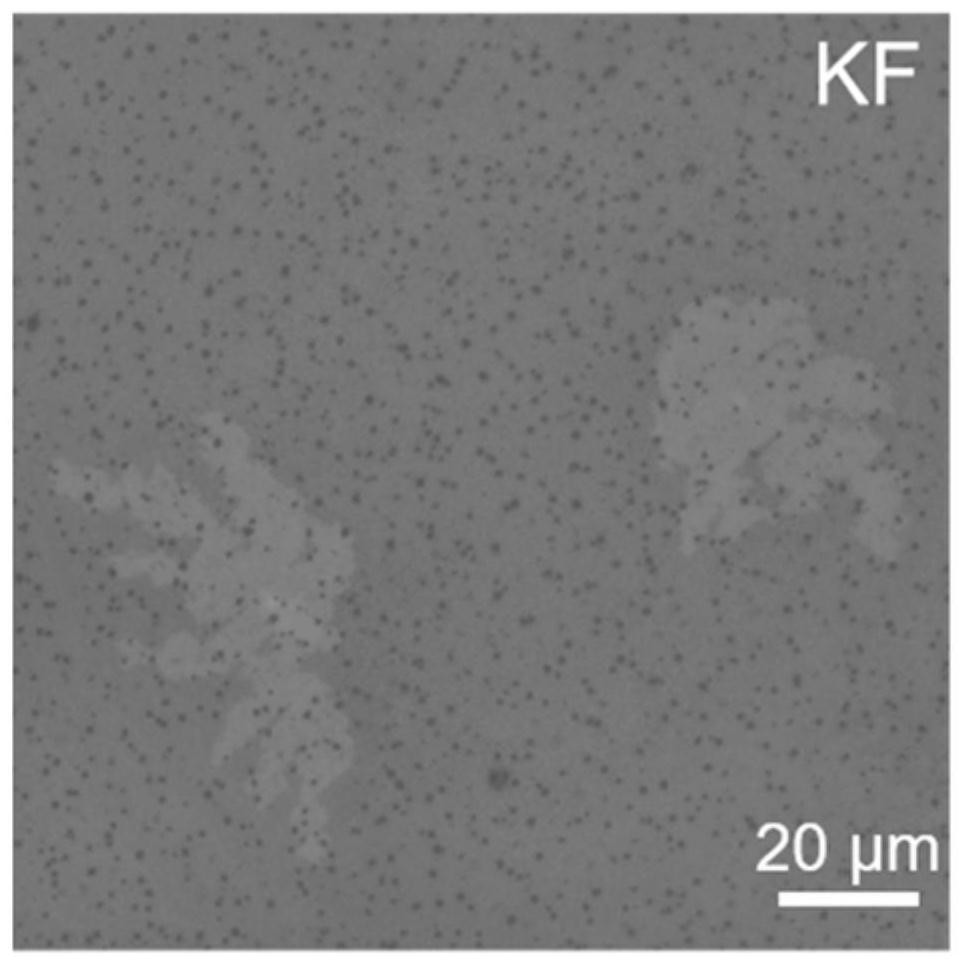

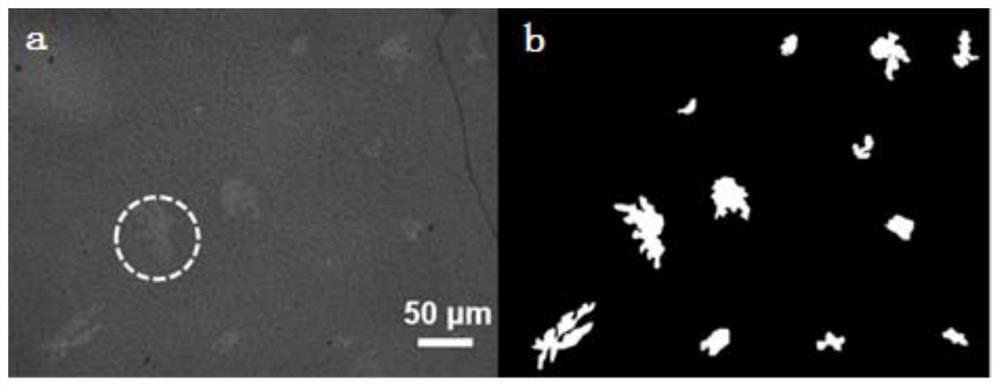

[0054] Put 5mg Cr powder, 35mg crystalline iodine powder and 5mg potassium fluoride powder into the bottom of the ampoule tube (with necking), after mixing, vacuumize, when the vacuum degree reaches 1.7×10 -4 Encapsulation at Pa, the iodine powder needs to be fixed with liquid nitrogen in the vacuum sealing process to prevent the volatilization of the iodine powder; then the ampoule tube is put into the raw material area in the double temperature zone tube furnace, and mica (mica) is placed in the reaction area. ) as the growth substrate; then set the following heating program in the double-temperature zone tube furnace for heat treatment: the raw material area is heated from room temperature at a heating rate of 6 ° C / min to 850 ° C for 2 hours, and then naturally cooled after 2 hours of heat preservation. Cooled to room temperature; the reac...

Embodiment 2

[0057] A kind of preparation of monolayer CrI based on chemical vapor transport 3 The method of flakes includes the following steps:

[0058] Put 5mg Cr powder, 35mg crystalline iodine powder and 5mg potassium chloride powder into the bottom of the ampoule tube (with necking), mix and vacuumize, when the vacuum degree reaches 1.7×10 -4 The iodine powder needs to be fixed with liquid nitrogen in the vacuum sealing process to prevent the volatilization of the iodine powder; then the ampoule tube is put into the raw material area in the double temperature zone tube furnace, and mica is placed in the reaction area for growth. Then set the following heating program in the double-temperature zone tube furnace for heat treatment: the raw material zone is heated from room temperature at a heating rate of 7 °C / min, heated to 900 °C for 2 hours, and then naturally cooled for 2.5 hours. to room temperature; the reaction zone was heated from room temperature to 580 °C at a heating rate o...

Embodiment 3

[0061] A kind of preparation of monolayer CrI based on chemical vapor transport 3 The method of flakes includes the following steps:

[0062] Put 5mg Cr powder, 35mg crystalline iodine powder and 5mg potassium bromide powder into the bottom of the ampoule tube (with necking), after mixing, vacuumize, when the vacuum degree reaches 1.7×10 -4 The iodine powder needs to be fixed with liquid nitrogen in the vacuum sealing process to prevent the volatilization of the iodine powder; then the ampoule tube is put into the raw material area in the double temperature zone tube furnace, and mica is placed in the reaction area for growth. Then set the following heating program in the double-temperature zone tube furnace for heat treatment: heat the raw material area from room temperature to 950 °C at a heating rate of 8 °C / min for 2 hours, and then heat it for 3 hours and then naturally cool down to room temperature. ; The reaction zone was heated from room temperature to 600 °C at a hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com