Separating method for chromium and iron in hydrochloric acid system

A separation method and system technology, applied in the direction of chromium halide, iron oxide, iron halide, etc., can solve the problems of difficult filtration, low iron removal rate, sensitive pH value, etc., and achieve the effect of simple process, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

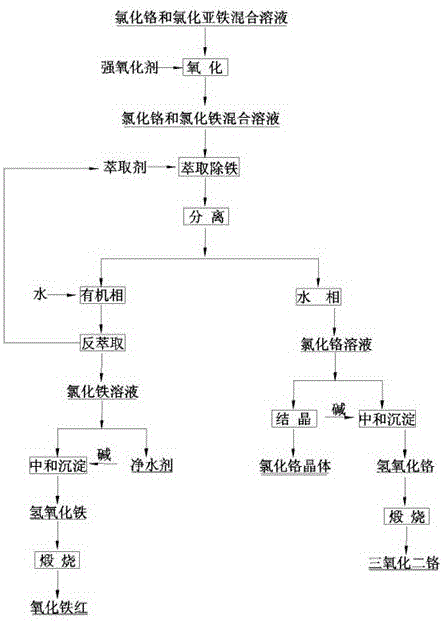

Image

Examples

Embodiment 1

[0015] Embodiment 1: the chromium chloride and the ferrous chloride mixed solution that leaching carbon ferrochrome gained with hydrochloric acid are raw material, Cr in the solution 3+ Concentration of 120.6g / l, Fe 2+ Concentration 56.5g / l according to Fe 2+ Add appropriate amount of hydrogen peroxide, stir at room temperature to make Fe 2+ All oxidized to Fe 3+ , and then add secondary octanol extractant for extraction, the extraction ratio O / A=2:1, after three-stage countercurrent extraction, the Cr in the obtained aqueous chromium chloride solution 3+ Concentration of 120.6g / l, Fe 2+ The concentration is 0.005g / l, the iron removal rate is 99.99%, no chromium is extracted, and the chromium chloride solution is obtained by direct crystallization method to obtain chromium chloride crystals, and the chromium hydroxide can also be obtained by adding alkali and neutralizing the precipitation method, and then the chromium hydroxide Chromium trioxide is obtained by high-temper...

Embodiment 2

[0016] Embodiment 2: With the electroplating sludge hydrochloric acid leaching solution containing chromium and iron as raw material, Cr in the solution 3+ Concentration of 18g / l, Fe 2 + Concentration 12g / l according to Fe 2+ Add appropriate amount of hydrogen peroxide, stir at room temperature to make Fe 2+ All converted to Fe 3+ , and then add secondary octanol extractant for extraction, the extraction ratio O / A=1:1, after secondary countercurrent extraction, the Cr in the obtained aqueous chromium chloride solution 3+ The concentration is 18g / l, the Fe2+ concentration is 0.002g / l, the iron removal rate is 99.98%, no chromium is extracted, and the chromium chloride solution is obtained by direct crystallization method, and hydrogen can also be obtained by adding alkali and precipitation method Chromium oxide and chromium hydroxide are then calcined at high temperature to obtain chromium trioxide; the organic phase is back-extracted with water to obtain the extractant 2-o...

Embodiment 3

[0017] Embodiment 3: the chromium chloride and the ferrous chloride mixed solution that leaching carbon ferrochrome gained with hydrochloric acid are raw material, Cr in the solution 3+ Concentration of 118g / l, Fe 2+ Concentration 55.8g / l according to Fe 2+ Add appropriate amount of hydrogen peroxide, stir at room temperature to make Fe 2+ All converted to Fe 3+ , and then add extractant for extraction, the extractant composition is a mixture of N235 and 2-octanol, sulfonated kerosene is used as a diluent, the extraction ratio O / A=1:1, after three-stage countercurrent extraction, the obtained aqueous phase chlorine Cr in chromium solution 3+ Concentration of 118g / l, Fe 2+ The concentration is 0.02g / l, the iron removal rate is 99.96%, and no chromium is extracted. The chromium chloride solution can be obtained by direct crystallization method to obtain chromium chloride crystals, and the chromium hydroxide can also be obtained by adding alkali and neutralizing the precipita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com