Treatment method of papermaking black liquor

A technology for papermaking black liquor and treatment methods, applied in chemical instruments and methods, methods based on microorganisms, multi-stage water/sewage treatment, etc., can solve the problems of unreachable pollution control, limited application, low lignin content, etc. Achieve the effect of reducing treatment cost, reducing dosage and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the biological identification of bacterial strain

[0038] 1. Morphological characteristics of the strain

[0039] (1) Morphological characteristics of the colony: more regular round, larger and denser, with rough surface and jagged edges; the front of the colony is white when it is born; the colony gradually turns red from the center in the middle stage of growth; the colony in the late growth stage is concentric circles, with It is off-white, the outer circle is pink, the outermost circle is white, and the opposite side of the colony is yellowish brown. See figure 1 .

[0040] (2) Morphological characteristics of the bacteria: the aerial mycelium is in the shape of a long tube, with a transverse septum, and the top of the mycelium expands into spherical vesicles, and clusters of conidia are radially formed on the surface of the vesicles; and scanning electron microscopy Observe the bacterial strain, the scanning electron microscope photos of the bacte...

Embodiment 2

[0043] Embodiment 2. Taking a pulp and paper mill with an annual output of 10,000 tons as an example, with reeds as production raw materials, it can produce 400 tons of black liquor and 25 tons of pulp per day. The initial COD of the black liquor is about 83,000mg / l, the pH is 13.1-13.6, and the chromaticity is 225,000CU.

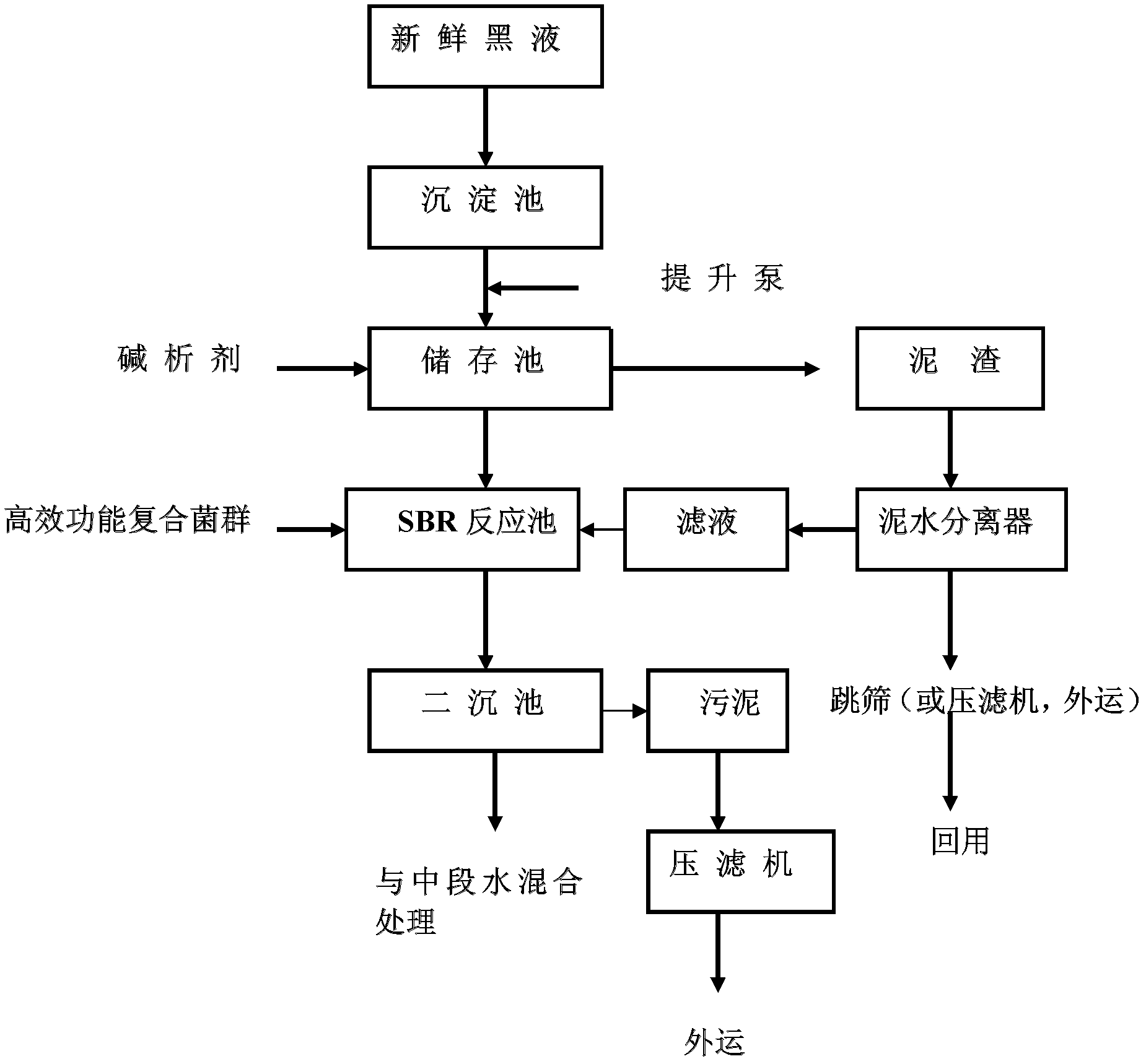

[0044] Such as image 3 As shown, the whole treatment process of the present invention is as follows: the papermaking black liquor enters the sedimentation tank first, and impurities such as silt and fiber mud in the black liquor are removed. After the black liquor is treated in the sedimentation tank, it is transported to the storage tank by the lifting pump, and a certain chemical agent is added. The wastewater is mixed with the chemical agent in the storage tank. After filtration, it is treated in the biochemical treatment tank, and the effluent is settled in the secondary sedimentation tank and then mixed with the middle papermaking wastewater. After ...

Embodiment 4

[0058] Embodiment 4. Taking the pulp and paper mill with an annual output of 10,000 tons as an example, using Asparagus as a production raw material, the daily output of black liquor is 350 tons, and the pulp is 22 tons. The initial COD of the black liquor is about 130,000mg / l, the pH is 13.2-13.6, and the chromaticity is 320,000CU.

[0059] The entire treatment process of the present invention is as follows: the papermaking black liquor first enters the sedimentation tank, and is mixed with part of the middle papermaking wastewater to reduce the COD of the black liquor to about 70,000, and simultaneously remove impurities such as silt and fiber mud in the black liquor. After the black liquor is treated in the sedimentation tank, it is transported to the storage tank by the lifting pump, and a certain chemical agent is added. The wastewater is mixed with the chemical agent in the storage tank. After filtration, it is treated in the biochemical treatment tank, and the effluent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com