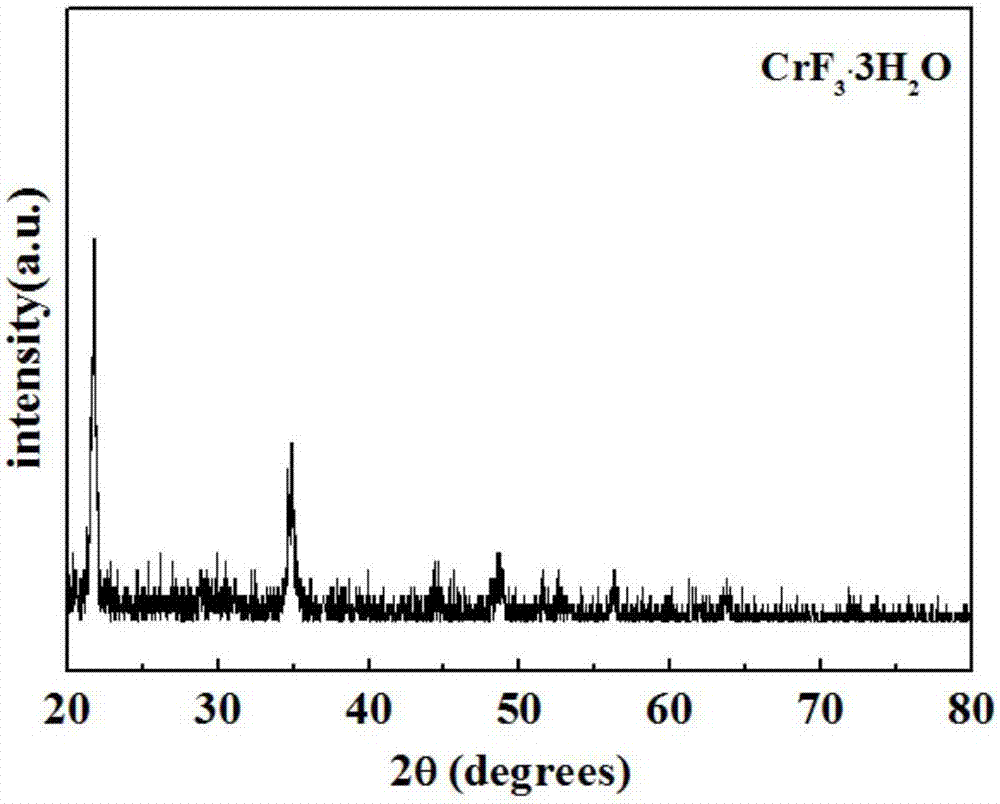

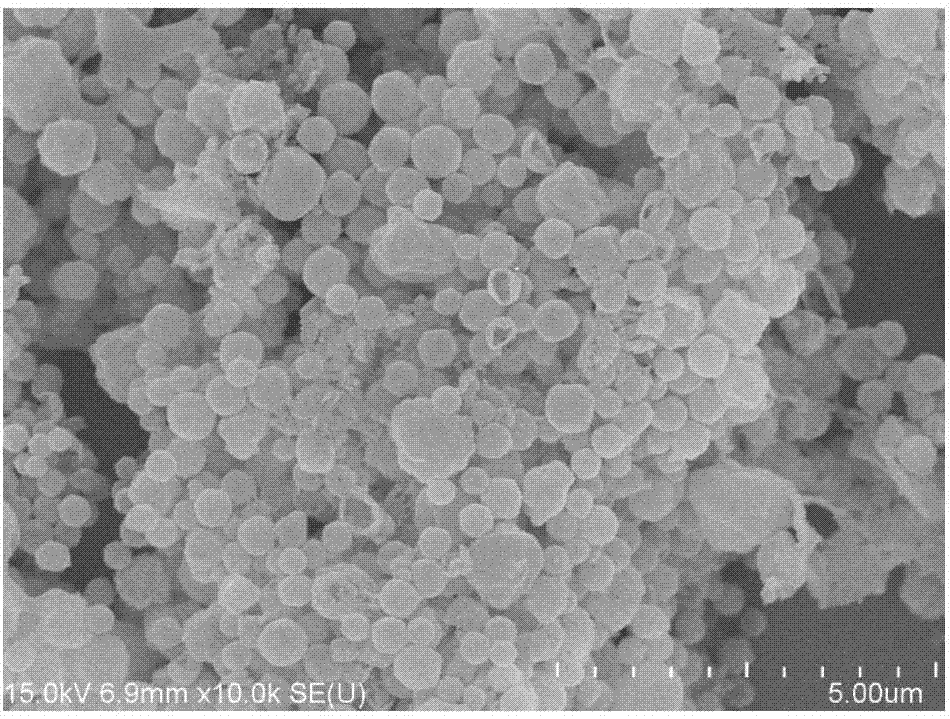

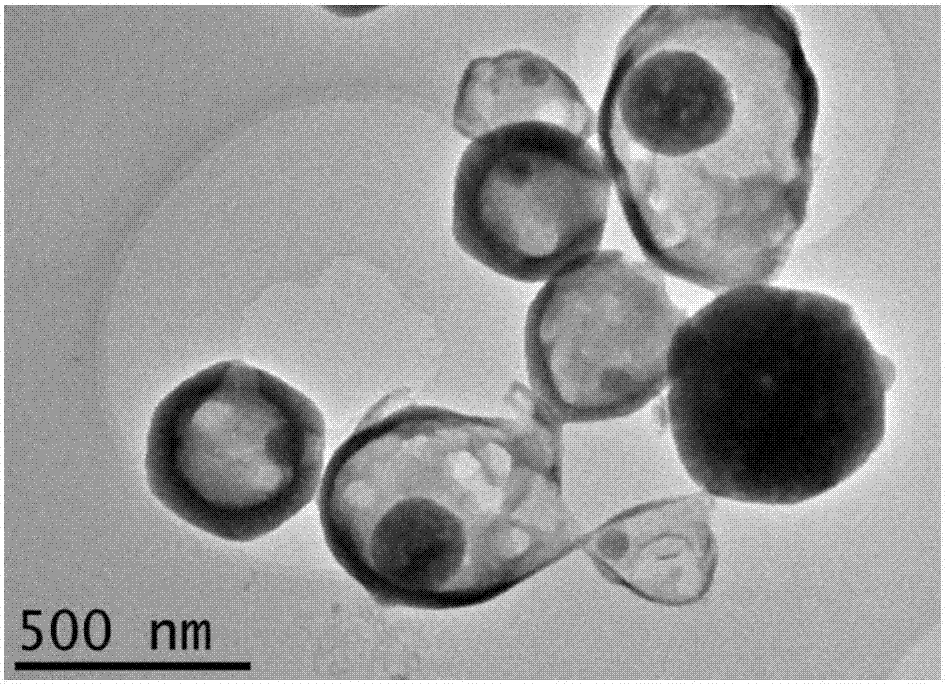

Preparation method of yolk-shell-structured CrF3.3H2O

A technology of crf3·3h2o and shell structure is applied in the field of preparation of egg yolk-shell structure CrF3·3H2O, which can solve problems such as no egg yolk-shell structure, and achieve the effects of simple method, low cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh CrCl 3 ·6H 2 O powder 0.5g, KF 2H 2 0.53g of O powder was mixed with 11g of n-octane, 2.5g of n-butanol, 1.5ml of deionized water and 3g of CTAB powder respectively to form a mixed solution. Ultrasonic the two prepared microemulsions for 10 minutes, then continue to stir for 20 minutes and put KF·2H 2 O solution was added to CrCl 3 ·6H 2 The reaction was carried out in O, and the reaction time was 5 minutes, and the process was stirred all the time. After the reaction is completed, add a mixed solution of chloroform and methanol (wherein the volume ratio of chloroform and methanol is equal to 1), after which there will be a green precipitate in the beaker, and after centrifugation and cleaning, the egg yolk-shell structure CrF 3 ·3H 2 O spherical particles.

Embodiment 2

[0023] Weigh CrCl 3 ·6H 2 O powder 0.5g, KF 2H 2 O powder 0.53g and n-octane 11g, n-butanol 2.5g, deionized water 1.5ml, CTAB powder 2g form a mixed solution respectively. Ultrasonic the two prepared microemulsions for 10 minutes, then continue to stir for 20 minutes and put KF·2H 2 O solution was added to CrCl 3 ·6H 2 The reaction was carried out in O, and the reaction time was 10 minutes, and the process was stirred all the time. After the reaction is completed, add a mixed solution of chloroform and methanol (wherein the volume ratio of chloroform and methanol is equal to 1), after which there will be a green precipitate in the beaker, and after centrifugation and cleaning, the egg yolk-shell structure CrF 3 ·3H 2 O spherical particles.

Embodiment 3

[0025] Weigh CrCl 3 ·6H 2 O powder 0.5g, KF 2H 2 O powder 0.53g and n-octane 11g, n-butanol 2.5g, deionized water 1.5ml, CTAB powder 2g form a mixed solution respectively. Ultrasonic the two prepared microemulsions for 10 minutes, then continue to stir for 20 minutes and put KF·2H 2 O solution was added to CrCl 3 ·6H 2 The reaction was carried out in O, and the reaction time was 20 minutes, and the process was stirred all the time. After the reaction is completed, add a mixed solution of chloroform and methanol (wherein the volume ratio of chloroform and methanol is equal to 1), after which there will be a green precipitate in the beaker, and after centrifugation and cleaning, the egg yolk-shell structure CrF 3 ·3H 2 O spherical particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com