Method for resource utilization of various metals in electroplating sludge

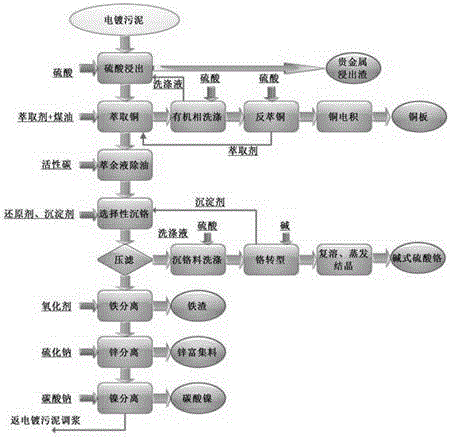

An electroplating sludge and multi-metal technology, applied in the extraction and separation of chromium, zinc, and high-value utilization, nickel, copper fields, can solve the problem of not realizing the resource utilization of valuable metals, and achieve high-value utilization of resources , The process is simple to operate and the effect of environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The dry basis of electroplating sludge raw material contains 9.0% chromium, 7.3% copper, 5.0% iron, 4.0% zinc, and 7.1% nickel. Take 1000g of electroplating sludge, slurry liquid-solid ratio of 8 / 1 (mL / g), add concentrated sulfuric acid 150g, stirring and self-heating leaching time of 2h, copper, nickel, zinc, and chromium were basically completely leached, and the iron leaching rate was 68%. The electroplating sludge sulfuric acid leaching solution uses LIX984N as the extractant and kerosene as the diluent. After four-stage extraction of copper (15% (v / v) Lix984N + kerosene, compared with O / A=1, stirring time at room temperature is 10min), the first-stage washing ( The concentration of sulfuric acid is 15 g / L, compared with O / A=2, and the stirring time at room temperature is 10min), after the first-stage stripping (the concentration of sulfuric acid is 250 g / L, compared with O / A=1, and the stirring time at room temperature is 10min), copper extraction The rate of coppe...

Embodiment 2

[0038] The dry base of electroplating sludge raw material contains chromium 18.3%, copper 7.7%, iron 7.2%, zinc 1.2%, nickel 9.9%, take electroplating sludge 1000g, slurry liquid-solid ratio 10 / 1 (mL / g), add concentrated sulfuric acid 250g, stirring and self-heating leaching time of 3h, copper, nickel, zinc, and chromium were basically completely leached, and the iron leaching rate was 73%. The electroplating sludge sulfuric acid leaching solution uses LIX984N as the extractant and kerosene as the diluent. After two-stage extraction of copper (30% (v / v) Lix984N + kerosene, compared to O / A=1, stirring time at room temperature for 10min), three-stage washing ( Sulfuric acid concentration 10 g / L, compared to O / A=2, stirring time at room temperature 10min), three-stage back extraction (sulfuric acid concentration 150 g / L, compared to O / A=1, stirring time at room temperature 10min), copper extraction The rate of copper extraction was 99.6%, and the copper extraction process did not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com