Thermal-spraying coating hole sealing agent, preparation method and using method

A technology of sealing agent and thermal spraying, applied in coating, metal material coating process, melt spraying and other directions, can solve the problems of poor thermal stability and unsuitability, achieve good high temperature resistance and increase disorder. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, 100 parts of phosphoric acid, 23 parts of aluminum hydroxide, 10 parts of chromic anhydride and 4 parts of methanol are used to prepare aluminum chromium phosphate.

[0034] First, heat it in a water bath to 80°C. At this temperature, mix and stir phosphoric acid and chromic anhydride until they are fully dissolved, then add aluminum hydroxide and stir until they are fully dissolved, then slowly drop in methanol to fully react, and then bathe in water for 20 minutes to obtain a dark green viscous thick aluminum chromium phosphate solution.

[0035] Add ethanol for dilution, the volume ratio of aluminum chromium phosphate and ethanol is 1:1.5.

[0036] Then add Cr 2 o 3 Filler, the weight ratio of diluted aluminum chromium phosphate and filler is 10:1 to make it evenly dispersed.

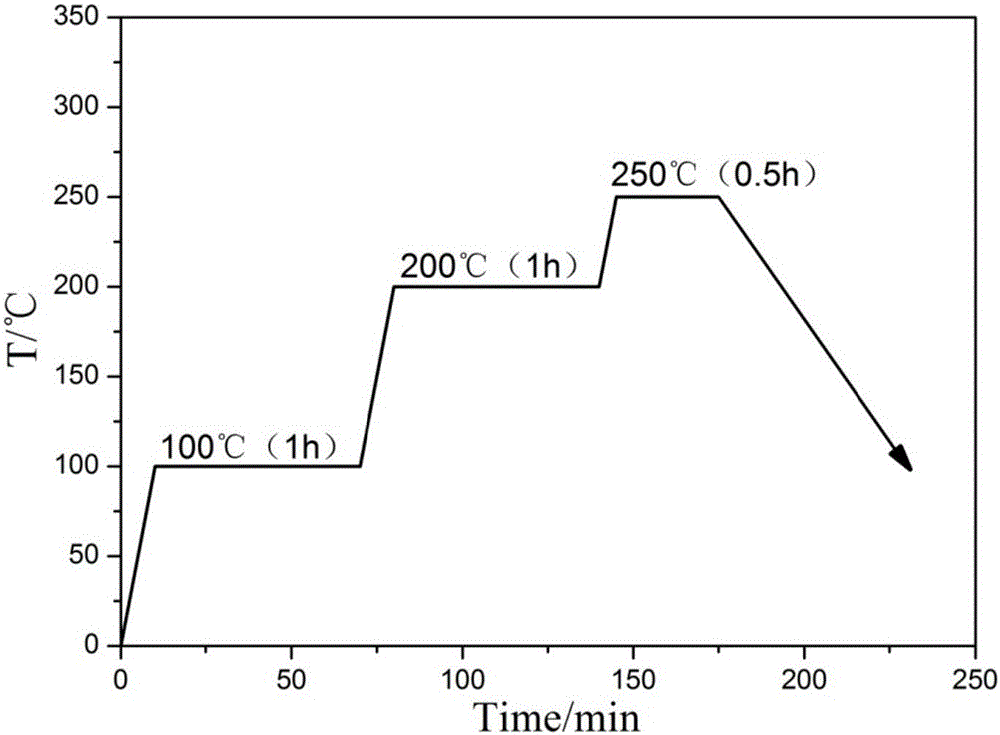

[0037] Use the method of brushing to evenly coat the sealing agent on the surface of the thermal spray coating, let it stand at room temperature for 24 hours, then heat ...

Embodiment 2

[0039] In this embodiment, 105 parts of phosphoric acid, 25 parts of aluminum hydroxide, 9.5 parts of chromic anhydride and 4 parts of methanol are used to prepare aluminum chromium phosphate.

[0040] First, heat it in a water bath to 70°C. At this temperature, mix and stir phosphoric acid and chromic anhydride until they are fully dissolved, then add aluminum hydroxide and stir until they are fully dissolved, then slowly drop in methanol to make it fully react, and then bathe in water for 15 minutes to obtain dark green viscous thick aluminum chromium phosphate solution.

[0041] Add ethanol for dilution, the volume ratio of aluminum chromium phosphate and ethanol is 1:1.5.

[0042] Then add Cr 2 o 3 Filler, the weight ratio of diluted aluminum chromium phosphate and filler is 10:1.5 to make it evenly dispersed.

[0043] Use the method of brushing to evenly coat the sealing agent on the surface of the thermal spray coating, let it stand at room temperature for 24 hours, t...

Embodiment 3

[0045] In this embodiment, 95 parts of phosphoric acid, 26.5 parts of aluminum hydroxide, 11.5 parts of chromic anhydride and 5 parts of methanol are used to prepare aluminum chromium phosphate.

[0046] First heat it in a water bath to 90°C, mix and stir phosphoric acid and chromic anhydride at this temperature until fully dissolved, then add aluminum hydroxide and stir until fully dissolved, then slowly drop in methanol to make it fully react, and then bathe in water for 25 minutes to obtain dark green viscous thick aluminum chromium phosphate solution.

[0047] Add ethanol for dilution, the volume ratio of aluminum chromium phosphate and ethanol is 1:1.

[0048] Then add Cr 2 o 3 Filler, the weight ratio of diluted aluminum chromium phosphate and filler is 10:1 to make it evenly dispersed.

[0049] Use the method of brushing to evenly coat the sealing agent on the surface of the thermal spray coating, let it stand at room temperature for 36 hours, and then heat the seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com