Preparation method of mullite whisker in-situ toughened chromium phosphate aluminum wave-transmitting material

A kind of technology of toughness chromium aluminum phosphate and mullite whiskers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

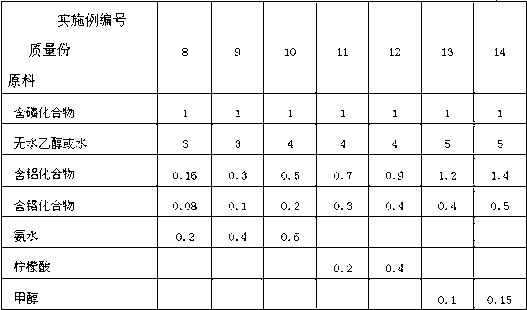

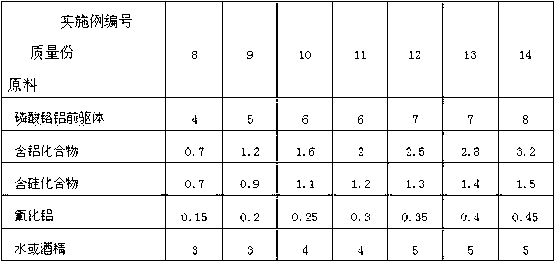

Examples

Embodiment 1

[0027] Take 10gAl(OH) 3 , 4.27gCrO 3 , 44.34gH 3 PO 4 (85% wt), 1.37g methanol is reacted to prepare chromium aluminum phosphate precursor, and 43.8g Al(OH) is taken 3 , 15.7gSiO 2 , 1.08g AlF is mixed with chromium aluminum phosphate precursor, ball milled for 24 hours, and the ball milling medium is water. After drying at 100°C, it is granulated through an 80-mesh sieve, and then compressed at 60MPa. Put the pressed product into a sealed corundum crucible, calcined at 1400°C for 4 hours, and cool down naturally with the furnace temperature, which is the in-situ toughened chromium aluminum phosphate wave-transmitting ceramic fired body of mullite whisker. Bulk density 2.59g / cm 3 , Dielectric constant 3-4, bending strength 150-200MPa.

Embodiment 2

[0029] Take Al(NO 3 ) 3 ·9H 2 O 8.02g, Cr(NO 3 ) 3 ·9H 2 O 2.85g, (NH 4 ) 2 HPO 4 8.47g, 7.28g (15% wt) ammonia water and 3.12g citric acid were reacted to prepare chromium aluminum phosphate precursor. Aluminosol 47.73g (10% wt), silica sol 8.72 (30% wt), 0.2g AlF and phosphoric acid The chromium-aluminum precursor is mixed and stirred for 24 hours for uniform mixing. After drying at 100°C, it is granulated through an 80-mesh sieve, and then compressed at 60MPa. Put the pressed product into a sealed corundum crucible, calcined at 1400°C for 4 hours, and cool down naturally with the furnace temperature, which is the in-situ toughened chromium aluminum phosphate wave-transmitting ceramic fired body of mullite whisker. Bulk density 2.51g / cm 3 , Dielectric constant 3-4, bending strength 1500-200MPa.

Embodiment 3

[0031] Take 10gAl(OH) 3 , 4.27gCrO 3 , 44.34gH 3 PO 4 (85% wt), 1.37g methanol is reacted to prepare chromium aluminum phosphate precursor, 33.09g TEOS (ethyl orthosilicate), 23.62g Al 2 O 3 , 1.64g AlF and chromium aluminum phosphate precursor are mixed, ball milled for 24 hours, the ball milling medium is water. After drying at 100°C, it is granulated through an 80-mesh sieve, and then compressed at 60MPa. Put the pressed product into a sealed corundum crucible, calcined at 1300°C for 4 hours, and cool down naturally with the furnace temperature, which is the in-situ toughened chromium aluminum phosphate wave-transmitting ceramic fired body of mullite whisker. Bulk density 2.63g / cm 3 , Dielectric constant 3-4, bending strength 150-200MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com