Phosphate-silicon dioxide low-dielectric high temperature-resistant coating and preparation thereof

A high-temperature-resistant coating and silicon dioxide technology, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of high brittleness and easy falling off, and achieve the effect of improving flexibility, low dielectric constant, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

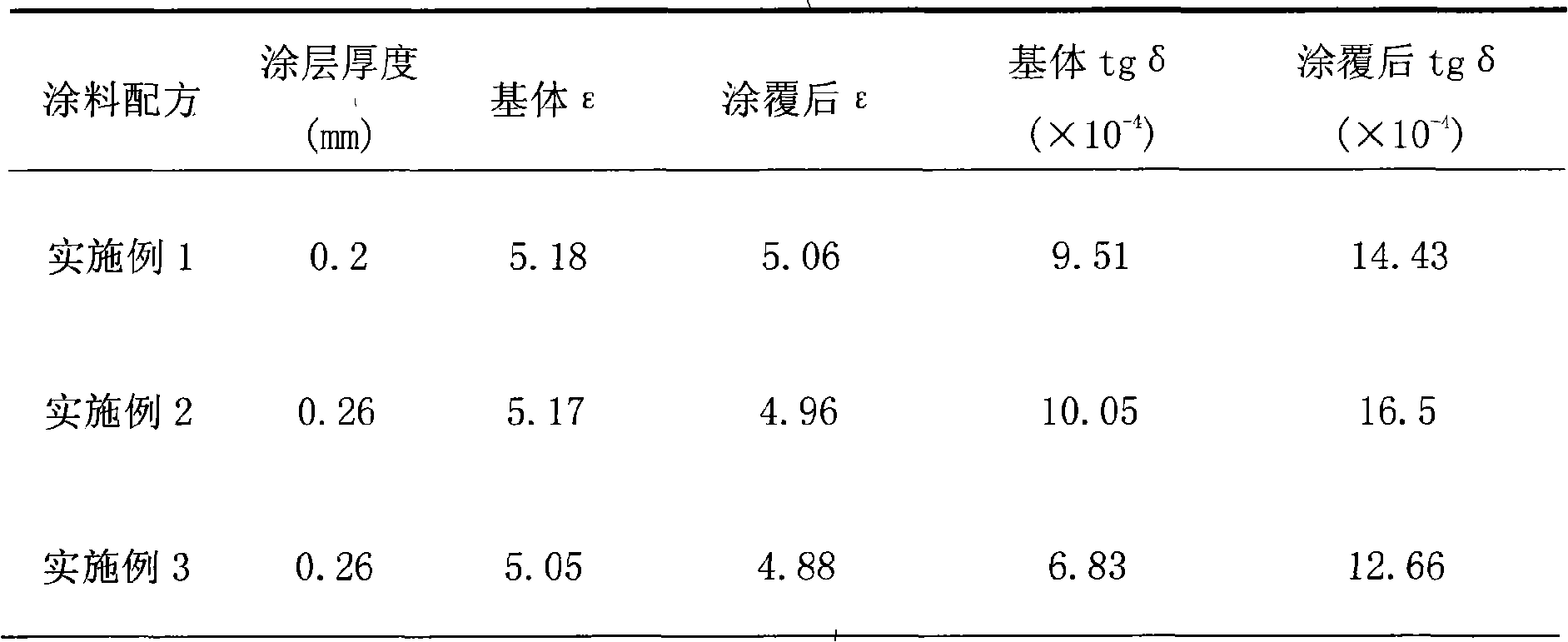

Examples

Embodiment 1

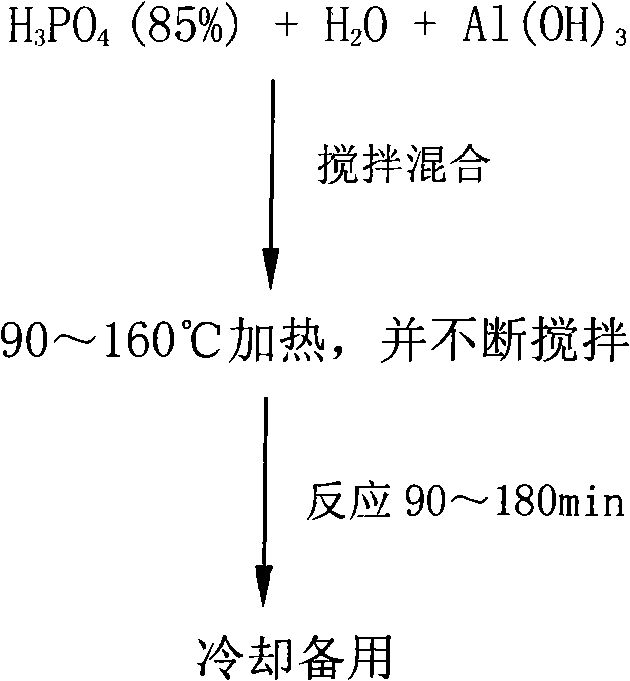

[0037] Preparation of acidic aluminum phosphate binder:

[0038] Weigh 1153g of phosphoric acid with a concentration of 85%, add water to 1960g, and dilute the concentration of phosphoric acid to 50%; heat phosphoric acid to 90°C; weigh Al(OH) 3 Slowly add 400g into phosphoric acid and keep stirring; heat up to 98°C and stir for 3 hours to react, after cooling, an acidic aluminum phosphate binder is prepared, and finally water is added to adjust the mass concentration of acidic aluminum phosphate to 35%.

[0039] Prepare the paint according to the following formula:

[0040] The acid aluminum phosphate binding agent 660g that above-mentioned steps prepares

[0041] 5μm fused silica powder 150g

[0042] 600 mesh refined quartz powder 150g

[0043] Fumed silica 27g

[0045] oπ-10 5g

[0046] According to the above formula, first add surfactant oπ-10, 5μm fused silica powder and 600 mesh refined quartz powder to the composite binder and ball mill...

Embodiment 2

[0051] Preparation of acidic aluminum phosphate binder:

[0052] Weigh 1153g of phosphoric acid with a concentration of 85%, add water to 1960g, and dilute the concentration of phosphoric acid to 50%; heat phosphoric acid to 98°C; weigh Al(OH) 3 Slowly add 400g into phosphoric acid and keep stirring; move the above reactants into an autoclave and raise the temperature to 150°C and stir for 1 hour. After cooling, an acidic aluminum phosphate binder is obtained. Finally, add water to adjust the mass concentration of acidic aluminum phosphate to 35%.

[0053] Take 600 g of the acidic aluminum phosphate binder prepared above, add 160 g of 20% acidic stable silica sol, and reflux at 50° C. for 2 hours to obtain a composite inorganic binder.

[0054] Prepare the paint according to the following formula:

[0055] The acid aluminum phosphate binding agent 600g that above-mentioned steps prepares

[0056] 2μ fused silica powder 200g

[0057] 400 mesh refined quartz powder 140g

[0...

Embodiment 3

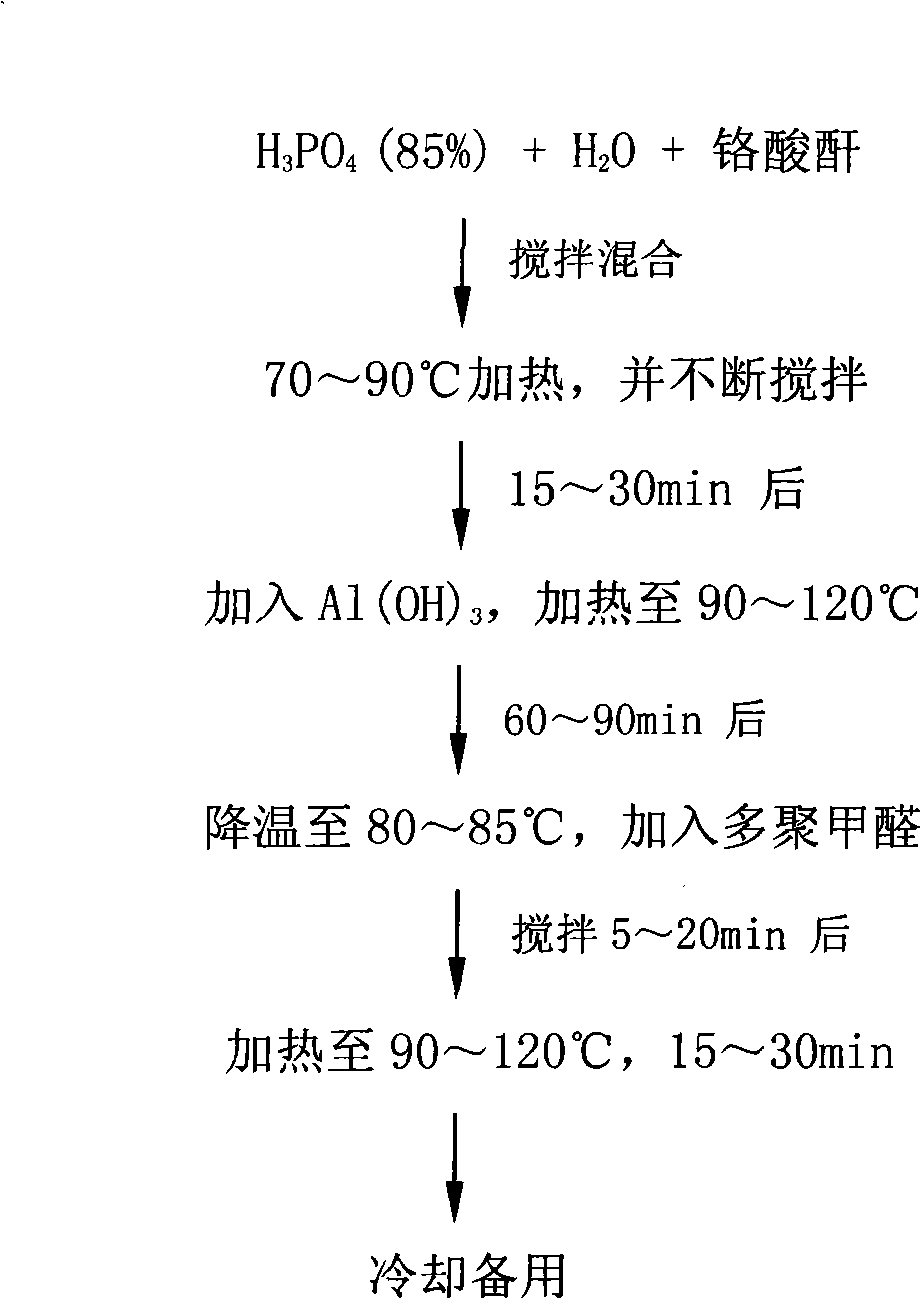

[0066] Preparation of aluminum chromium phosphate binder:

[0067] Weigh 1499g of 85% phosphoric acid solution, 1200g of water, and CrO 3 109g, added together to the reactor at 70°C for 15min, stirring constantly; then weighed Al(OH) 3 333g was added to the above solution, and the temperature was raised to 100°C. After reacting for 0.5 hours, the temperature was lowered to 80°C, and 10g of paraformaldehyde was added to the mixture. After 5min, the temperature was raised to 95°C, and the water bath was 20min. After cooling, add water to adjust to a concentration of 30% acid aluminum chromium phosphate binder.

[0068] Take 600 g of the acidic aluminum chromium phosphate binder prepared above, add 200 g of 30% acidic stable silica sol, and reflux at 30° C. for 2 hours to obtain a composite inorganic binder.

[0069] Prepare the paint according to the following formula:

[0070] The composite inorganic binder 720g that above-mentioned steps prepares

[0071] 5μm fused quart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com