Method for manufacturing high insulation resistor FeSiCr metal soft-magnetic material

A metal soft magnetic and manufacturing method technology, applied in the direction of inductor/transformer/magnet manufacturing, magnetic materials, circuits, etc., can solve the problems of non-densification, low insulation resistance, low withstand voltage, etc., and achieve the effect of overcoming low insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A kind of manufacture method of high insulation FeSiCr metal soft magnetic material, concrete steps are as follows:

[0029] (1) Melting: carried out in a melting furnace, the melting temperature is 1580 ℃ ~ 1680 ℃, the silicon content in the main component is 3.5 ~ 7.0wt%, the Cr content is 4.5 ~ 6.0wt%, the balance is iron and unavoidable Mn, Ni, C, S, P, O and other impurities, wherein the unavoidable sum of Mn, Ni, C, S, P, O and other impurities is less than 0.25wt%.

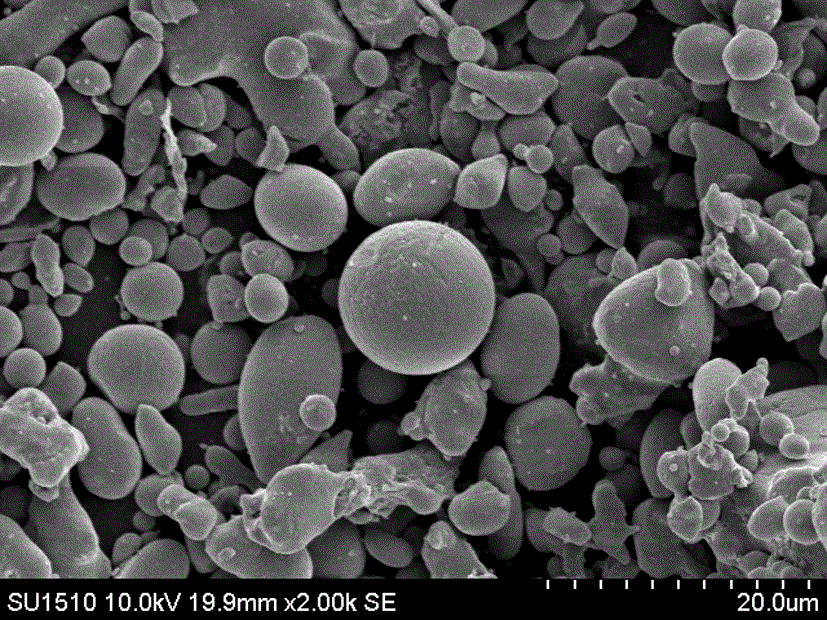

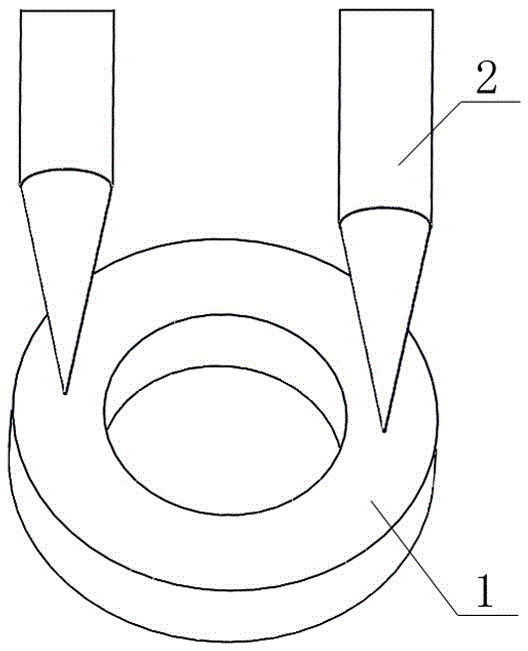

[0030] (2) Gas and water combined atomization: use gas and water combined atomization to control the O content in the powder to less than 0.15wt%. figure 1 shown;

[0031] (3) Screening: Screening with different meshes;

[0032] (4) Powder grading ratio: -500 mesh accounts for 55%, -600 mesh accounts for 35%, and -800 mesh accounts for 10%;

[0033] (5) Mixing: It is carried out in a three-dimensional motion mixer, and the powder after grading and proportioning is evenly mixed;

[0034] (6) Powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com