Recycling treatment method of electroplating sludge

A technology for electroplating sludge and treatment methods, applied in chemical instruments and methods, inorganic chemistry, phosphorus compounds, etc., can solve problems such as incomplete alkali conversion of chromium phosphate and impure chromium hydroxide slag, and improve metal recovery rate The utilization rate of alkali and alkali, the effect of improving the efficiency of alkali leaching and eliminating the discharge of waste residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

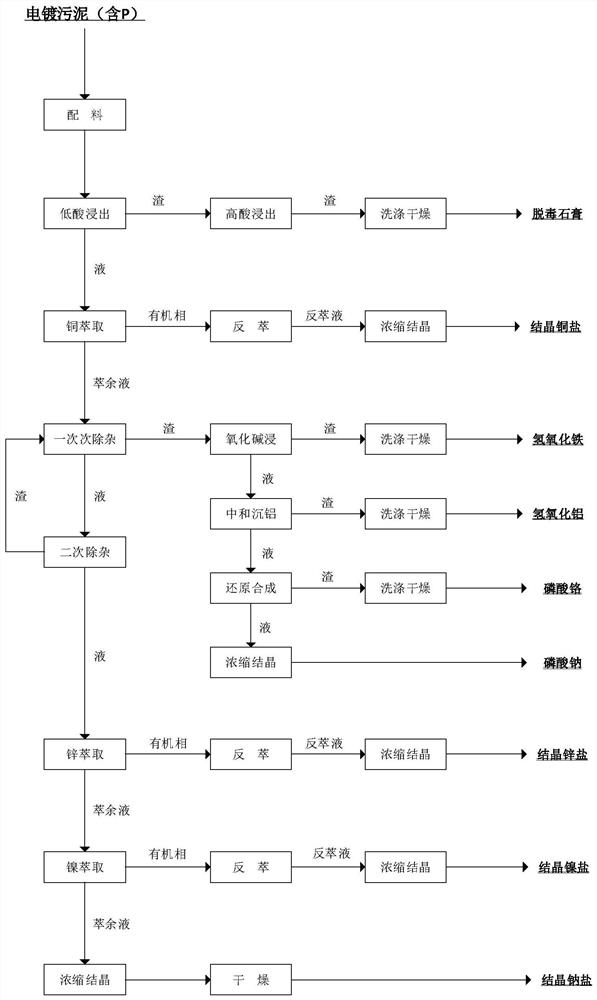

[0078] This embodiment provides a resource treatment method of electroplating sludge (such as figure 1 shown), including the following steps:

[0079] S1: Ingredients: The electroplating sludge with different phosphorus content is mixed according to a certain ratio, and 1kg of raw materials is prepared, with a moisture content of 60.58%. The dry basis components are: Ni 6.30%, Zn 5.01, Cr 6.79%, Fe 3.34%, Al 0.80%, P 10.11% (the sum of the molar weights of Cr, Fe, and Al is 1.08±0.01 times the molar weight of P).

[0080] S2: Low-acid leaching: Put the prepared material in step S1 into the reactor, the liquid-solid ratio is 6:1 (calculated on a dry basis), start stirring, add sulfuric acid, and perform low-acid leaching, and control the pH of the leaching end point to 3.0, The temperature is 65°C, react for 2 hours, filter after the reaction, and use the low-acid leaching liquid and the low-acid leaching residue for later use.

[0081] S3: High-acid leaching: Put the low-aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com