High-entropy alloy matrix self-lubrication composite with imitation lattice structure and containing solid lubricant

A technology of solid lubricants and high-entropy alloys, applied in the field of composite materials, can solve the problems of poor mechanical and tribological properties of composite materials, achieve good mechanical properties and tribological properties, good application prospects, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 A high-entropy alloy-based self-lubricating composite material with a pseudo-lattice structure containing a solid lubricant, which uses CoCrFeNiMo 0.2 The high-entropy alloy is used as the matrix, the unit cell lattice of the pseudo-lattice structure is SC structure, and the solid lubricant filled is graphite + MoS 2 . Concrete preparation method is as follows:

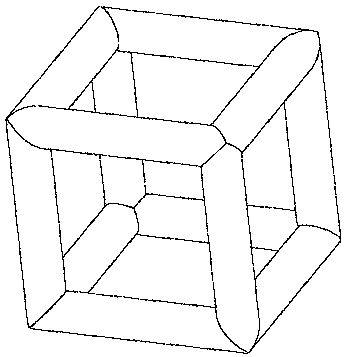

[0035] ⑴Establish the model of the SC lattice structure unit cell on the computer (such as figure 1 ), the side length of the SC lattice unit cell is 0.1mm, the cross-section of the connecting rod is cylindrical, and the diameter of the cylinder is 0.02mm. By periodically arranging 1000×1000×1000 unit cells, the composition size is 100mm×100mm×100mm Pseudo-lattice structure.

[0036] (2) Input the model into selective laser melting (SLM) metal 3D printer, using 1~6μm CoCrFeNiMo 0.2 The high-entropy alloy powder is used as the raw material, and the 316 stainless steel plate is used as the printing ...

Embodiment 2

[0045] Example 2 A high-entropy alloy-based self-lubricating composite material with imitation lattice structure containing solid lubricants. The composite material uses AlCoCrFeNi high-entropy alloy as the matrix, and the unit cell lattice of the imitation lattice structure is a BCC structure. The solid lubricant filled for MoS 2 +Hexagonal BN+Graphite. Concrete preparation method is as follows:

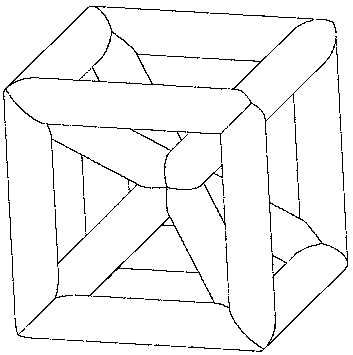

[0046] ⑴Establish the model of the BCC lattice structure unit cell on the computer (such as figure 2 ), the side length of the BCC lattice unit cell is 5mm, the connecting rod is a square, and the side length of the square is 3mm. By periodically arranging 50×50×50 unit cells, a pseudo-lattice structure with a size of 250mm×250mm×250mm is formed. .

[0047] (2) Input the model into the selective electron beam melting (SEBM) metal 3D printer, use 20~40μm AlCoCrFeNi high-entropy alloy powder as raw material, use 316 stainless steel plate as the printing substrate, and print under ...

Embodiment 3

[0056] Example 3 A high-entropy alloy-based self-lubricating composite material with a pseudo-lattice structure containing a solid lubricant, which uses Al 0.2 co 1.5 CrFeNi 1.5 Ti 0.5 CnZn high-entropy alloy is used as the matrix, the unit cell lattice of imitation lattice structure is FCC structure, and the solid lubricant filled is graphite+MoS 2 +PbO+BaF 2 +CaF 2 +CeF 3 +Ag. Concrete preparation method is as follows:

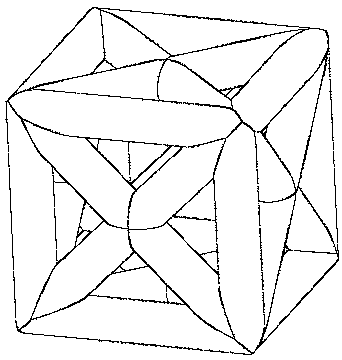

[0057] ⑴Establish the model of the FCC lattice structure unit cell on the computer (such as image 3 ), the side length of the FCC lattice unit cell is 5mm, the connecting rod is cylindrical, and the diameter of the cylinder is 3mm. By periodically arranging 50×50×50 unit cells, a pseudo-lattice with a size of 250mm×250mm×250mm is formed. structure.

[0058] (2) Input the model into the SEBM metal 3D printer, using 15~50μm Al 0.2 co 1.5 CrFeNi 1.5 Ti 0.5 CnZn high-entropy alloy powder was used as raw material, and 316 stainless steel plate was u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com