Method for producing water-soluble calcium nitrate dihydrate and phosphoric acid by decomposing phosphorite through nitric acid

A calcium nitrate, water-soluble technology, applied in the direction of phosphoric acid, calcium/strontium/barium nitrate, phosphorus oxyacid, etc., to reduce the storage space, improve the competitive advantage, and facilitate crop absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

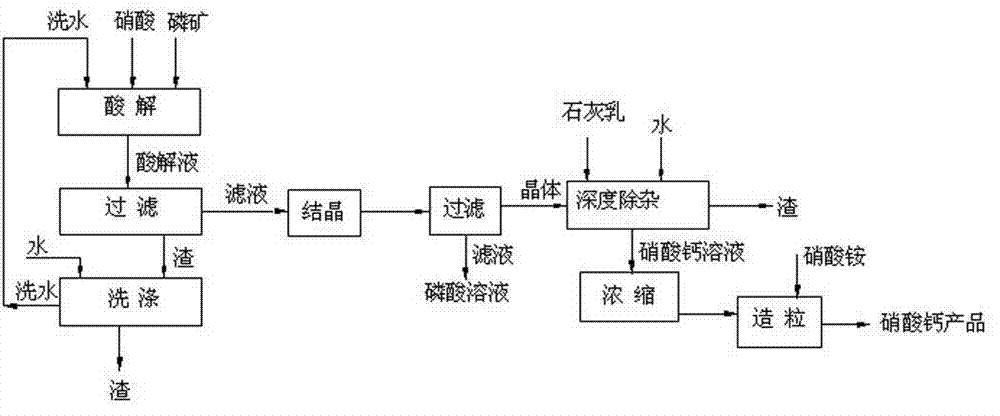

Image

Examples

Embodiment

[0020] Adopt nitric acid of the present invention to decompose phosphate rock to produce water-soluble calcium nitrate dihydrate and co-produce phosphoric acid, and the specific operations are:

[0021] Table 1 Composition of phosphate rock powder

[0022] project Ore size P 2 o 5 SiO 2 Al 2 o 3 Fe 2 o 3 MgO CaO F content / % 80%≤-200 mesh 28.21 17.10 1.70 1.94 1.98 43.0 2.41

[0023] A), acid hydrolysis

[0024] Nitric acid with a concentration of 60% to 66% is mixed with the washing liquid during the filtration of acid insoluble matter. The concentration of nitric acid is 50% to 55%. The nitric acid solution is added to the acidolysis tank, and phosphate rock powder is added under stirring to carry out the acidolysis reaction. The amount of nitric acid is 95%~110% of the theoretical amount, the temperature of the acidolysis reaction is 50℃~70℃, and the residence time of the acidolysis reaction is 0.5~4h. Then filter the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com