Process for preparing phosphate concentrate as well as byproducts magnesium ammonium sulfate and calcium ammonium nitrate by use of medium and low grade phosphorus ores

A technology of magnesium ammonium sulfate and calcium ammonium nitrate, which is applied in the direction of magnesium sulfate, calcium/strontium/barium nitrate, phosphorus compounds, etc., can solve the problems of land occupation and processing difficulties, and achieve the reduction of magnesium content, improvement of purity, and good economy benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

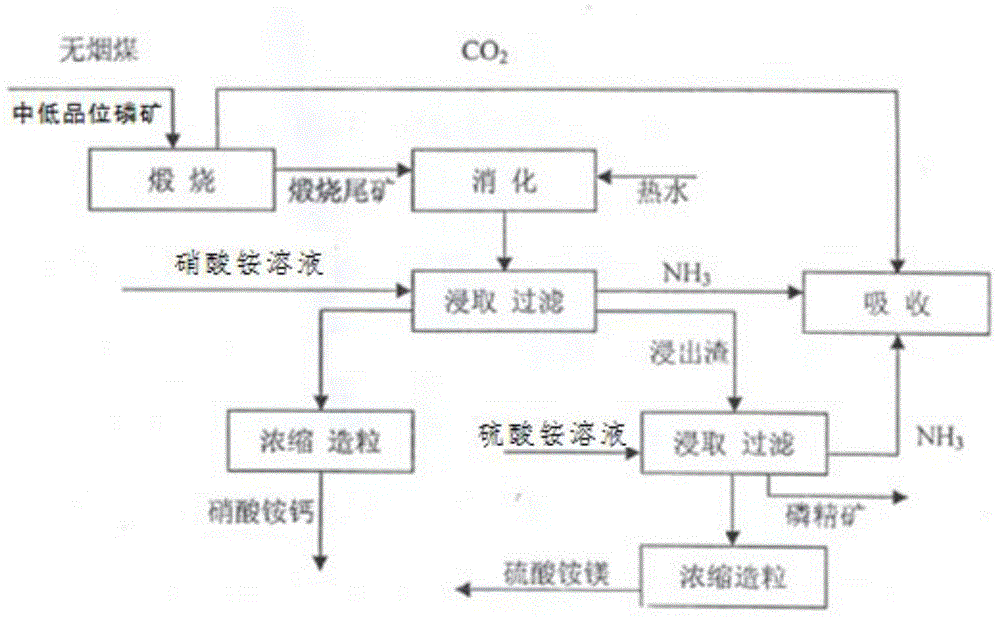

[0032] A process for preparing phosphate concentrate by-product ammonium magnesium sulfate and calcium ammonium nitrate from medium and low-grade phosphate rock, the process flow is as follows figure 1 shown, including the following steps:

[0033] (1) Calcining 100g of medium and low-grade phosphate rock at a temperature of 900-1100°C (the factory produces mixed calcination of medium and low-grade phosphate rock and anthracite coal) to obtain calcined slag and carbon dioxide; research shows that low- and medium-grade phosphorus Dolomite (CaCO 3 · MgCO 3 ), calcite (CaCO 3 ) and fluorapatite (Ca 5 F(PO 4 ) 3 ), where dolomite and calcite begin to decompose at high temperatures above 750°C, as follows:

[0034] CaCO 3 · MgCO 3 =CaO+MgO+2CO 2

[0035] CaCO 3 =CaO+CO 2

[0036] At the same time, fluoroapatite (Ca 5 F(PO 4 ) 3 ) has a decomposition temperature of 1650°C and will not decompose in the range of 900-1100°C;

[0037] (2) Calcined slag is digested with ...

Embodiment 2

[0050] A process for preparing phosphate concentrate by-product ammonium magnesium sulfate and calcium ammonium nitrate from medium and low-grade phosphate rock, the process flow is as follows figure 1 shown, including the following steps:

[0051] (1) Calcining 100g of low- and medium-grade phosphate rock at a temperature of 900-1100°C to obtain calcined slag and carbon dioxide; studies have shown that dolomite (CaCO 3 · MgCO 3 ), calcite (CaCO 3 ) and fluorapatite (Ca 5 F(PO 4 ) 3 ), where dolomite and calcite begin to decompose at high temperatures above 750°C, as follows:

[0052] CaCO 3 · MgCO 3 =CaO+MgO+2CO 2

[0053] CaCO 3 =CaO+CO 2

[0054] At the same time, fluoroapatite (Ca 5 F(PO 4 ) 3 ) has a decomposition temperature of 1650°C and will not decompose in the range of 900-1100°C;

[0055] (2) Calcined slag is digested with 100°C water; the use of higher temperature water can accelerate the reaction of CaO and MgO with water:

[0056] CaO+MgO+2H 2 O...

Embodiment 3

[0068] A process for preparing phosphate concentrate by-product ammonium magnesium sulfate and calcium ammonium nitrate from medium and low-grade phosphate rock, the process flow is as follows figure 1 shown, including the following steps:

[0069] (1) Calcining 100g of low- and medium-grade phosphate rock at a temperature of 900-1100°C to obtain calcined slag and carbon dioxide; studies have shown that dolomite (CaCO 3 · MgCO 3 ), calcite (CaCO 3 ) and fluorapatite (Ca 5 F(PO 4 ) 3 ), where dolomite and calcite begin to decompose at high temperatures above 750°C, as follows:

[0070] CaCO 3 · MgCO 3 =CaO+MgO+2CO 2

[0071] CaCO 3 =CaO+CO 2

[0072] At the same time, fluoroapatite (Ca 5 F(PO 4 ) 3 ) has a decomposition temperature of 1650°C and will not decompose in the range of 900-1100°C;

[0073] (2) The calcined slag is digested with water at 80°C; the use of higher temperature water can accelerate the reaction of CaO and MgO with water:

[0074] CaO+MgO+2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com