Patents

Literature

45 results about "Saturated Level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

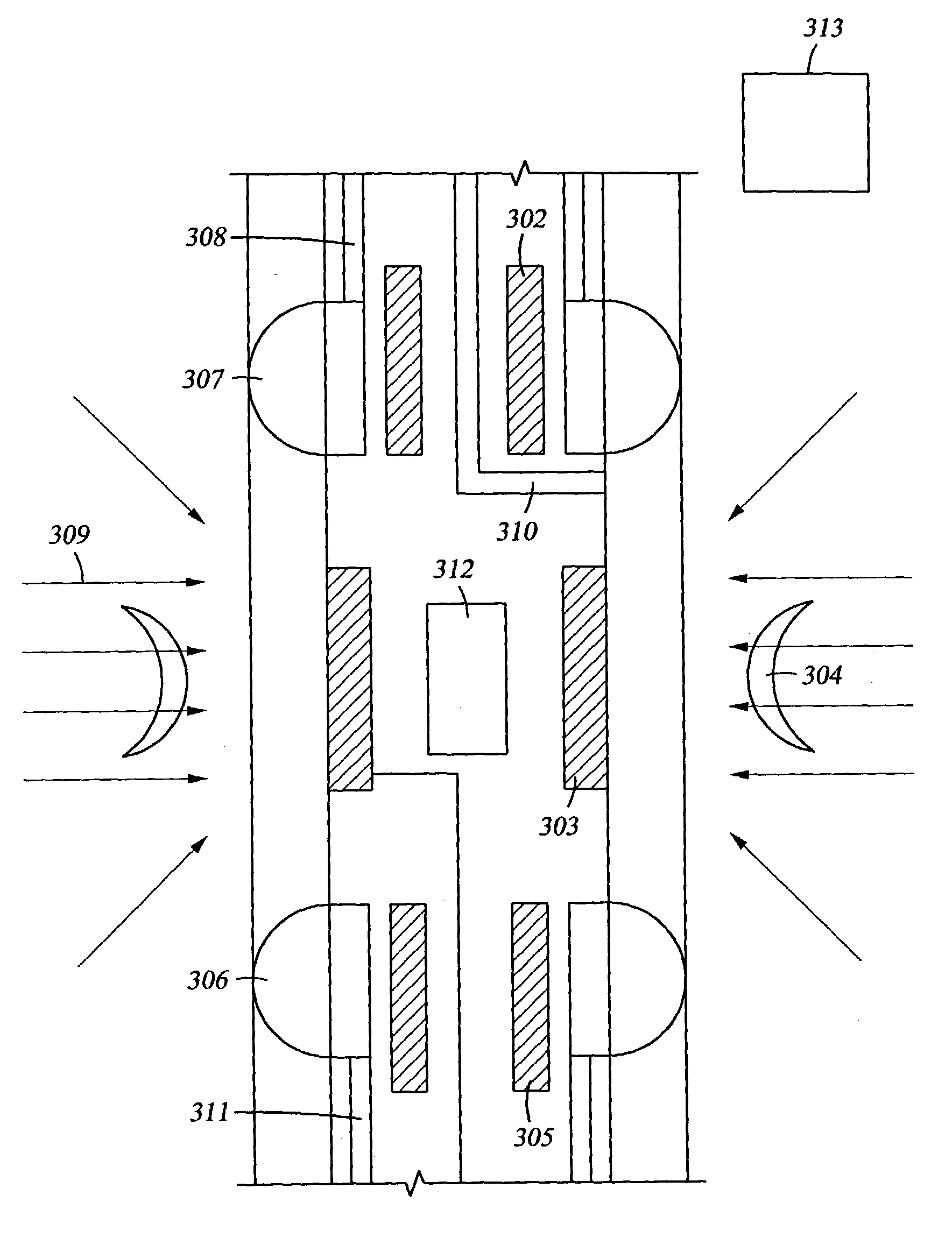

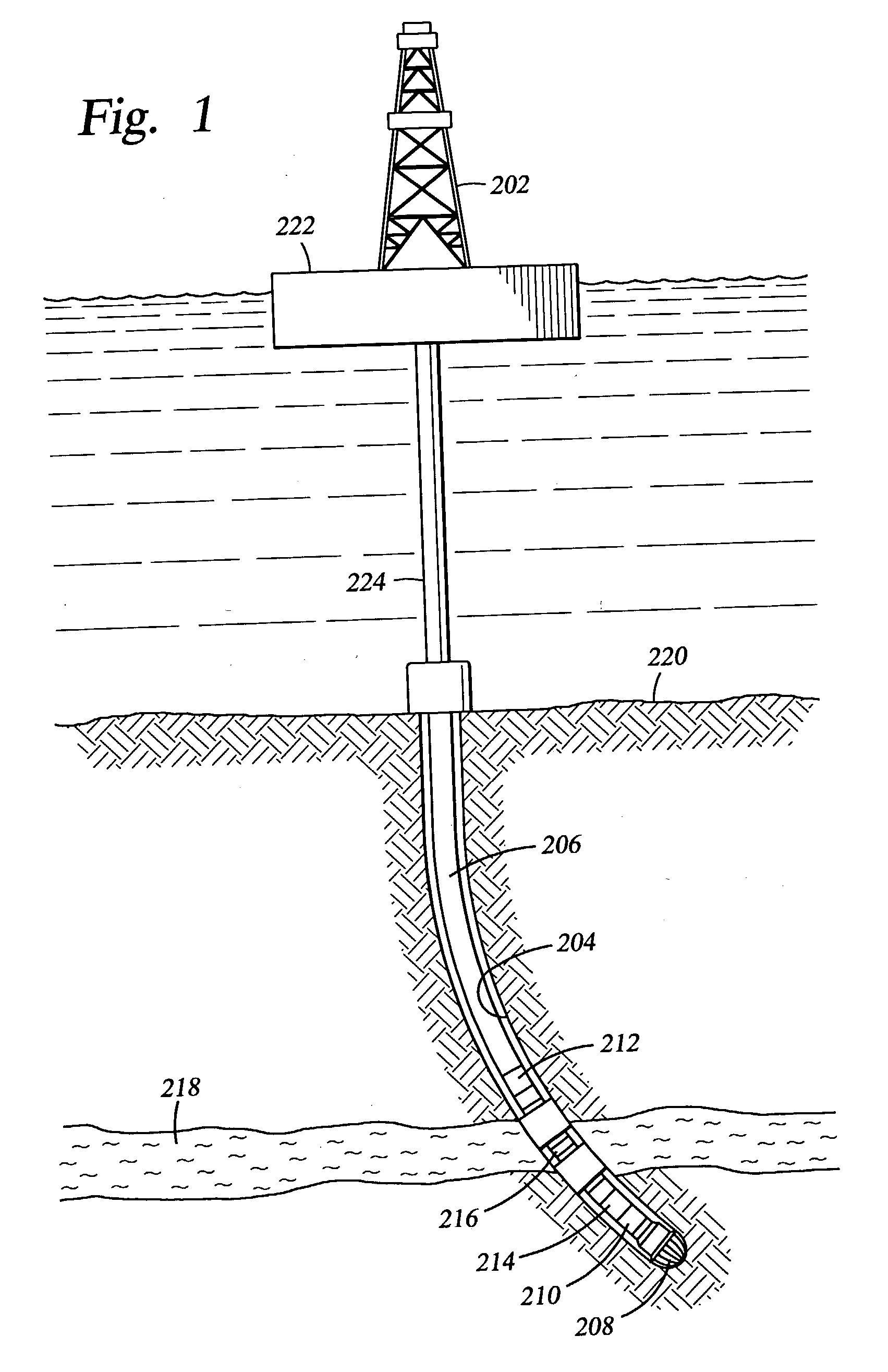

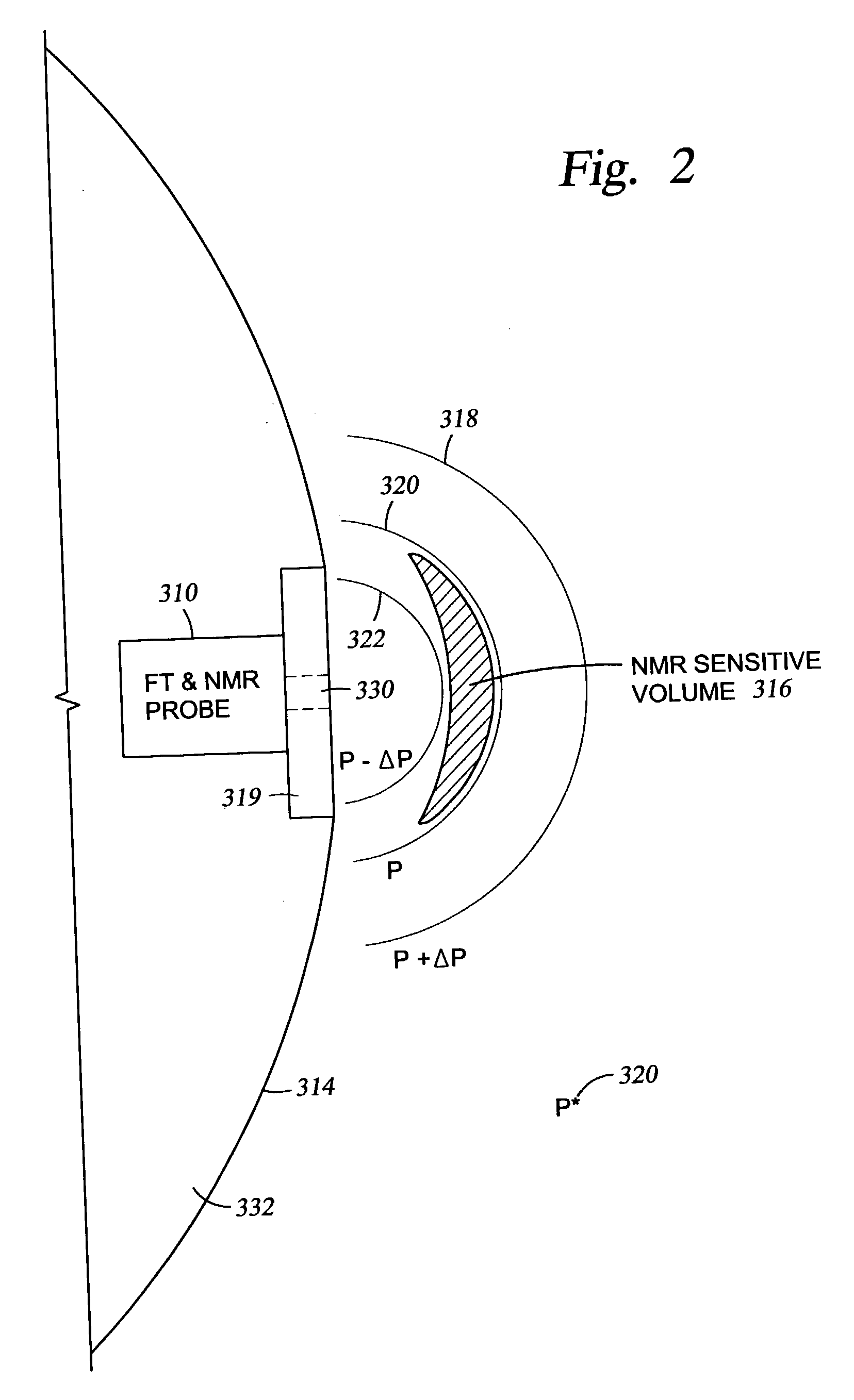

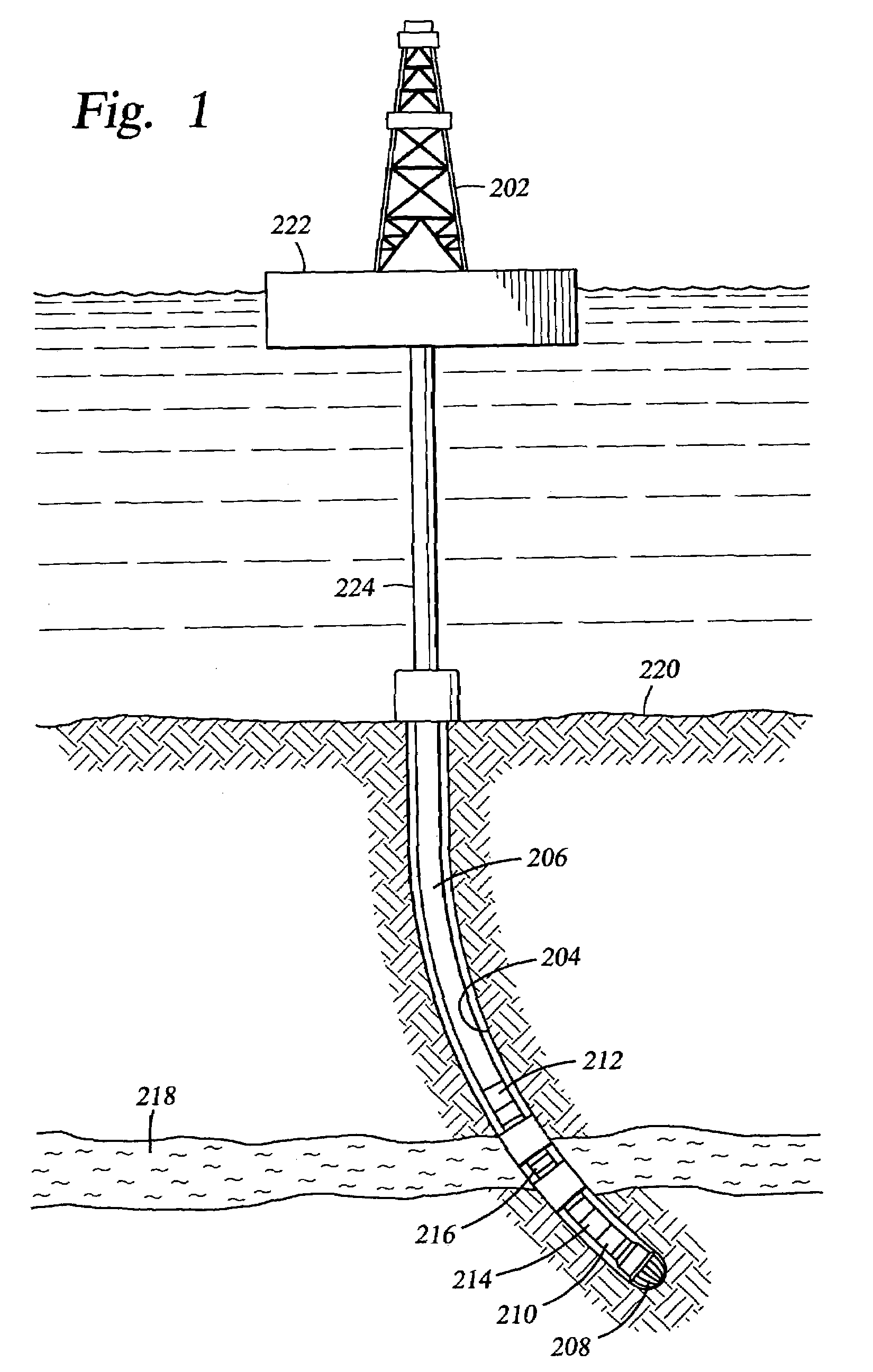

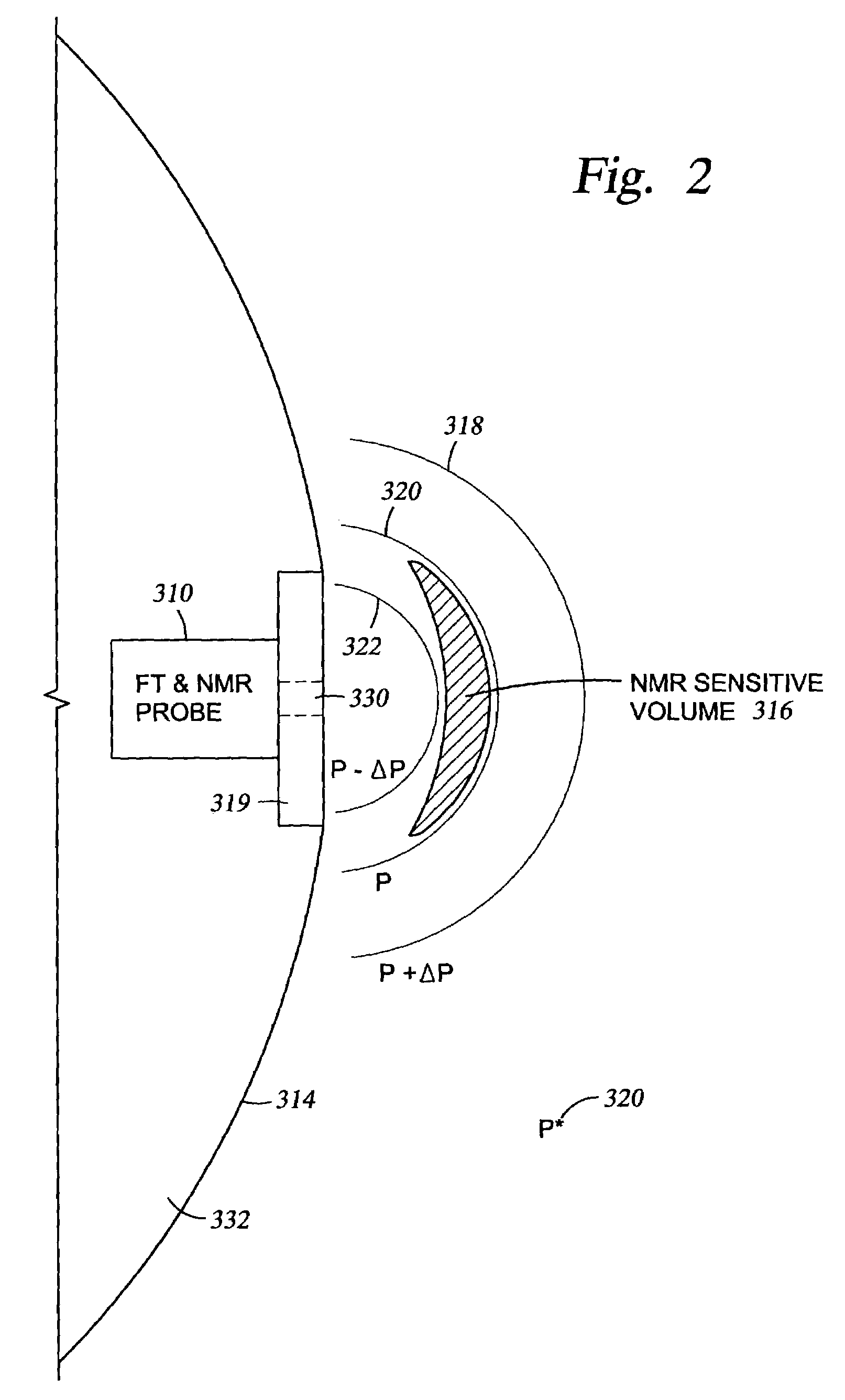

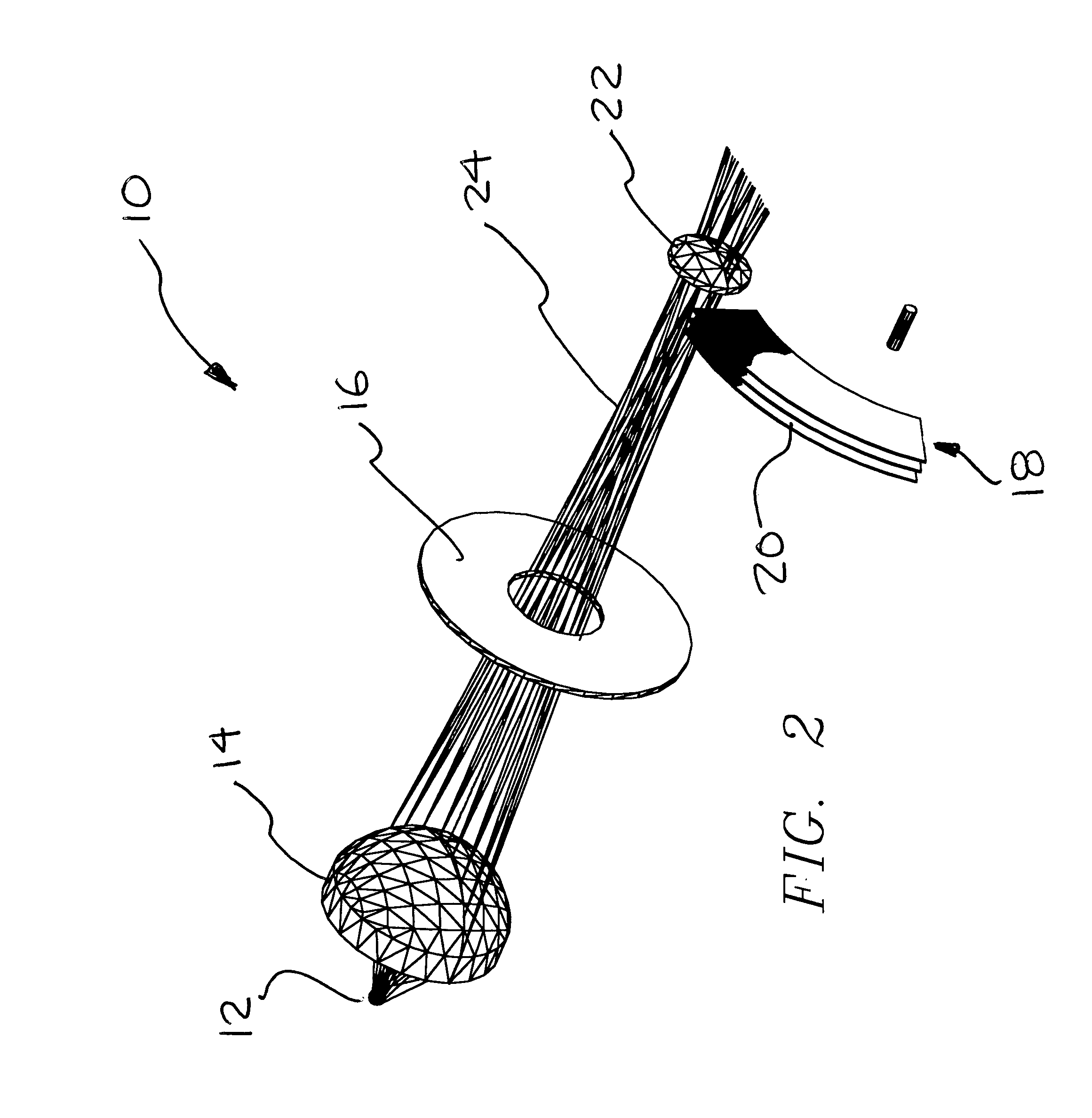

Method and apparatus for combined NMR and formation testing for assessing relative permeability with formation testing and nuclear magnetic resonance testing

InactiveUS20040055745A1Electric/magnetic detection for well-loggingSurveyProduction rateNMR - Nuclear magnetic resonance

Formation testing, resistivity and NMR measurements are used concurrently to determine a relative permeability representative of a formation surrounding the borehole. A method and apparatus is provided for accurate determination of the relative permeability for a formation by measuring saturation levels in a region of interest determined from resistivity or NMR readings versus time during formation draw down pressure testing. The method and apparatus determines and effective permeability over time for various saturation levels to determine the relative permeability for the formation at each saturation level and also enables determination of the efficacy of utilizing completion fluids in the formation to increase formation productivity. The method and apparatus enables more accurate determination of effective permeability and the irreducible saturation level. The method and apparatus also provides for determination of whether a pad is sealed properly against a borehole wall and determines if a probe is clogged.

Owner:BAKER HUGHES INC

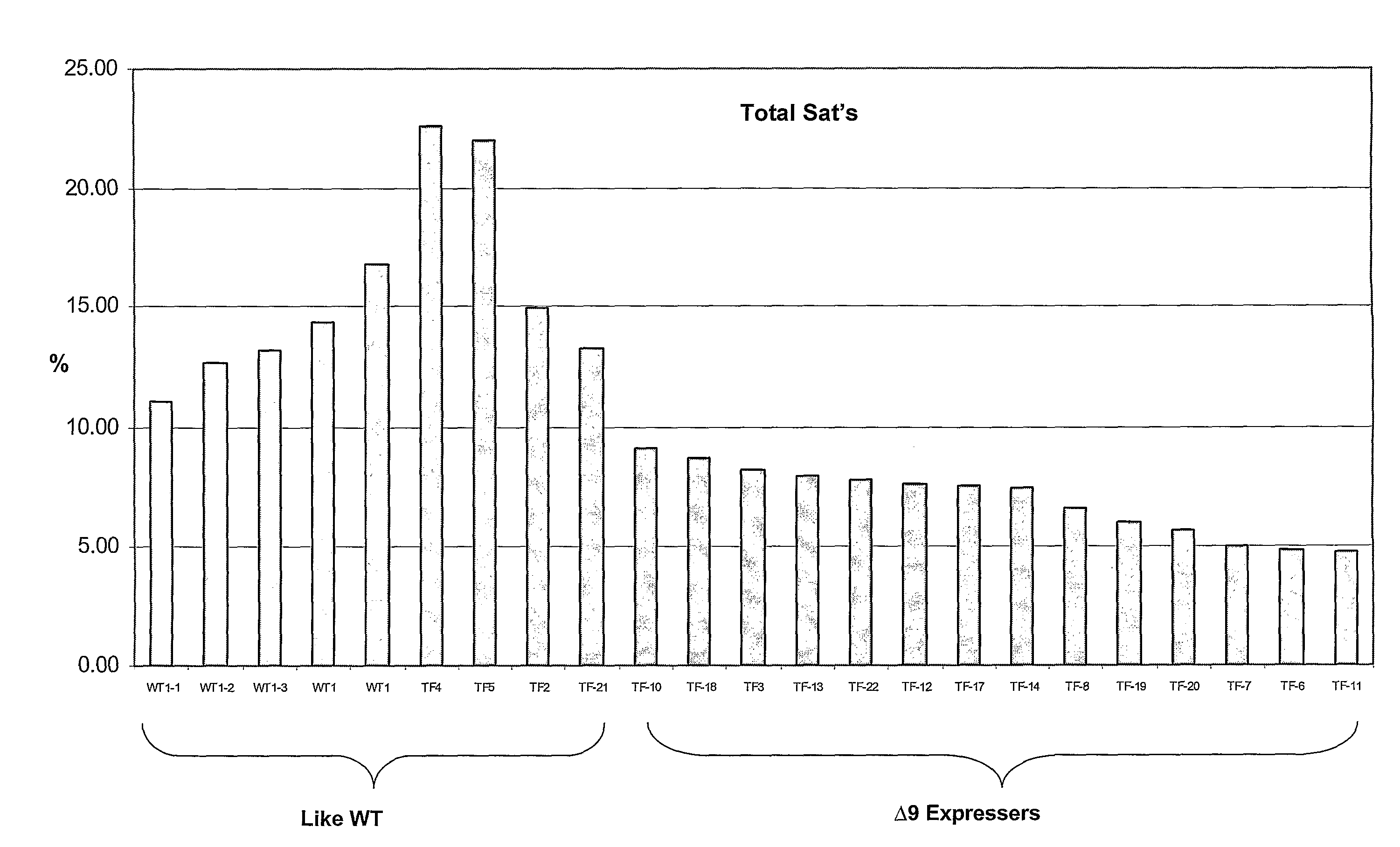

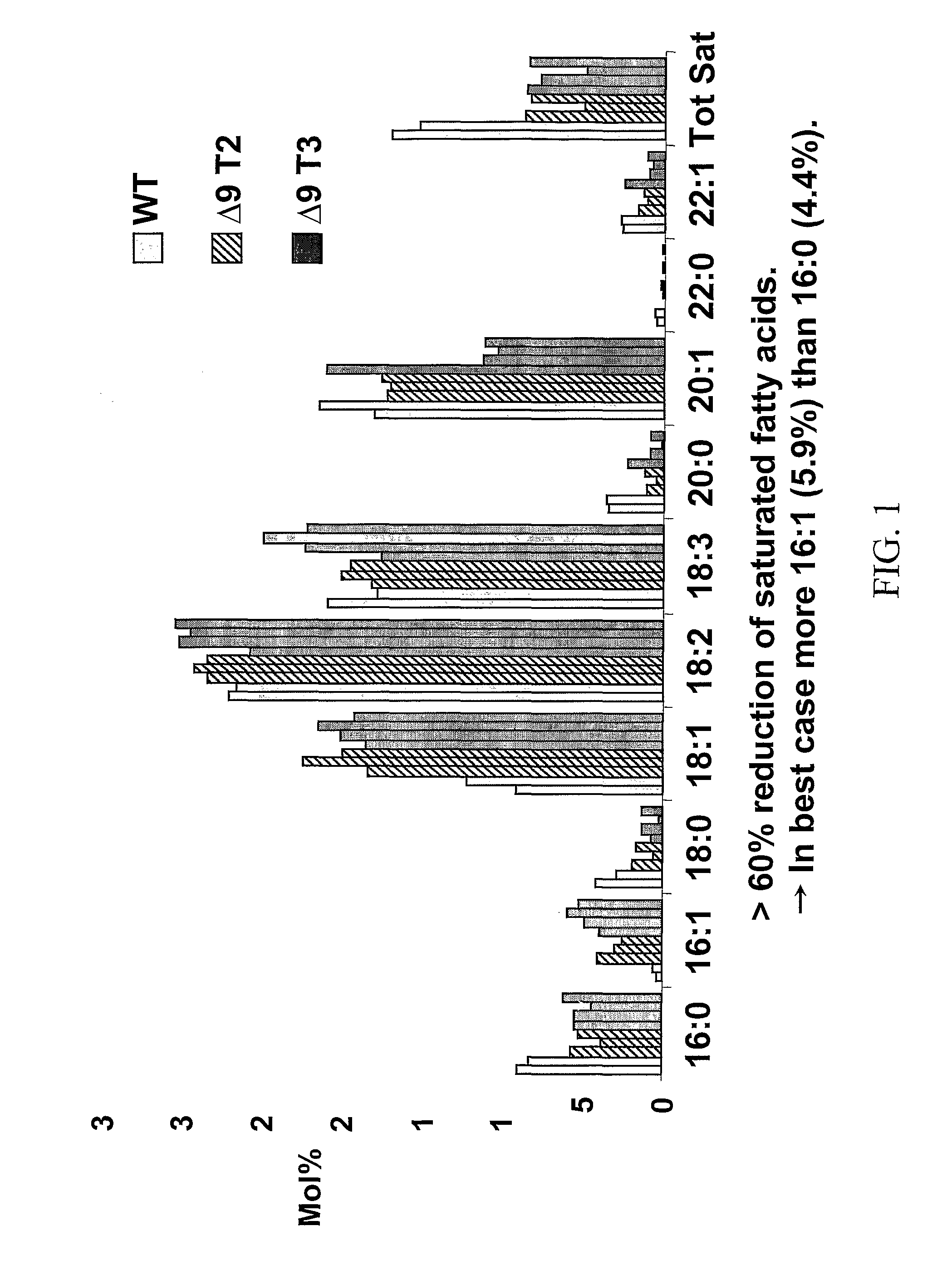

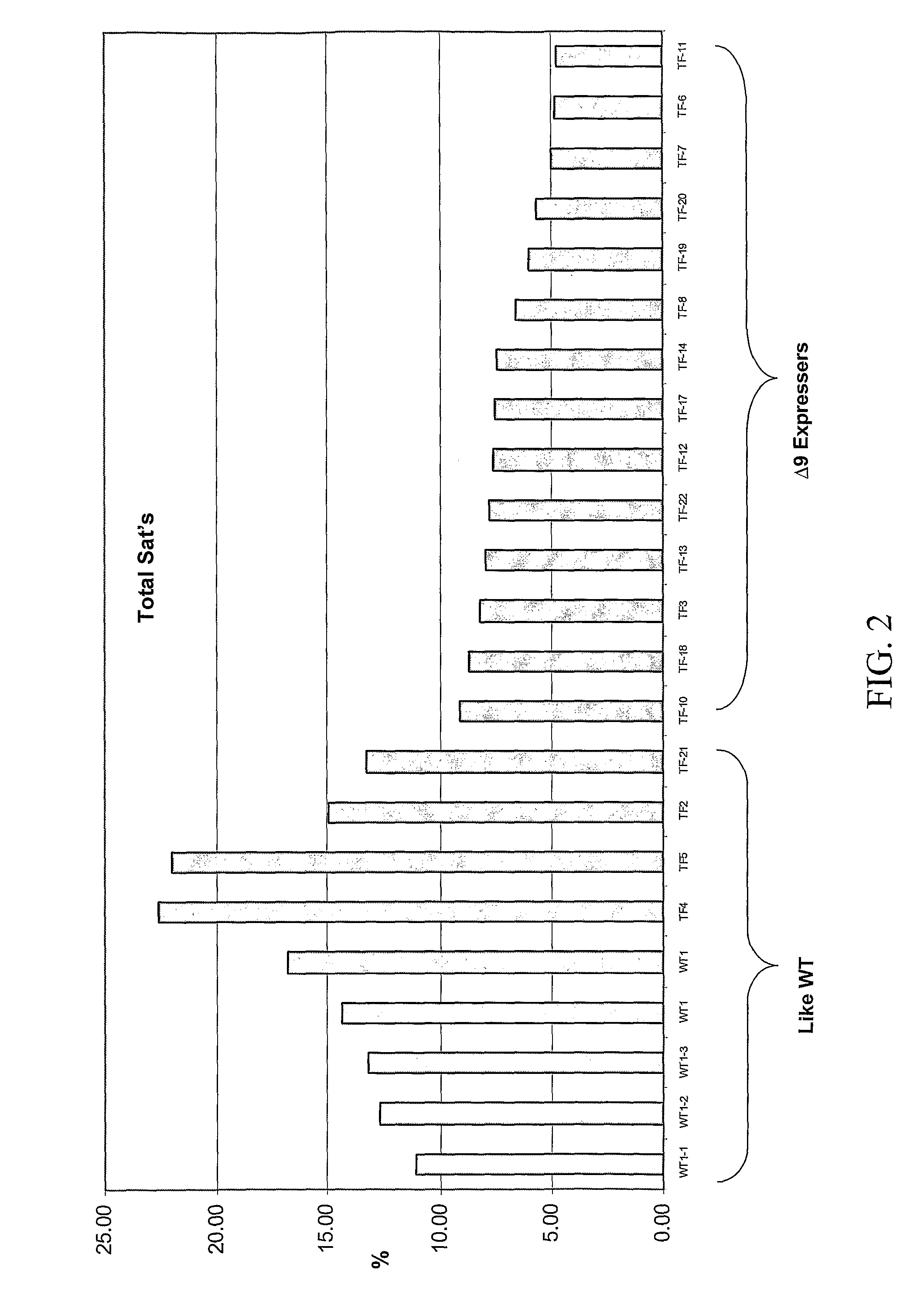

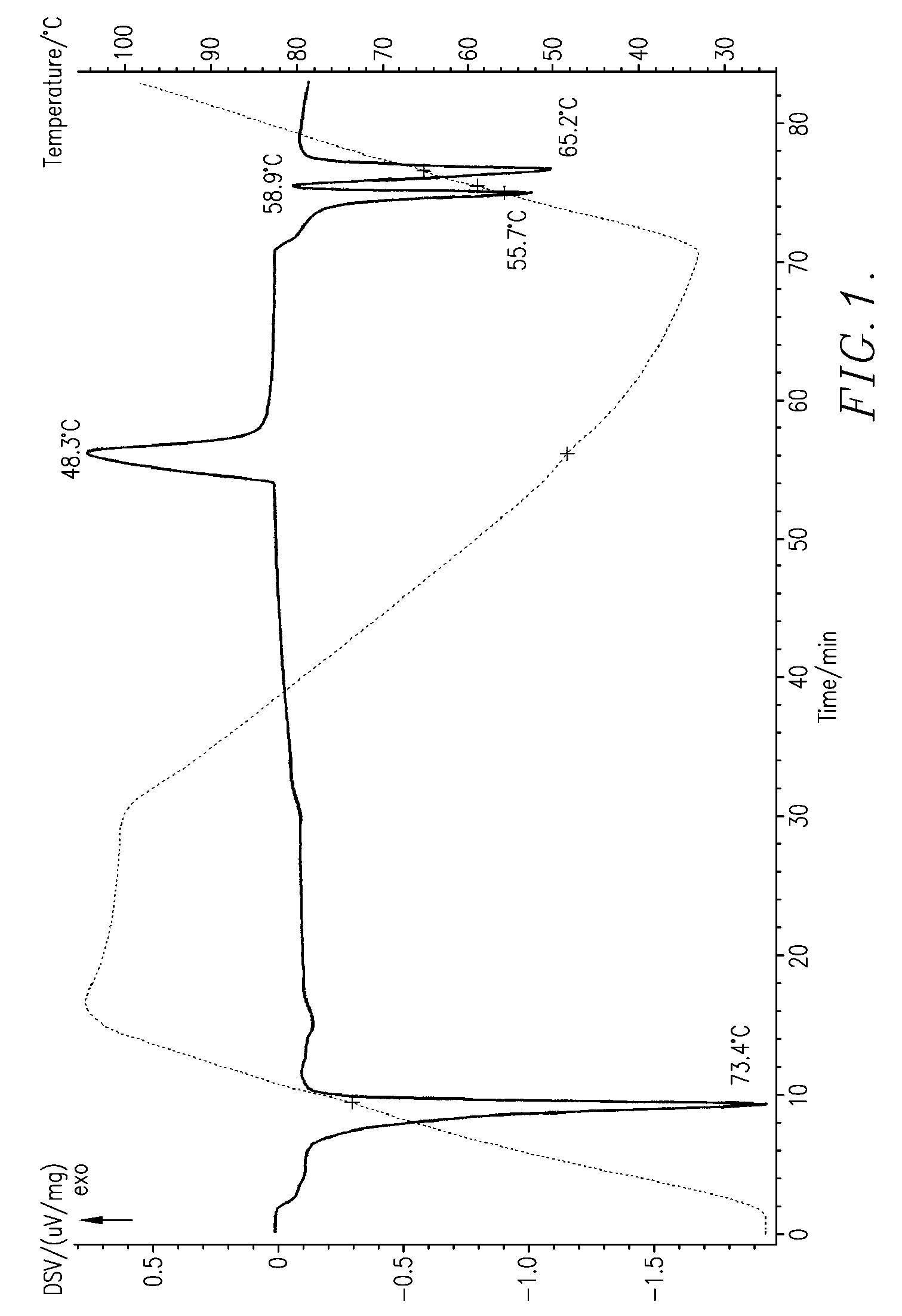

Certain Plants with "No Saturate" or Reduced Saturate Levels of Fatty Acids in Seeds, and Oil Derived from the Seeds

InactiveUS20080260933A1Sugar derivativesOther foreign material introduction processesBiotechnologySaturated Level

The subject invention provides “no sat” canola oil. The subject invention also provides seeds that can be used to produce such oils. Plants that produce these seeds are also included within the subject invention. All of this was surprisingly achieved by using a delta-9 desaturase gene in canola. This technology can be applied to other plants as disclosed herein. Oils of the subject invention have particularly advantageous characteristics and fatty acid profiles, which were not heretofore attained. The subject invention still further provides a plant-optimized delta-9 desaturase gene. The subject invention still further provides a plant-optimized delta-9 desaturase gene. In some preferred embodiments, a preferred plant comprises at least two copies of a delta-9 desaturase gene of the subject invention. Seeds produced by such plants surprisingly do not exhibit effects of gene silencing but rather have further surprising reductions in levels of total saturates.

Owner:CORTEVA AGRISCIENCE LLC

Method and apparatus for combined NMR and formation testing for assessing relative permeability with formation testing and nuclear magnetic resonance testing

InactiveUS7032661B2Electric/magnetic detection for well-loggingSurveyProduction rateNMR - Nuclear magnetic resonance

Formation testing, resistivity and NMR measurements are used concurrently to determine a relative permeability representative of a formation surrounding the borehole. A method and apparatus is provided for accurate determination of the relative permeability for a formation by measuring saturation levels in a region of interest determined from resistivity or NMR readings versus time during formation draw down pressure testing. The method and apparatus determines and effective permeability over time for various saturation levels to determine the relative permeability for the formation at each saturation level and also enables determination of the efficacy of utilizing completion fluids in the formation to increase formation productivity. The method and apparatus enables more accurate determination of effective permeability and the irreducible saturation level. The method and apparatus also provides for determination of whether a pad is sealed properly against a borehole wall and determines if a probe is clogged.

Owner:BAKER HUGHES INC

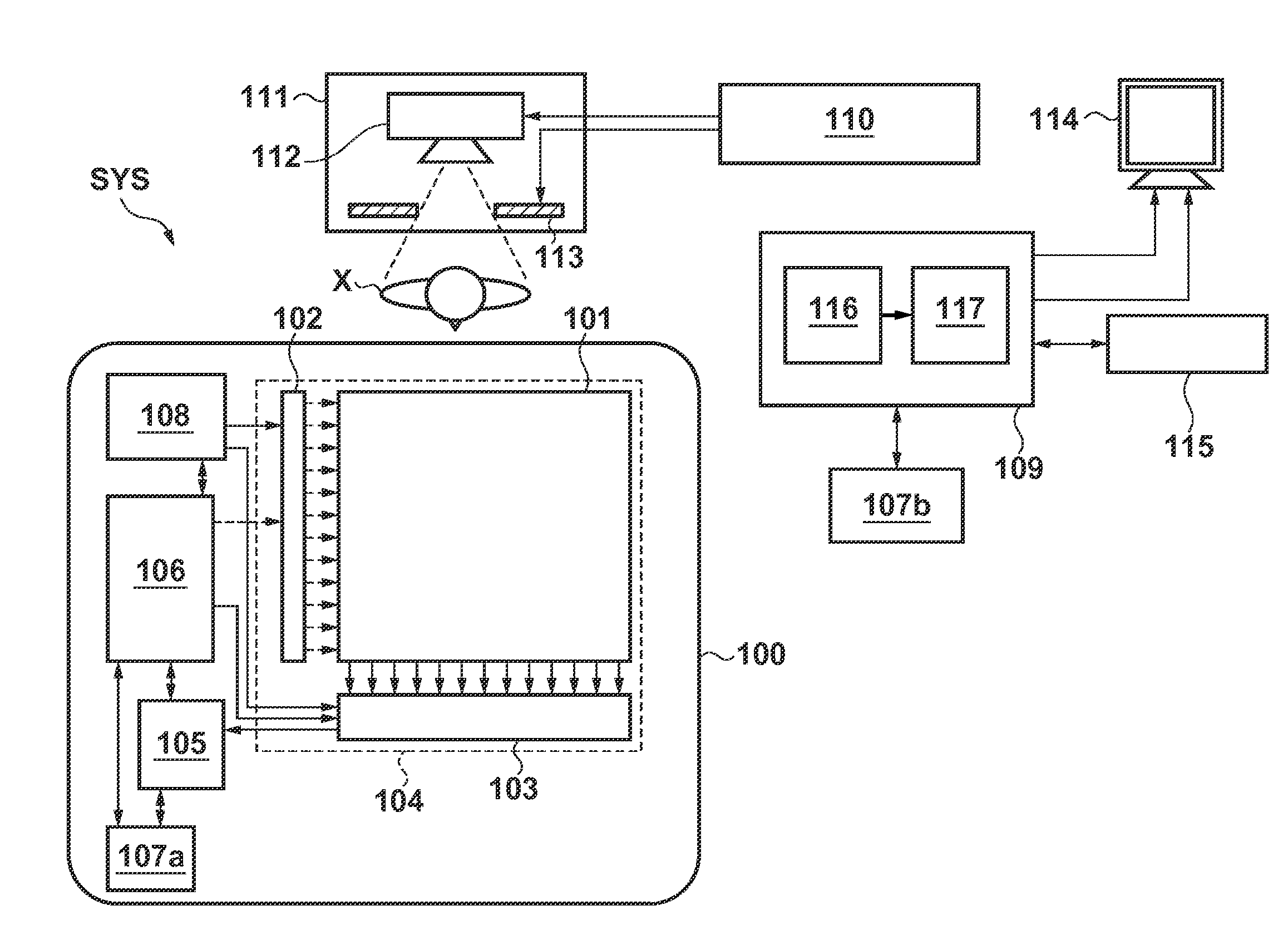

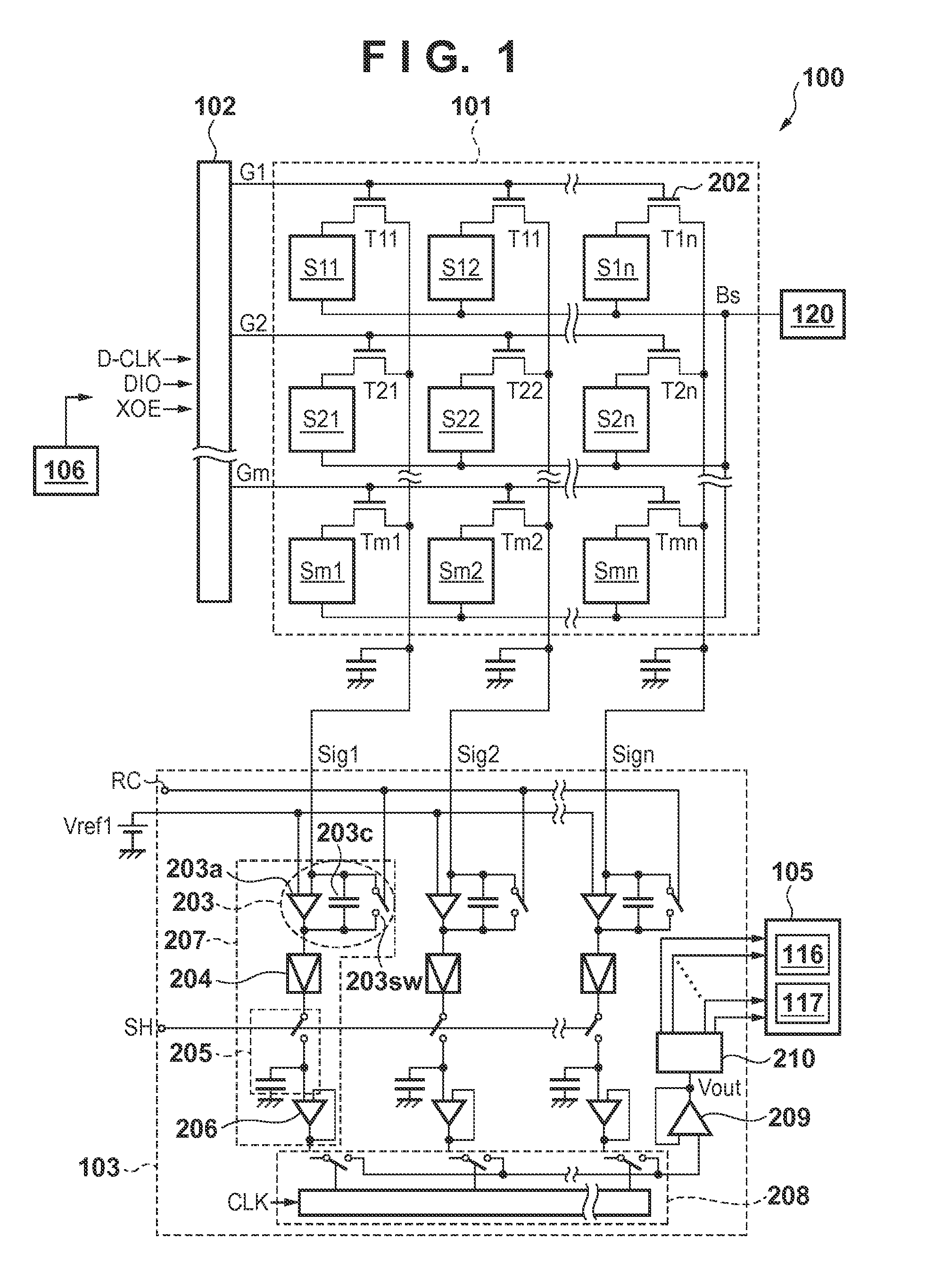

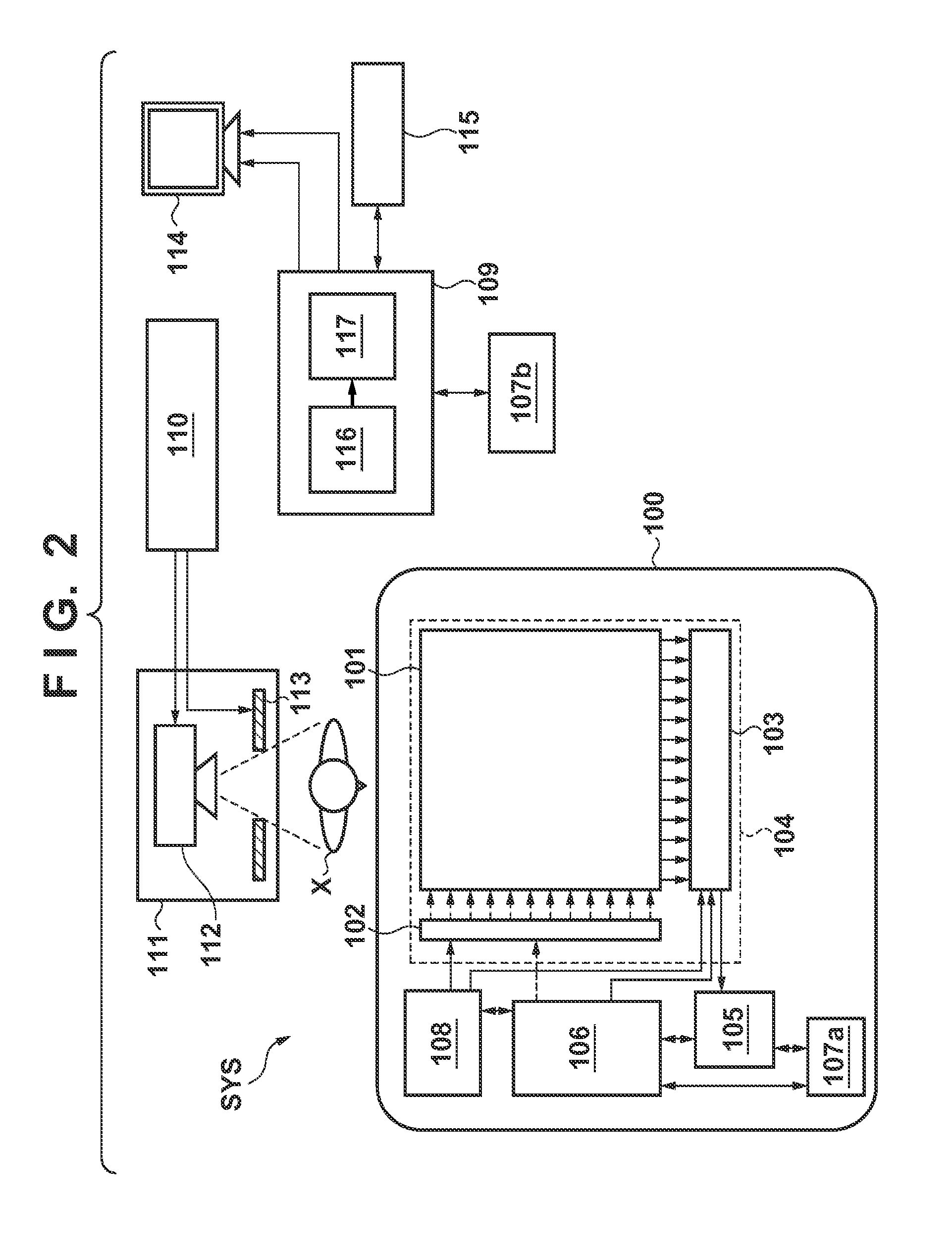

Radiation imaging apparatus, radiation inspection apparatus, method for correcting signal, and computer-readable storage medium

InactiveUS20140239186A1Improve image qualityTelevision system detailsRadiation diagnostic device controlComputer hardwareSaturated Level

A radiation imaging apparatus, comprising a pixel array on which a plurality of pixels are arrayed, a readout unit configured to read out a signal from the pixel array, a first unit configured to specify a portion of the signal read out by the readout unit, at which a saturated signal whose value has reached a saturation level of an output by the readout unit and a non-saturated signal whose value has not reached the saturation level are mixed, and a second unit configured to correct, based on the non-saturated signal, the saturated signal at the portion specified by the first unit.

Owner:CANON KK

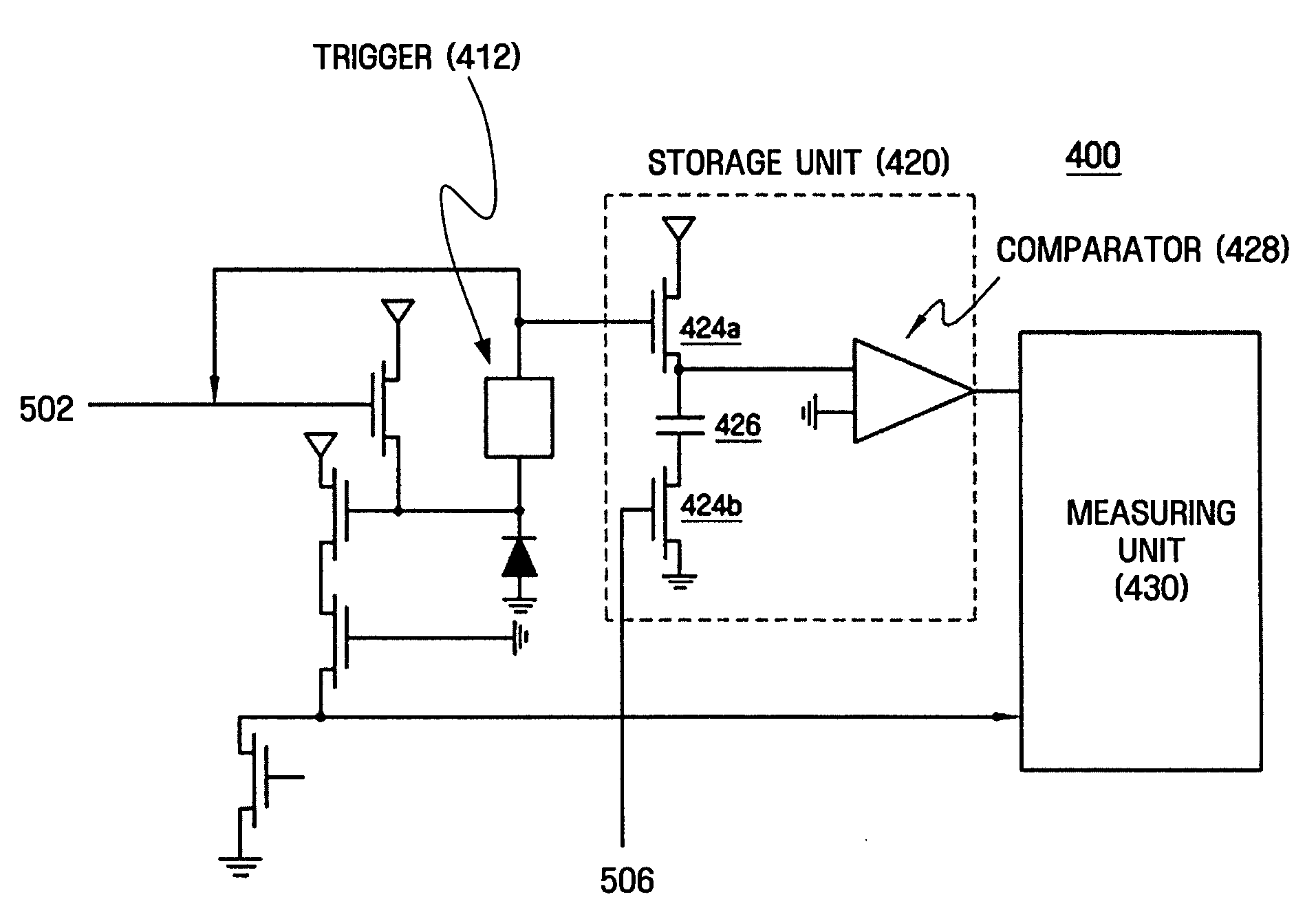

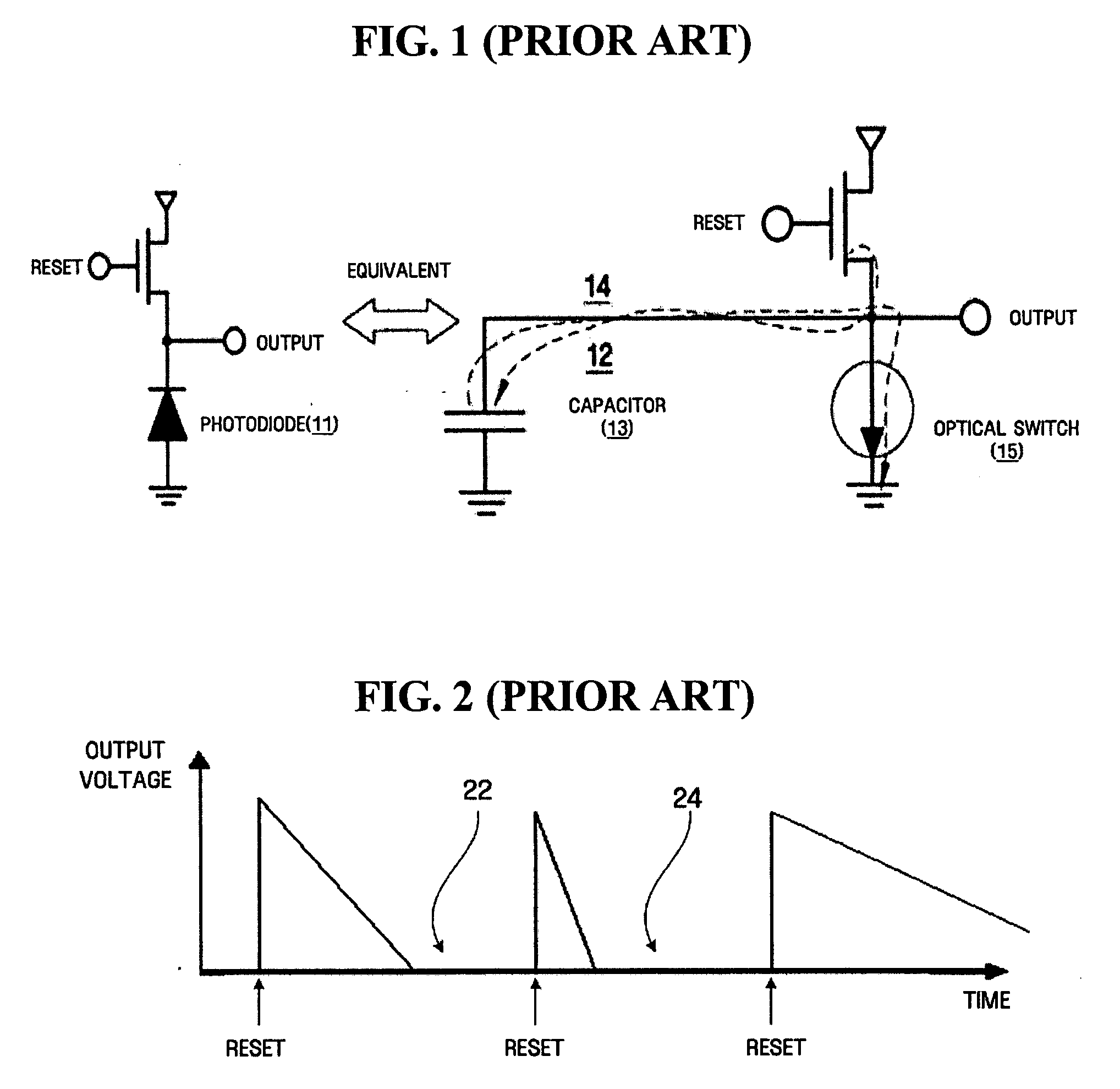

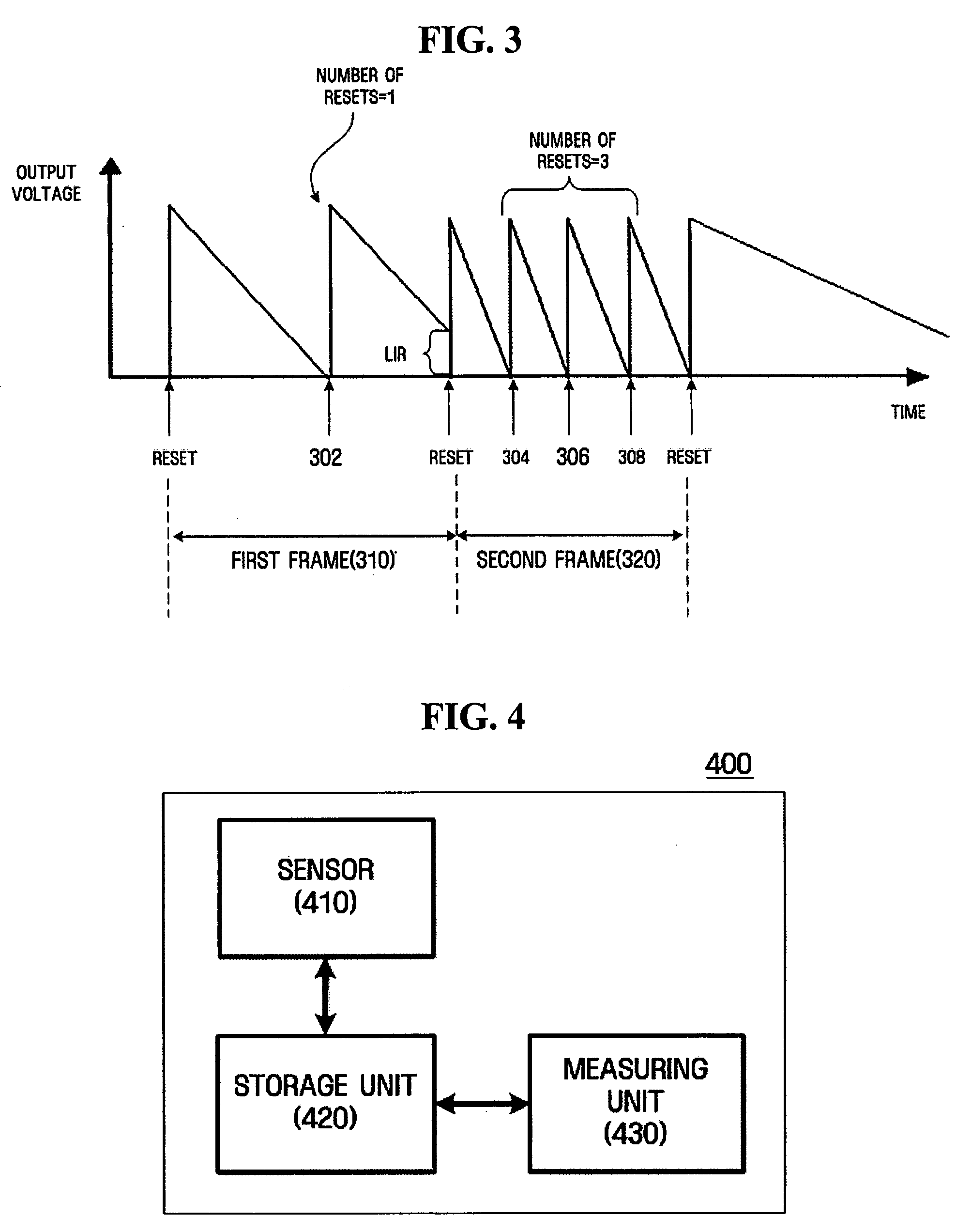

High dynamic range image sensor and method and medium for measuring charges in pixel

InactiveUS20080112651A1High imagingImprove dynamic rangeTelevision system detailsTelevision system scanning detailsSaturated LevelComputer science

A high dynamic range image sensor and a method and medium for measuring charges in a pixel are provided. The high dynamic range image sensor includes a sensor that resets a predetermined pixel when the pixel has reached a saturation level, a storage unit that stores the number of times the pixel has been reset, and a measurement unit that measures the quantity of light received in the pixel using the number of times the pixel has been reset, which is simply referred to as the number of resets, and the quantity of charges remaining after the pixel is finally reset.

Owner:SAMSUNG ELECTRONICS CO LTD

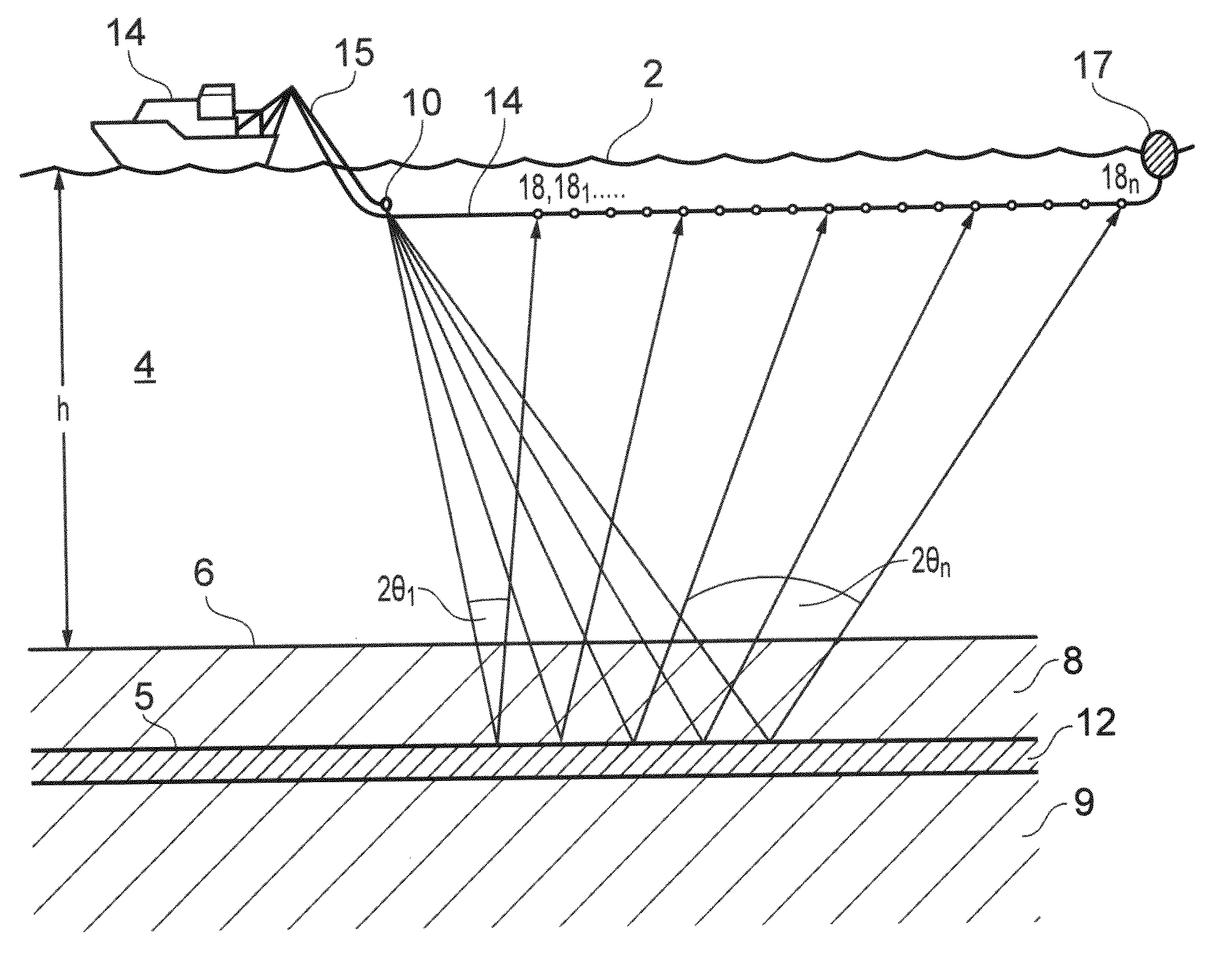

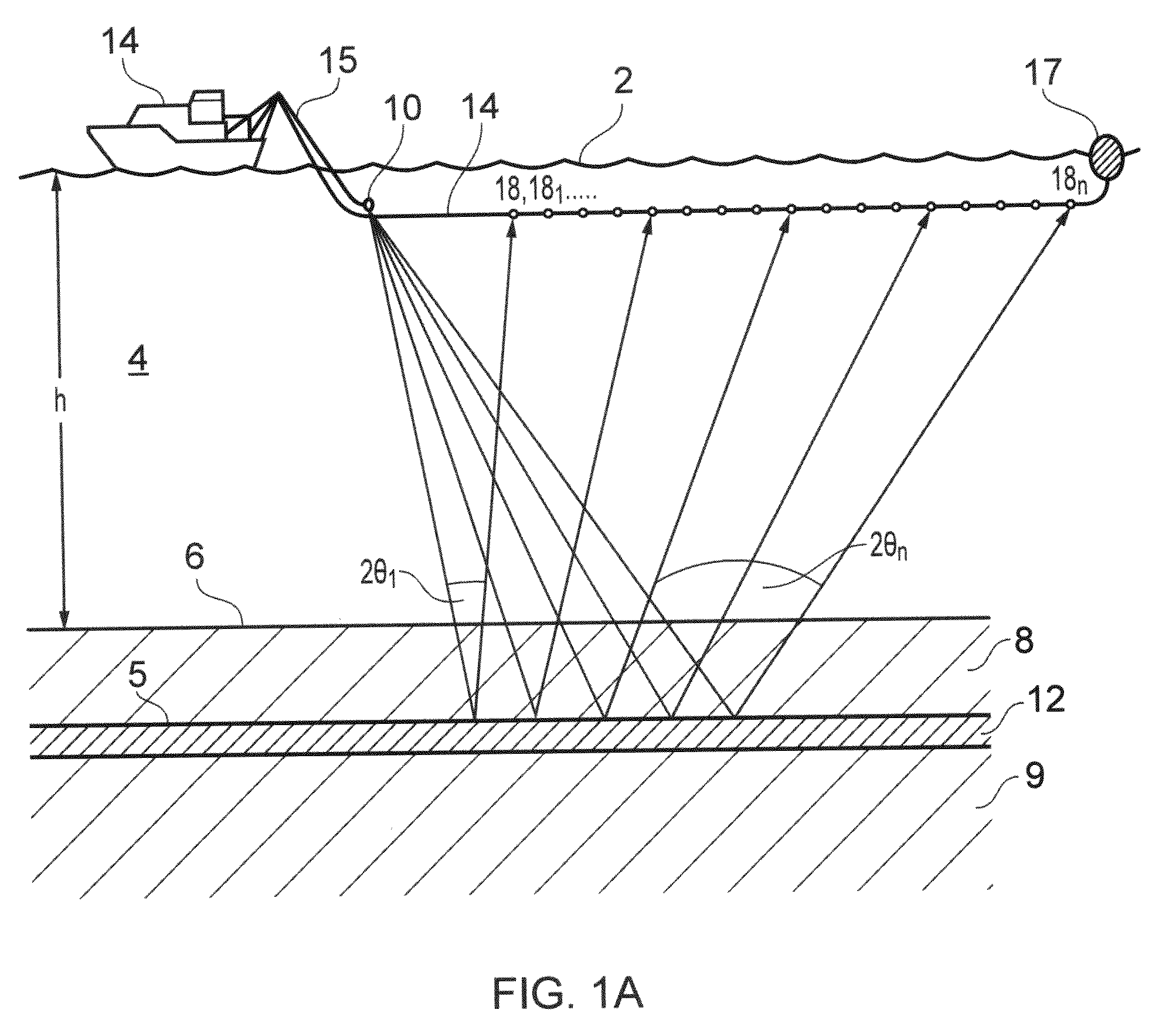

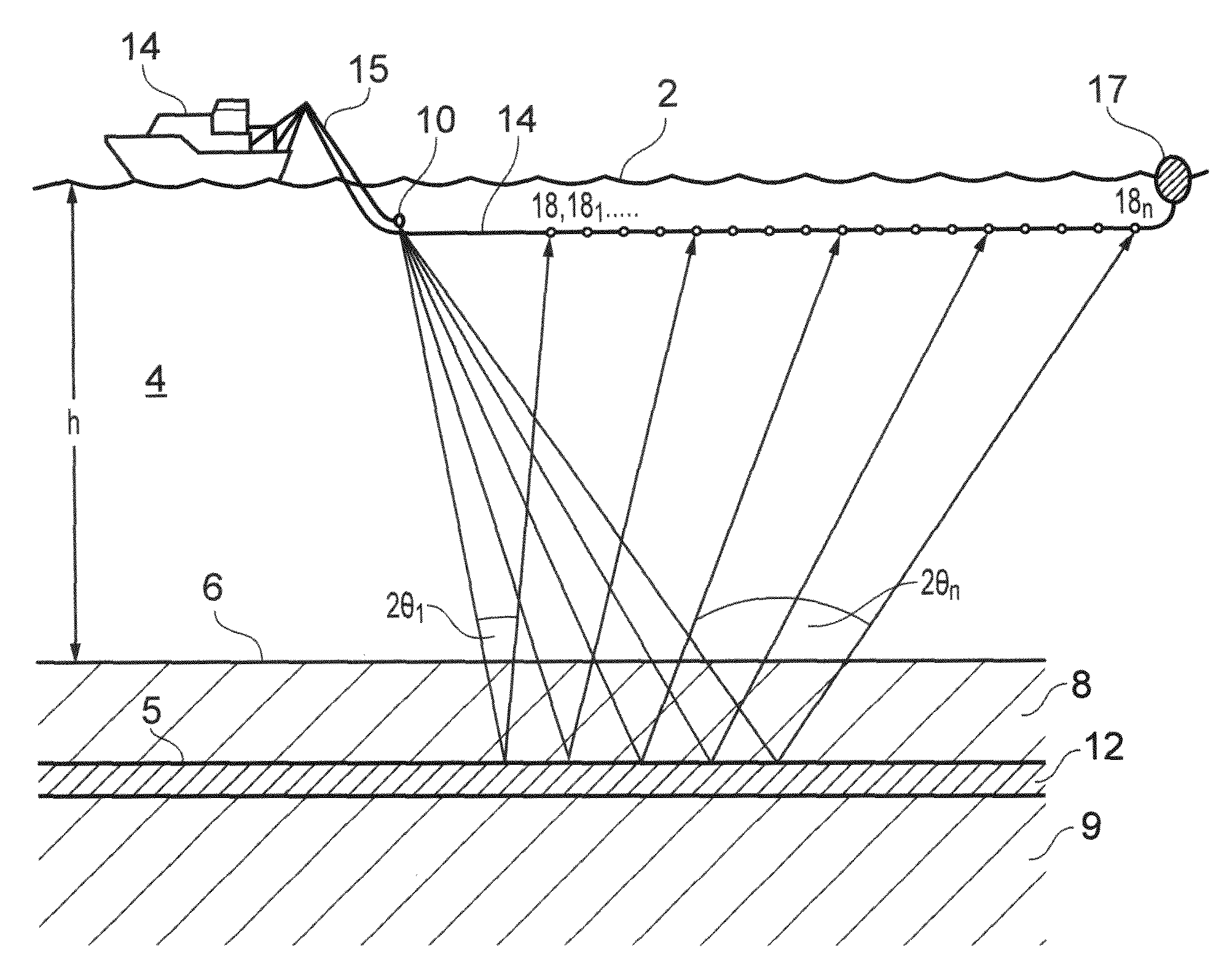

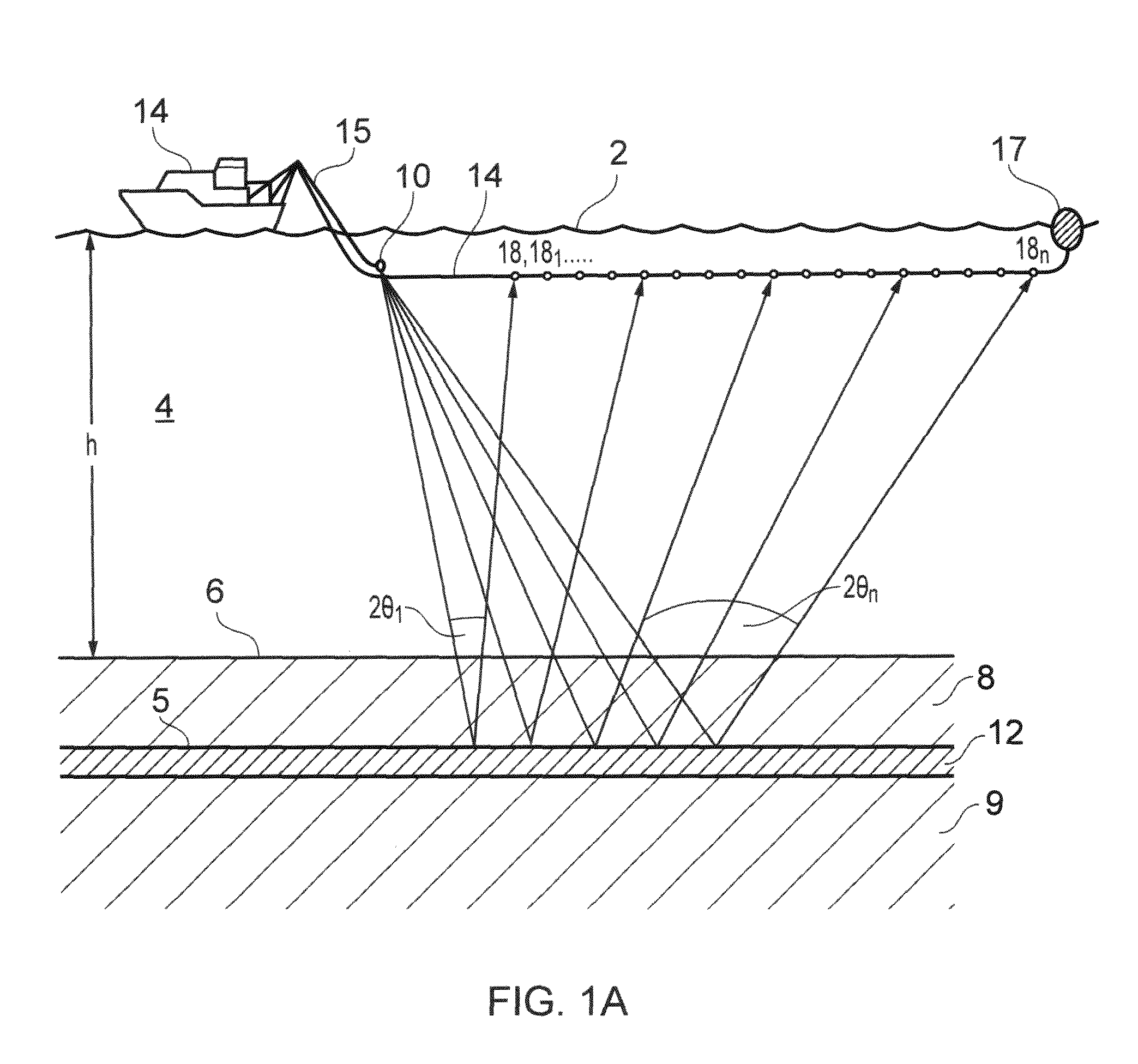

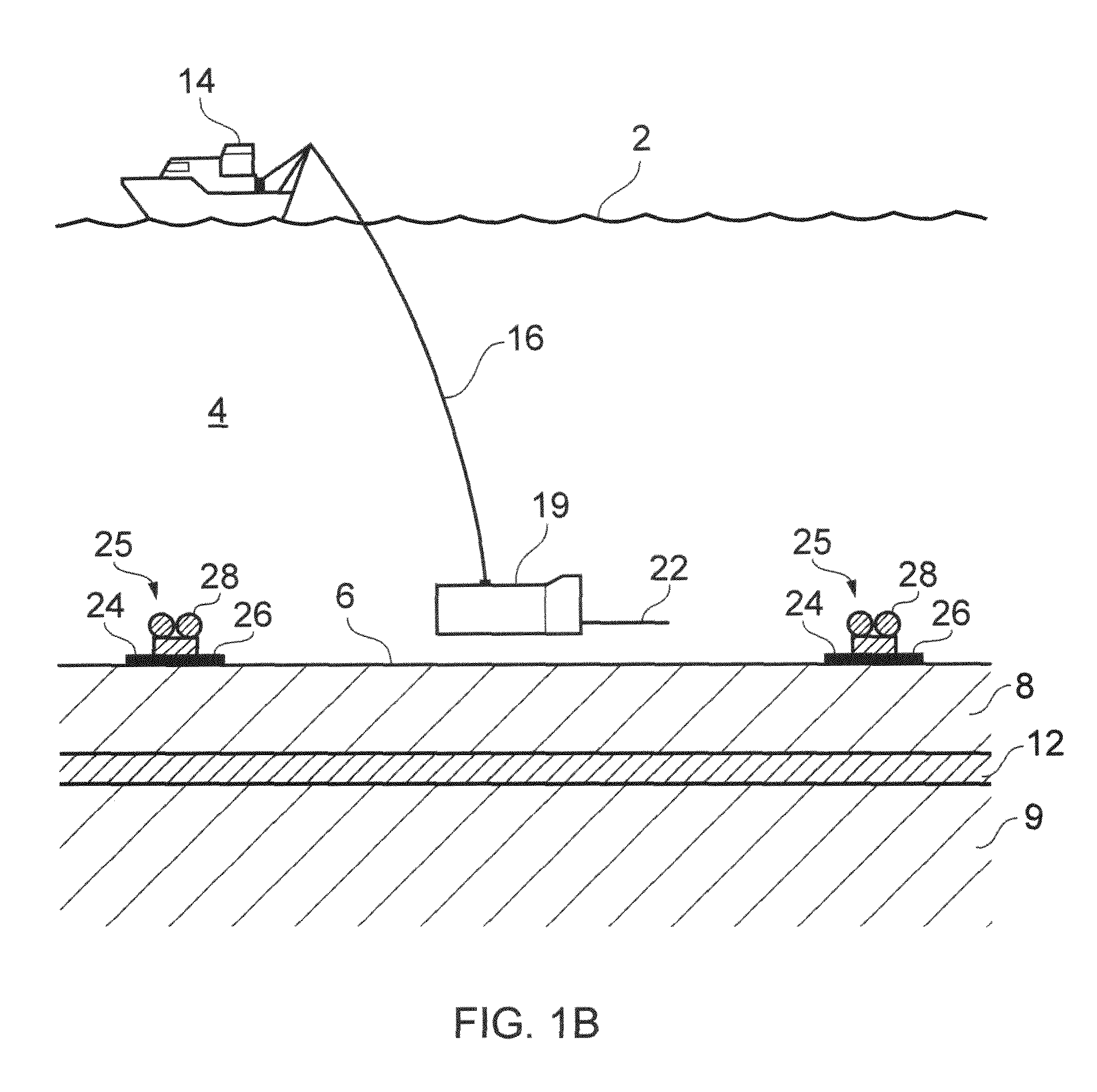

Geophysical surveying

ActiveUS20090306899A1Maximise distinguishabilityElectric/magnetic detection for well-loggingSeismic signal processingPorosityLithology

Joint processing of seismic and controlled source electromagnetic (CSEM) surface data is performed by using a common rock physics model which relates reservoir properties (such as porosity, lithology, saturation, and shaliness) to surface seismic AVO (or AVA) data. This allows one to determine how perturbations in the reservoir properties affect surface data. This can be carried out by systematically changing the reservoir properties and examining the effect on the synthetic data. This allows the hydrocarbon type of a reservoir to be established, e.g. oil or gas, as well as the saturation level of the hydrocarbon in the reservoir, which is useful for determining whether the reservoir has a non-commercial, low hydrocarbon saturation or a commercial, high hydrocarbon saturation.

Owner:PGS GEOPHYSICAL AS

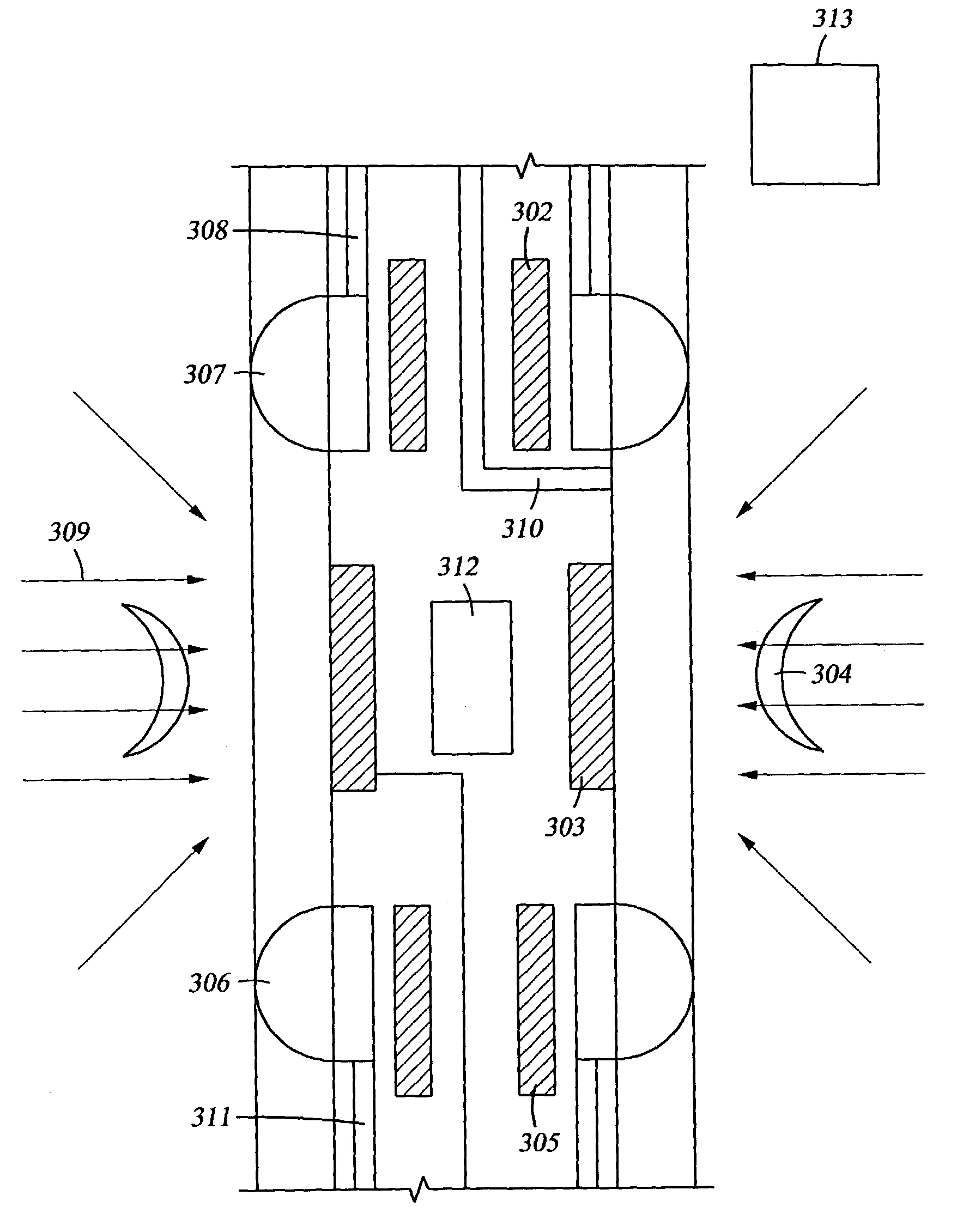

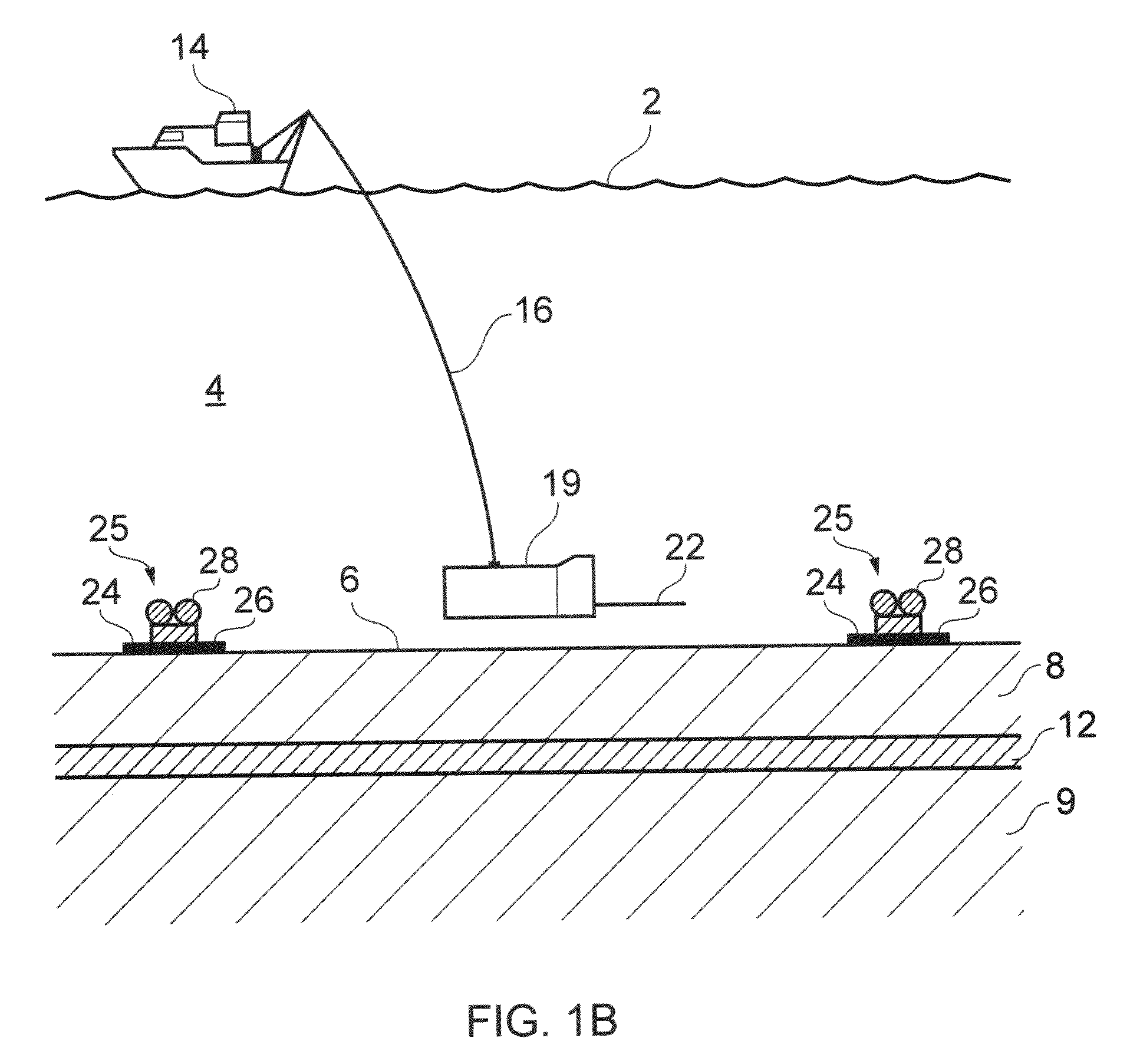

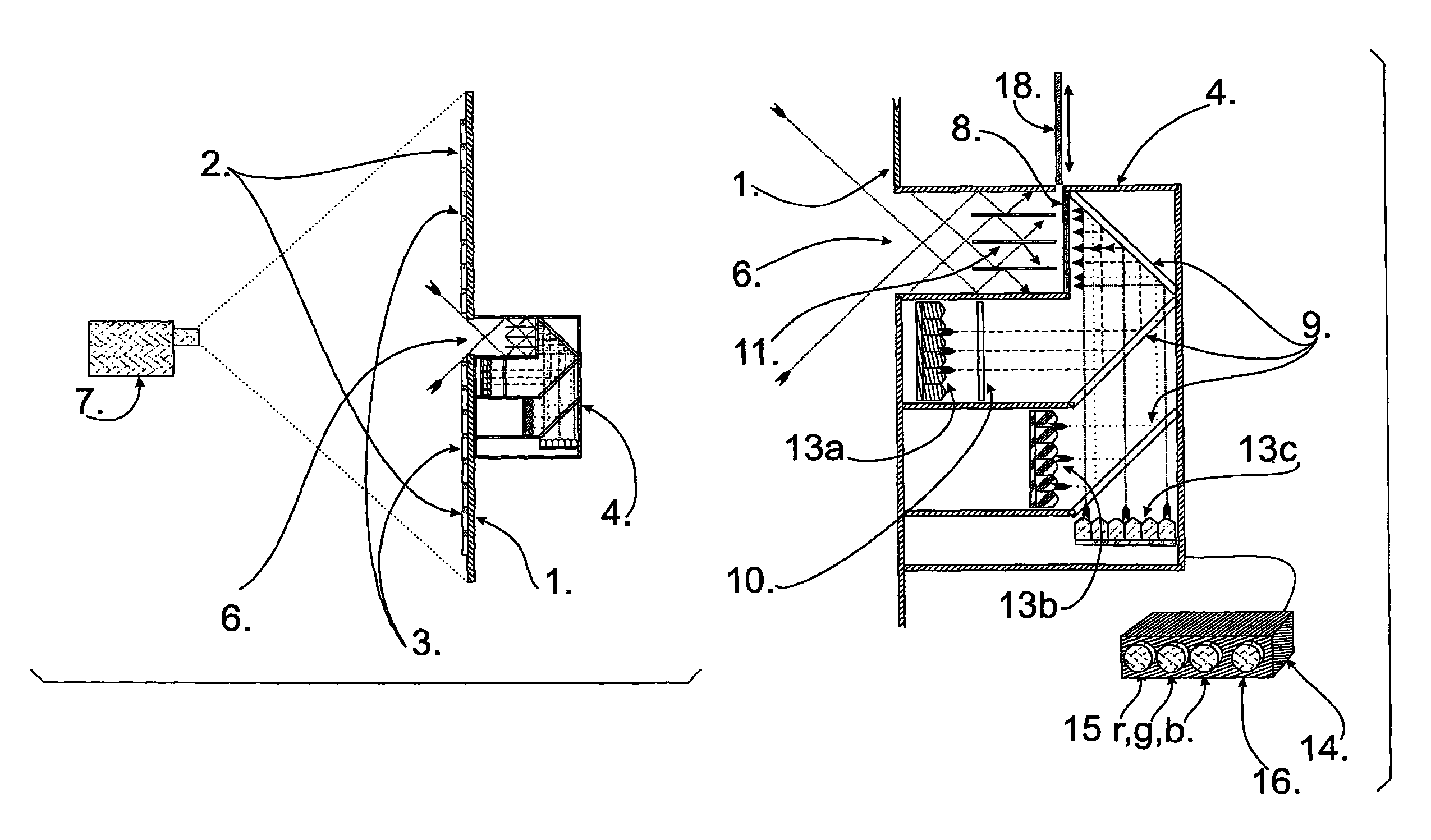

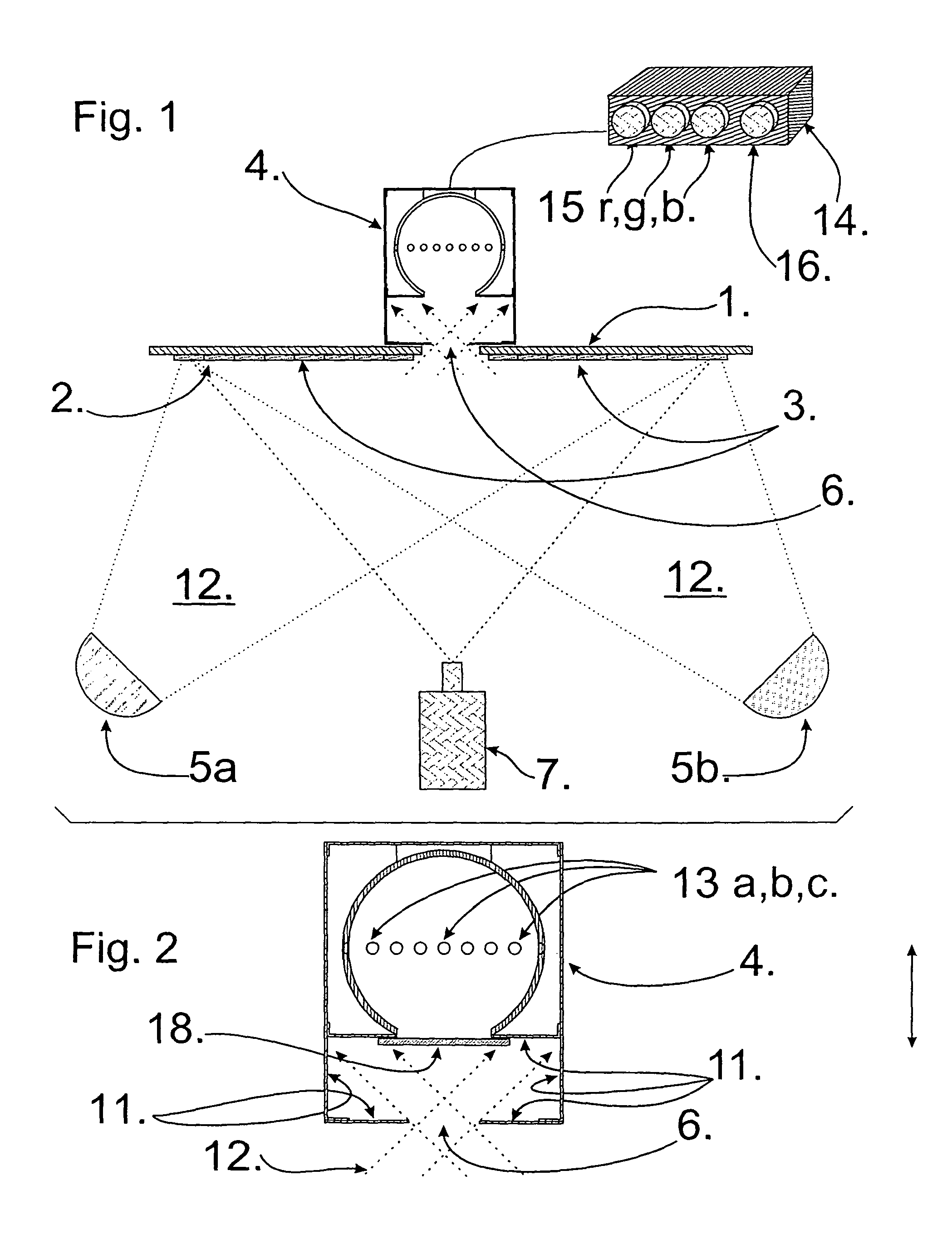

Compact lighting system with improved light transmission and color filters

InactiveUS6974232B1Minimized in sizeShorten the lengthLighting applicationsMechanical apparatusSmart lightingSaturated Level

A lighting system including a light source, a means of collecting and focusing light from the light source, an aperture, a filter module containing at least one color filter, and an image lens. A light beam from the light source is focused through the aperture to define the image to be projected. The aperture is positioned upstream of the color filter, with the filter and the image lens being deployed in the area of the light beam where the diameter is at a minimum. The filter elements used in the filter module are two stage filters, having a first stage for a pastel level of a particular filter color, and a second stage for a saturated level of the subject color. Each stage has a gradient segment and a solid color segment. The result is a filter element with four regions that blend into each other.

Owner:RAMBUS DELAWARE

Geophysical surveying

ActiveUS7912649B2Maximise distinguishabilityElectric/magnetic detection for well-loggingSeismic signal processingPorosityLithology

Joint processing of seismic and controlled source electromagnetic (CSEM) surface data is performed by using a common rock physics model which relates reservoir properties (such as porosity, lithology, saturation, and shaliness) to surface seismic AVO (or AVA) data. This allows one to determine how perturbations in the reservoir properties affect surface data. This can be carried out by systematically changing the reservoir properties and examining the effect on the synthetic data. This allows the hydrocarbon type of a reservoir to be established, e.g. oil or gas, as well as the saturation level of the hydrocarbon in the reservoir, which is useful for determining whether the reservoir has a non-commercial, low hydrocarbon saturation or a commercial, high hydrocarbon saturation.

Owner:PGS GEOPHYSICAL AS

Compositions for improved recovery of metals

InactiveUS6908570B2Effective dissolutionEasy to separateOther chemical processesContaminated soil reclamationSteelmakingElectrolysis

Liquor compositions for the extraction of metallic elements from solid and liquid metal-contaminated starting material such as mineral ores, recyclable wastes, contaminated soils, engraving solutions, metal finishing solutions, battery manufacturing solutions, toxic wastes such as dusts producing through steelmaking processes by effectuating preferably prolonged contacting of such starting material with the liquor to cause the underlying structure of the starting material to be broken down. The contaminated starting materials are more susceptible to metal separation because the released metallic element are readily solubilized in the contacting liquor. Compositions of the contacting liquor comprise caustic silicate solutions containing essentially saturating levels of silica. Once the plurality of metallic elements contained in the starting material have been solubilized, they tend to remain in solution, and then may be routinely extracted and removed using conventional extraction methodologies such as precipitation of insoluble salts, electrowinning, or electrodeposition.

Owner:DISCOVERY RESOURCES

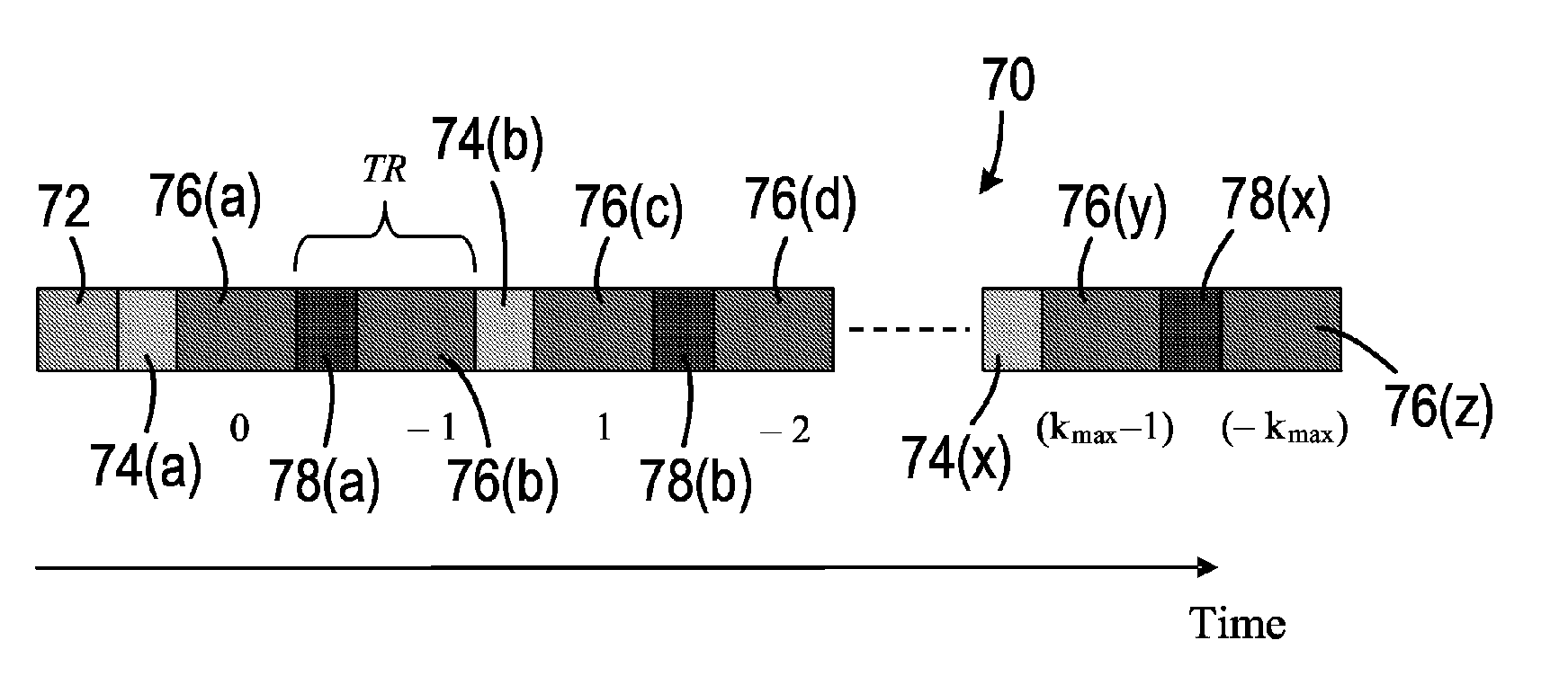

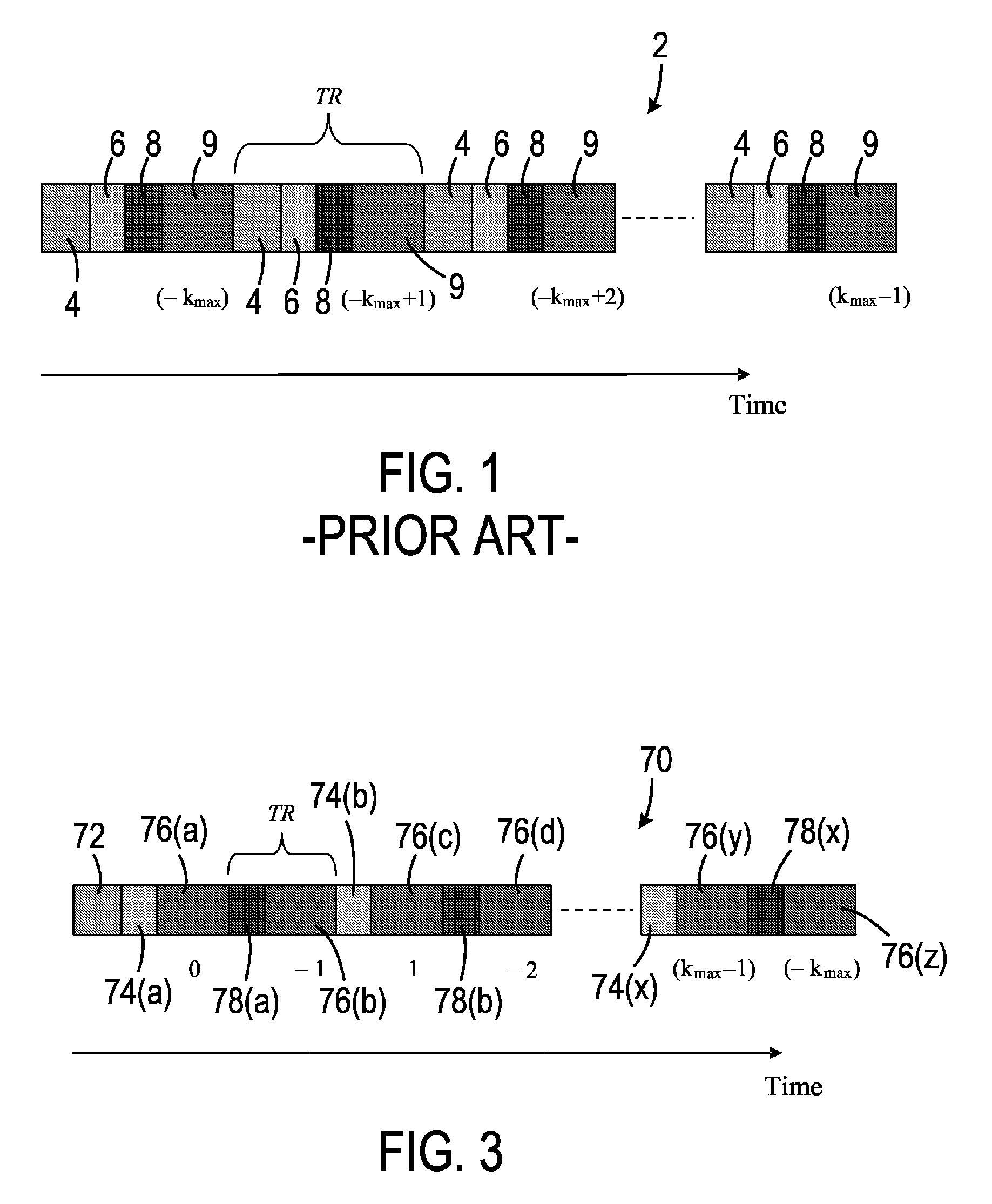

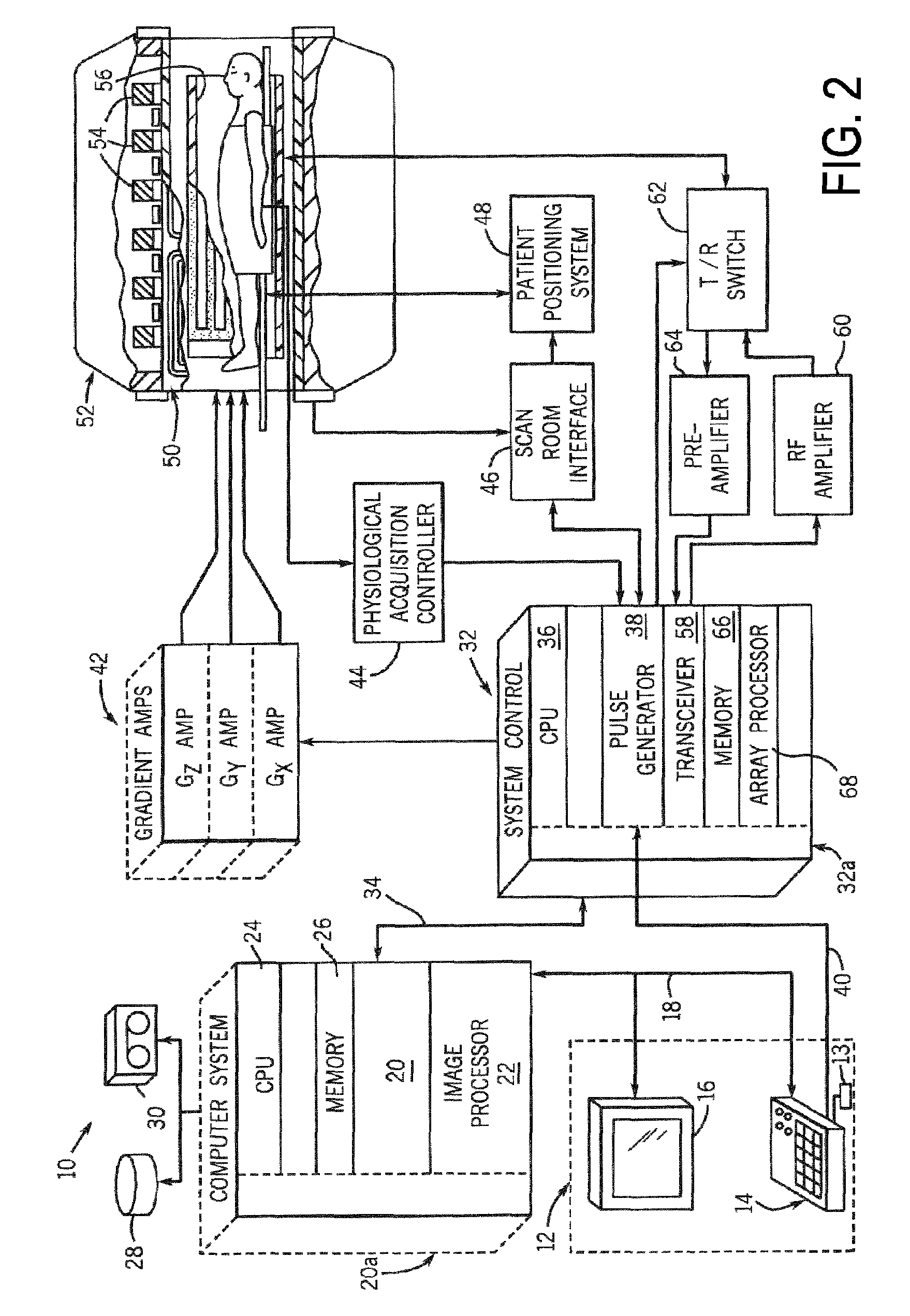

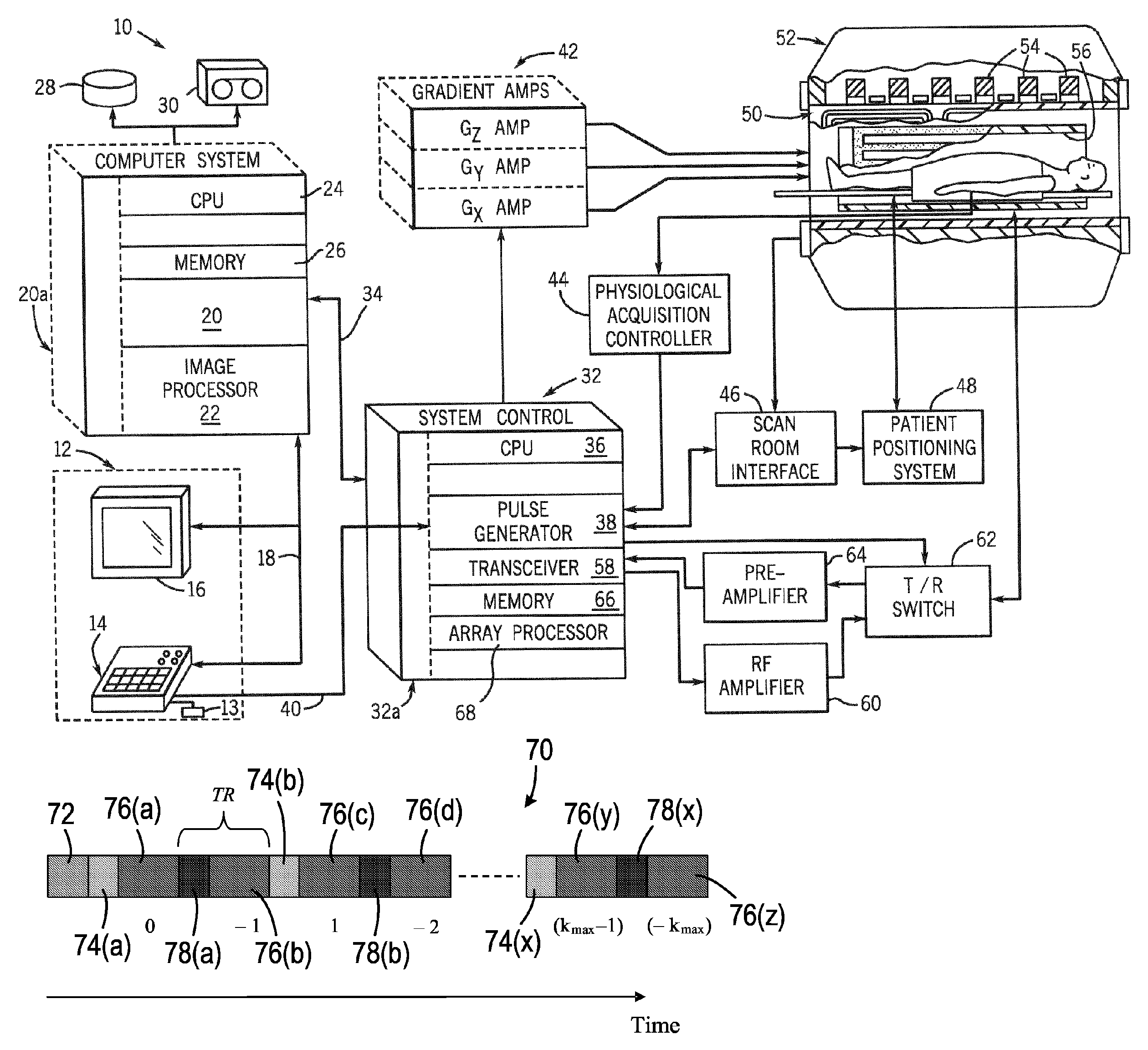

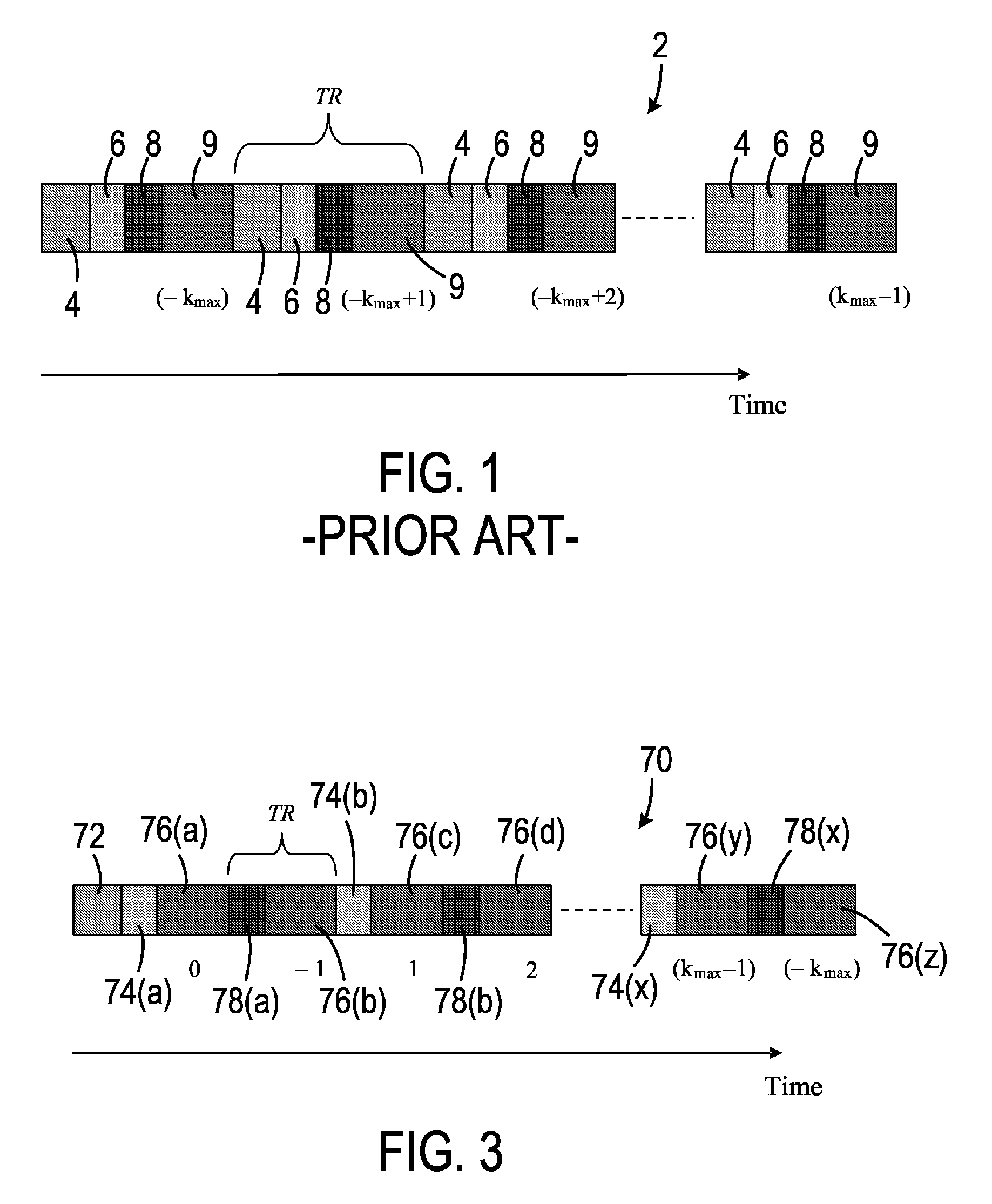

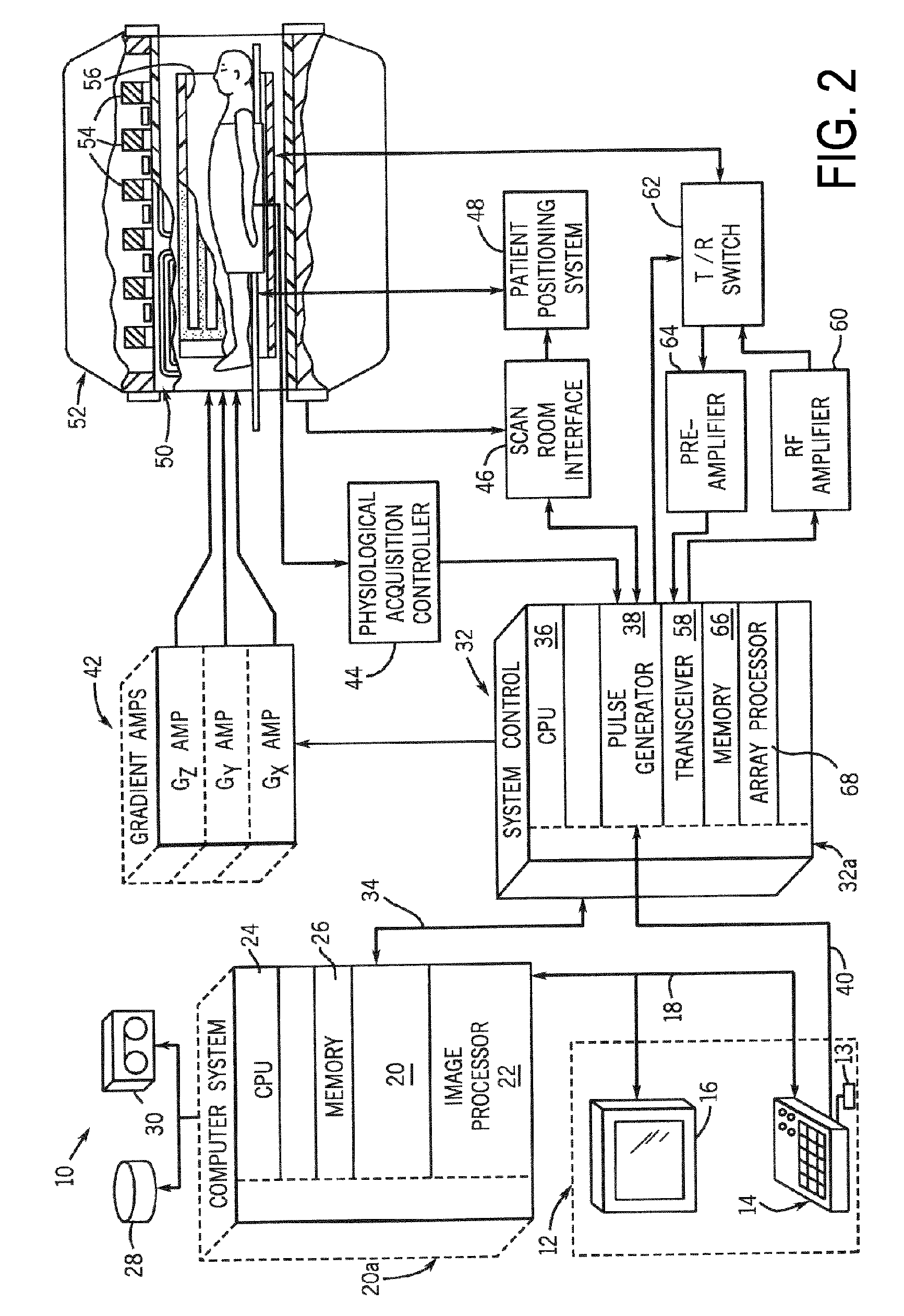

Apparatus and method of simultaneous fat suppression, magnetization transfer contrast, and spatial saturation for 3D time-of-flight imaging

ActiveUS7330028B2Improve image qualityIncrease contrastMagnetic measurementsElectric/magnetic detectionFat suppressionImaging quality

A pulse sequence for time-of-flight (TOF) magnetic resonance angiography (MRA) includes a fatsat segment, a magnetization transfer segment, and a spatial saturation segment that are applied by an MR apparatus to acquire MR data for image reconstruction with improved image quality. The pulse sequence is constructed such that at the beginning of each iteration of the inner loop of a 3D acquisition, a fatsat pulse is applied. After the fatsat pulse, MR data is acquired in a series of imaging segments with well-suppressed fat signal. Effective fat suppression is achieved by sampling central k-space data first, before signal from fat relaxes back to a pre-saturation level. Each imaging segment is immediately preceded by one of a MT pulse or a spatial saturation pulse and immediately followed by the other one of the MT pulse or the spatial saturation pulse.

Owner:GENERAL ELECTRIC CO

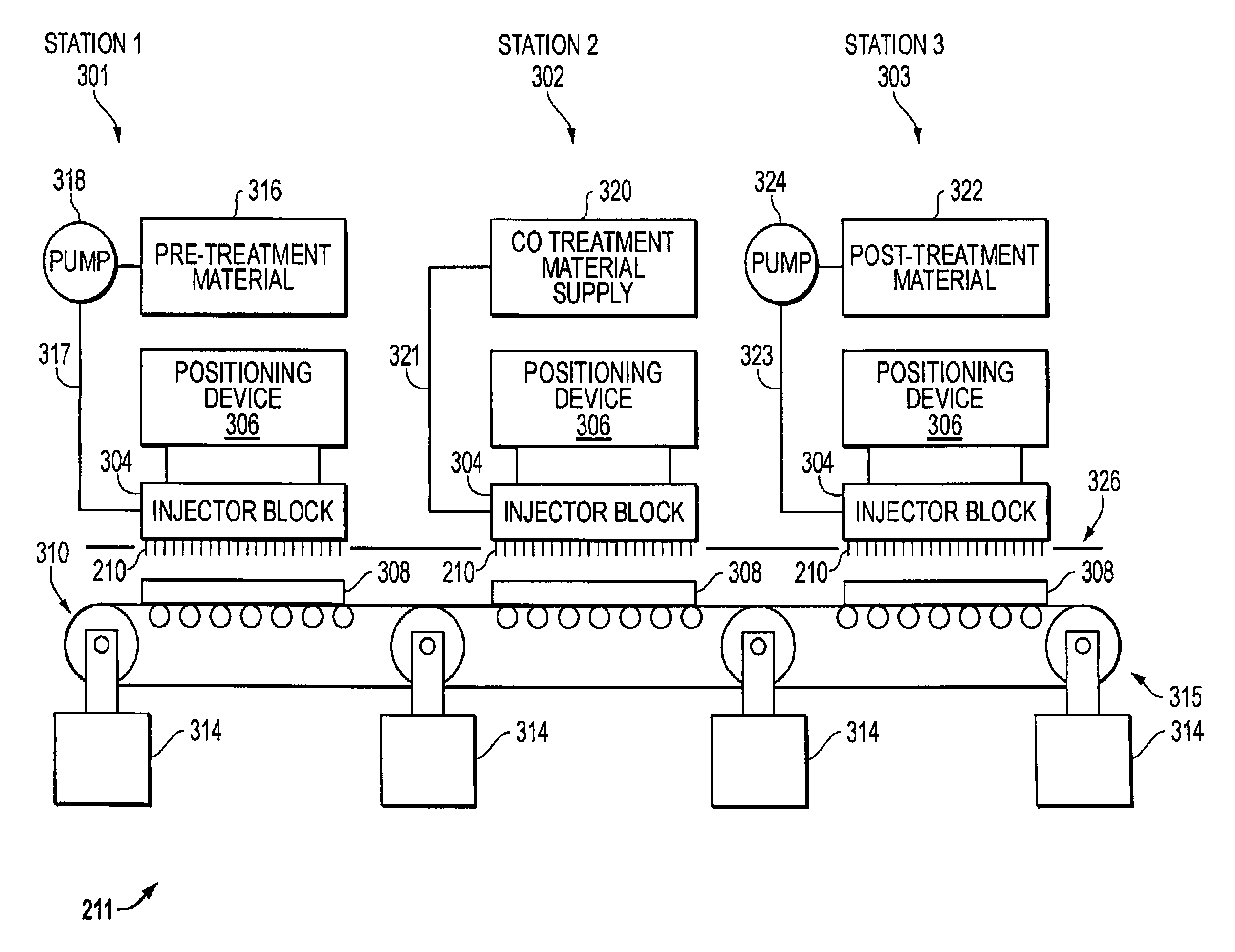

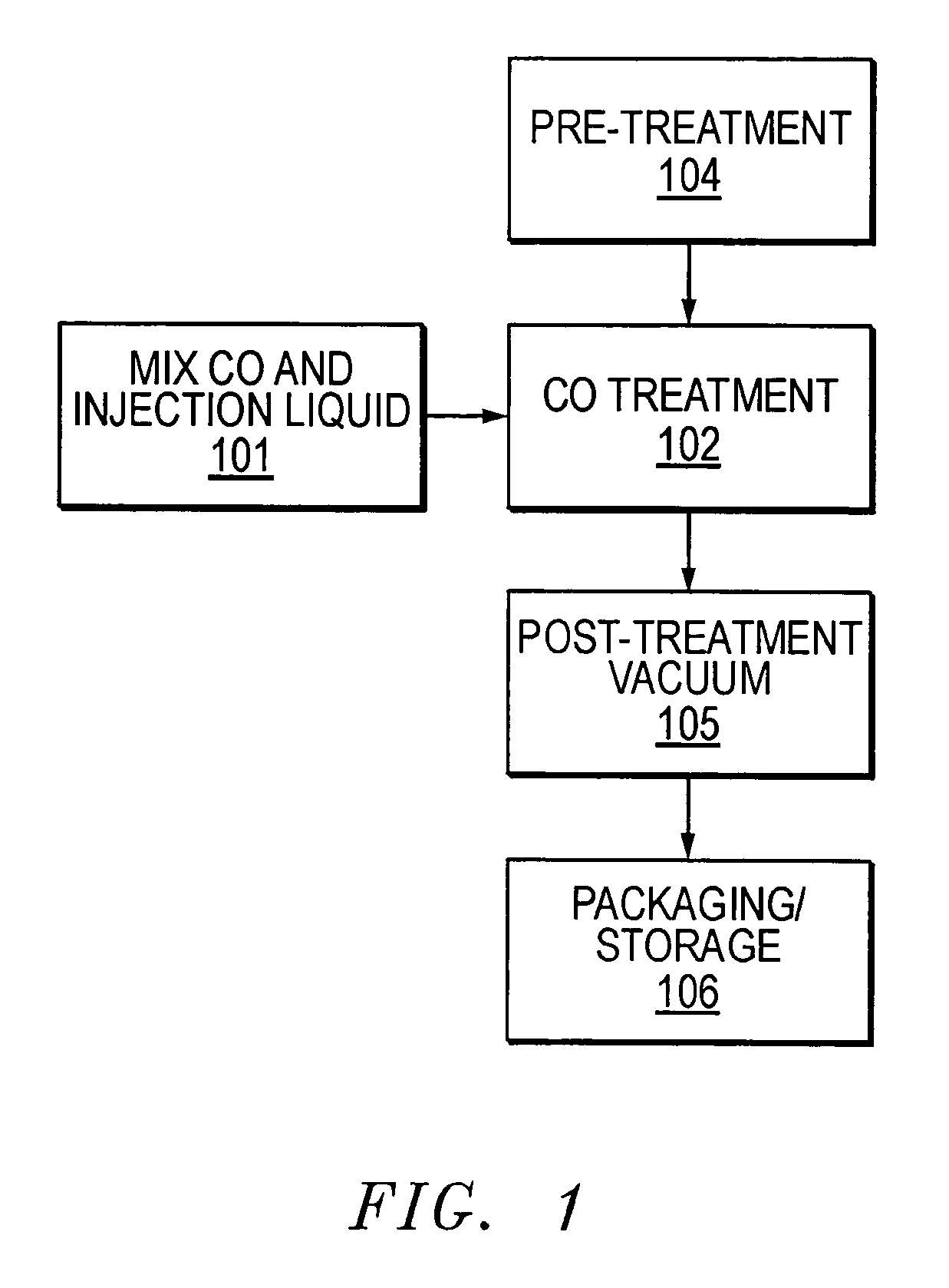

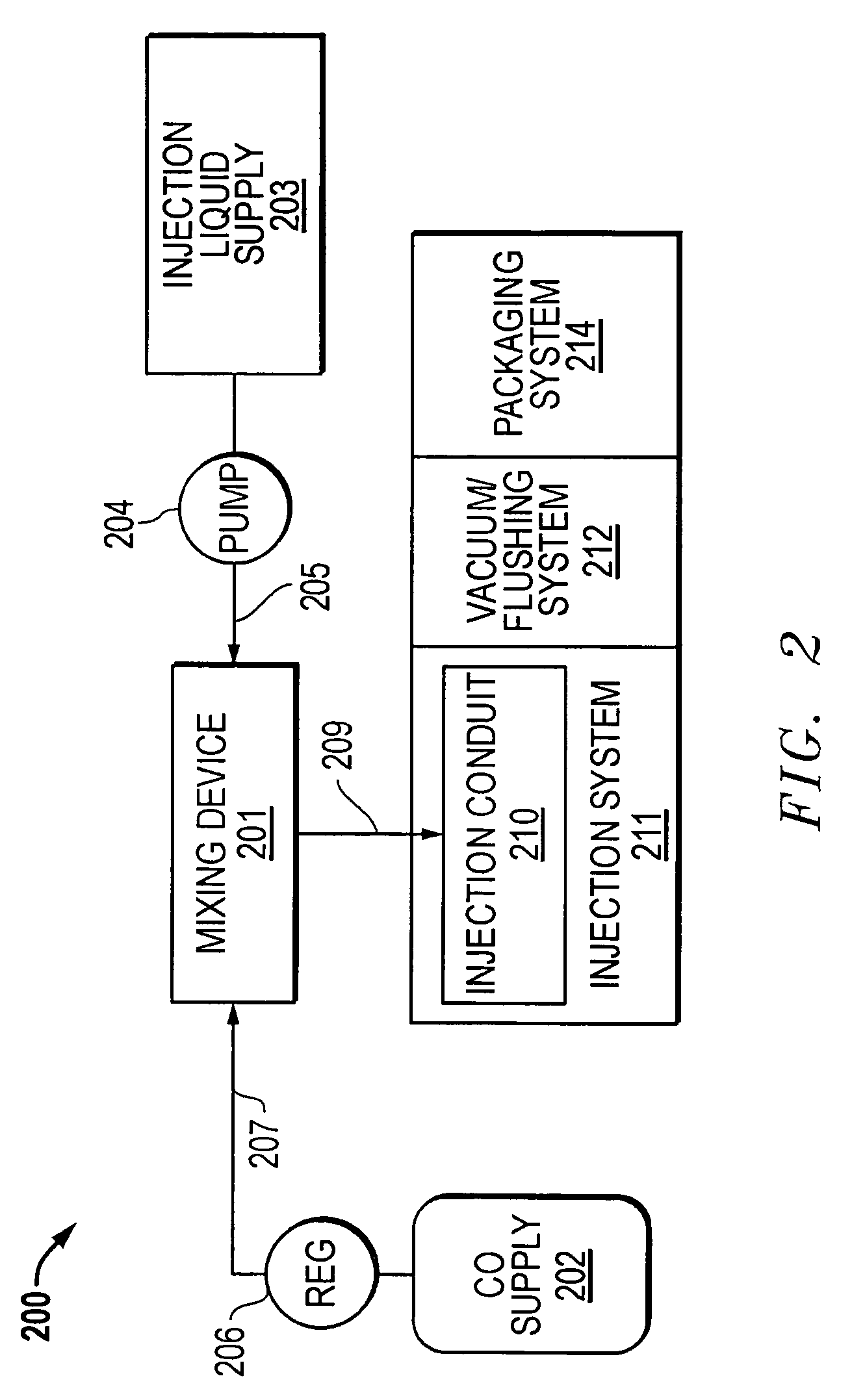

Method for treating meat products with carbon monoxide

ActiveUS7094435B2Reduce eliminateRaise the pHMilk preservationMeat/fish preservation using liquidsSaturated LevelPre treatment

Carbon monoxide is injected into the interior of the meat product along with other materials to produce a desired carbon monoxide saturation level. The amount of carbon monoxide in the added fluid is controlled to produce a desired carbon monoxide saturation level distributed substantially evenly throughout the volume of the meat product. This desired saturation level may vary depending upon the nature of the meat product being treated, however, the saturation level will generally remain at less than 100% or complete saturation for most meat products. The liquid added to meat product may be added simultaneously with the carbon monoxide or may be added as a pre-treatment before application of carbon monoxide or as a post-treatment after the application of carbon monoxide.

Owner:FREEZING MACHINES

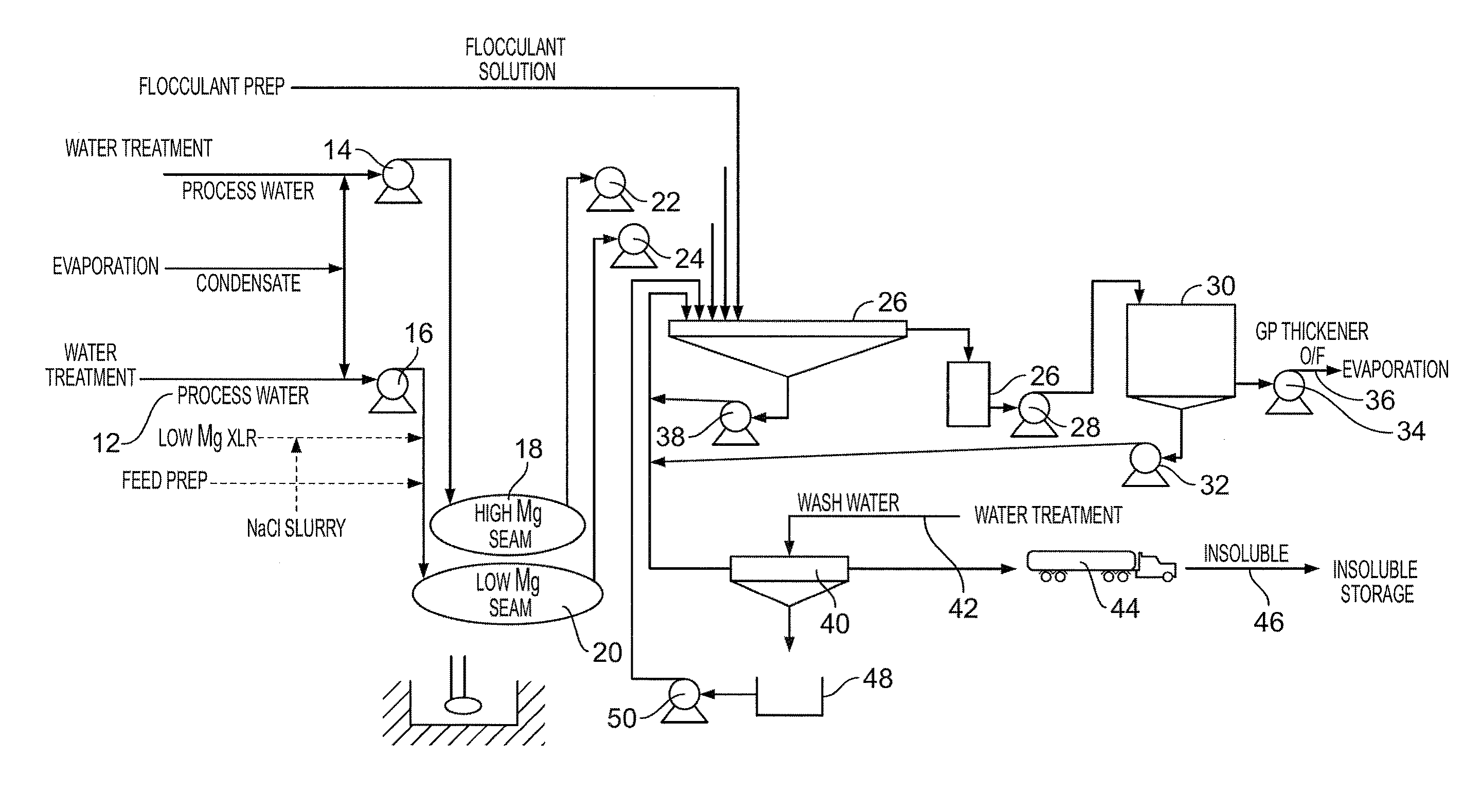

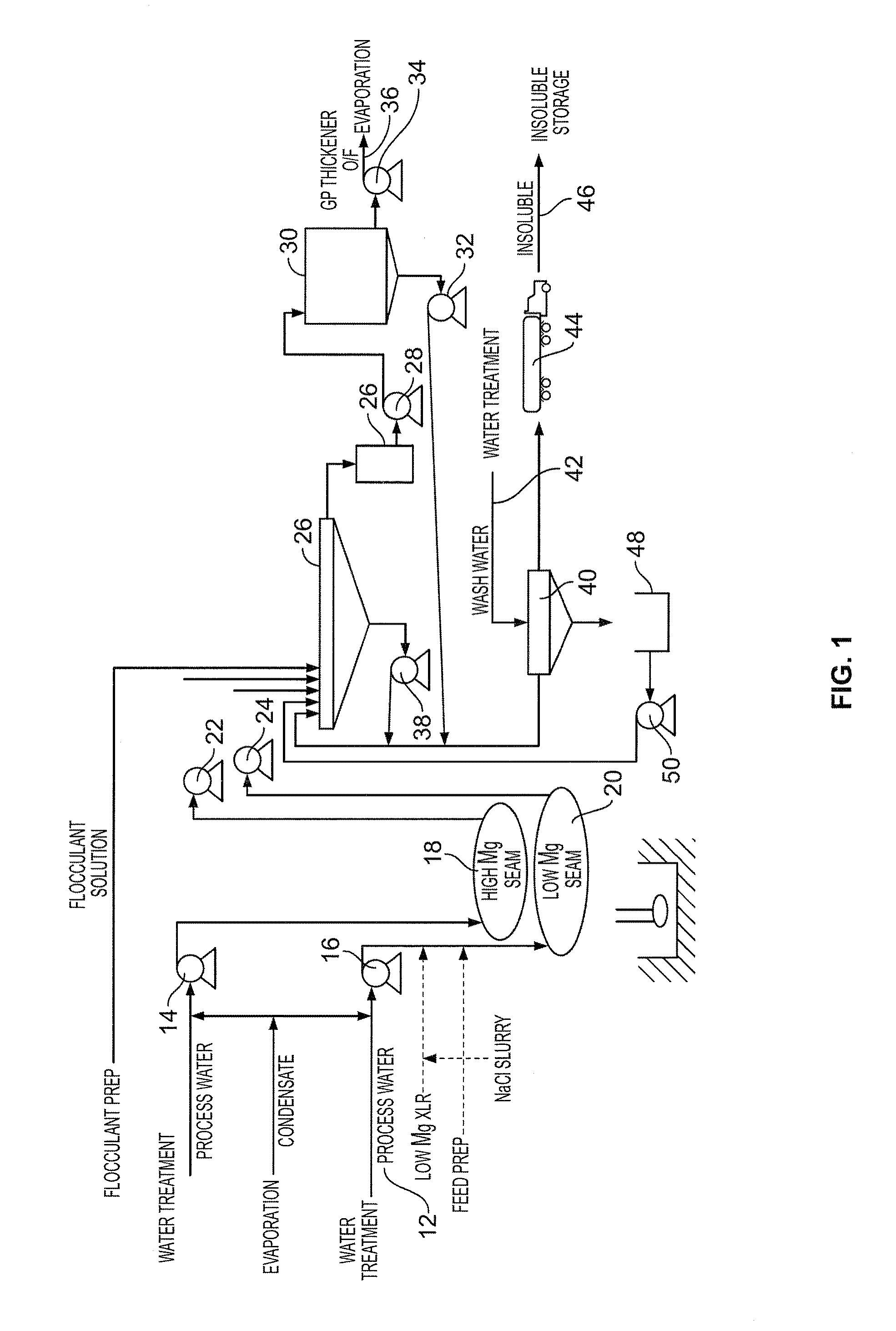

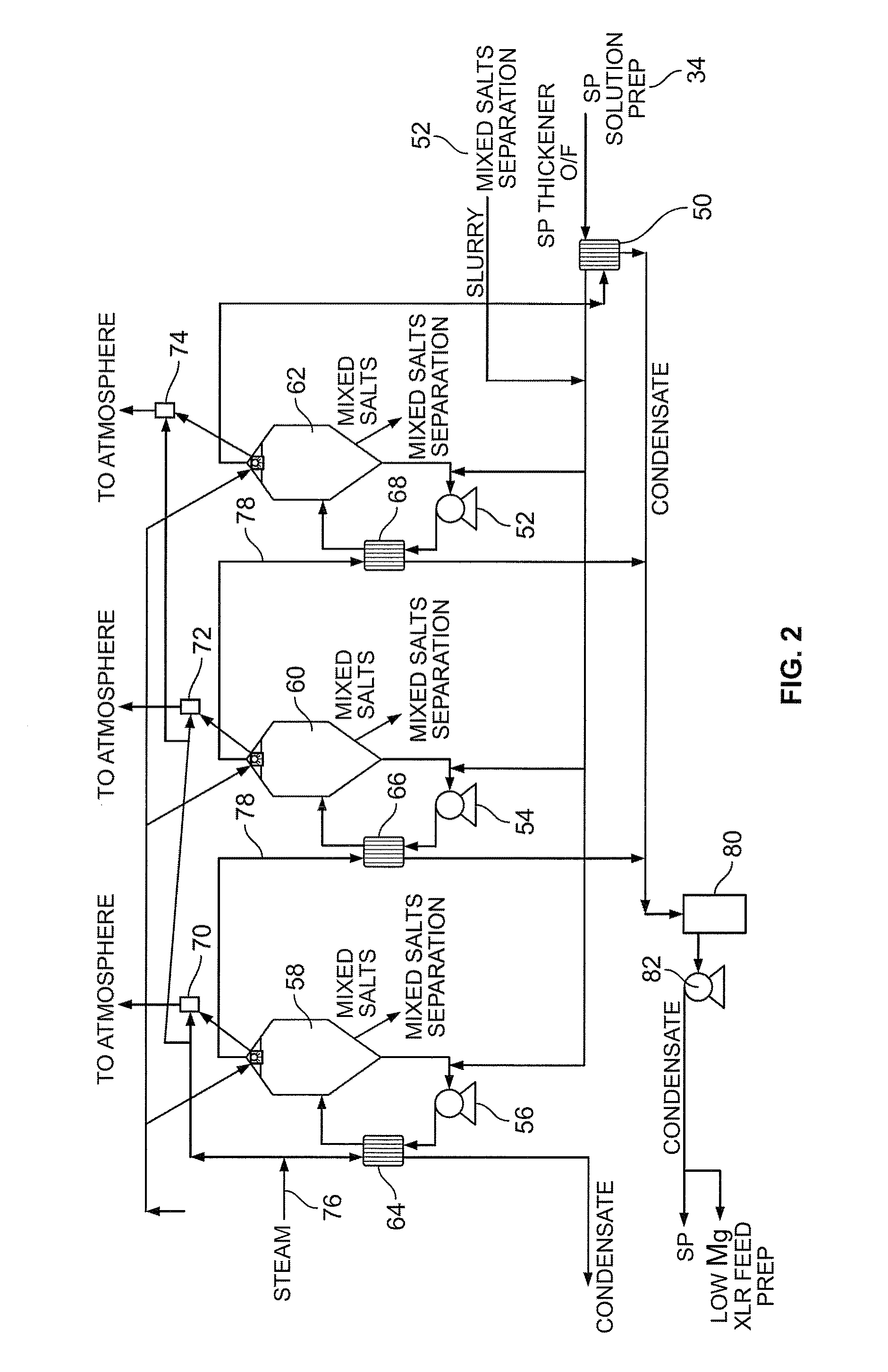

Process for the formulation of potassium chloride from a carnallite source

ActiveUS20110123420A1Speed up the processSolvent extractionCrystallization separationSolubilitySaturated Level

A process for formulating high purity potassium chloride from a carnallite source. The process takes advantage of solubility differences and saturation levels in a multiple salt system generated upon dissolution of carnallite. In the system, the sodium chloride is kept in solution and the magnesium chloride present in the system is controlled to be in a concentration range of between 12% and 25% by weight. This avoids co-precipitation of sodium chloride with the potassium chloride during crystallization and therefore prevents the sodium chloride from contaminating the potassium chloride. The result is high grade potassium chloride.

Owner:KARNALYTE RESOURCES

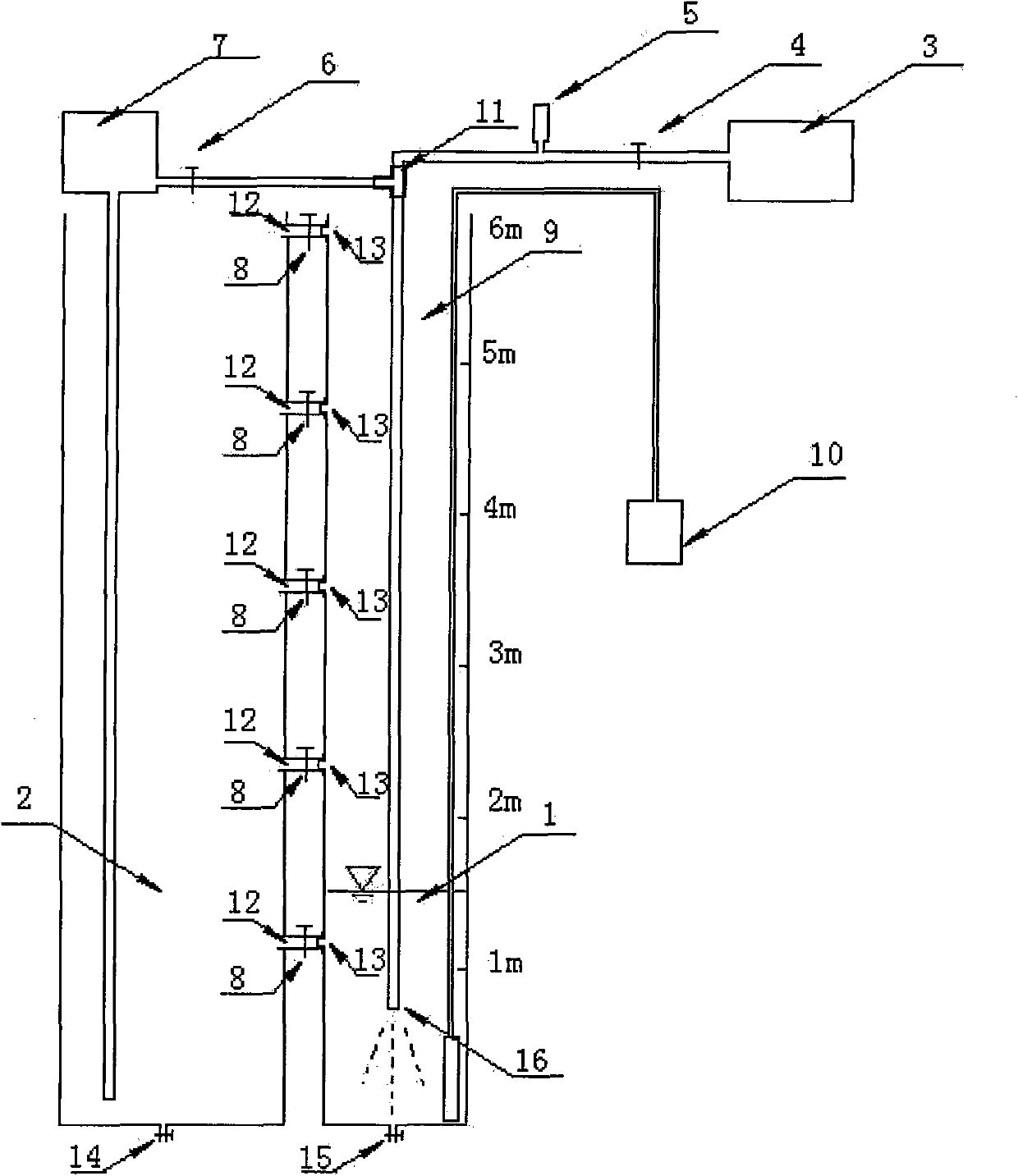

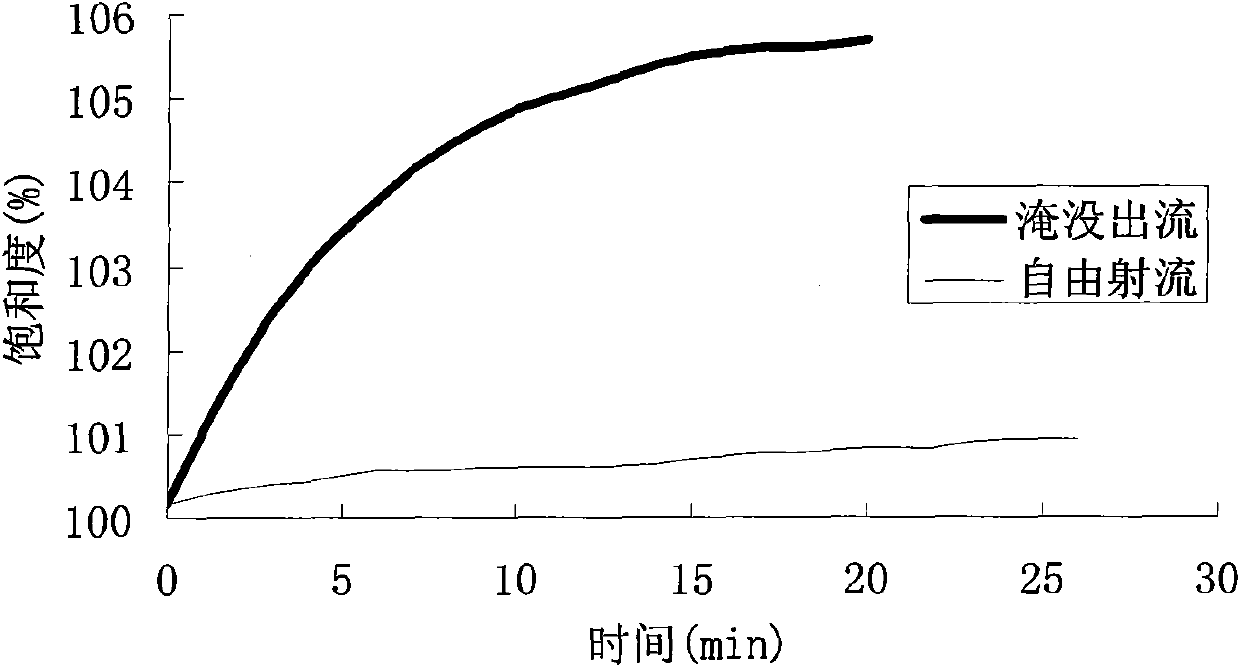

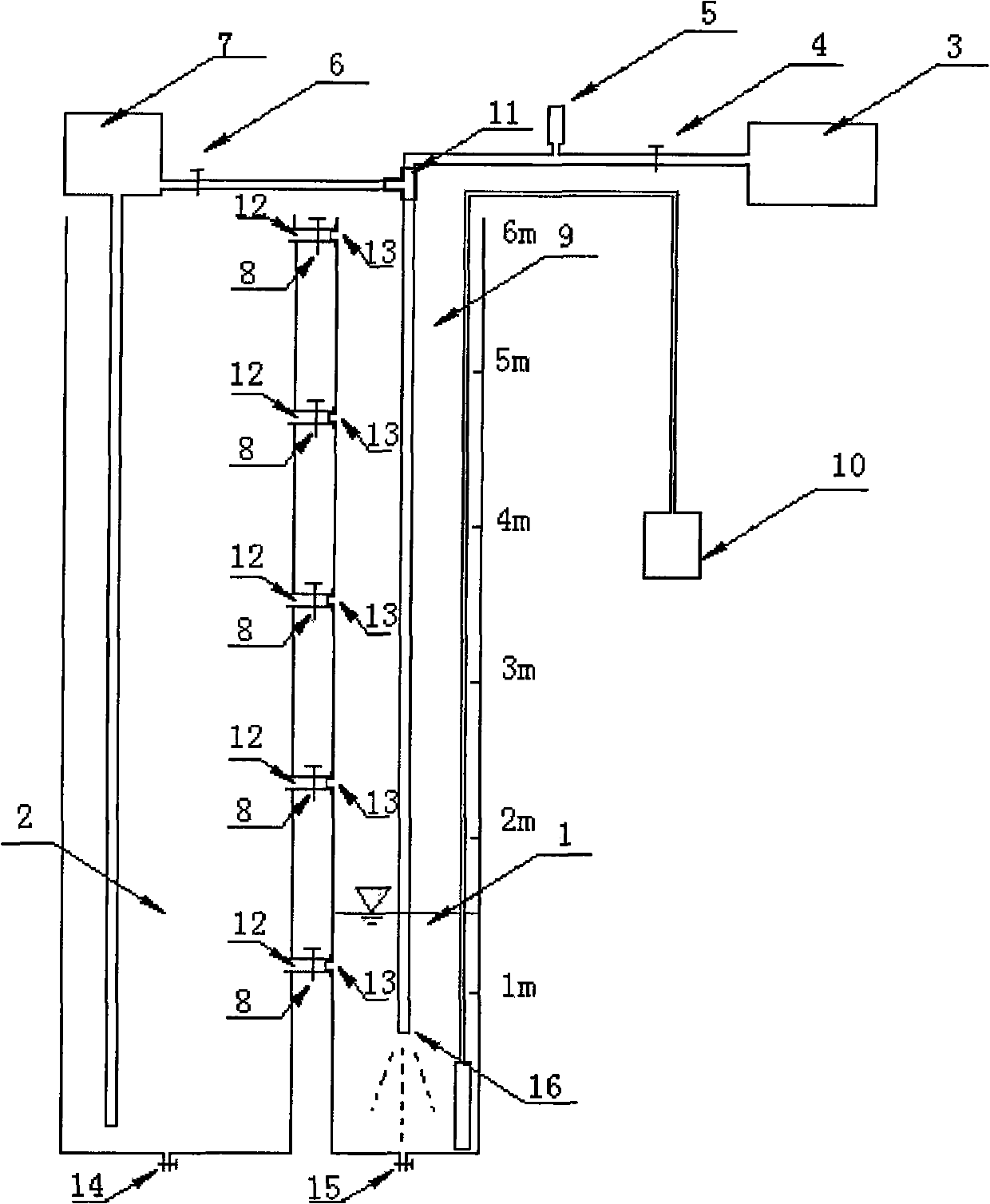

Experimental device for forming jet flow by drifting water with high-speed airflow and generating supersaturated total dissolved gas

The invention relates to an experimental device for forming jet flow by drifting water with a high-speed airflow and generating supersaturated total dissolved gas, which comprises a water column, a flowmeter, an air compressor, valves, a total dissolved gas determinator, a water pump, a jet pipe, a nozzle and a nozzle hole. The water column is designed into a main water column and an auxiliary water column, the nozzle hole in the wall of the main water column is connected with a rubber hose, a third valve is mounted on the rubber hose and communicated with the auxiliary water column, the air compressor is connected with one end of the flowmeter by a first valve, the other end of the flowmeter is connected with the jet pipe by a three-way pipe, the jet pipe is connected with the nozzle which is arranged in the main water column, the three-way pipe is connected with the water pump by a second valve, the water pump is arranged in the auxiliary water column by a pipeline, a fourth valve is mounted at the bottom of the auxiliary water column, a fifth valve is mounted at the bottom of the main water column, and a probe of the total dissolved gas determinator is inserted in the main water column. The experimental device can be used for simulating the submerged discharge, the free discharge and the total dissolved gas saturation process of different front-dam flows to research the relation between the supersaturation level and the front-dam total dissolved gas saturation.

Owner:SICHUAN UNIV

Aluminium production cells with iron-based metal alloy anodes

InactiveUS20050000823A1Reduce pollutionMachining electrodesElectrical-based machining electrodesElectrolysisRare earth

An iron-based metal anode for the electrowinning of aluminium by the electrolysis of alumina in a molten fluoride electrolyte has an electrochemically active integral outside oxide layer on an iron-based alloy that consists of 75 to 90 weight % iron; 0.5 to 5 weight % in total of at least one rare earth metal, in particular yttrium; 1 to 10 weight % aluminium; 0 to 10 weight % copper; 0 to 10 weight % nickel; and 0.5 to 5 weight % of other elements. The total amount of aluminium, copper and nickel is in the range from 5 to 20 weight %; and the total amount of rare earth metal(s), aluminium and copper is also in the range from 5 to 20 weight %. The electrochemically active surface layer is predominantly of iron oxide that slowly dissolves into the electrolyte during operation and is maintained by progressive slow oxidation of iron at the interface of the bulk metal of the alloy with the oxide layer. This progressive slow oxidation of iron corresponds to the dissolution of iron into the electrolyte which remains at or below saturation level at the operating temperature, the operating temperature being maintained sufficiently low to limit the contamination of the product aluminium to an acceptable level, and the electrolyte being circulated to maintain a sufficient concentration of alumina in the anode cathode gap.

Owner:NGUYEN THINH T +2

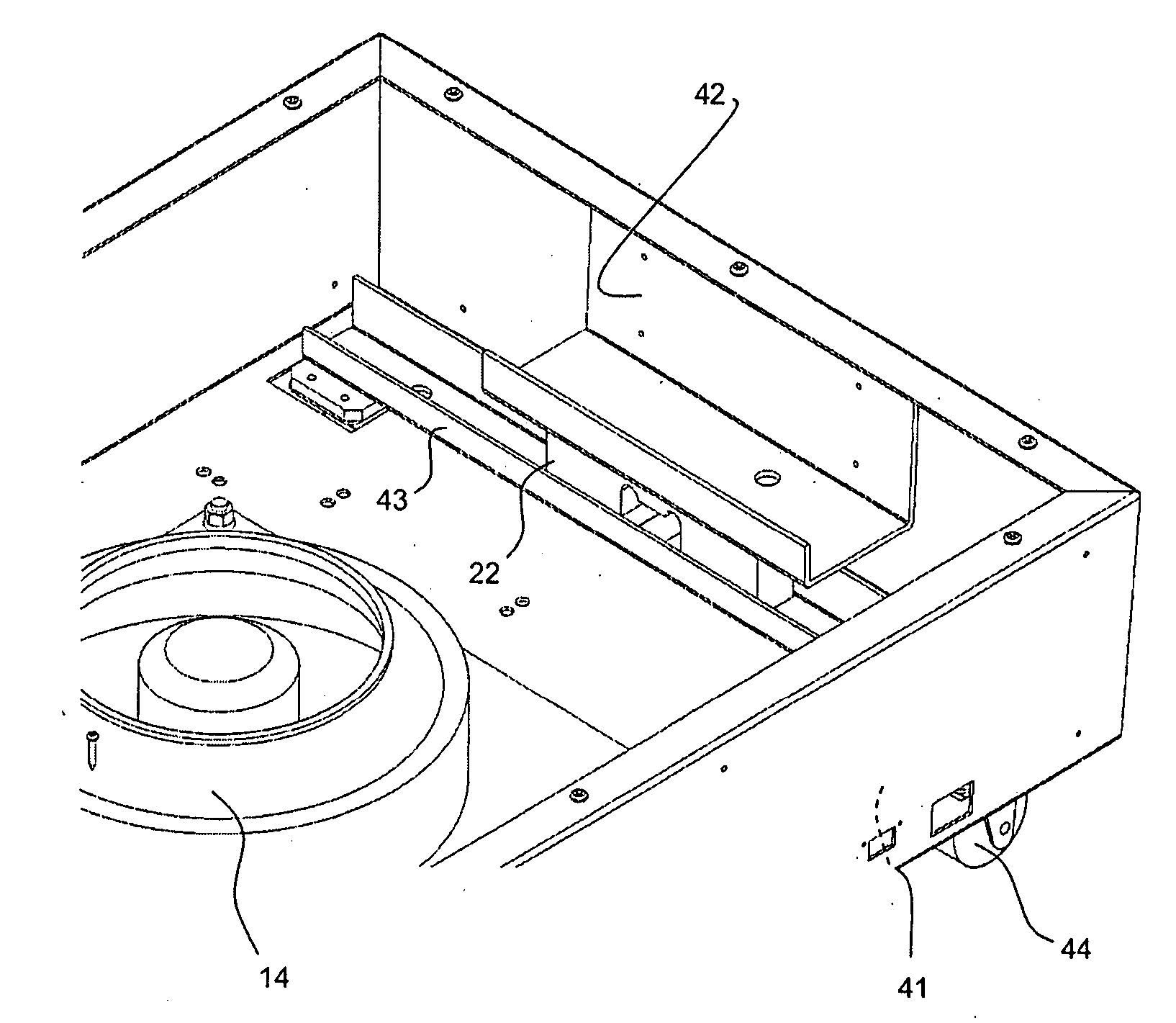

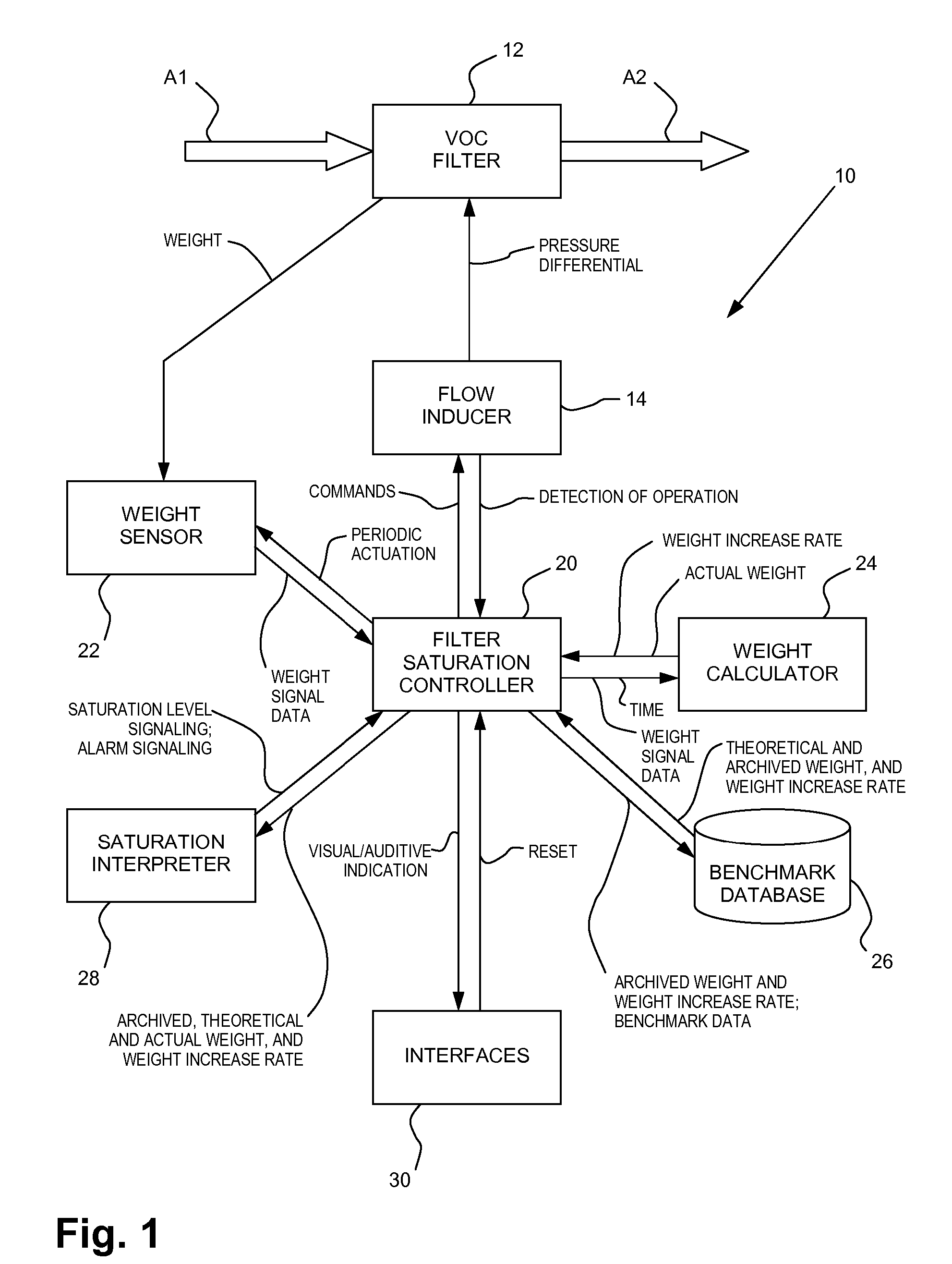

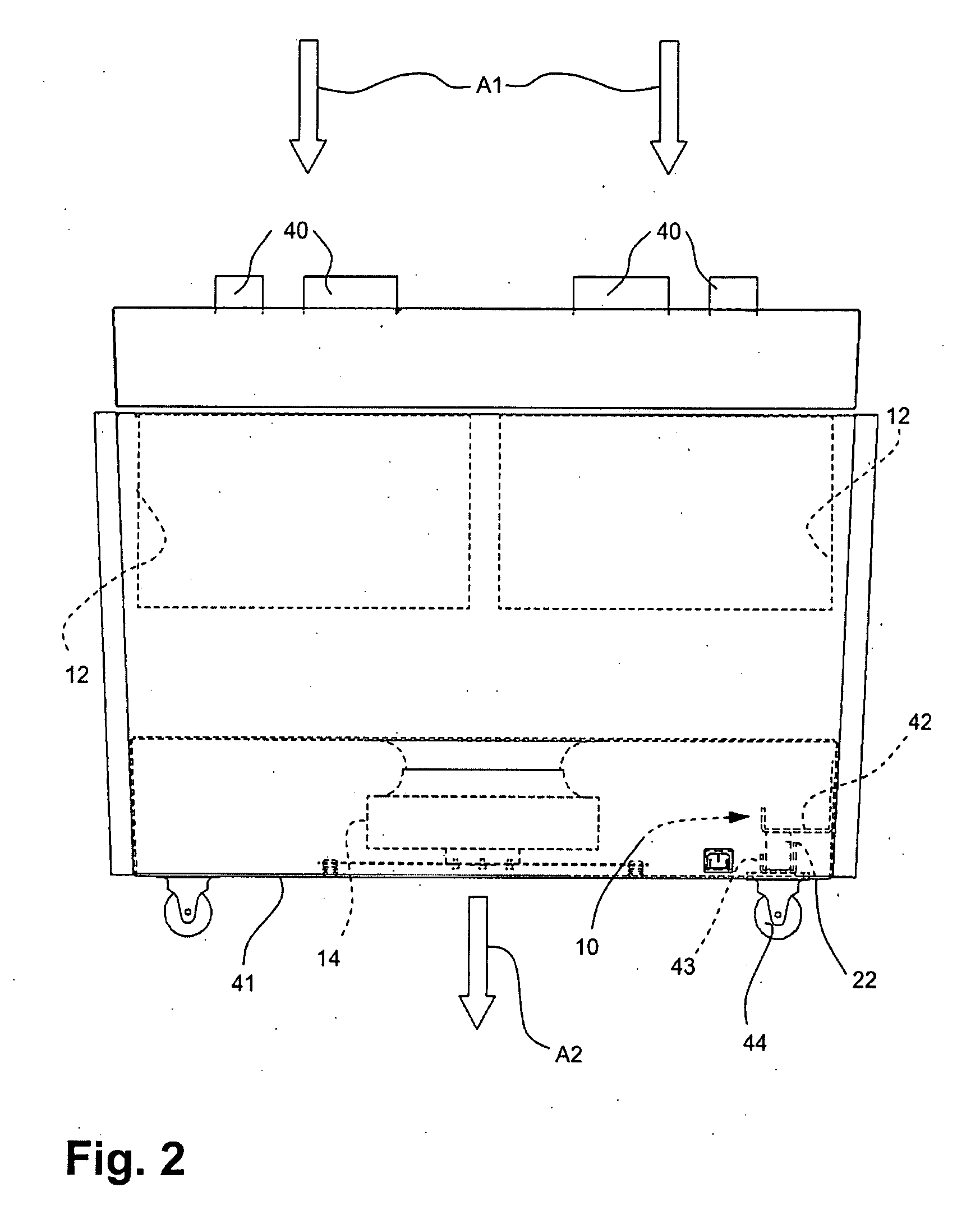

Filter saturation control system

A system for determining a level of saturation of a VOC filter in a filtering apparatus, including a weight sensor for sensing a weight of at least a portion of the filtering apparatus including the VOC filter and for producing a corresponding weight signal, a weight calculator for determining an actual weight of the VOC filter based on the weight signal and for producing corresponding actual weight data, a saturation interpreter for determining the level of saturation of the VOC filter based on a comparison between the actual weight data and benchmark weight data, and an interface for providing an indication of the level of saturation.

Owner:PUREX NORTH AMERICA

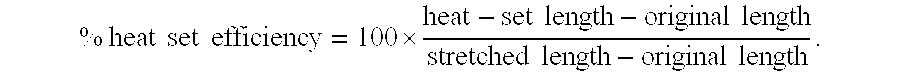

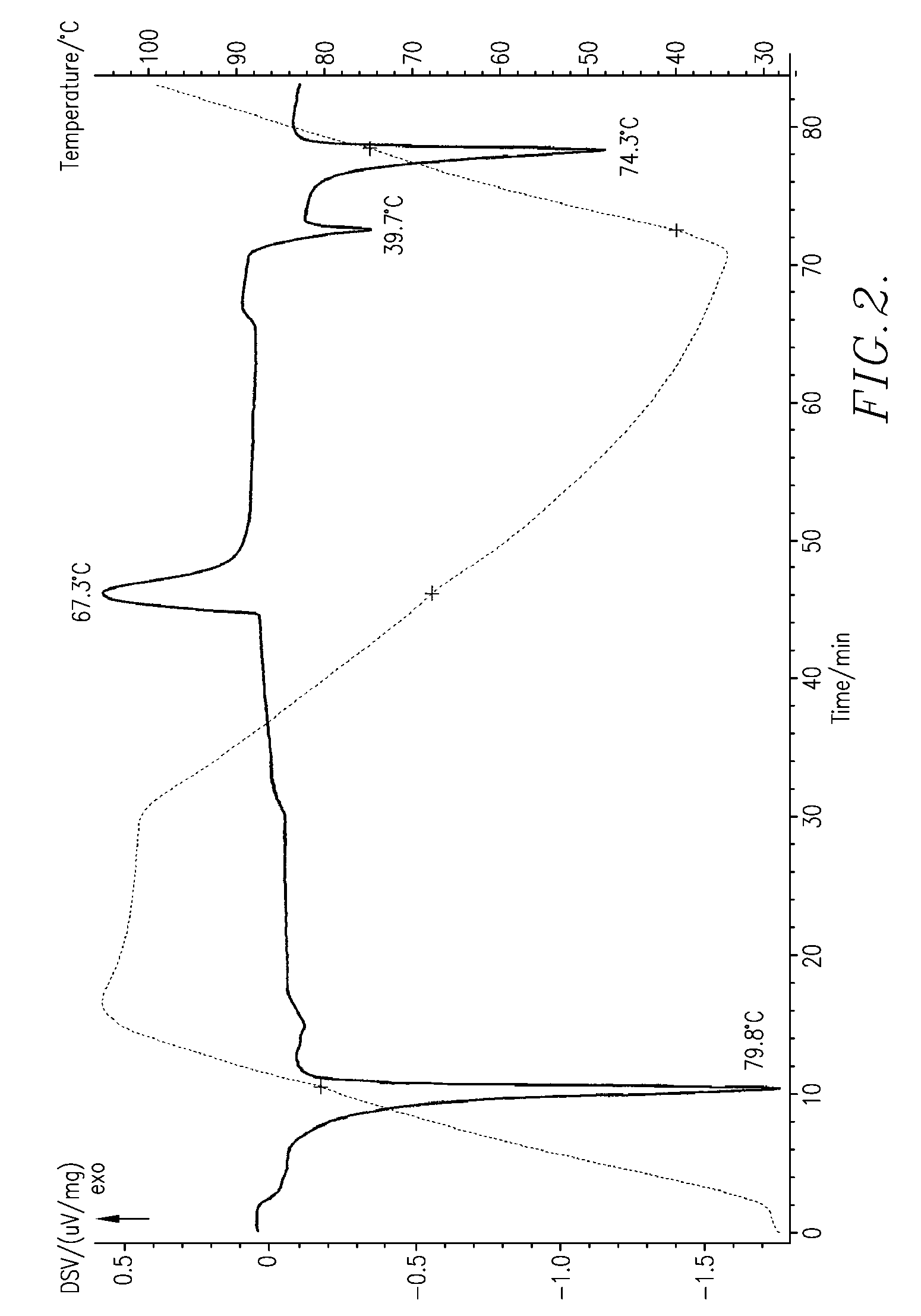

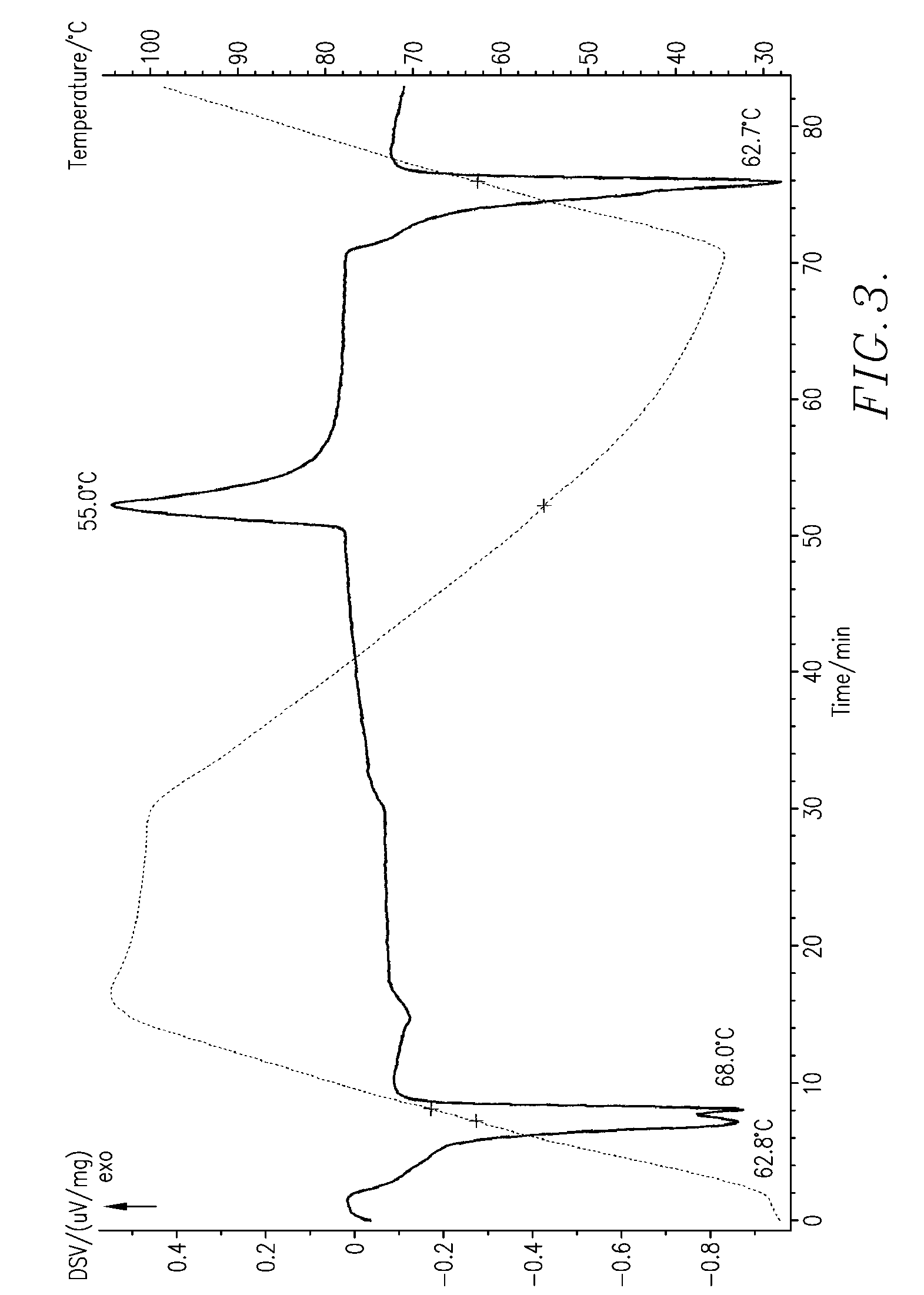

Spandex having low heat-set temperature and materials for their production

InactiveUS20060135724A1Improve efficiencyProduct can be usedMonocomponent polyurethanes artificial filamentEthylenediamineSaturated Level

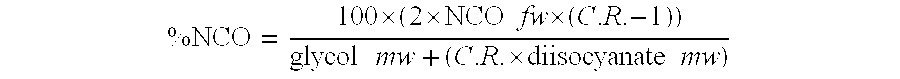

Segmented polyurethane / ureas useful in the production of spandex with improved heat set are produced by chain extending an isocyanate-terminated prepolymer with a diamine chain extender that includes: (1) greater than 25 to 75 equivalent percent of an asymmetric aliphatic and / or cycloaliphatic diamine and (2) a linear diamine such as ethylene diamine in the presence of a solvent. The isocyanate-terminated prepolymer having an isocyanate group content of from about 2.25 to about 4 is produced by reacting a stoichiometric excess of an isocyanate with an isocyanate-reactive component that includes: (1) from about 25 to about 75 equivalent percent of a polyoxypropylene diol having a molecular weight in excess of 1500 Da and an average unsaturation level of less than about 0.03 meq / g and (2) from about 25 to about 75 equivalent percent of a polytetramethylene ether glycol having a molecular weight of at least 600 Da.

Owner:BAYER MATERIALSCIENCE AG +1

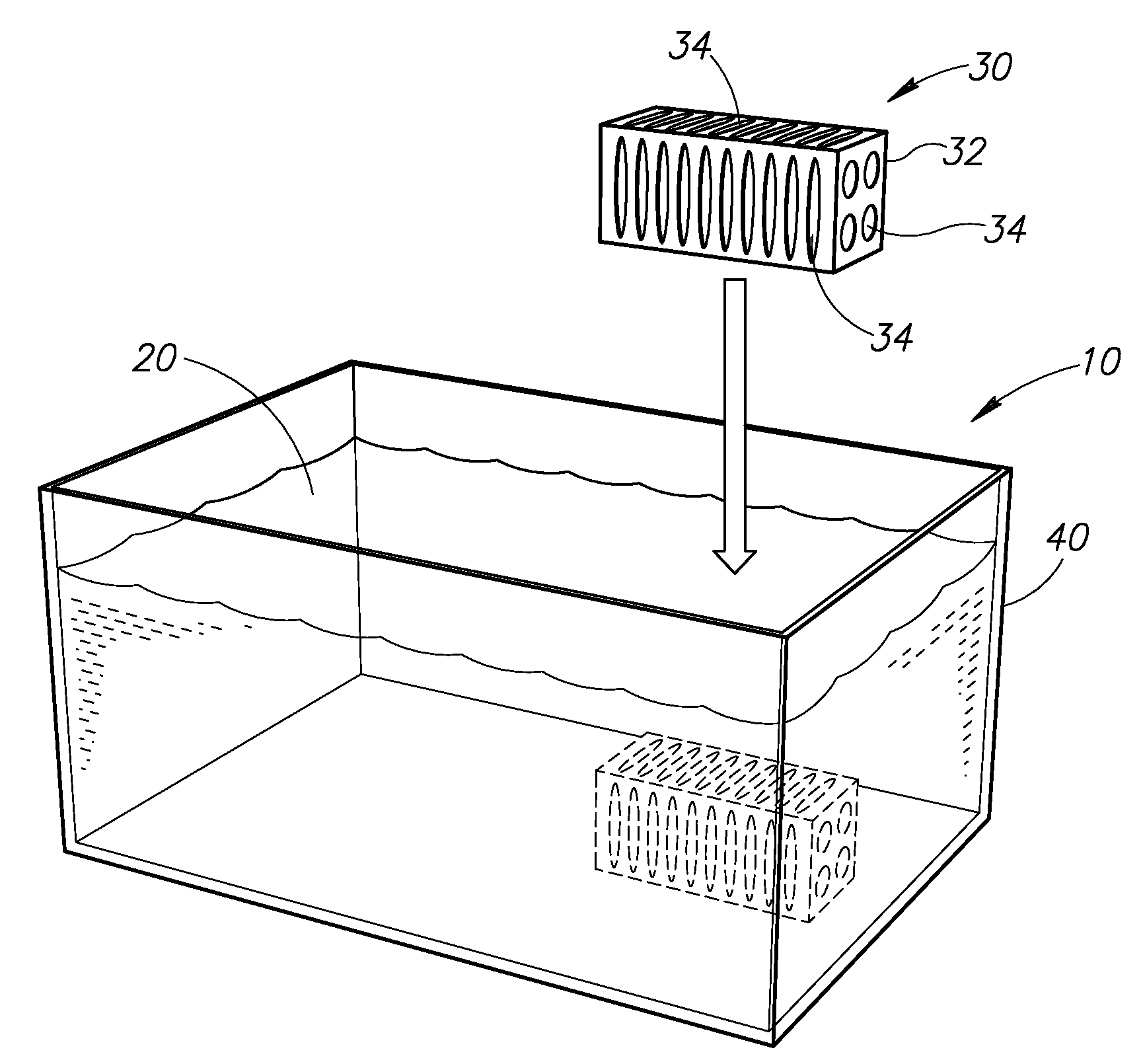

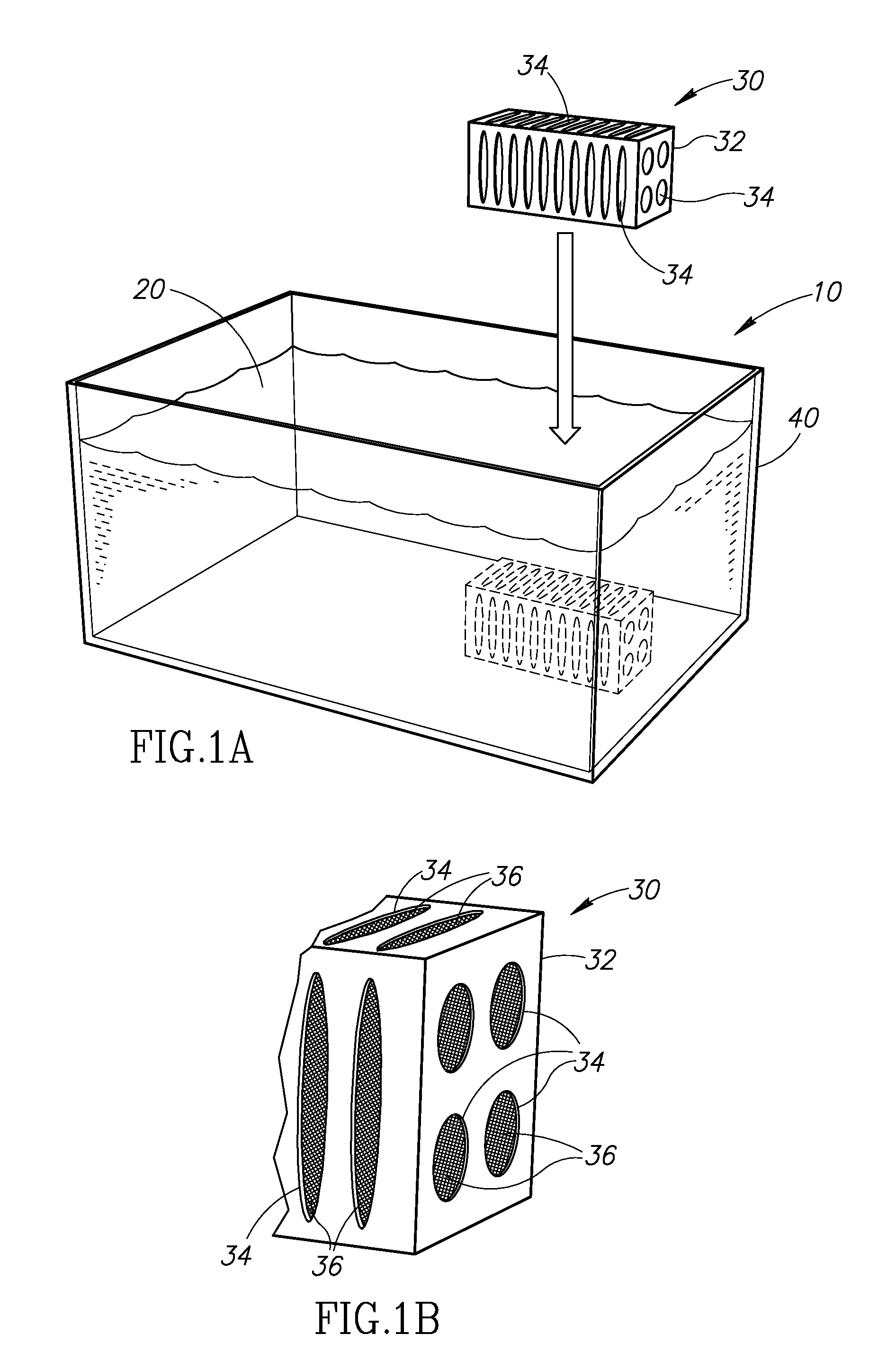

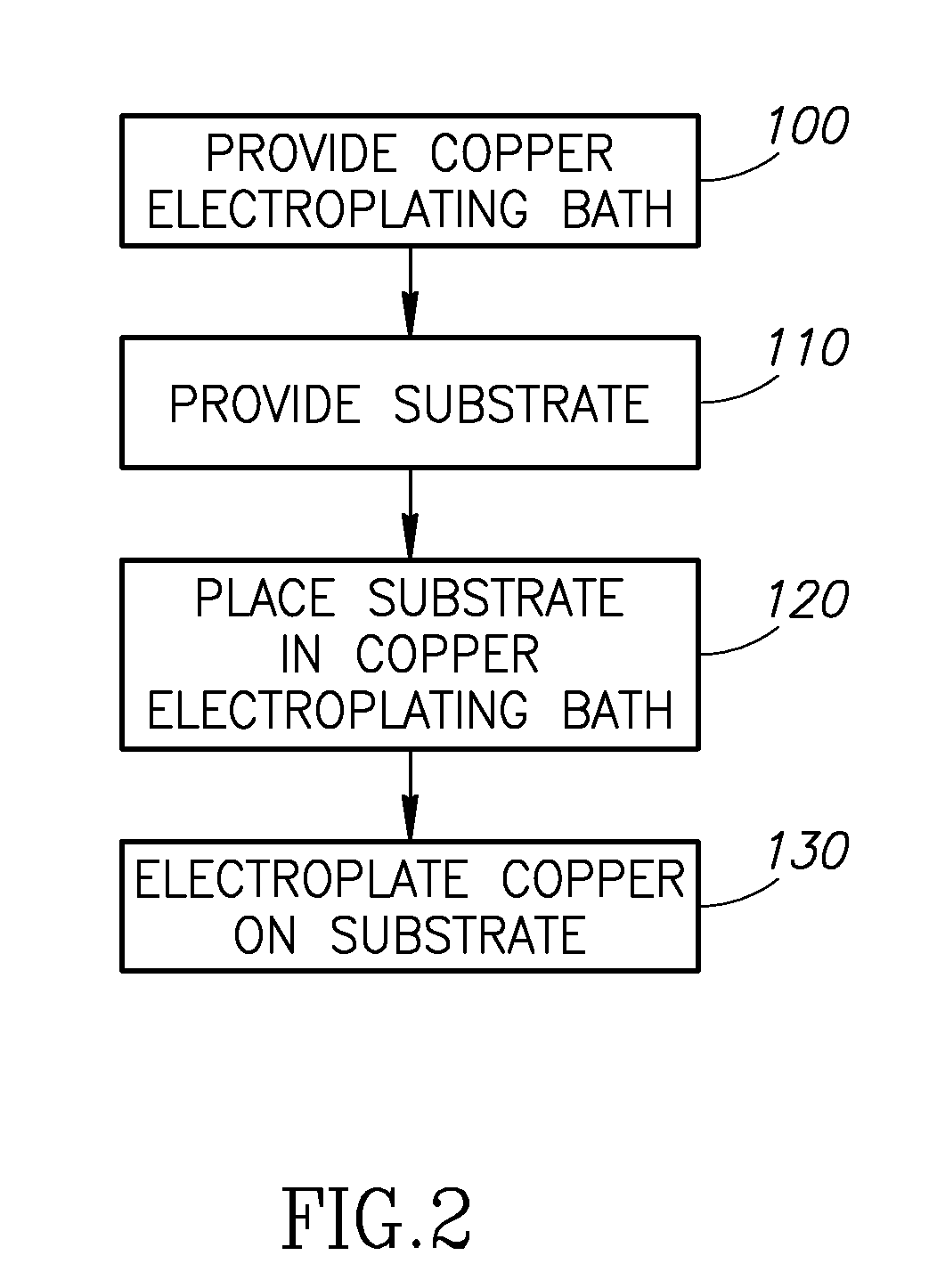

High speed copper plating bath

ActiveUS20100276292A1Increase speedImprove solubilityCellsSemiconductor/solid-state device manufacturingCopper platingSaturated Level

A copper electroplating bath that includes an aqueous solution that comprises a copper salt and at least one acid and a container that comprises a copper salt in solid form, is disclosed. The container supplies copper ions to the aqueous solution to maintain the copper ion concentration of the aqueous solution at saturation levels while retaining the copper salt in solid form within the container.

Owner:MOSES LAKE INDS

Apparatus and method of simultaneous fat suppression, magnetization transfer contrast, and spatial saturation for 3D time-of-flight imaging

ActiveUS20070069724A1Improve image qualityEffective applicationMagnetic measurementsElectric/magnetic detectionFat suppressionImaging quality

A pulse sequence for time-of-flight (TOF) magnetic resonance angiography (MRA) includes a fatsat segment, a magnetization transfer segment, and a spatial saturation segment that are applied by an MR apparatus to acquire MR data for image reconstruction with improved image quality. The pulse sequence is constructed such that at the beginning of each iteration of the inner loop of a 3D acquisition, a fatsat pulse is applied. After the fatsat pulse, MR data is acquired in a series of imaging segments with well-suppressed fat signal. Effective fat suppression is achieved by sampling central k-space data first, before signal from fat relaxes back to a pre-saturation level. Each imaging segment is immediately preceded by one of a MT pulse or a spatial saturation pulse and immediately followed by the other one of the MT pulse or the spatial saturation pulse.

Owner:GENERAL ELECTRIC CO

Non-hydrogenated vegetable oil based shortening containing an elevated diglyceride emulsifier composition

ActiveUS7691428B2Without the attendant negative effects on cardiovascular healthDesirable consistencyFatty acid esterificationEdible oils/fats with aqeous phaseSaturated LevelTriglyceride

A mono-, di-, and triglyceride emulsifier composition is provided that is obtained by the interesterification or glycerolysis of triglycerides with glycerol. The diglyceride portion w / w is at least about 65% to about 80%, and most preferably from about 70% to about 80% (HiDi). The high diglyceride emulsifier is useful in preparing a trans free shortening from a non-hydrogenated vegetable oil for use in bakery goods, which then have a significantly lower saturated fat content and a substantially higher polyunsaturated level than heretofore available when a conventional mono- and diglyceride emulsifier is used in the goods. A preferred shortening that is predominantly in stable beta prime crystalline form is prepared by mixing on a weight to weight basis from about 10% to about 30%, and preferably about 15% to 20%, of the HiDi composition, with the remainder being non-hydrogenated soybean oil.

Owner:CARAVAN INGREDIENTS

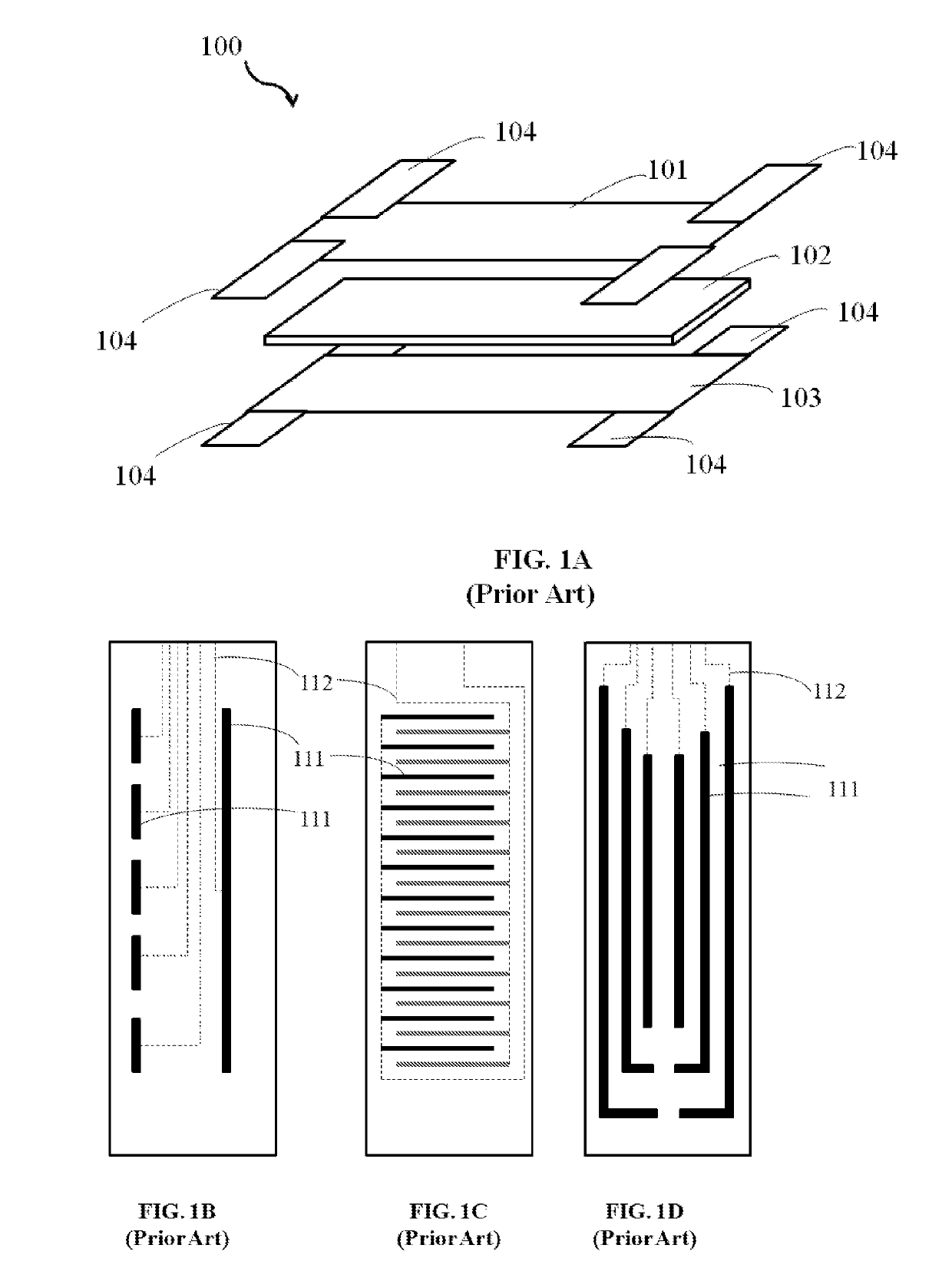

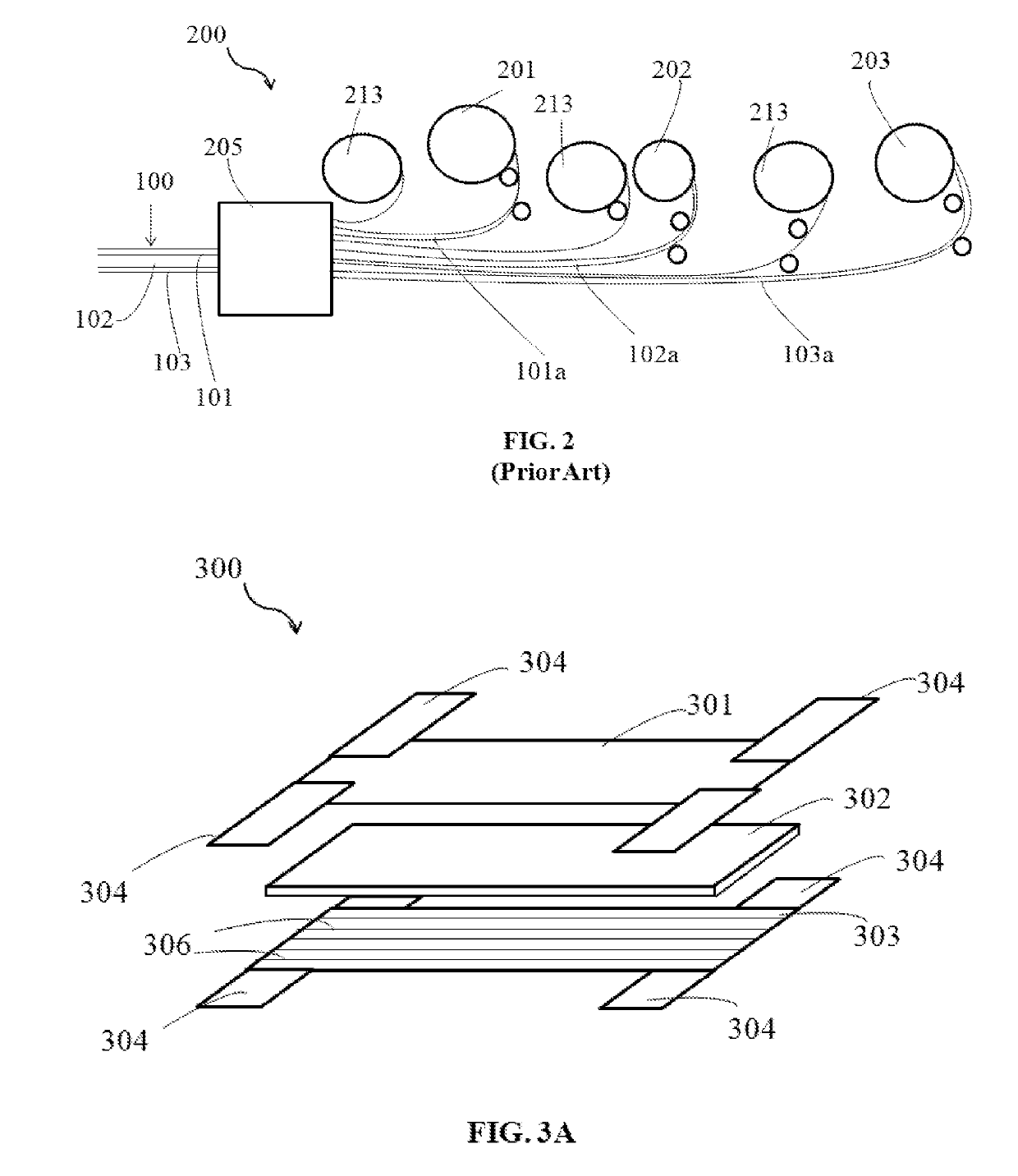

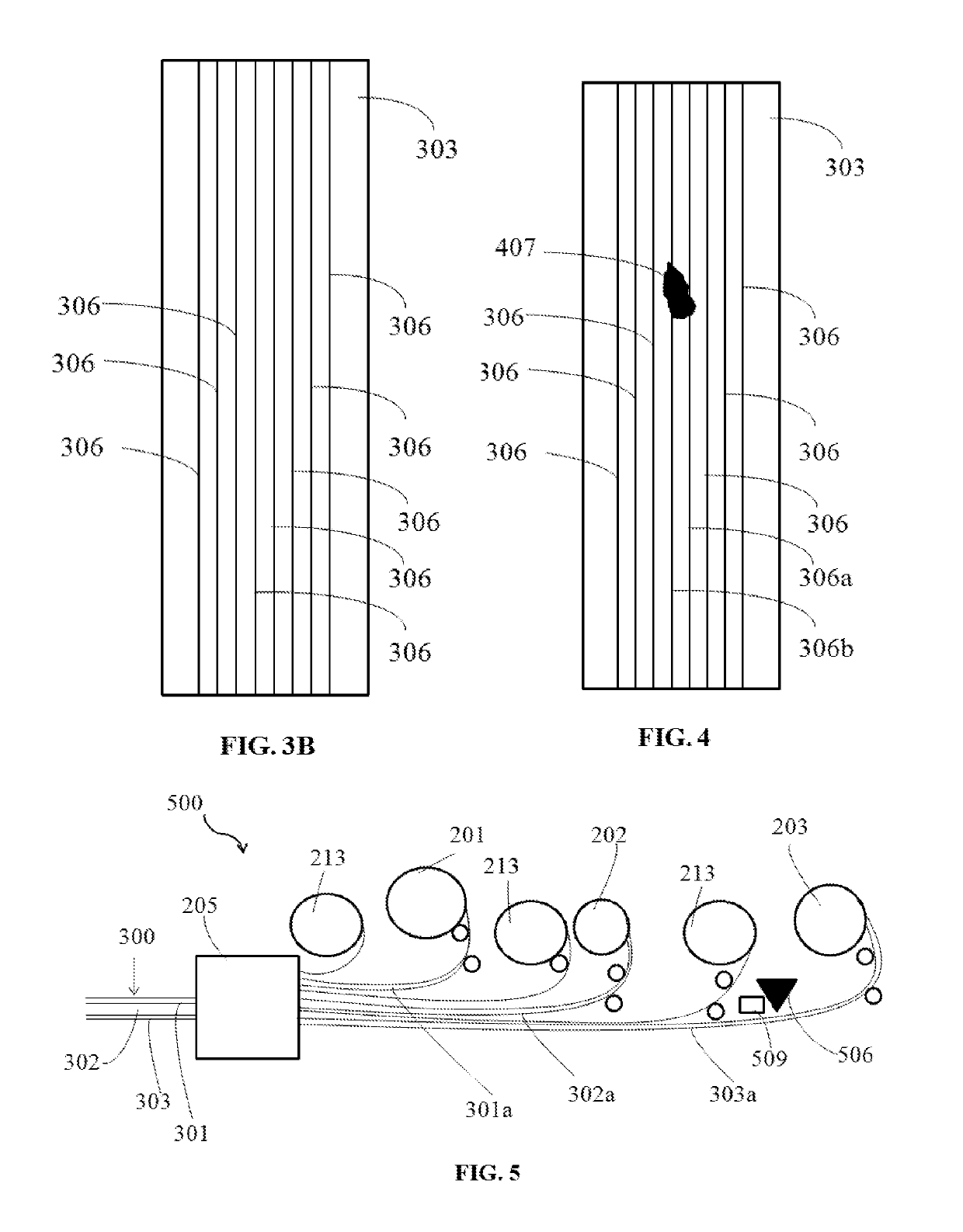

Method of manufacturing a diaper with moisture sensors

ActiveUS20190240079A1Increase volumeResistanceAbsorbent padsPrinted circuit manufactureSaturated LevelAssembly line

The present invention discloses a method of manufacturing a diaper that has multiple moisture sensing elements on interior side of its bottom impermeable layer or on any surface of the top permeable layer. The moisture sending elements are made by spraying conductive ink on a moving sheet of either the bottom impermeable layer or the top permeable layer, before other layers of the diaper are attached. Spraying of conductive ink on the moving sheet causes parallel lines of conductive inks to be formed on the layer. The parallel lines of conductive ink run through the entire length of either of the layers and are designed to get connected with a detecting device. When a user urinates inside the diaper, the moisture causes a closed circuit between at least two of the parallel lines of conductive inks. These formations of closed circuits, between parallel lines of conductive inks, are detected by the detecting device. Also, with increasing volume of moisture, the resistance of the closed circuits also tends to decrease. This rate of decrease of resistance is also detected by the detecting device and is used to calculate a volume of moisture present in the diaper. The detecting device then generates a suitable alarm to give an idea about the saturation level of the diaper. The process of manufacturing sensing elements by spraying conductive inks on moving sheet of layer reduces the processing and modification overhead of specially designed conductive ink printers and also does not impact the manufacturing time of a diaper manufacturing assembly line.

Owner:TULI RAJA SINGH

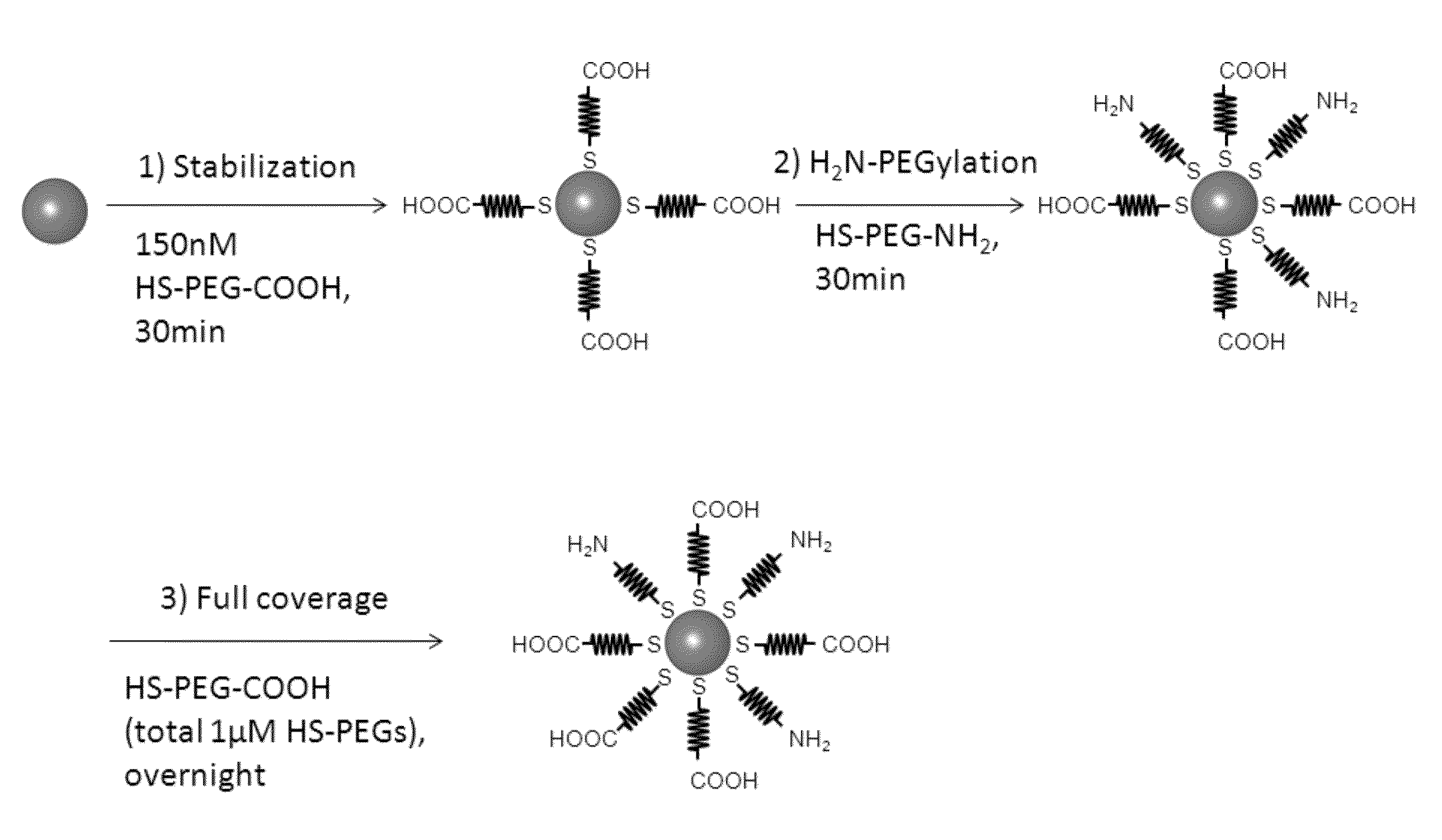

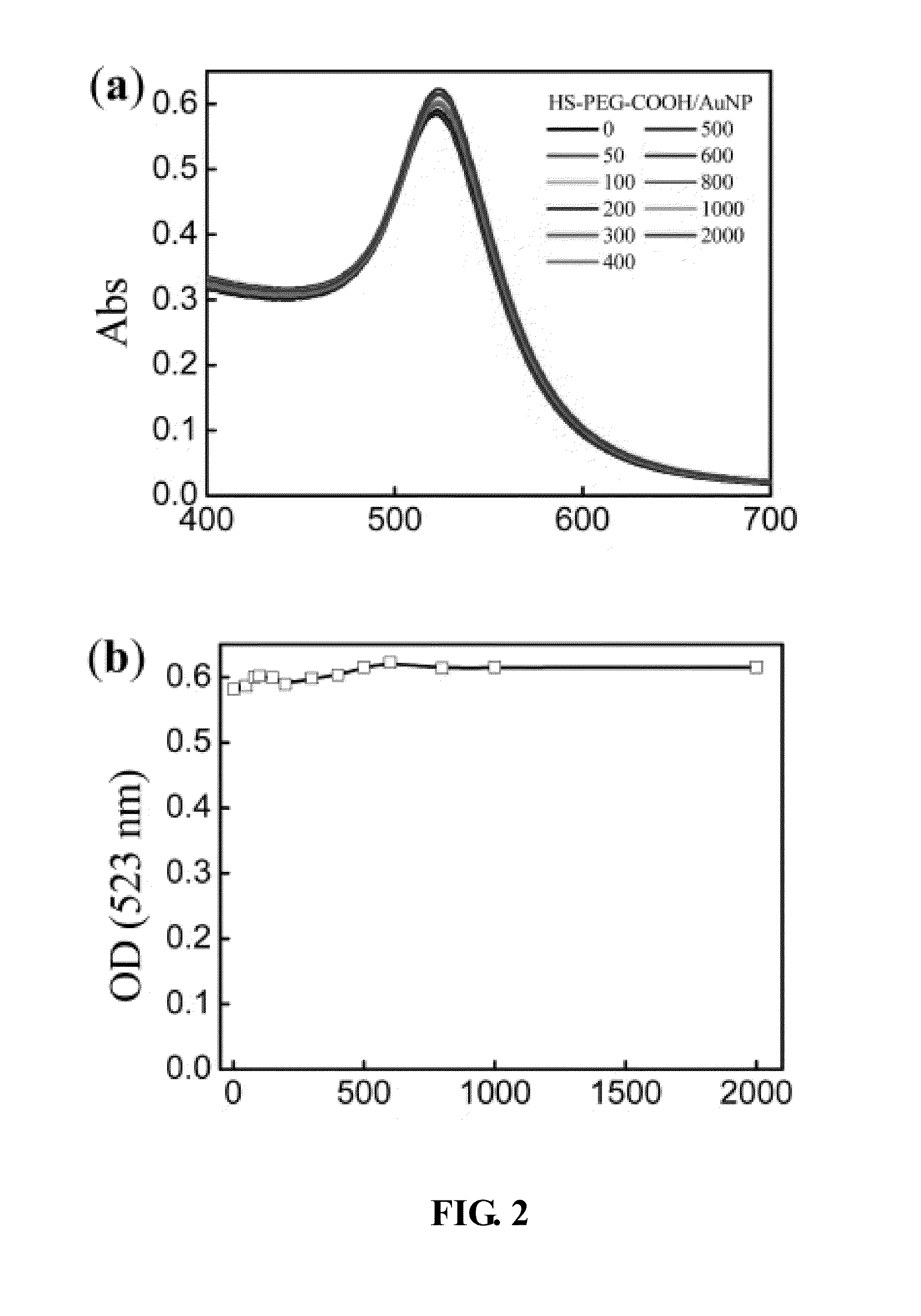

Conjugated gold nanoparticles

ActiveUS20140296551A1Minimizing nonMaximizing colloidal stability of colloidalGroup 1/11 element organic compoundsEnergy modified materialsNanoparticleSaturated Level

The present invention relates to methods, compositions, and kits for generating conjugated gold nanoparticles. In certain embodiments, the present invention provides methods of generating unsaturated conjugated gold nanoparticles by mixing naked gold nanoparticles with a first type of attachment molecules at a molar ratio such that the attachment molecules attach to the naked gold particles at a density level below the saturation level of the naked gold particles (e.g., at a saturation level of 1-99%). In some embodiments, a second type of attachment molecules (e.g., with the opposite charge as the first type of attachment molecules) are mixed with the unsaturated conjugated gold nanoparticles to generate double-conjugated gold nanoparticles (e.g., that are zwitterionic)

Owner:IMRA OF AMERICA +1

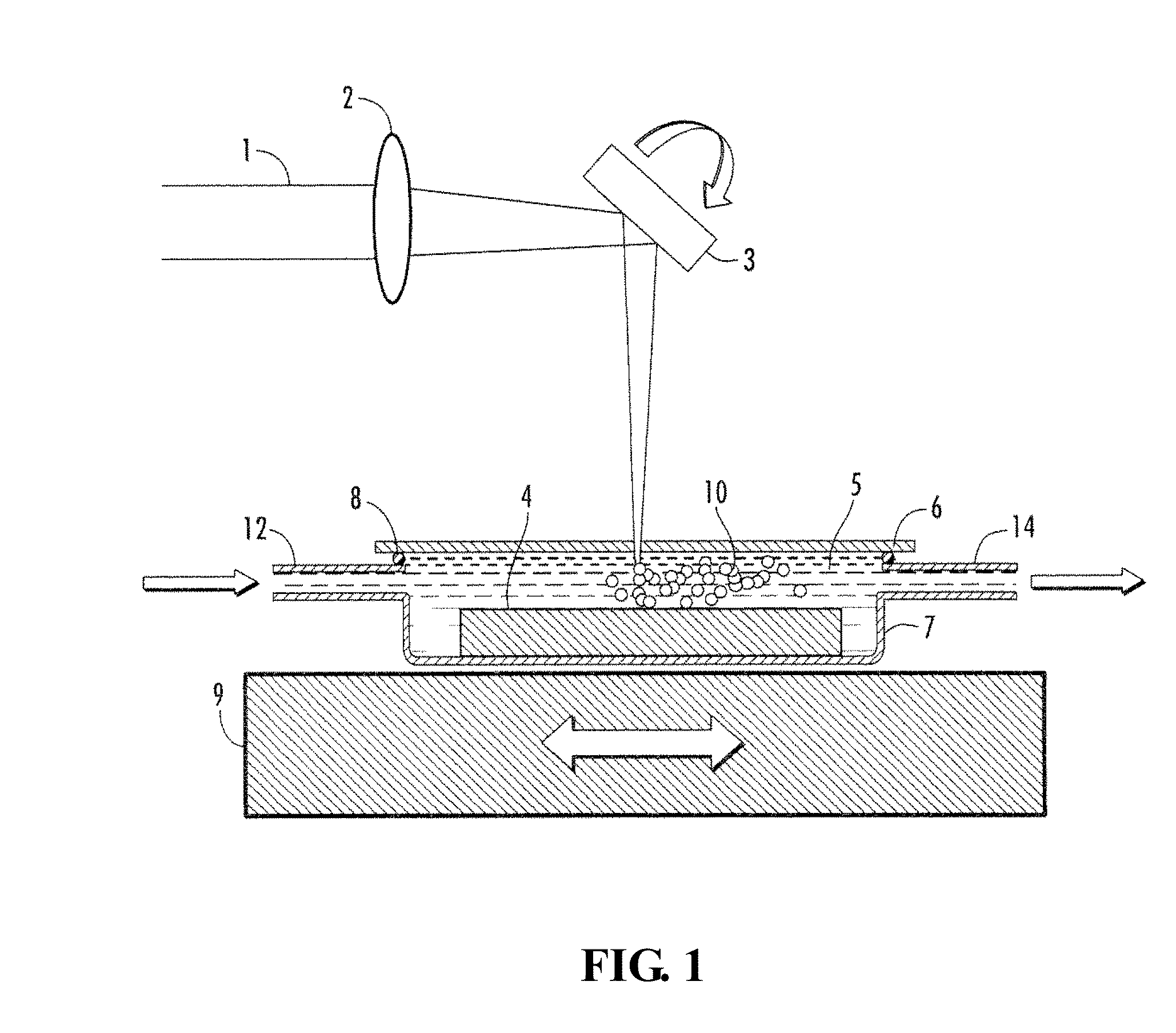

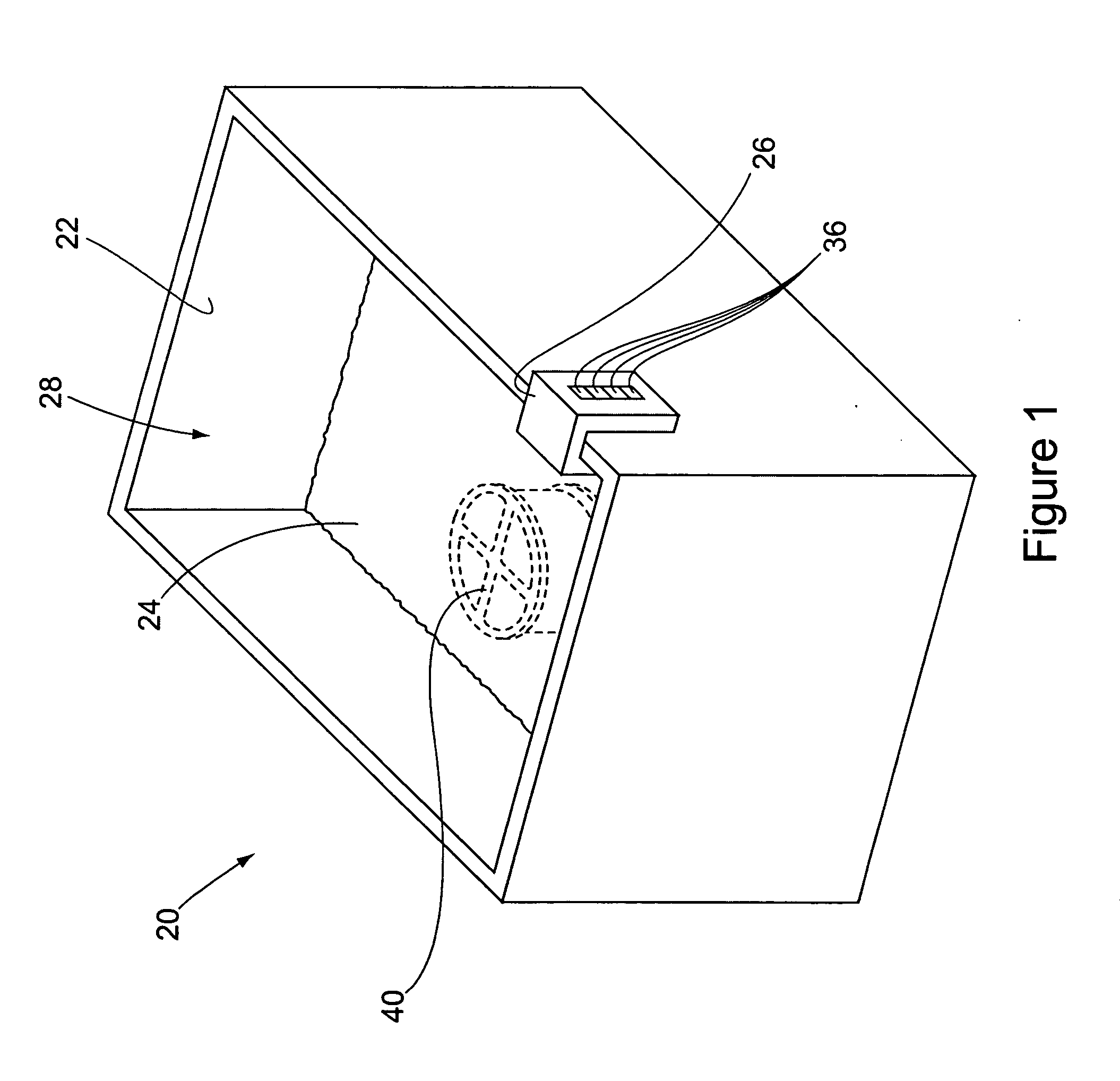

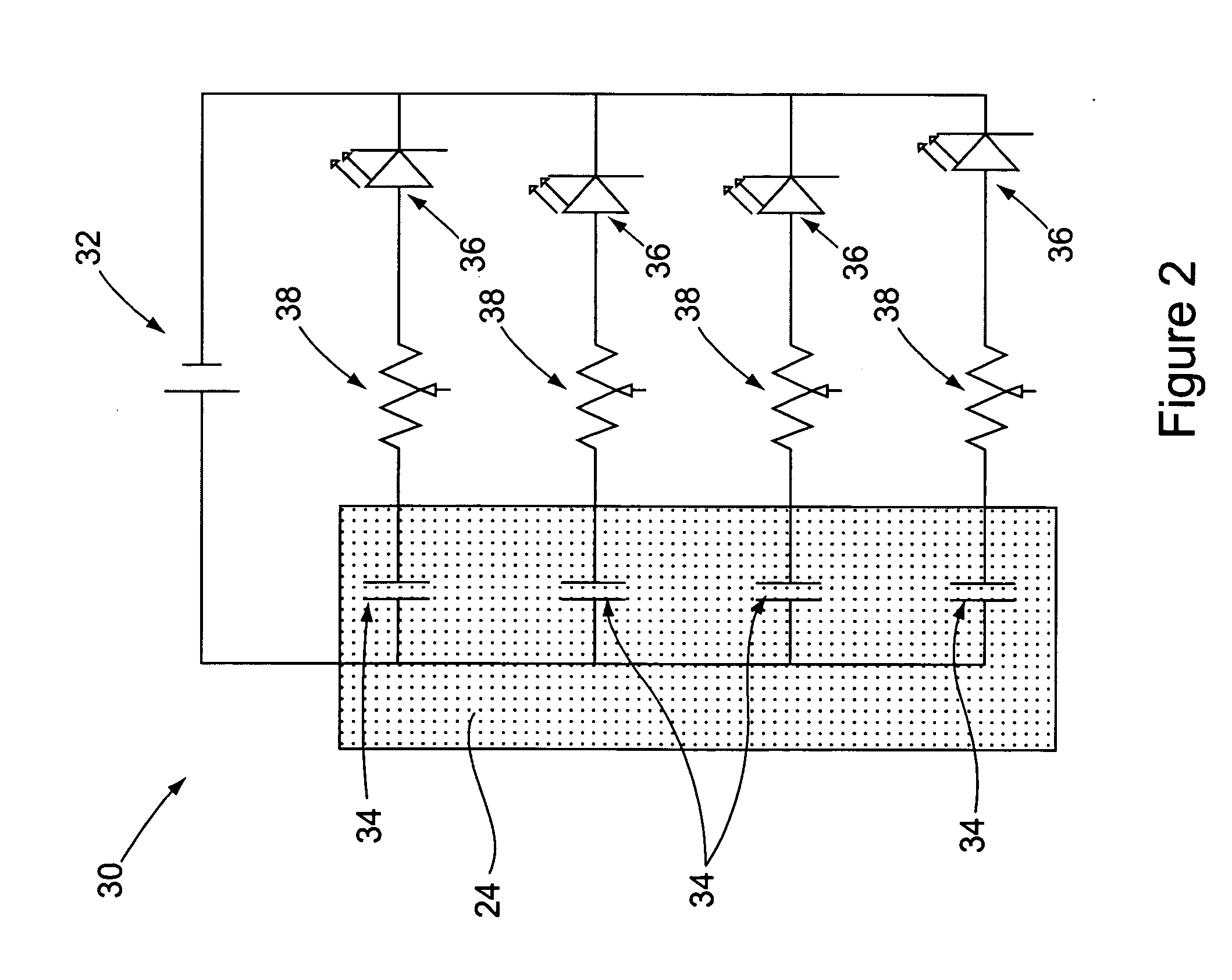

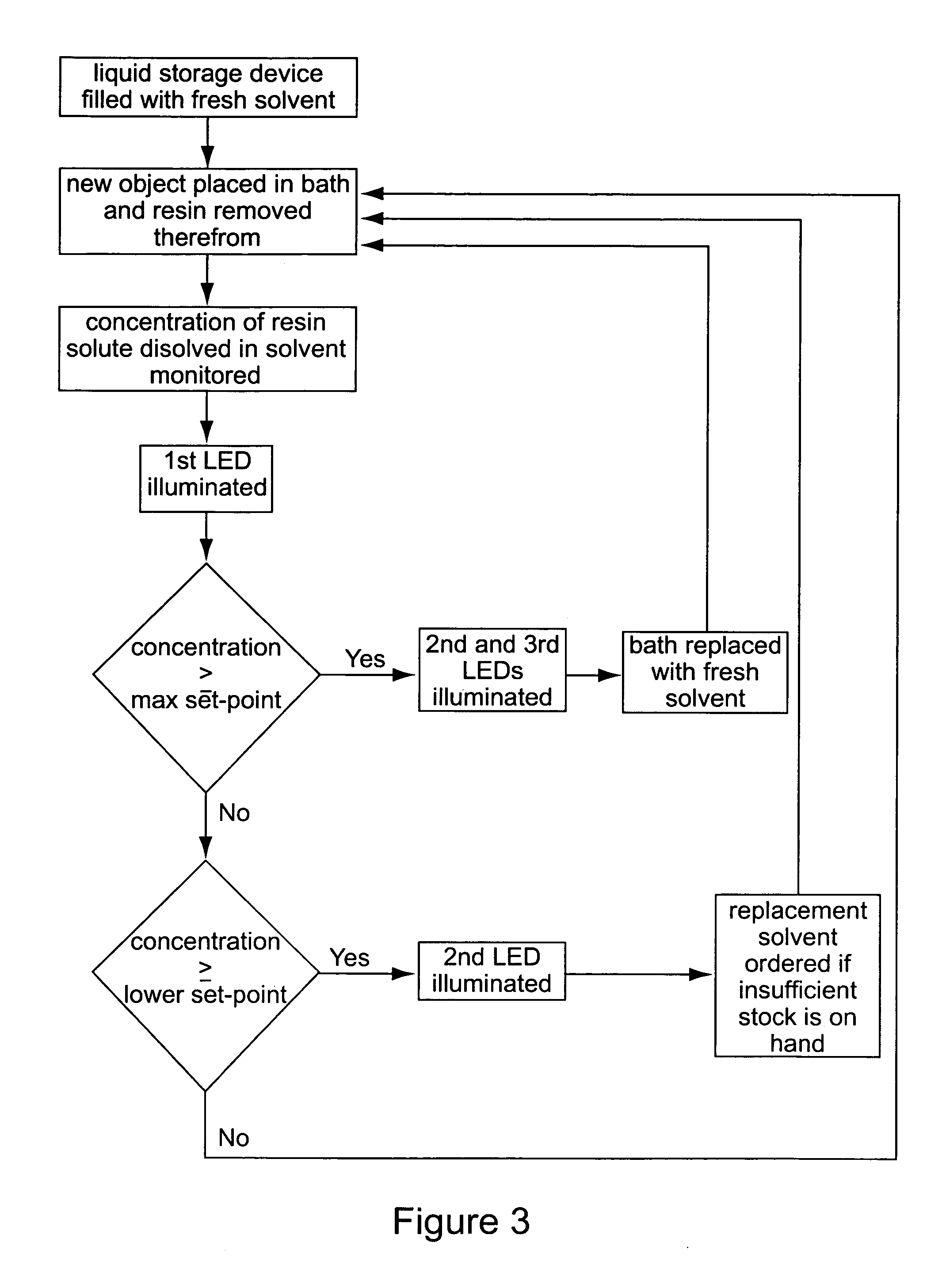

Method and apparatus for monitoring saturation levels of solvents used during rapid prototyping processes

InactiveUS20050233261A1Eliminate difficultiesAdditive manufacturing apparatusPhotomechanical apparatusSaturated LevelEngineering

A monitoring device and method is disclosed for monitoring the saturation level of resin in solvent baths, such as those used to remove resin from objects form by stereolithography. The monitoring device operates by monitoring an electrical characteristic, such as impedance, of the solvent bath as the resin-to-solvent ratio of the bath increases during use. Signals are provided by the monitoring device to the operator of the liquid storage device containing the solvent bath in a manner allowing the operator to determine when the solvent bath has reached the end of its useful life.

Owner:THE BOEING CO

Konjac bean curd and production method thereof

InactiveCN104351687AThorough digestionQuality improvementFood preparationCalcium hydroxideSaturated Level

The invention relates to the technical field of konjac bean curd food processing and particularly relates to konjac bean curd and a production method thereof. The method comprises the steps: lime and clear water are mixed according to a certain proportion for preparing, and then, the contact reaction time and the contact reaction temperature of the lime and the clear water are controlled, and the lime is digested relatively completely in clear water, so that the quality of obtained lime water is relatively good; and the content of calcium hydroxide in the lime water reaches a relatively saturated level, so that the microcosmic biochemical reaction of the lime water and konjac can be sufficiently performed when the lime water contacts with the konjac, and therefore, the structural composition of nutrient components in the raw material konjac of the konjac bean curd is improved, and the guarantee is provided for keeping the mouthfeeel and the strength of the konjac bean curd in the follow-up konjac bean curd food production process.

Owner:GUIZHOU TAIJIANG HUANONG ECOLOGICAL AGRI DEV CO LTD

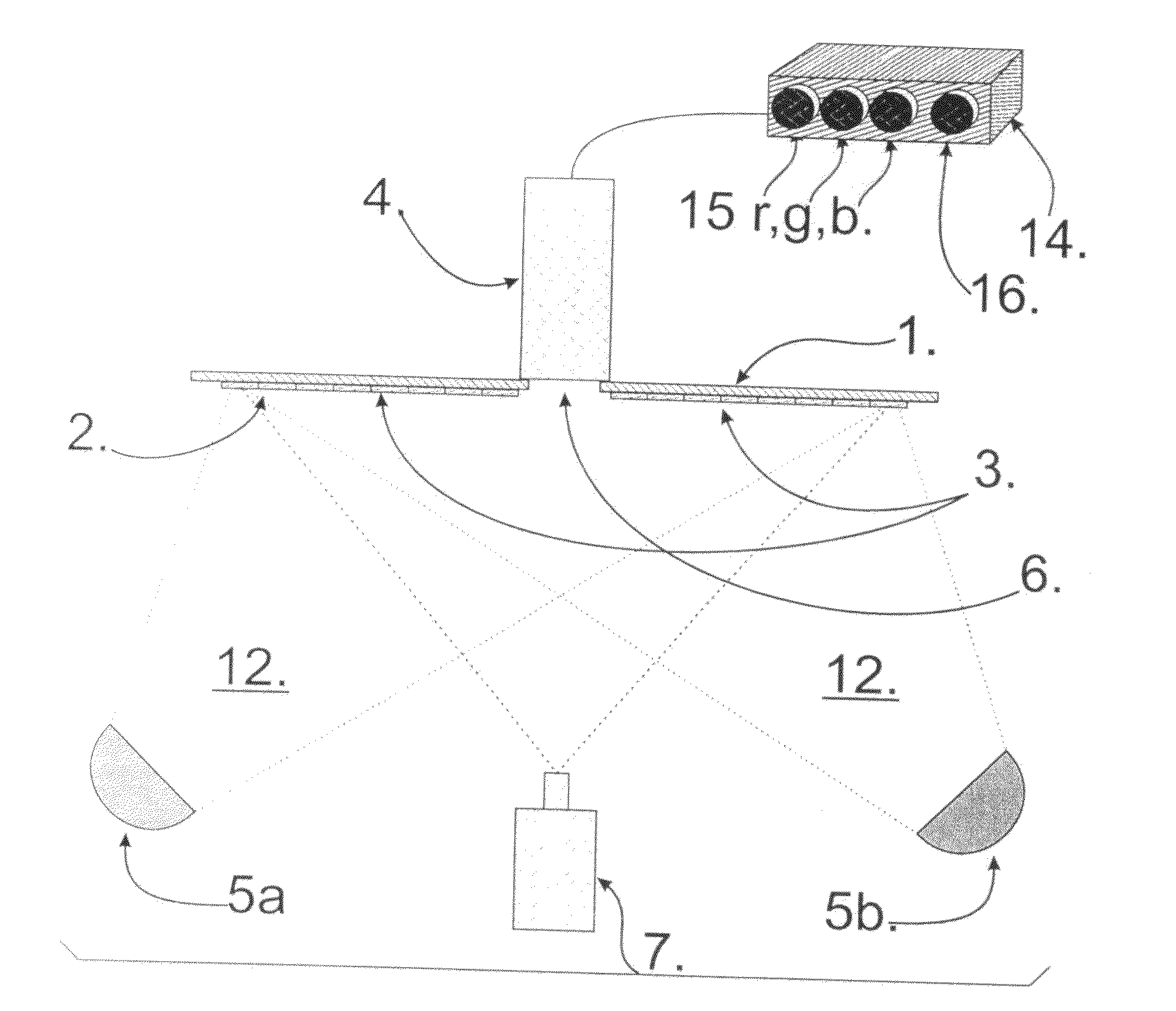

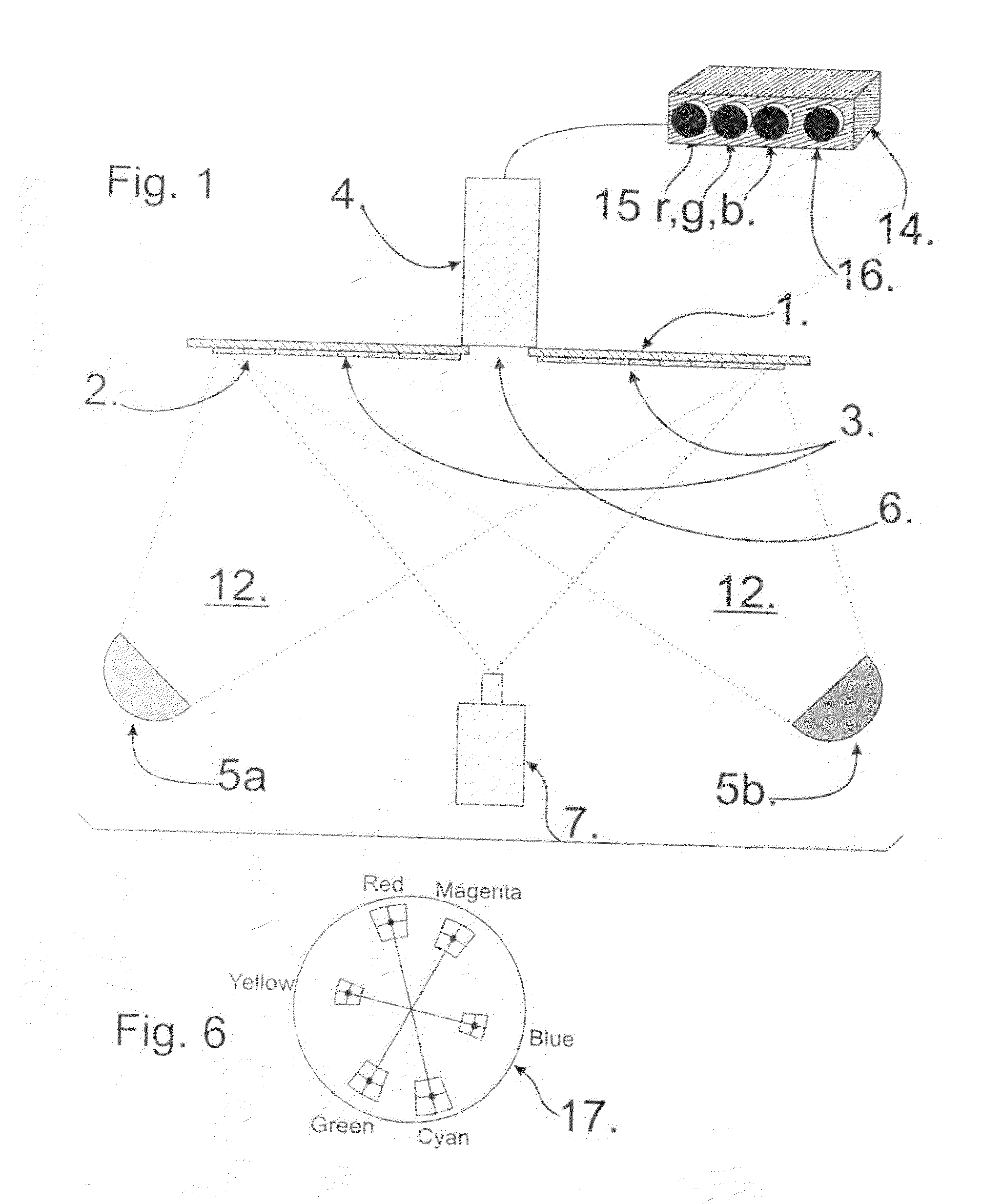

Apparatus and method used to evaluate and optimize image quality in high color gamut imaging systems

InactiveUS8797411B2Maintain maximum saturationRadiation pyrometryTelevision systemsImaging qualityDisplay device

Owner:CORLEY FERRAND DAVID E

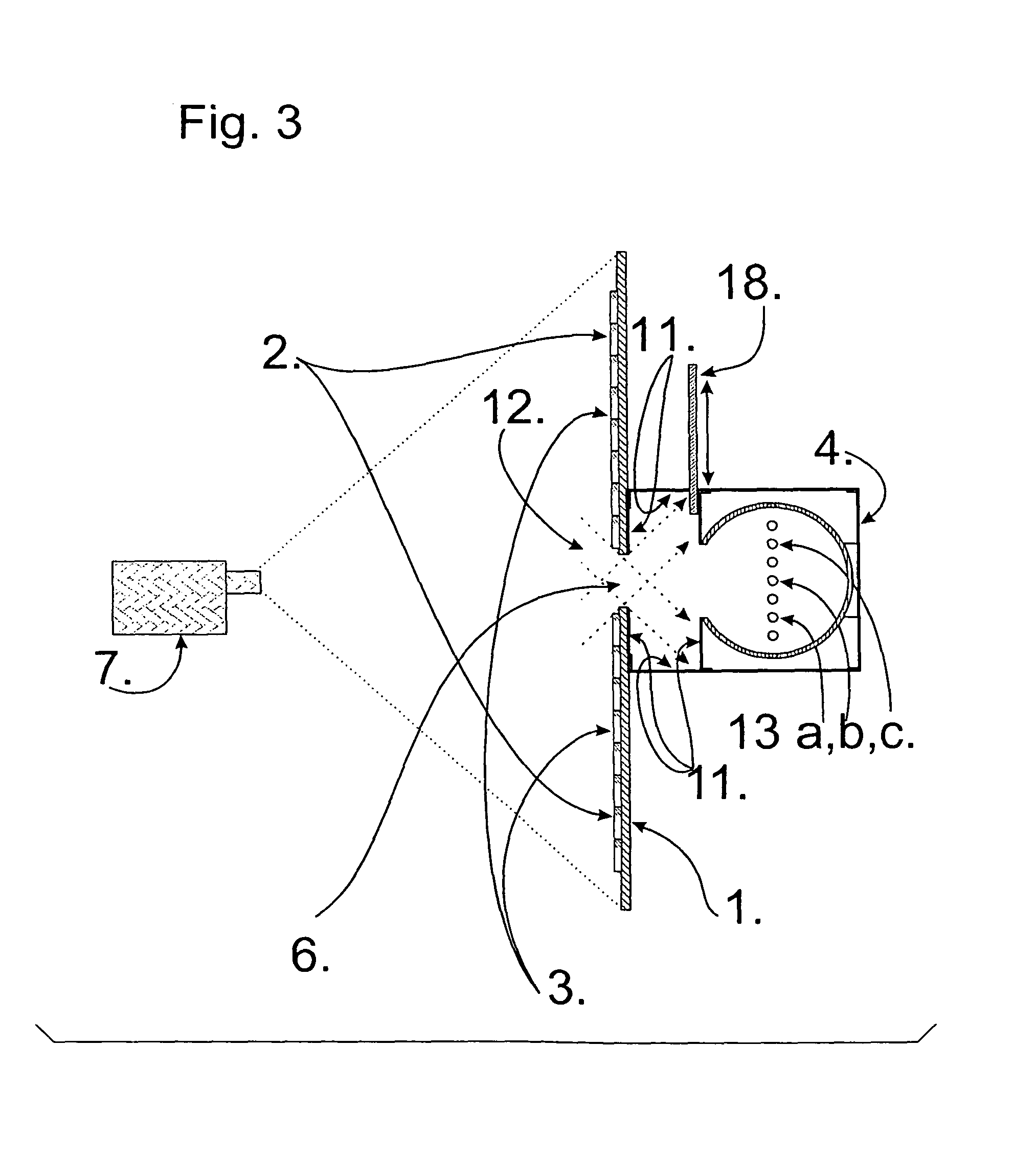

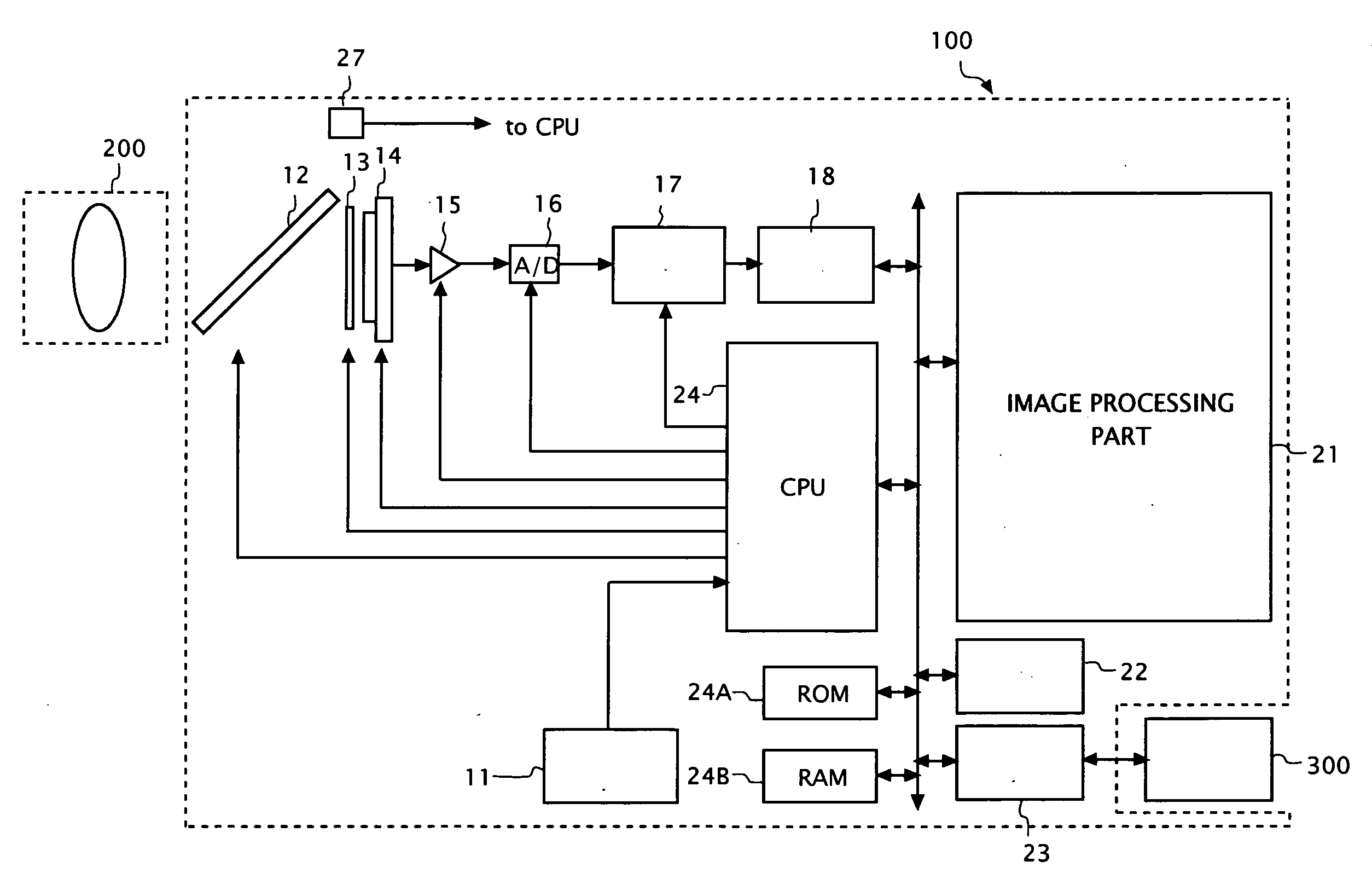

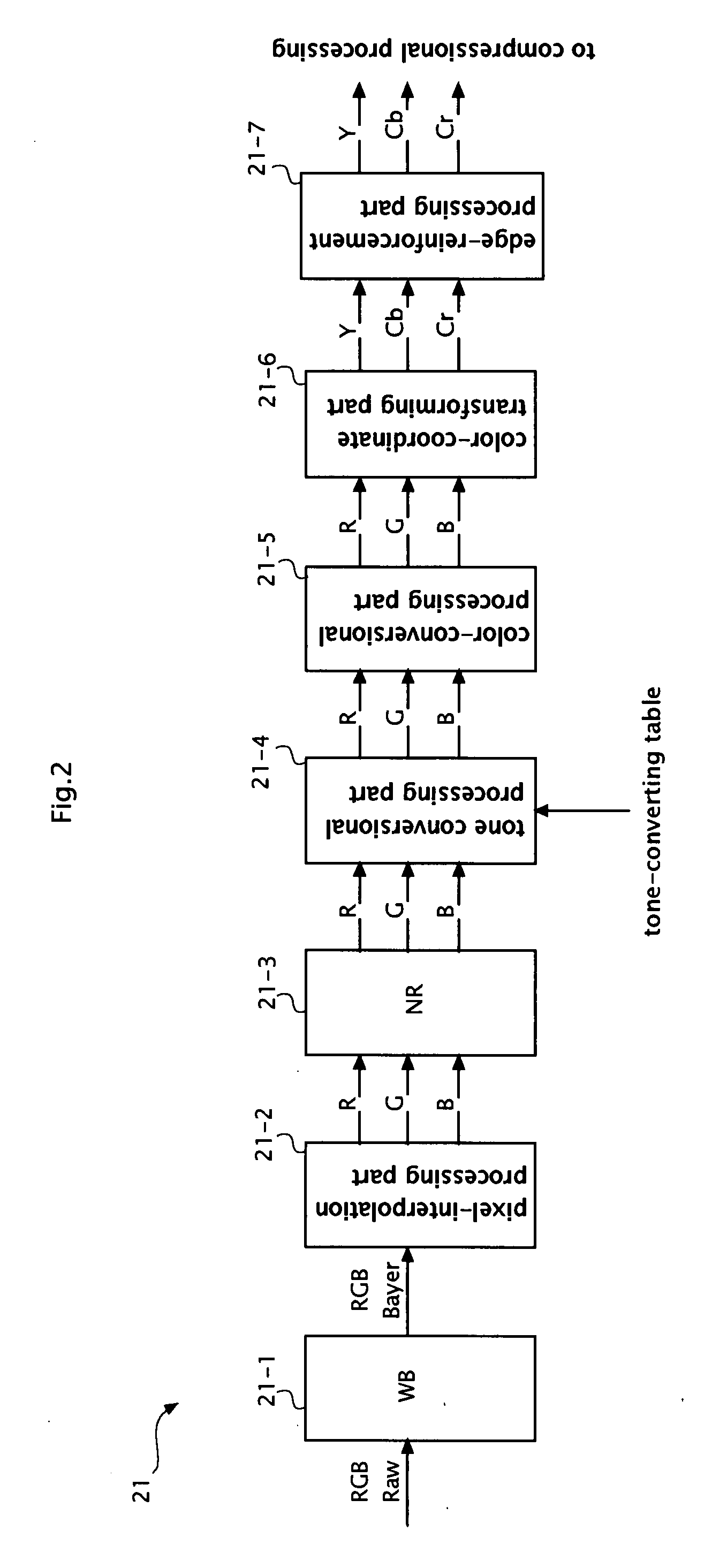

Image processing apparatus, imaging apparatus, and computer readable medium

InactiveUS20080111893A1Excellent in highlight expressionImage enhancementTelevision system detailsImaging processingSaturated Level

An image processing apparatus, a computer readable medium and the like in which a dither effect in a neighborhood of a highlight area can be obtained easily and certainly. For this purpose, an image processing apparatus includes an inputting unit which inputs a pixel signal group representing a field image, an averaging unit (21-2 and 21-3) which performs a processing having an averaging effect among the pixel signal group input by the inputting unit, and an irregularizing unit (21-4) which irregularizes mutually continuous signal-values at least near a saturated level among the pixel signal group after having been processed by the averaging unit, into discontinuous signal-values.

Owner:NIKON CORP

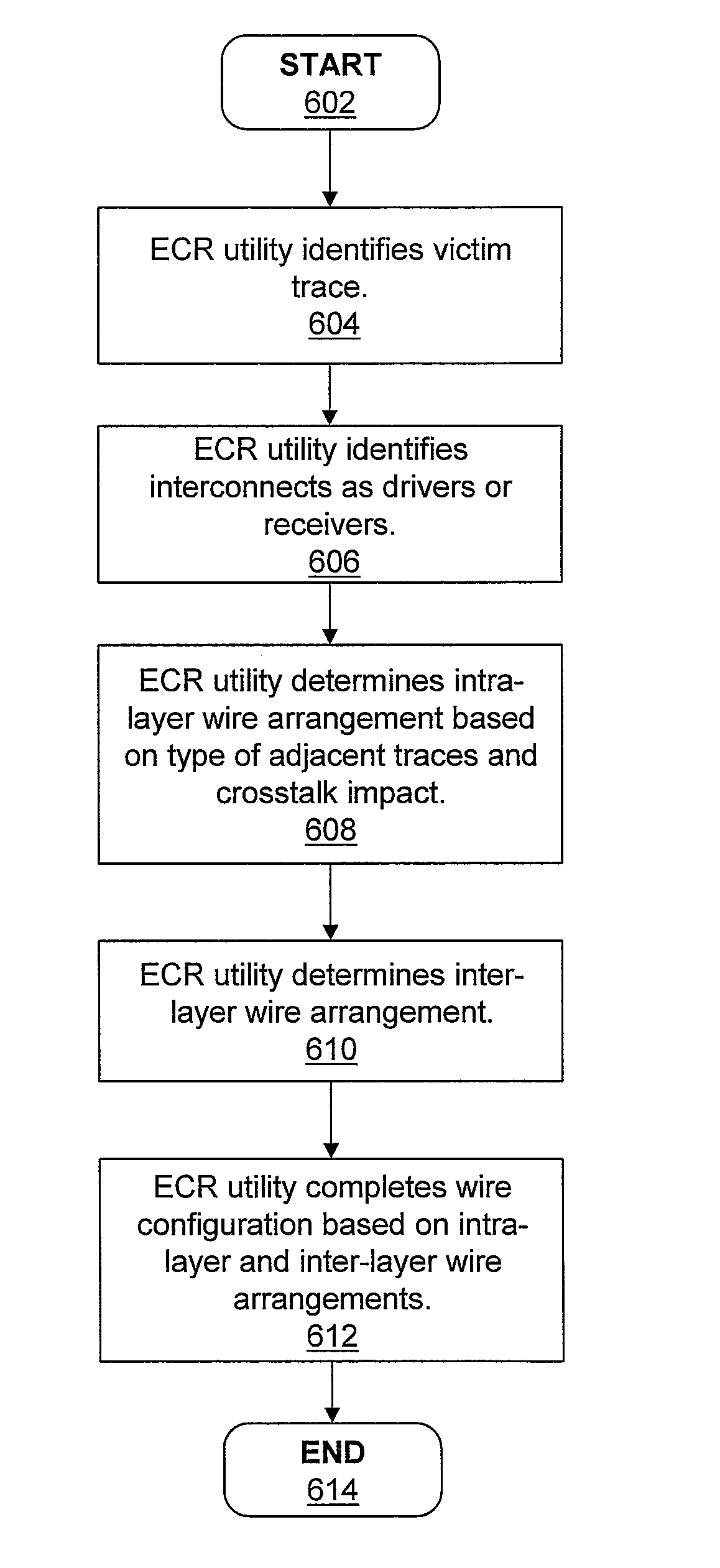

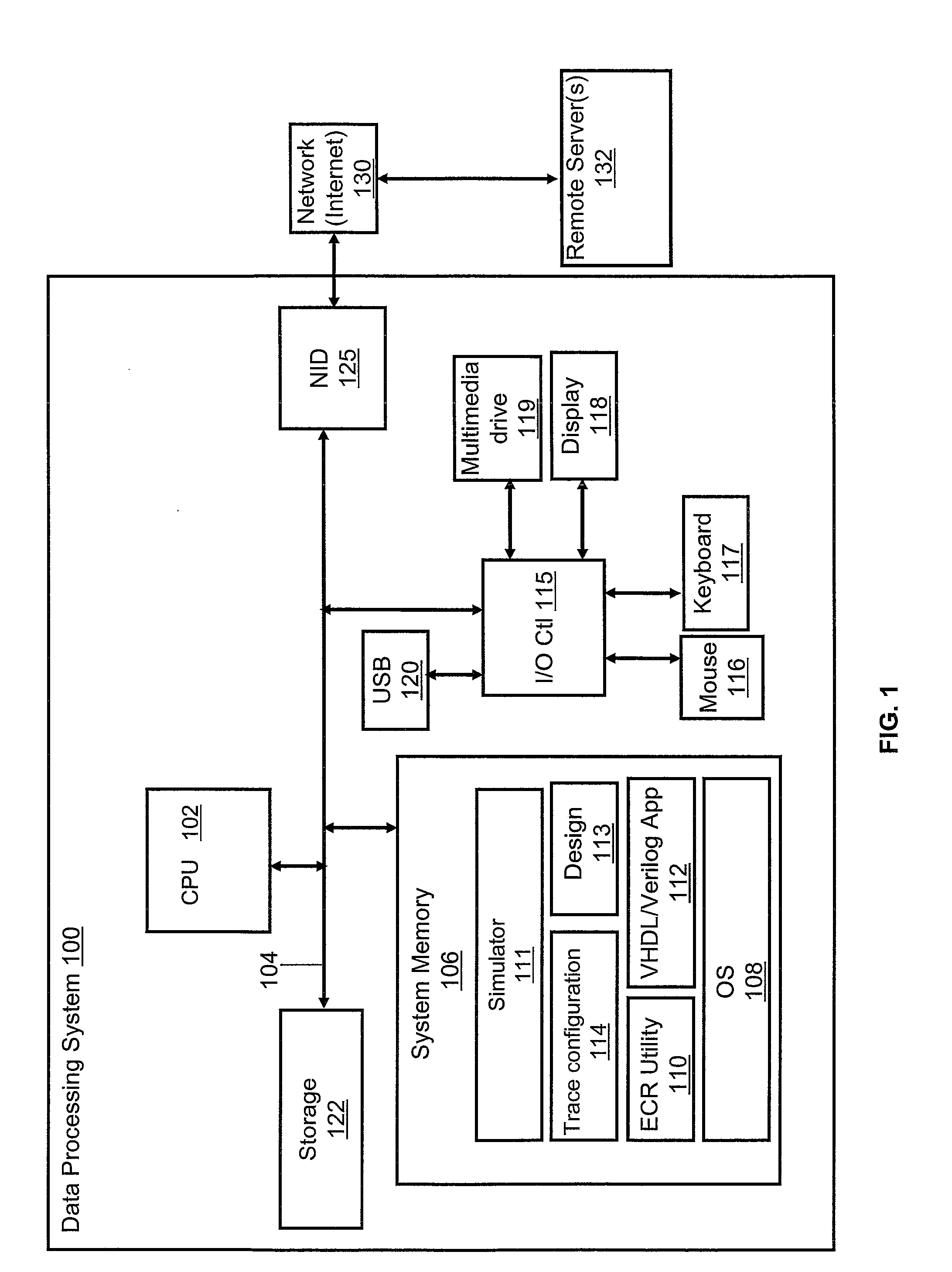

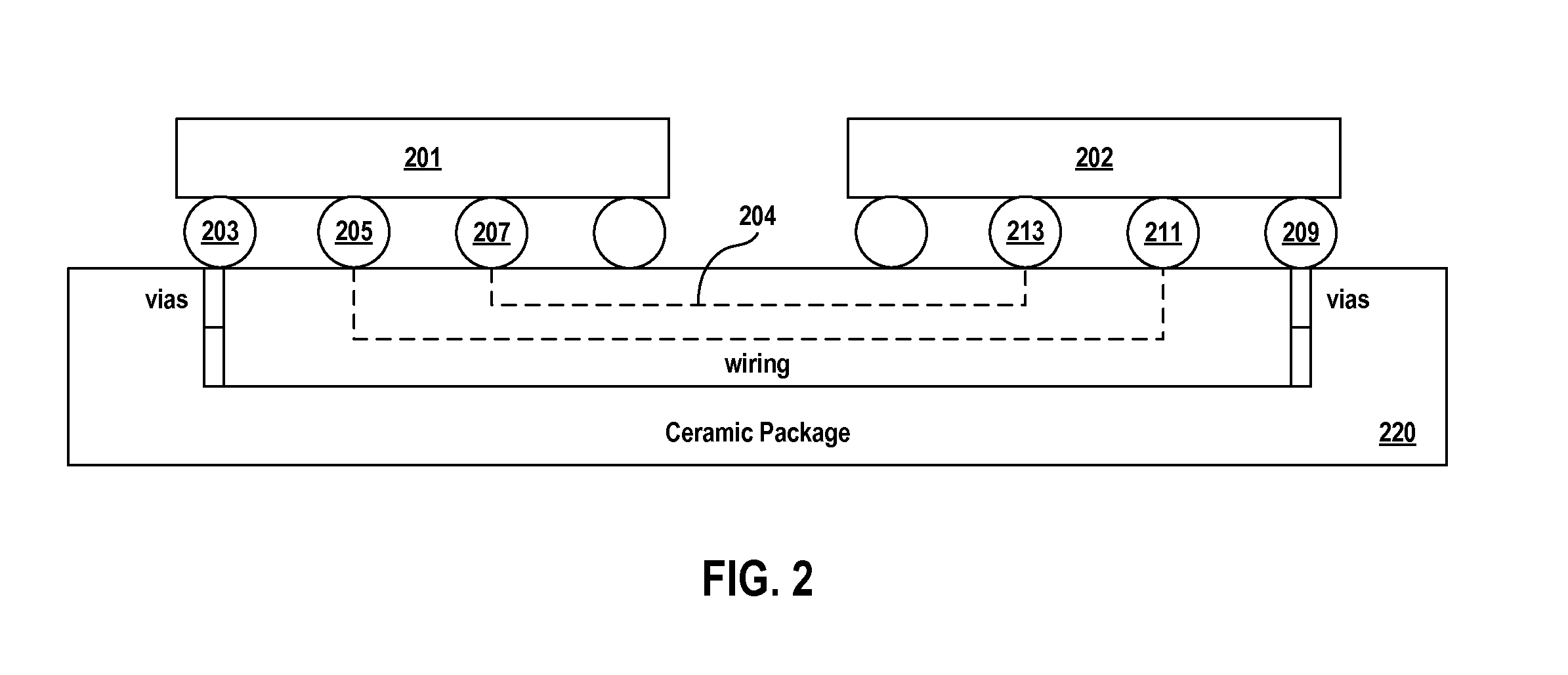

Reducing Crosstalk In The Design Of Module Nets

InactiveUS20110031627A1Reduce coupling noiseEnhanced Crosstalk Reduction (ECR)Semiconductor/solid-state device detailsSolid-state devicesSaturated LevelIsolation layer

A method, a system and a computer program product for reducing coupling noise in low loss on-module wires used for connecting module components in electrical circuits / devices. During the design stage, an Enhanced Crosstalk Reduction (ECR) utility identifies interconnect wires as driven / aggressor traces or receiver traces. The ECR utility substantially avoids forward crosstalk in a victim trace by specially arranging driver traces adjacent to the receiver victim trace in order to provide a lower level and saturated level of backward crosstalk. In particular, the ECR utility provided a configuration of wire / trace layers based on one or more of: (a) the crosstalk impact of a trace when positioned in a particular location; (b) the crosstalk impact of the trace upon remaining components based on placement in the particular location; and (c) system component specifications. In addition, the ECR utility reduces crosstalk by providing a configuration of receiver wires and transmitter wires without the use of isolation layers.

Owner:GLOBALFOUNDRIES INC

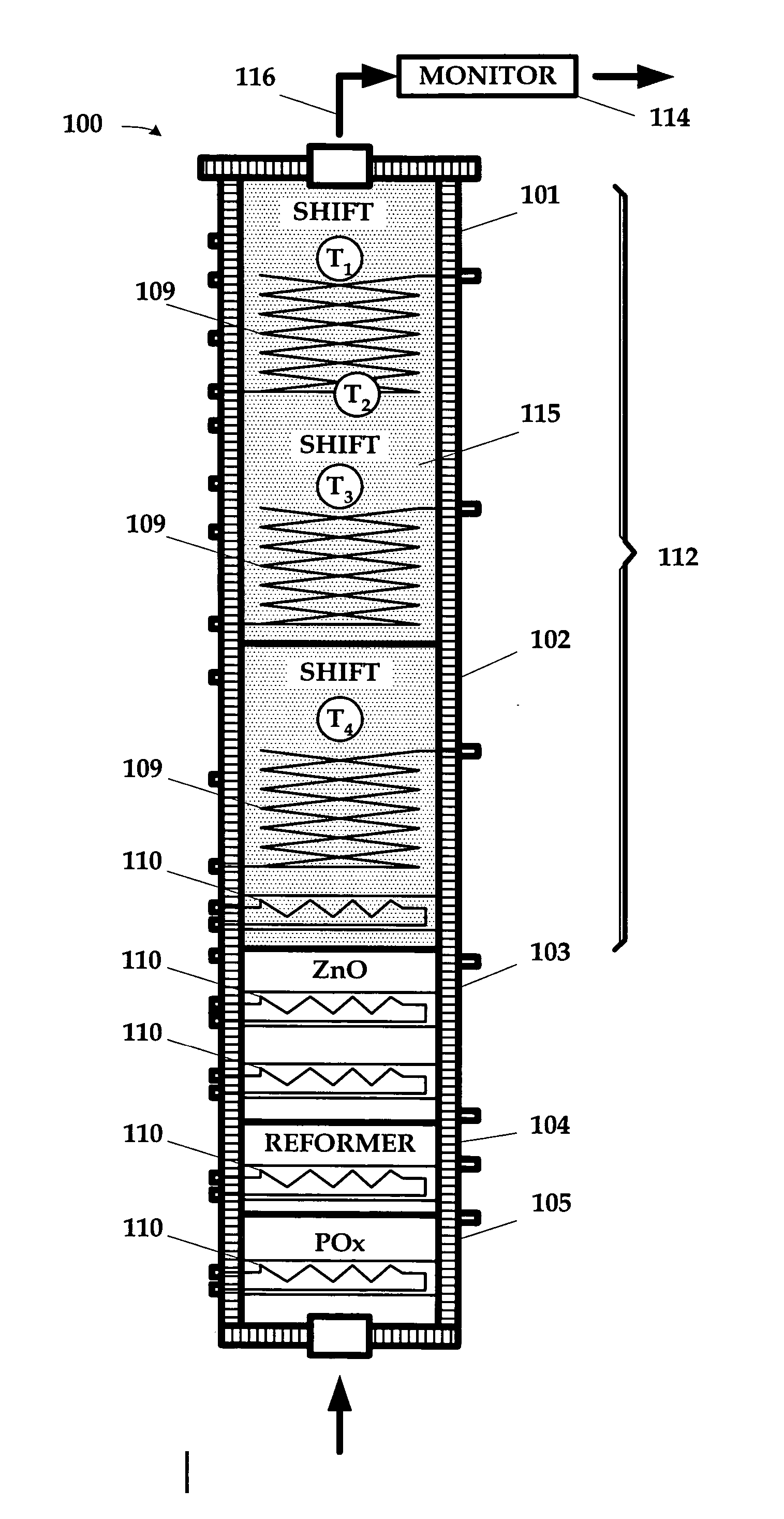

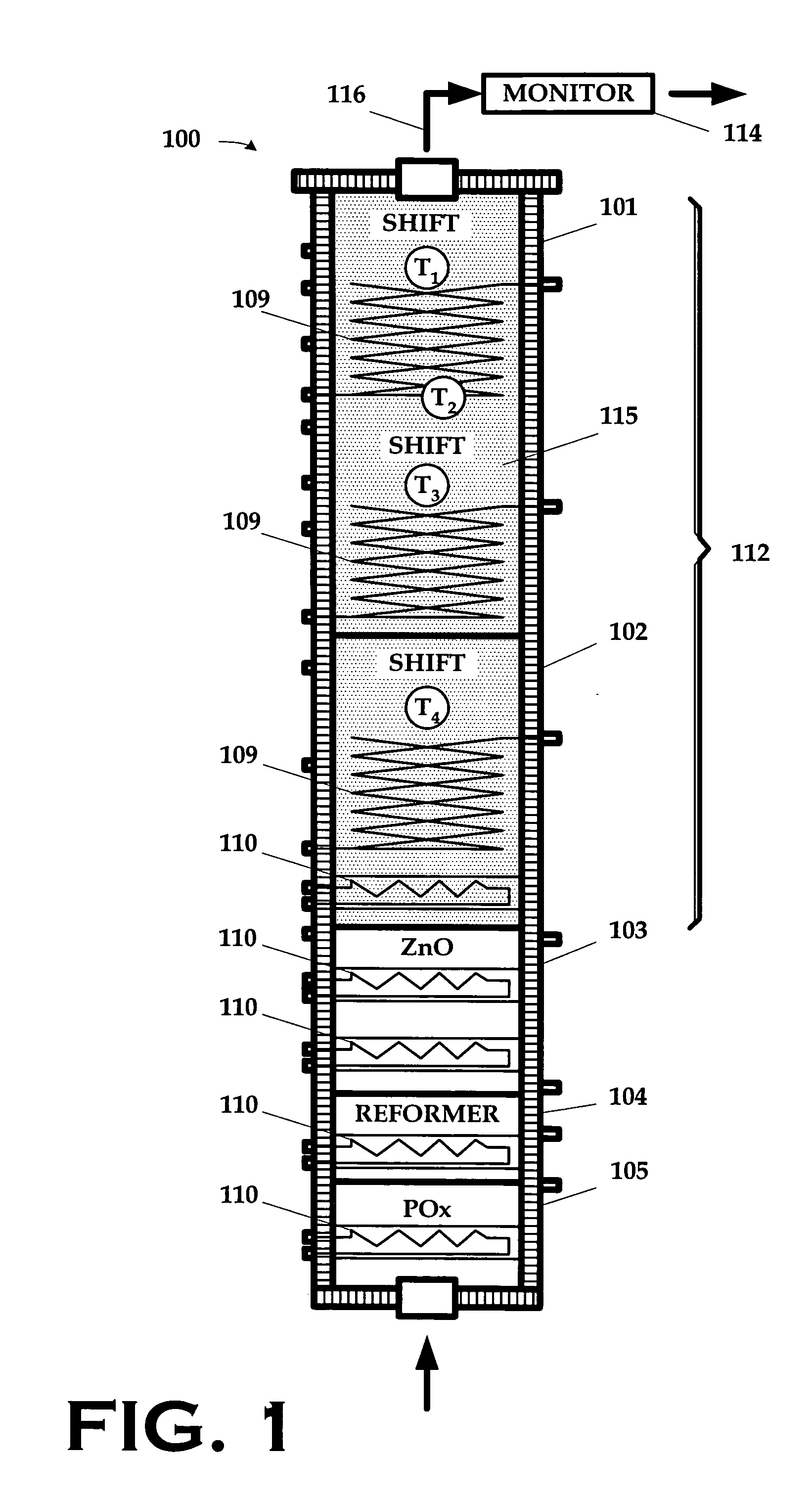

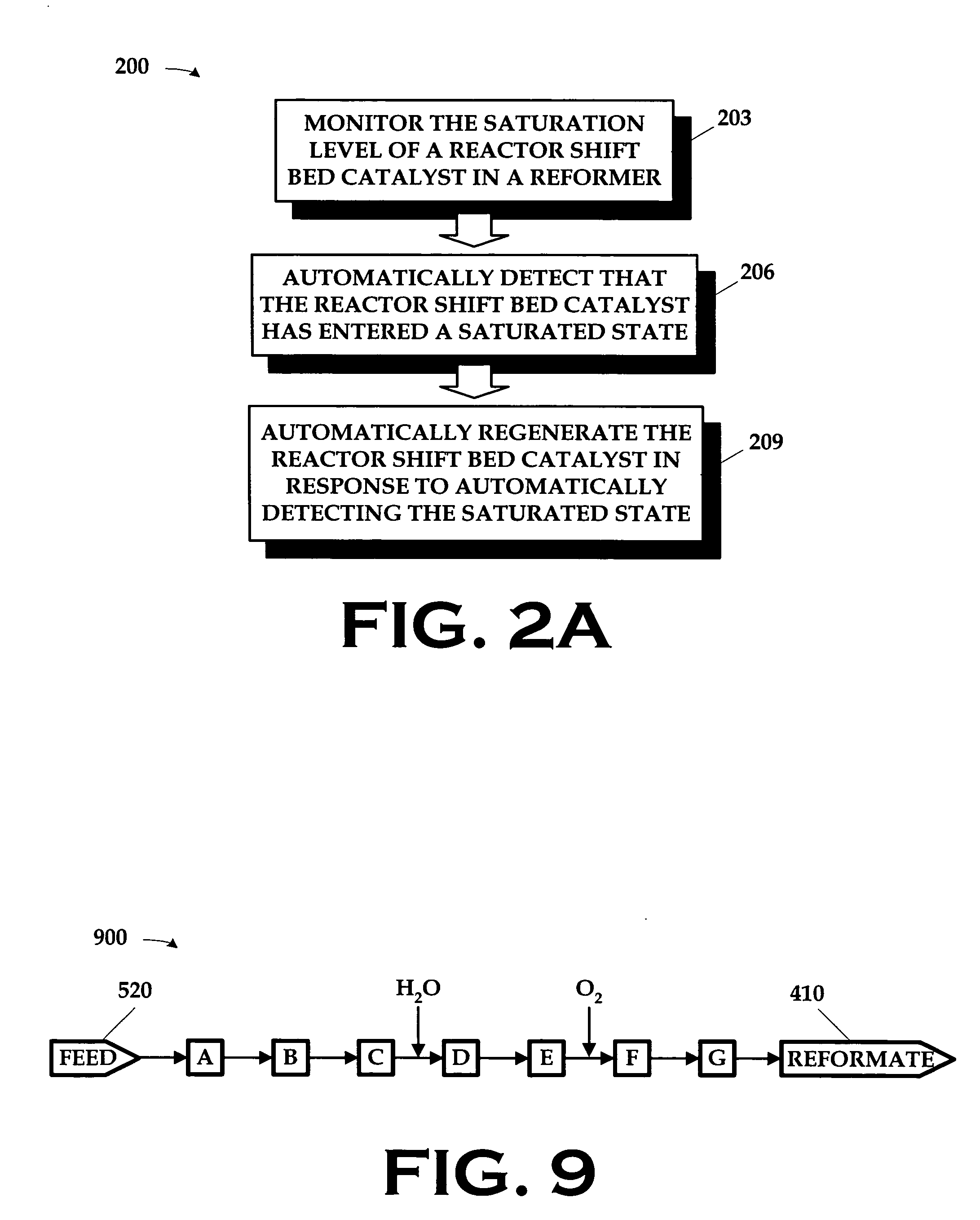

Automated control strategy for fuel processor reactor shift catalyst regeneration

InactiveUS20050143862A1Programme controlSampled-variable control systemsAutomatic controlSaturated Level

A method and apparatus for use in regenerating a reactor shift bed catalyst are disclosed. The method comprises monitoring the saturation level of a reactor shift bed catalyst in a reformer; automatically detecting that the reactor shift bed catalyst has entered a saturated state; and automatically regenerating the reactor shift bed catalyst in response to automatically detecting the saturated state. The apparatus may be, in various aspects, a program storage method encoded with instructions that, when executed by a computing device, performs such a method; a computing apparatus programmed to perform such a method, or a control system performing such a method.

Owner:TEXACO INC

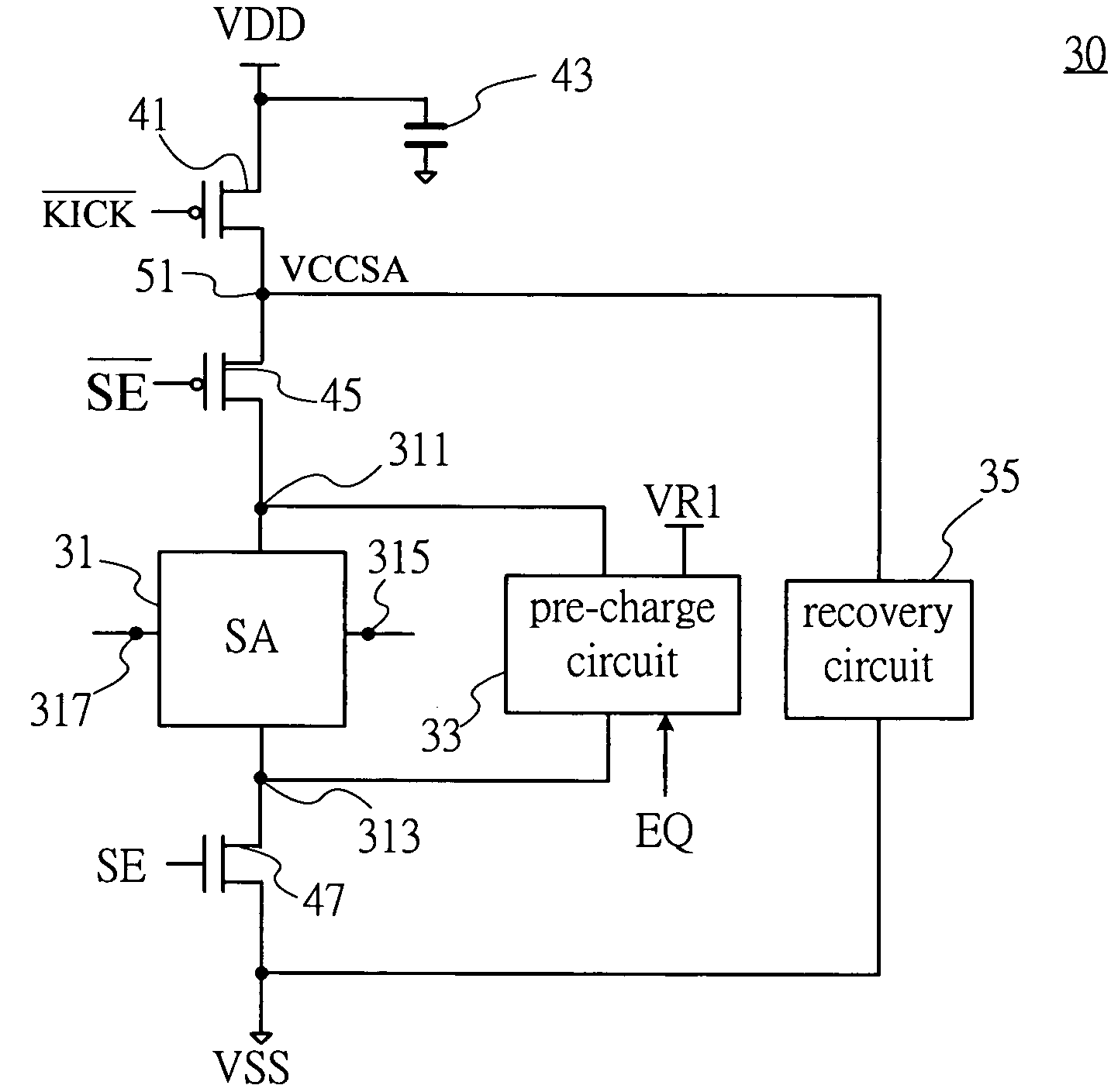

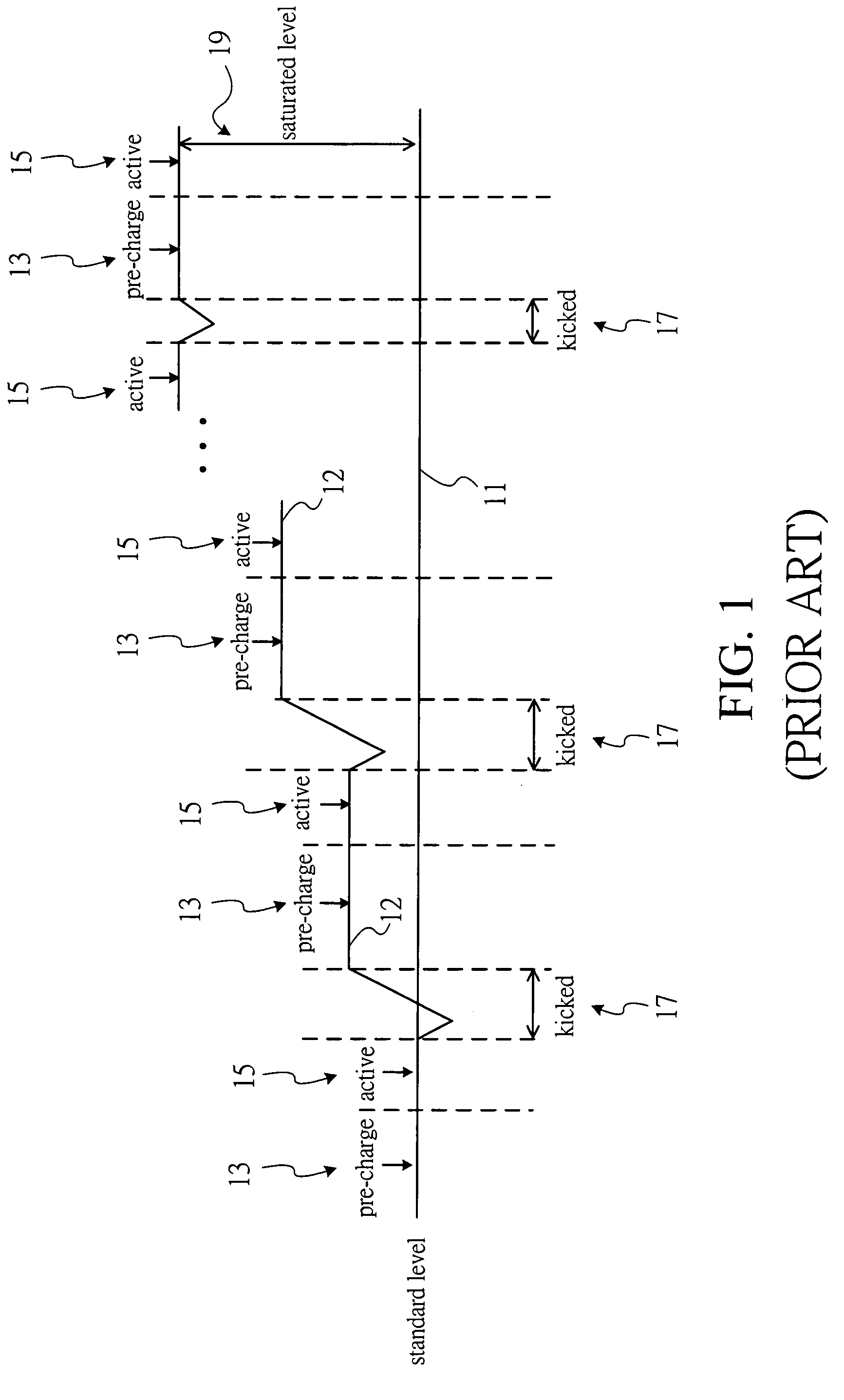

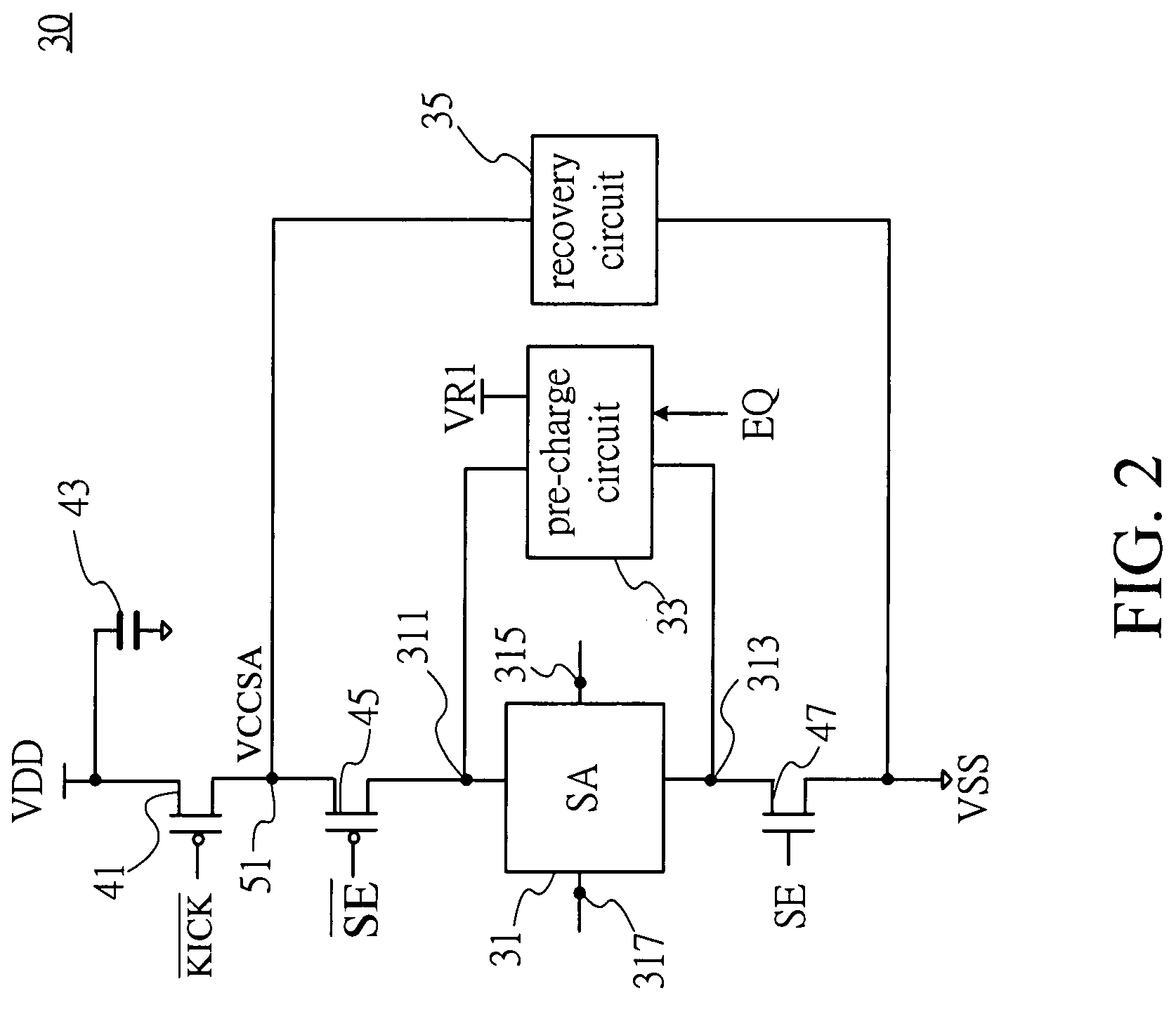

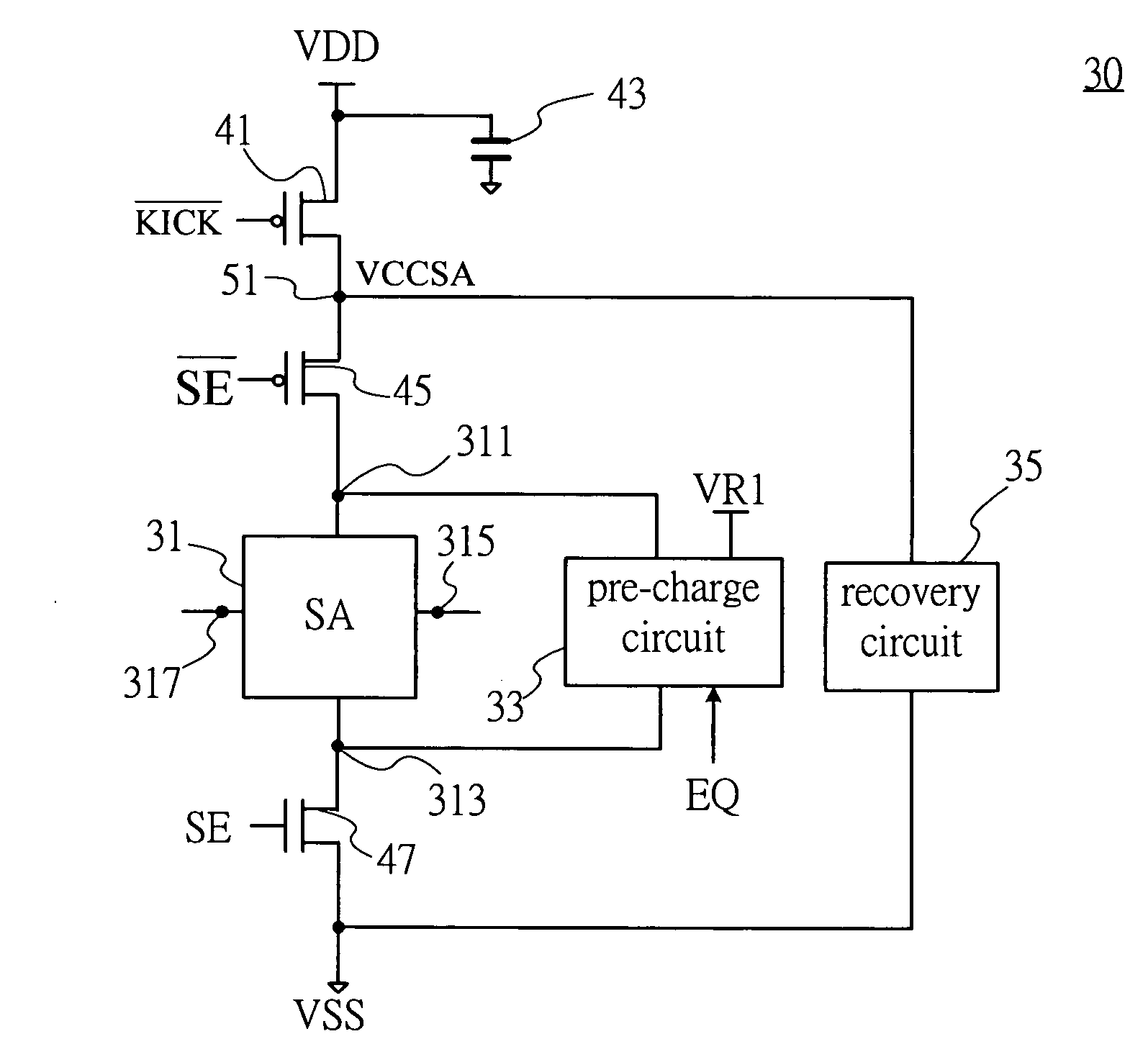

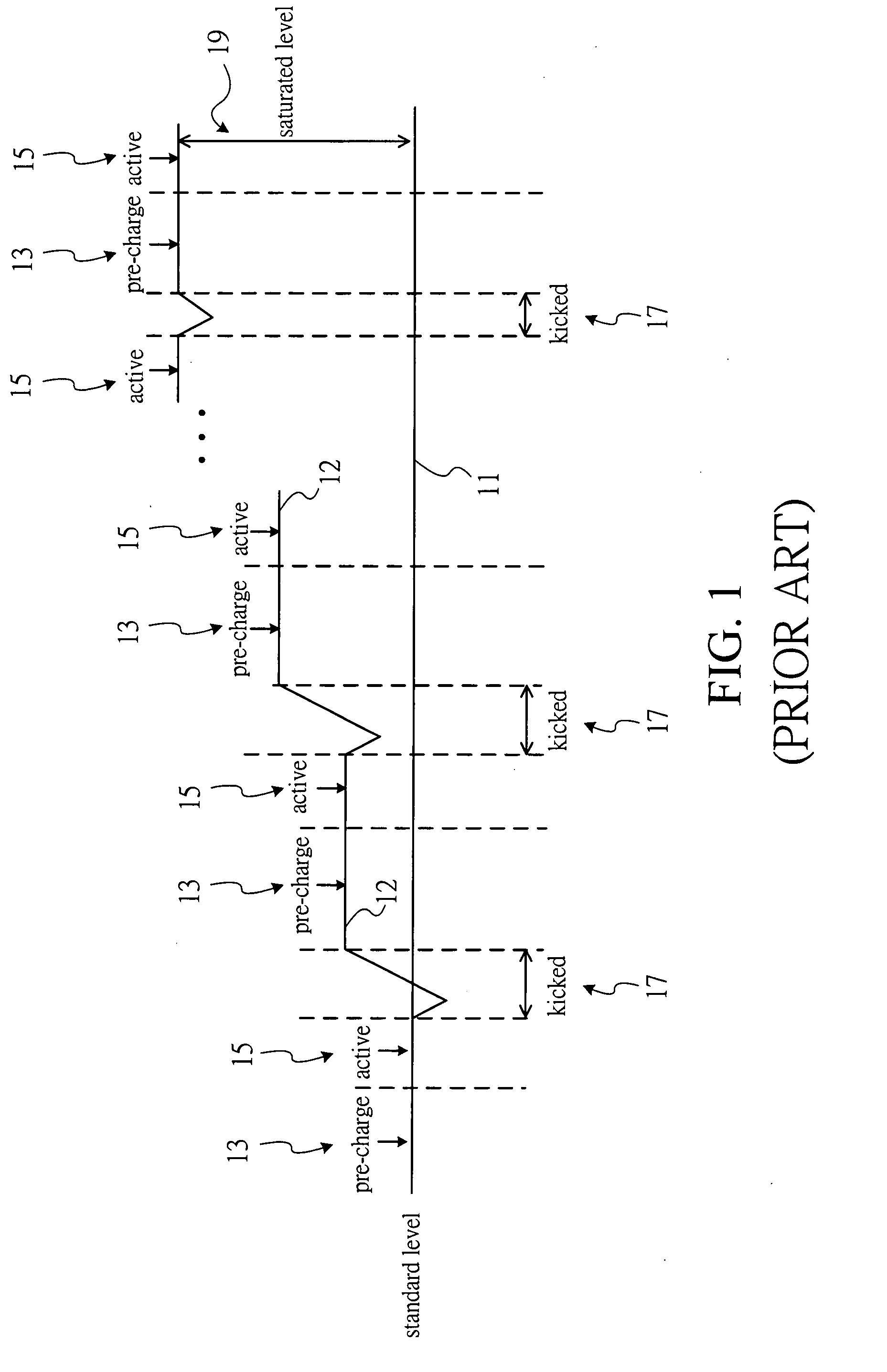

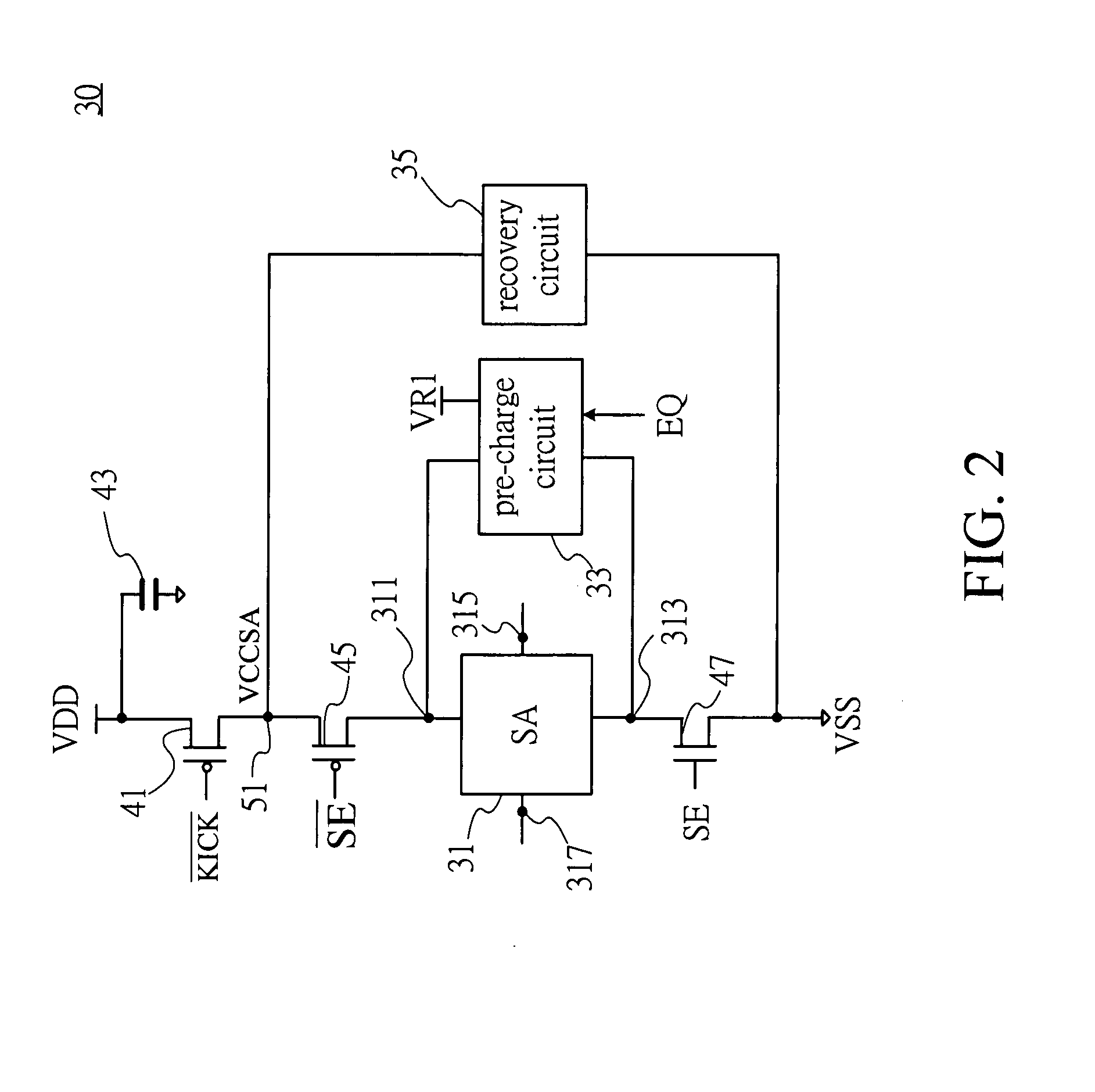

Signal sensing circuit and semiconductor memory device using the same

A signal sensing circuit and a semiconductor memory device using the same are provided. The signal sensing circuit comprises a sense amplifier, a kick transistor, a first control transistor, a second control transistor, a pre-charge circuit, and a recovery circuit. The kick transistor is used to pull up the operation voltage of the sense amplifier to improve the small signal sensing speed of the sense amplifier. After the signal is sensed, the recovery circuit will pull down the operation voltage of the sense amplifier to the standard level. In the present invention, the small signal sensing speed is greatly improved and the operation voltage of sense amplifier is kept away from the saturated level.

Owner:ETRON TECH INC

Apparatus and method used to evaluate and optimize image quality in high color gamut imaging systems

InactiveUS20110063454A1Maintain maximum saturationCathode-ray tube indicatorsTelevision systemsDisplay deviceHue

A test apparatus comprising a combination of front illuminated and rear illuminated optical reference test elements designed to produce predetermined electronic signals. The front illuminated elements comprise spectrophotometrically neutral gray patches and primary and secondary color patches of predetermined hues. Additional color patches having the same hue as the primaries and secondaries, but at lower saturation levels, generate unique logical patterns on display devices well known to the broadcasting and image reproducing industries. The rear illuminated test elements comprise wide color gamut hues at levels of saturation not attainable in reflected light systems. Also disclosed is a method of evaluating and optimizing the image quality in high gamut imaging systems, using the above described apparatus.

Owner:CORLEY FERRAND D E

Signal sensing circuit and semiconductor memory device using the same

A signal sensing circuit and a semiconductor memory device using the same are provided. The signal sensing circuit comprises a sense amplifier, a kick transistor, a first control transistor, a second control transistor, a pre-charge circuit, and a recovery circuit. The kick transistor is used to pull up the operation voltage of the sense amplifier to improve the small signal sensing speed of the sense amplifier. After the signal is sensed, the recovery circuit will pull down the operation voltage of the sense amplifier to the standard level. In the present invention, the small signal sensing speed is greatly improved and the operation voltage of sense amplifier is kept away from the saturated level.

Owner:ETRON TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com