Patents

Literature

47 results about "Segmented polyurethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coatings for implantable medical devices comprising hydrophilic substances and methods for fabricating the same

A segmented polyurethane and an amphiphilic random or block copolymer are disclosed. The segmented polyurethane and the amphiphilic random or block copolymer can be used for fabricating a coating for an implantable medical device such as a stent.

Owner:ABBOTT CARDIOVASCULAR

Hydroswellable, Segmented, Aliphatic Polyurethanes and Polyurethane Ureas

InactiveUS20090233887A1Increase volumeRestoring the function of diseased or defective articulating jointsBiocideImpression capsPolyethylene glycolSegmented polyurethane

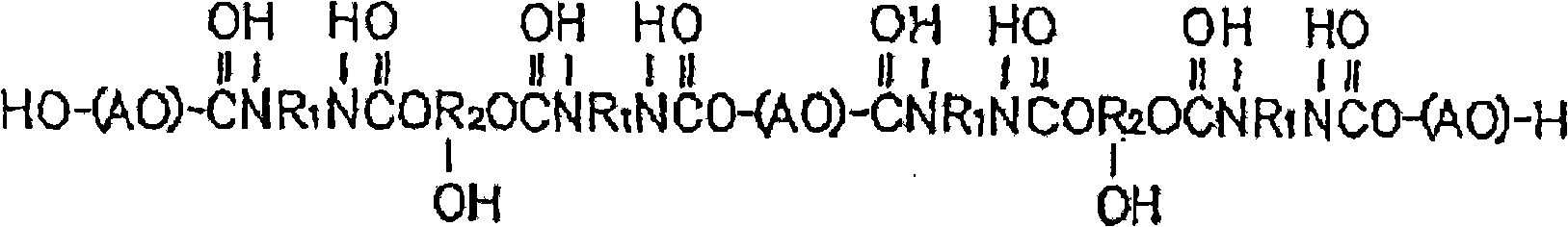

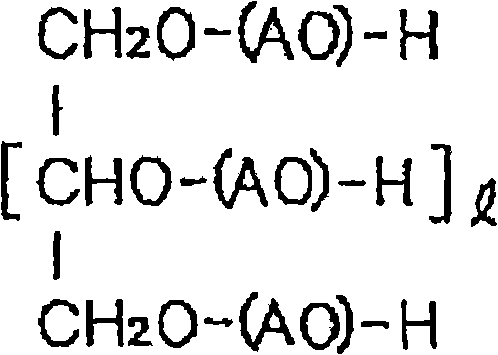

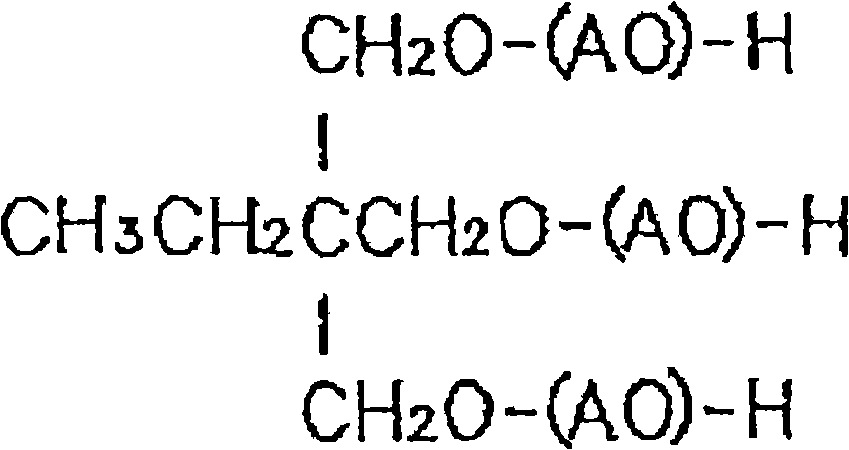

Hydroswellable, absorbable and non-absorbable, aliphatic, segmented polyurethanes and polyurethane-urea capable of swelling in the biological environment with associated increase in volume of at least 3 percent have more than one type of segments, including those derived from polyethylene glycol and the molecular chains are structurally tailored to allow the use of corresponding formulations and medical devices as carriers for bioactive agents, rheological modifiers of cyanoacrylate-based tissue adhesives, as protective devices for repairing defective or diseased components of articulating joints and their cartilage, and scaffolds for cartilage tissue engineering.

Owner:POLY MED

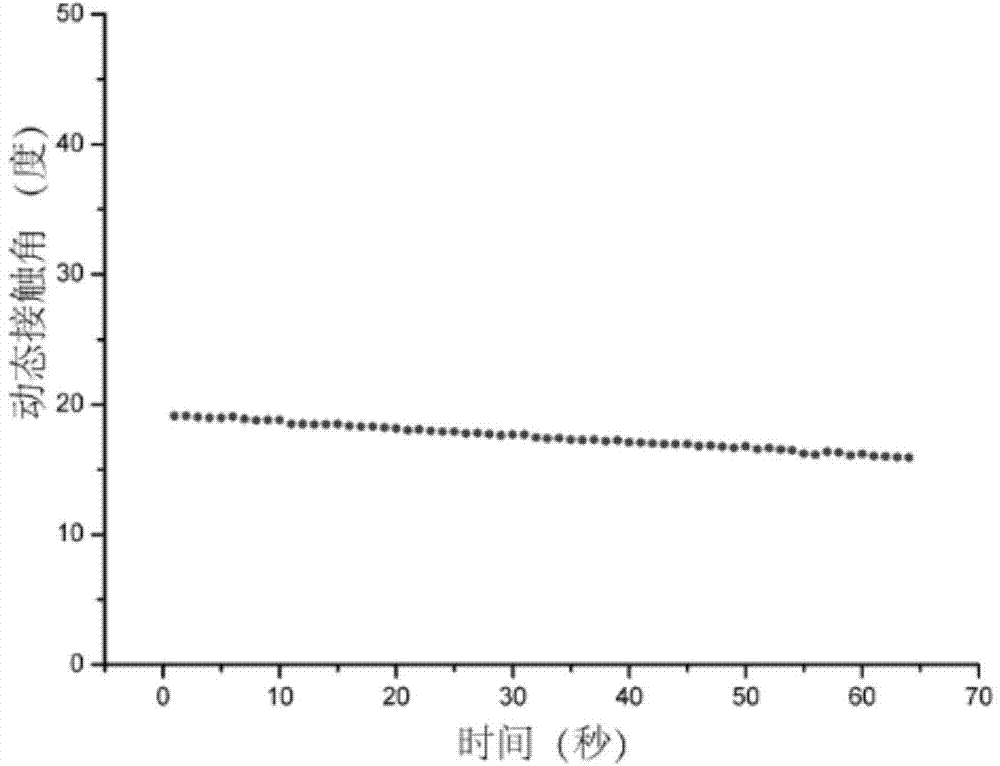

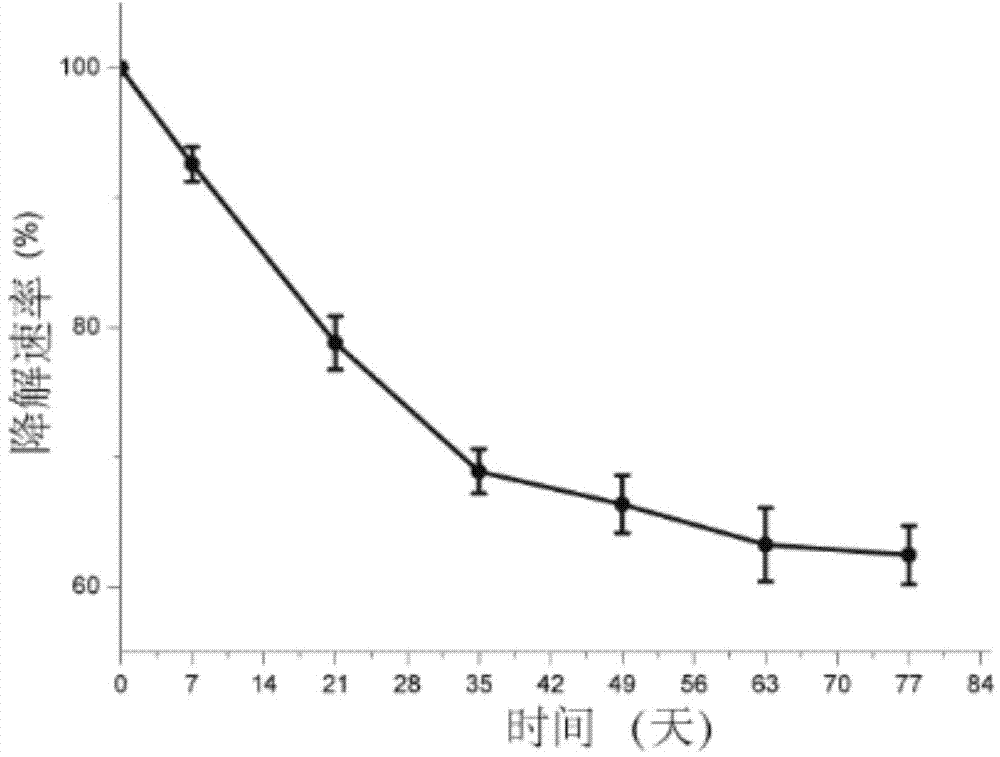

Hydrophilic degradable segmented polyurethane as well as preparation method and application thereof

InactiveCN104744661AGood biocompatibilityFast degradation rateAdditive manufacturing apparatusSurgeryPolyesterPolymer science

The invention relates to hydrophilic degradable segmented polyurethane as well as a preparation method and application thereof. The segmented polyurethane provided by the invention is a polymer of tri-block polyester polyol, diisocyanate, a chain extender and a catalyst, wherein the tri-block polyester polyol is a polymer of e-caprolactone monomer and polyethylene glycol with the molecular weight of 2000 according to a mol ratio of (8.75-70):1. The preparation method comprises the following steps: sufficiently mixing the e-caprolactone monomer, the polyethylene glycol and the catalyst, and polymerizing to form the tri-block polyester polyol; dissolving the tri-block polyester polyol in an organic solvent, adding the diisocyanate and the catalyst to obtain a prepolymer; and finally adding the organic solvent and the chain extender, sufficiently stirring and mixing for 7h, pouring into a mould and evaporating the organic solvent to obtain the product. The segmented polyurethane provided by the invention is excellent in tensile strength, hydrophilia and biodegradability, suitable for use in the tissue engineering and tissue repair, and particularly suitable for use as a rack and a rack coating.

Owner:NINGBO MEDICAL CENT LIHUILI HOSPITACL

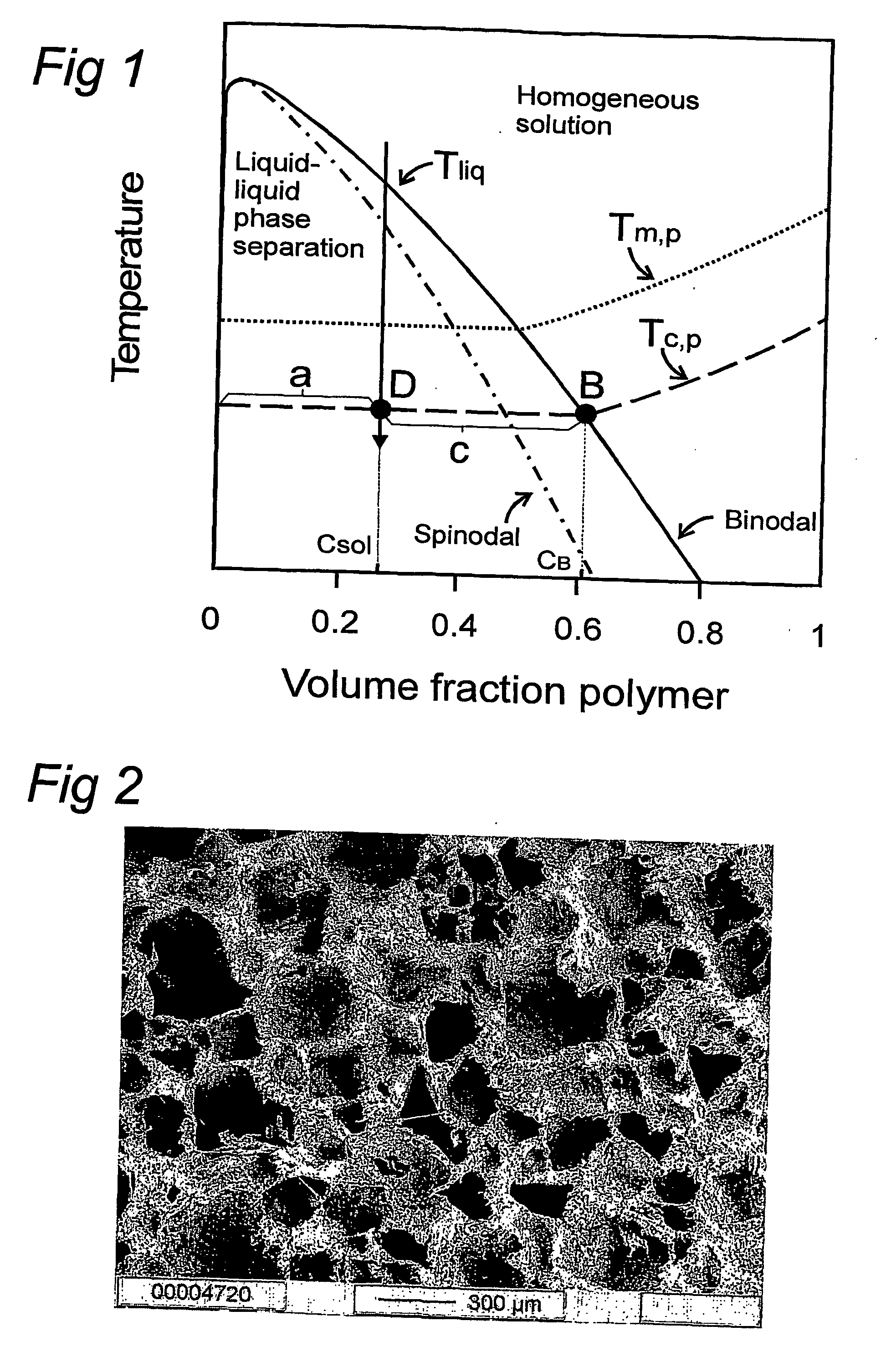

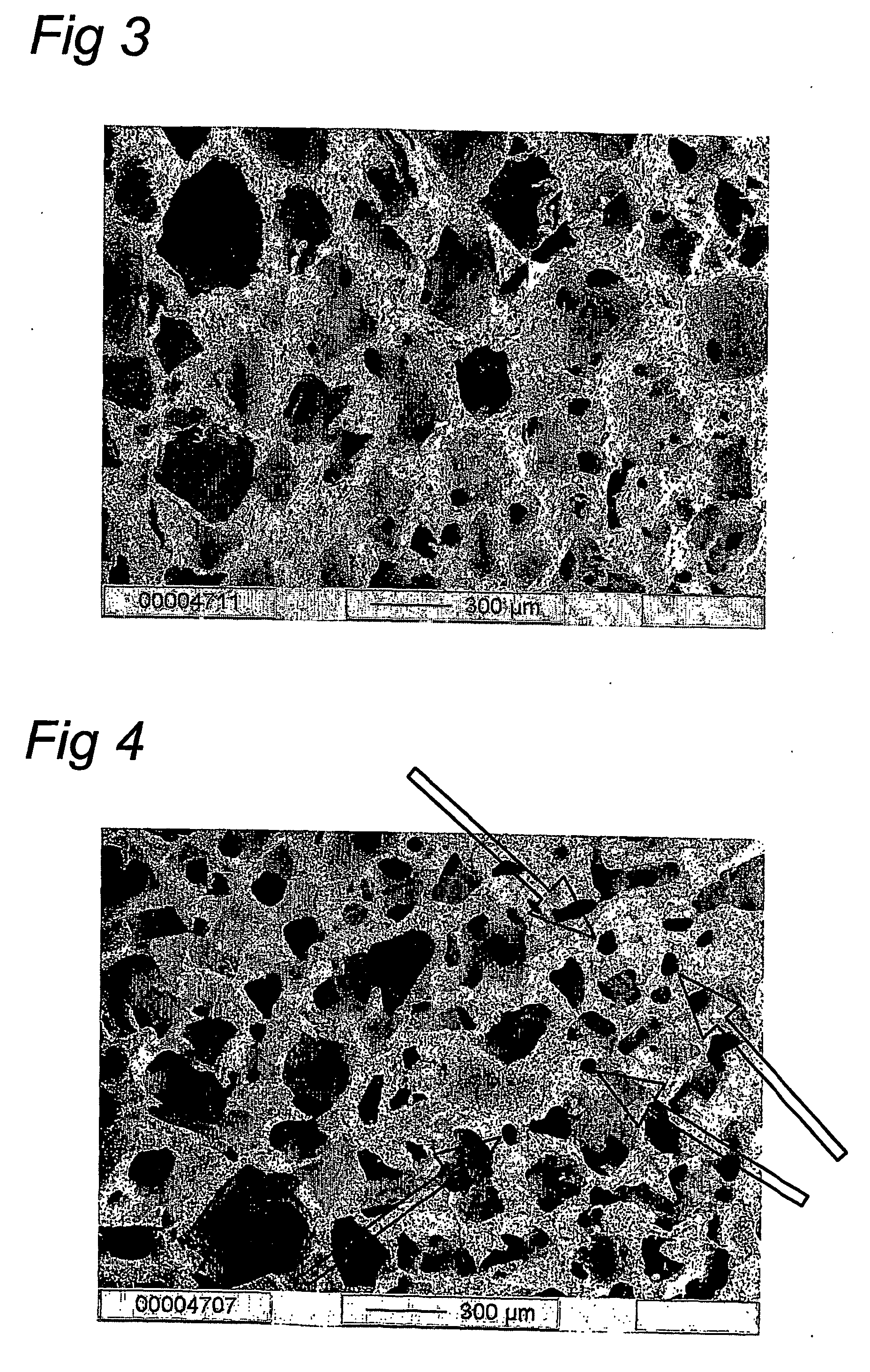

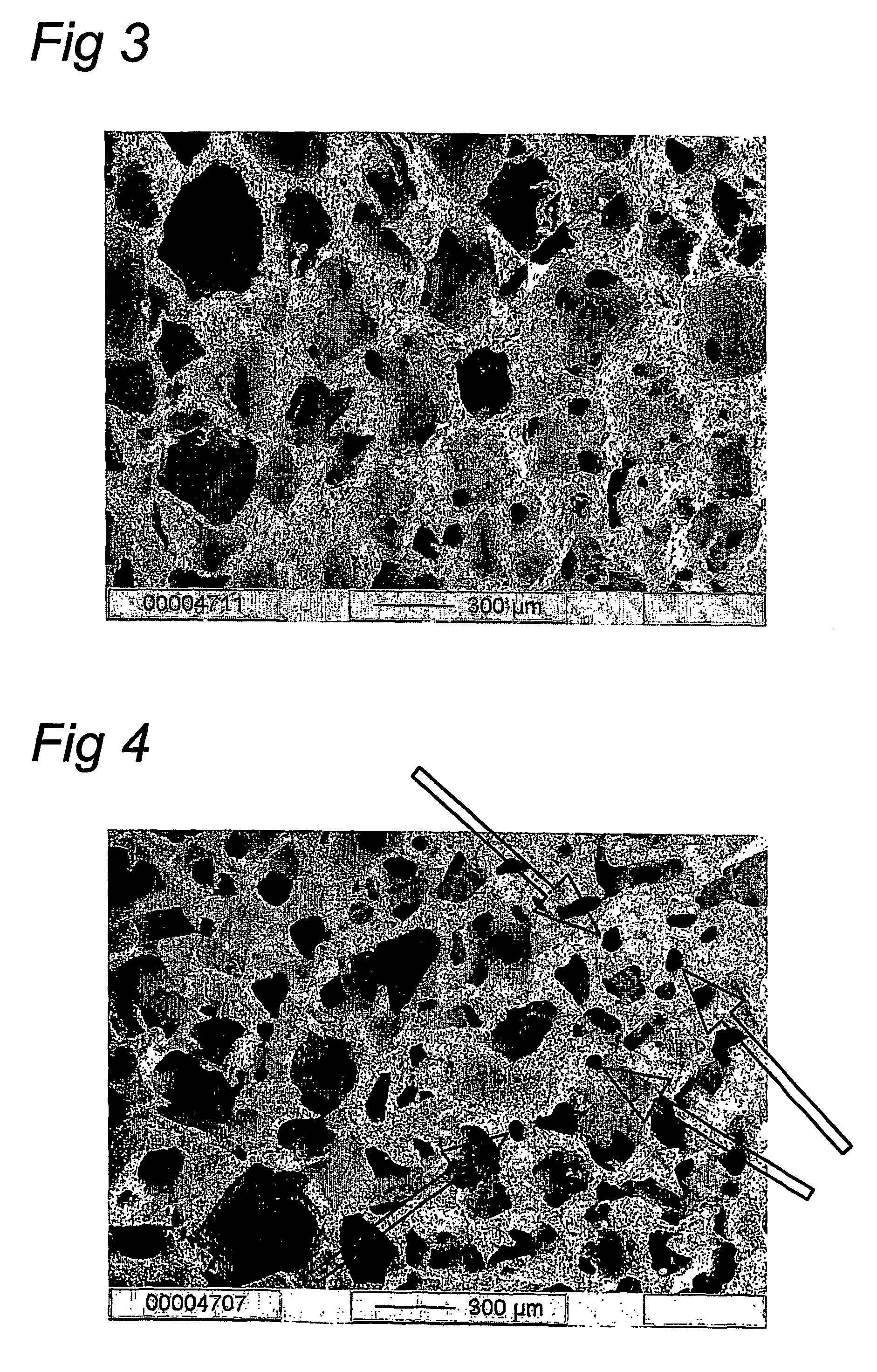

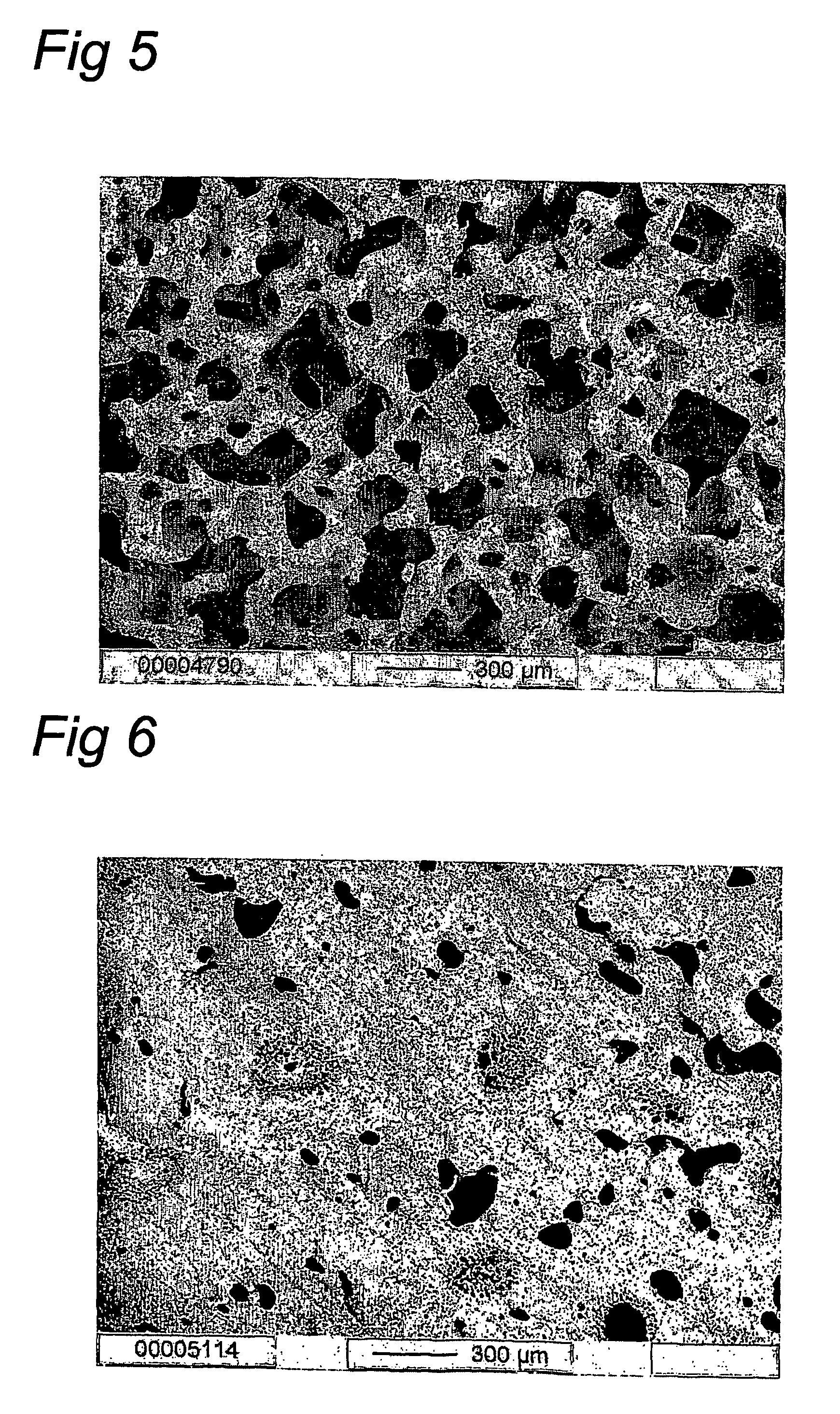

Method for the preparation of new segmented polyurethanes with high tear and tensile strengths and method for making porous scaffolds

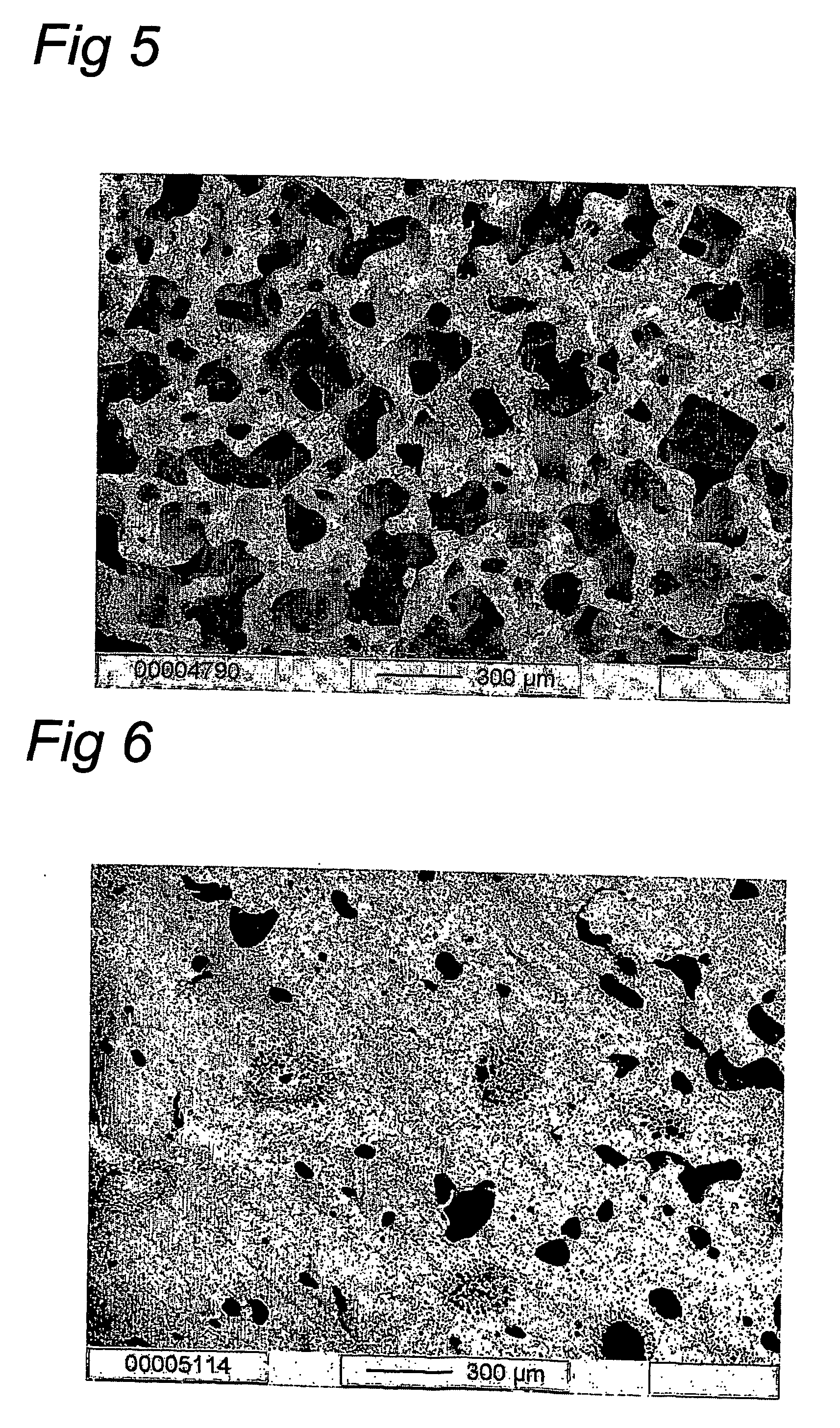

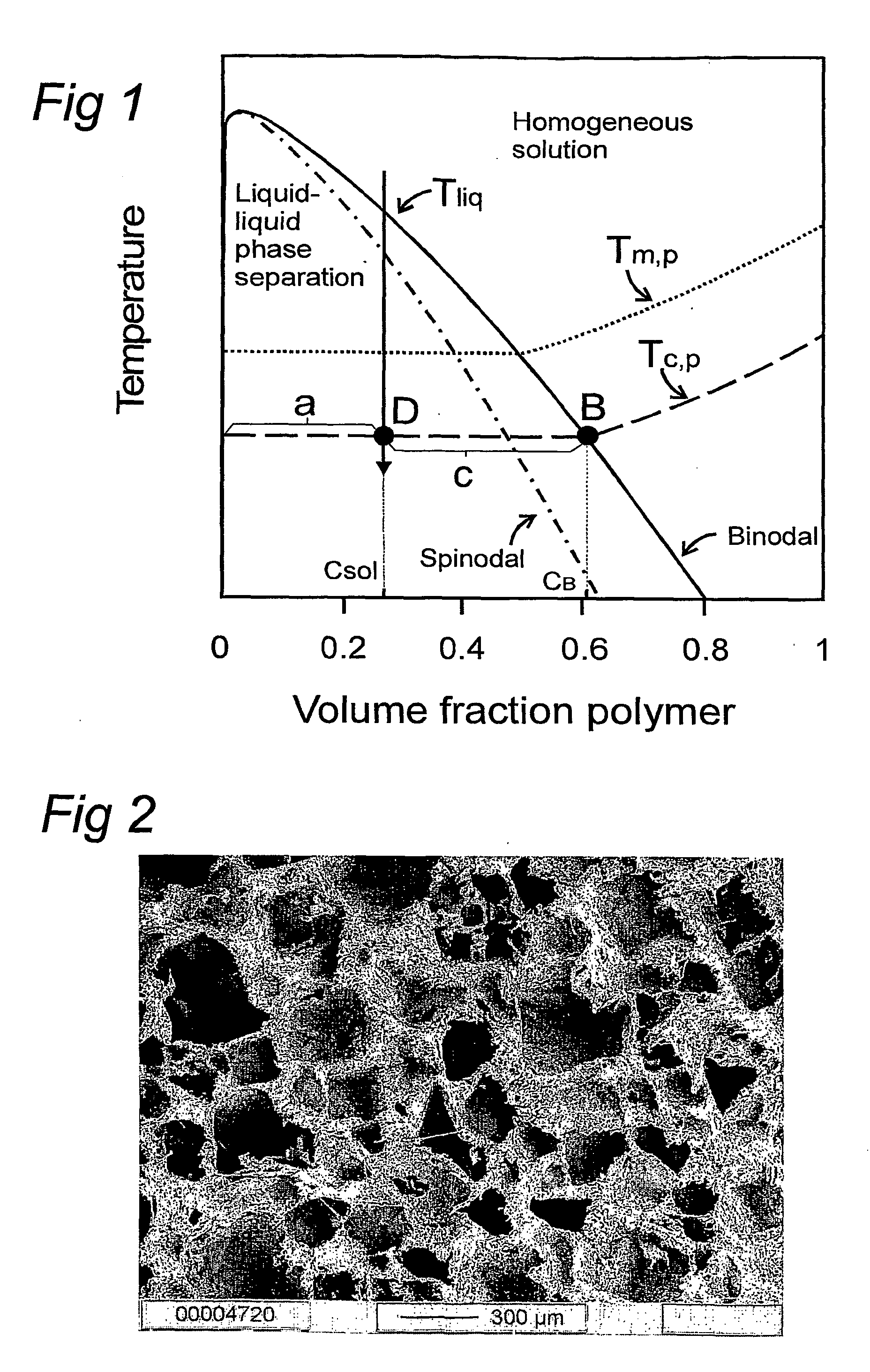

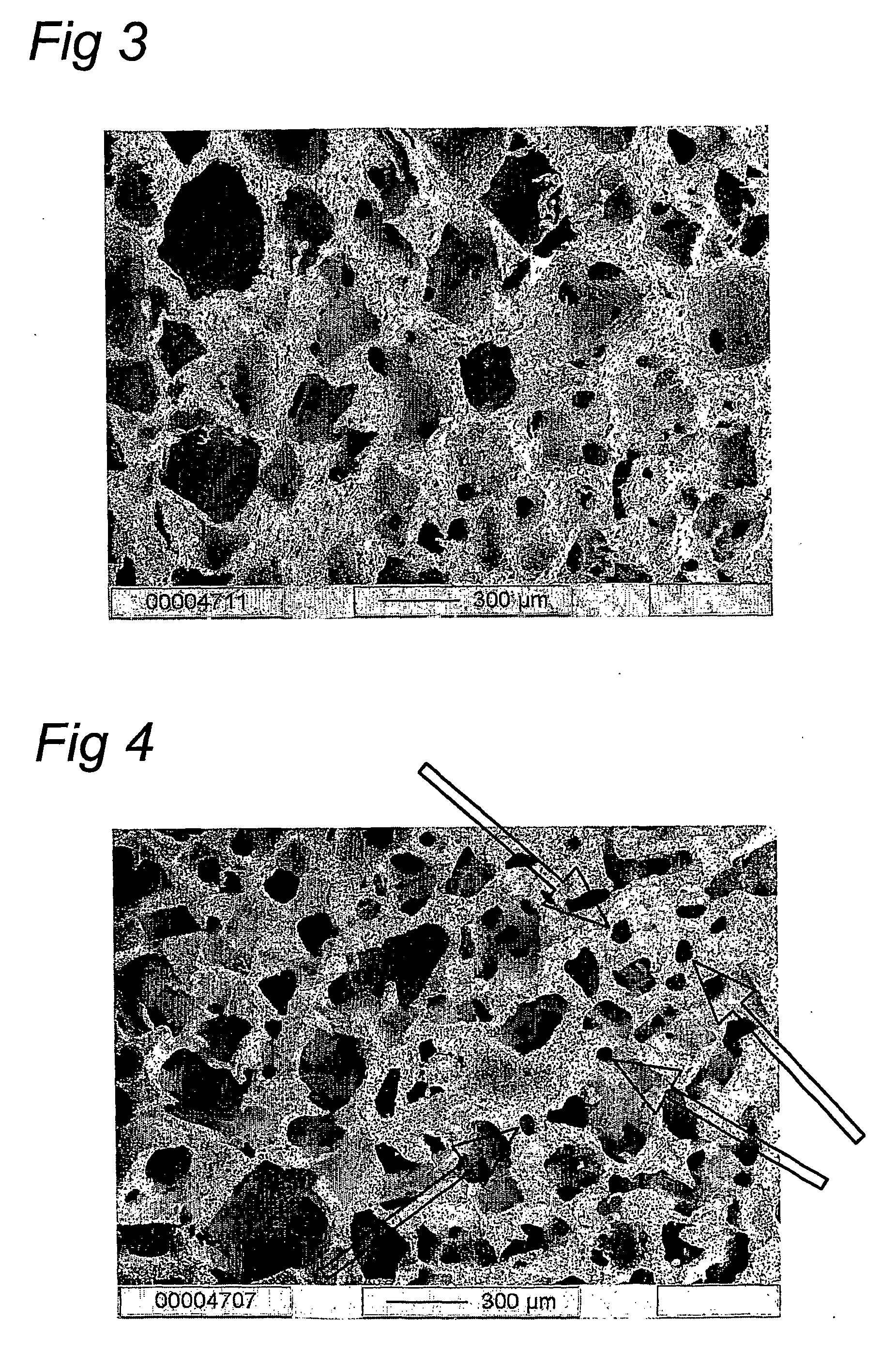

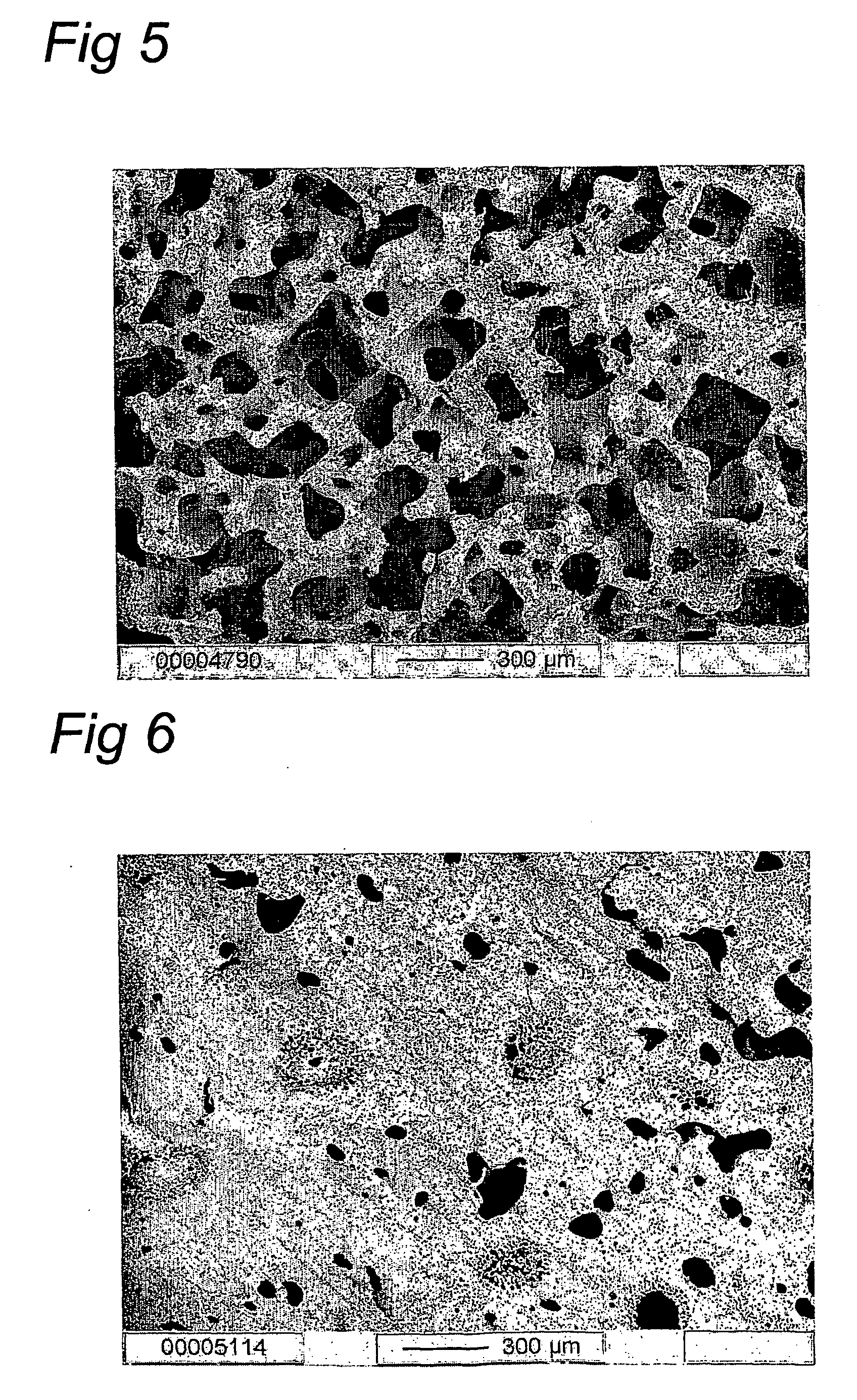

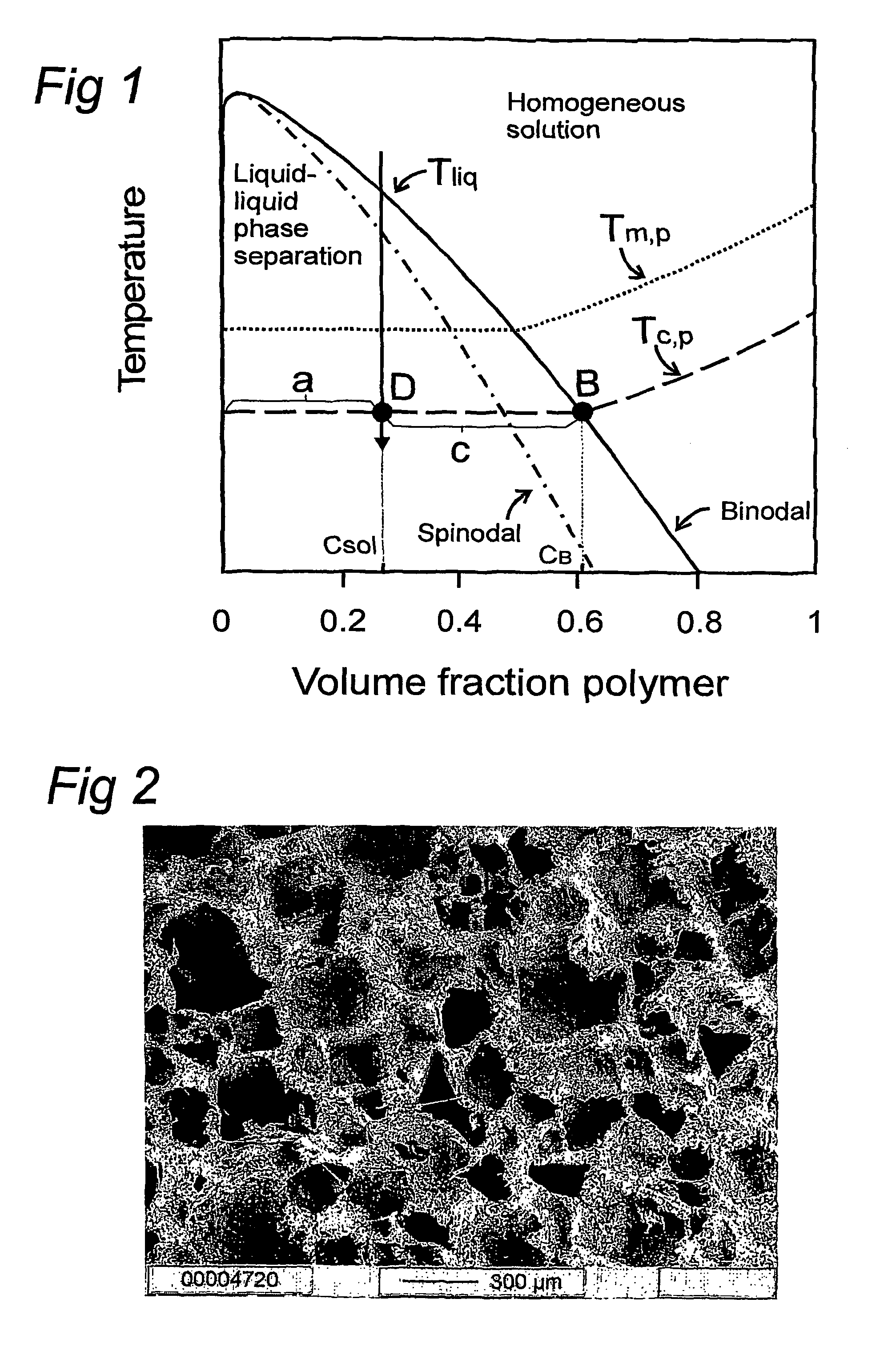

The invention presents a new method to prepare biomedical polyurethanes with high tensile and tear strengths. Such polyurethanes are especially interesting for making foams thereof, e.g. as meniscus implants. A new method, applicable to the biomedical polyurethanes, has been found to make such foams, that can be used as scaffolds. This method is based on salt leaching and phase separation.

Owner:ORTEQ

Segmented polyurethane hotmelt adhesives

A reactive hotmelt adhesive is prepared which contains a reaction product of a stoichiometric excess of a polyisocyanate with a hydroxyl-functional polyester-ether block copolymer based on aromatic dicarboxylic acids. The adhesive additionally contains a reaction product of a polyisocyanate and at least one of either a polyether polyol or a polyester polyol. A thermoplastic polymer may also be present.

Owner:HENKEL KGAA

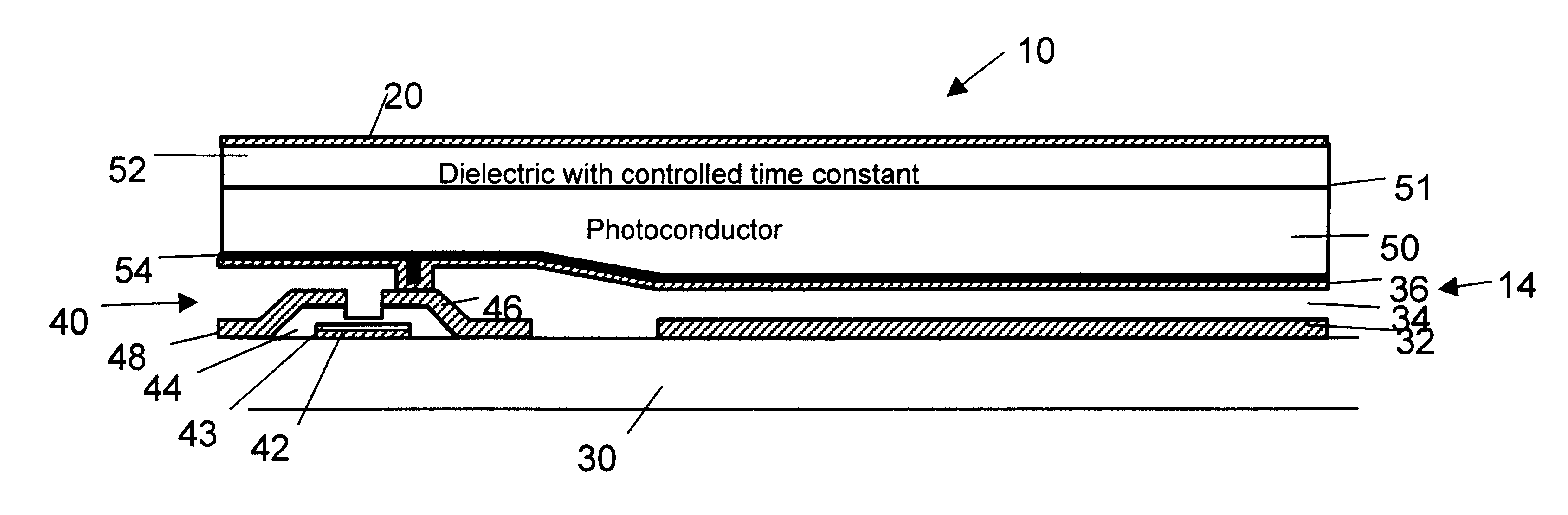

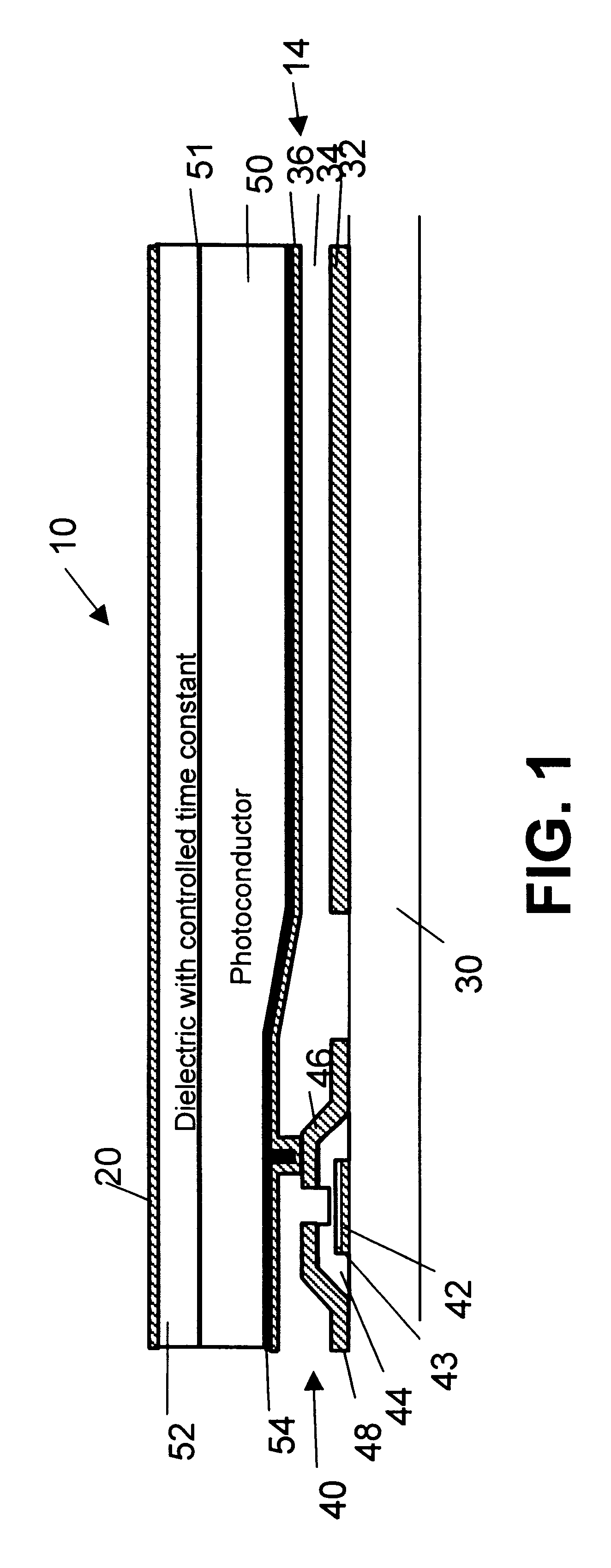

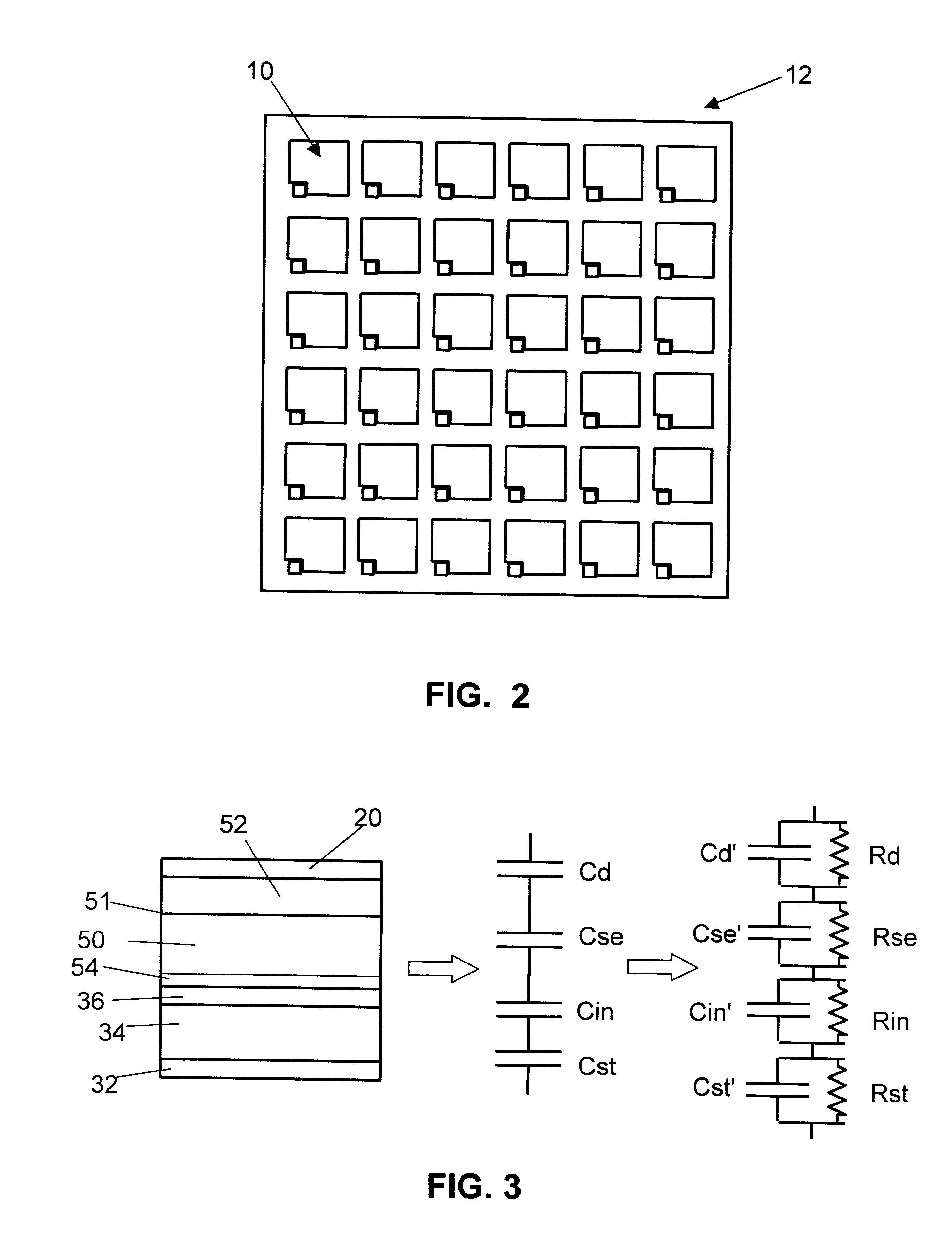

Direct radiographic imaging panel having a dielectric layer with an adjusted time constant

InactiveUS6194727B1Solid-state devicesMaterial analysis by optical meansSensor arrayElectrical conductor

A panel for radiation detection having a plurality of sensors arrayed thereon. Each sensor includes a charge storage capacitor, a radiation sensitive layer over the charge storage capacitor and a dielectric layer over the radiation sensitive layer. The dielectric layer has an adjusted resistivity resulting in a time constant τ=rhokappaepsi0 between 0.050 and 20 seconds, wherein kappa is the dielectric constant of the dielectric layer, and epsi0 is the permitivity of free space. The radiation detection layer is a photoconductor, and the dielectric layer is, preferably, a linear segmented polyurethane.

Owner:DIRECT RADIOGRAPHY

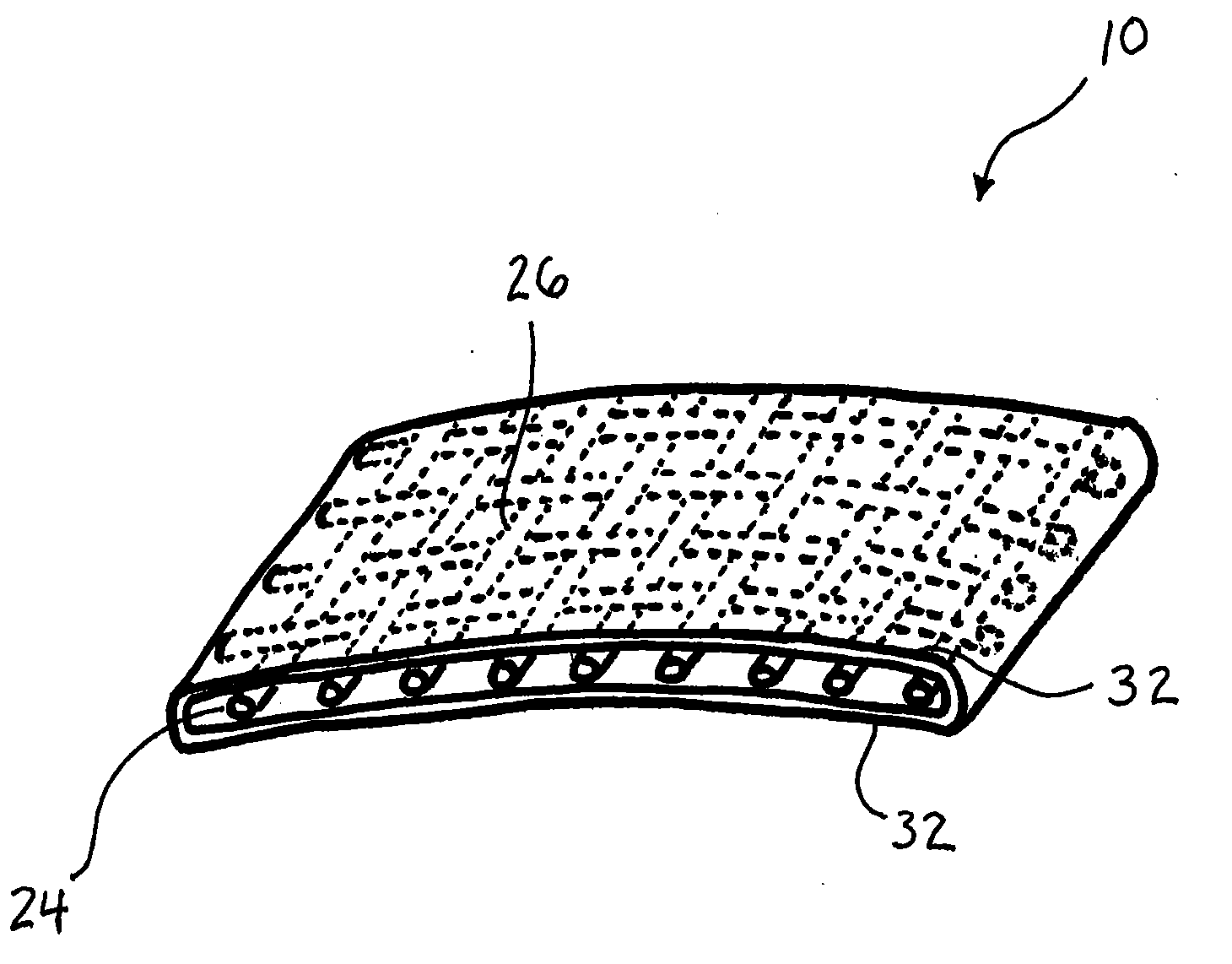

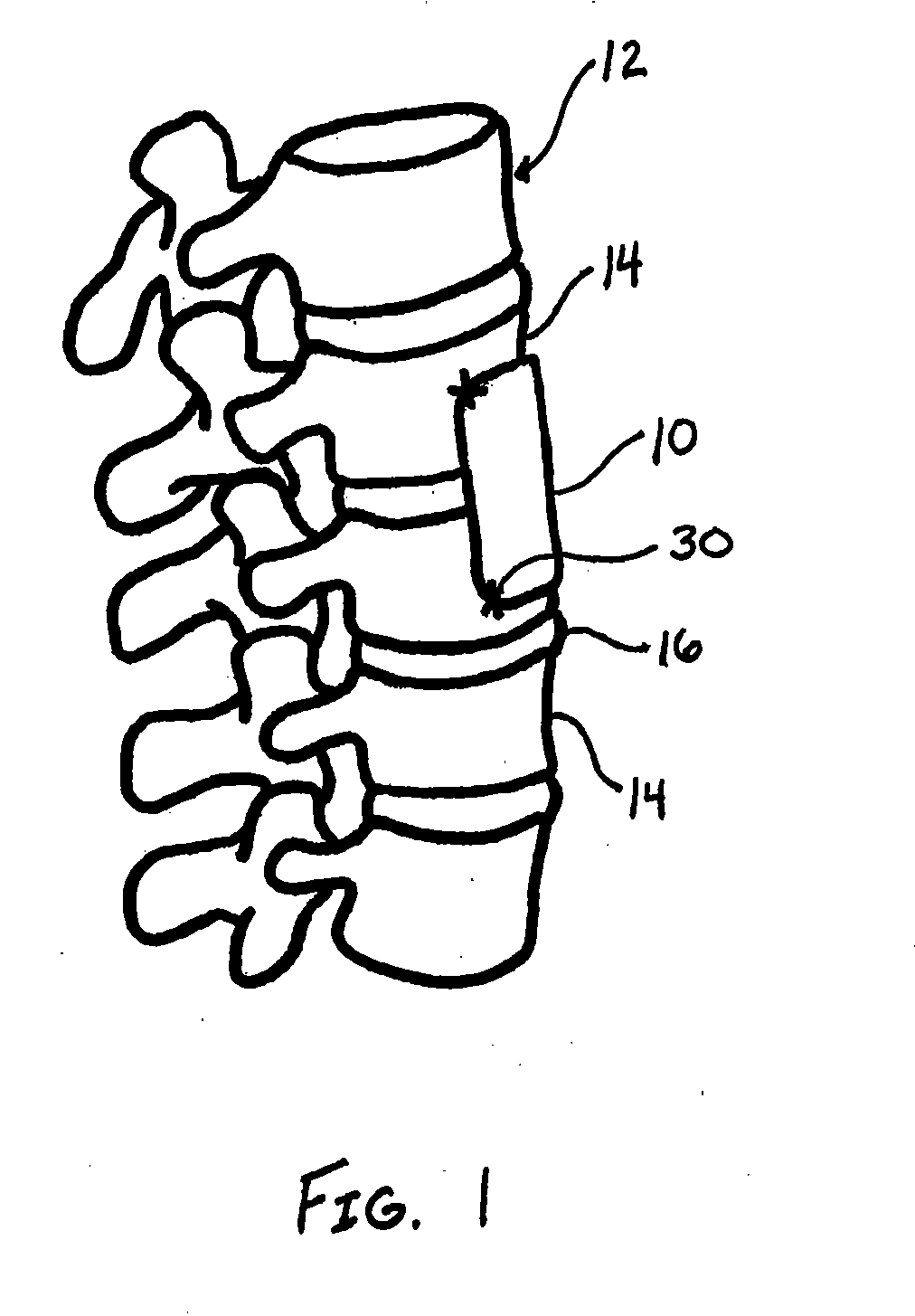

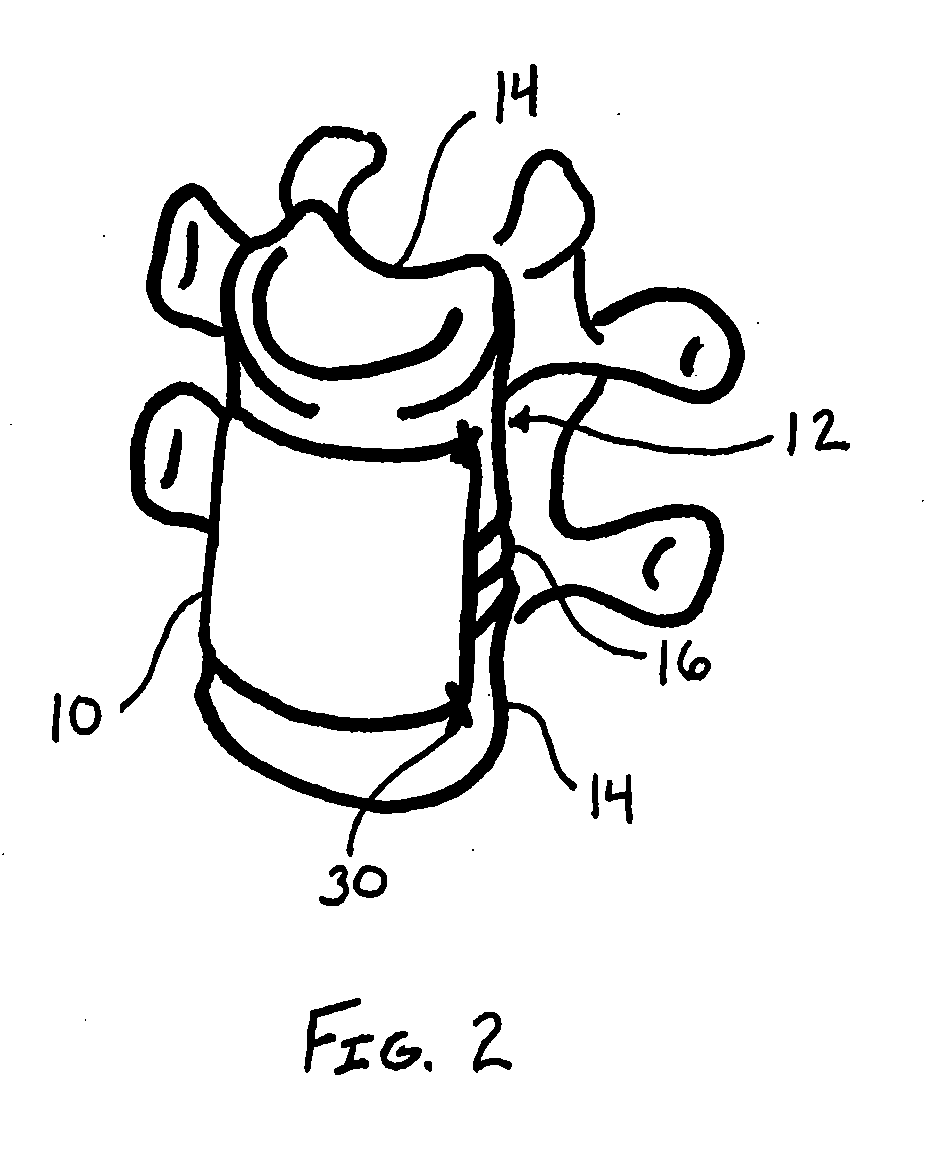

Vessel protection device

The present disclosure relates to a vessel / tissue protection device having a polymer coated reinforcing layer. The polymer can comprise a biocompatible polymer that will not promote tissue in-growth or attachment, such as segmented polyurethane, polycarbonate urethane, polyether urethane, polyacrylonitrile, etc. The reinforcing layer can comprise any suitable woven, non-woven, knitted, or braided reinforcing polymer, fabric, or foil that is biocompatible and capable of holding a suture, staple, or other attachment device.

Owner:REPLICATION MEDICAL

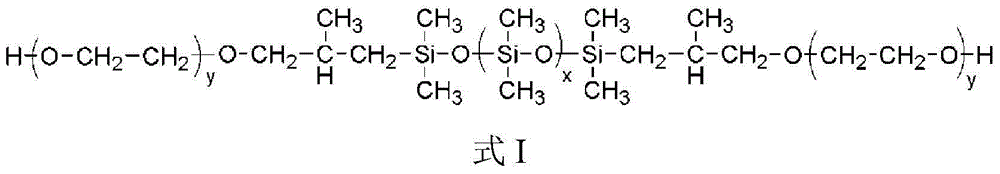

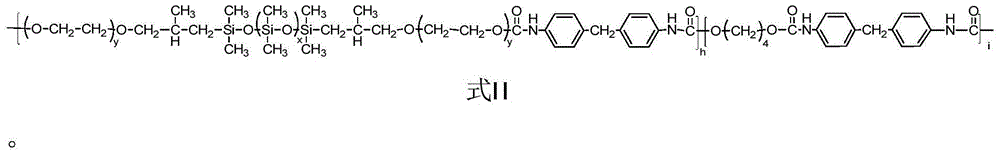

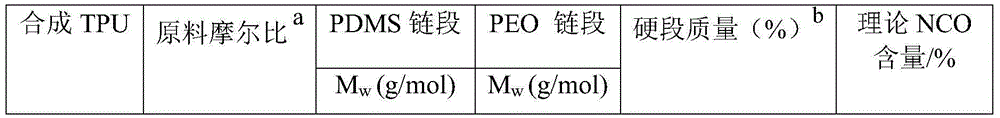

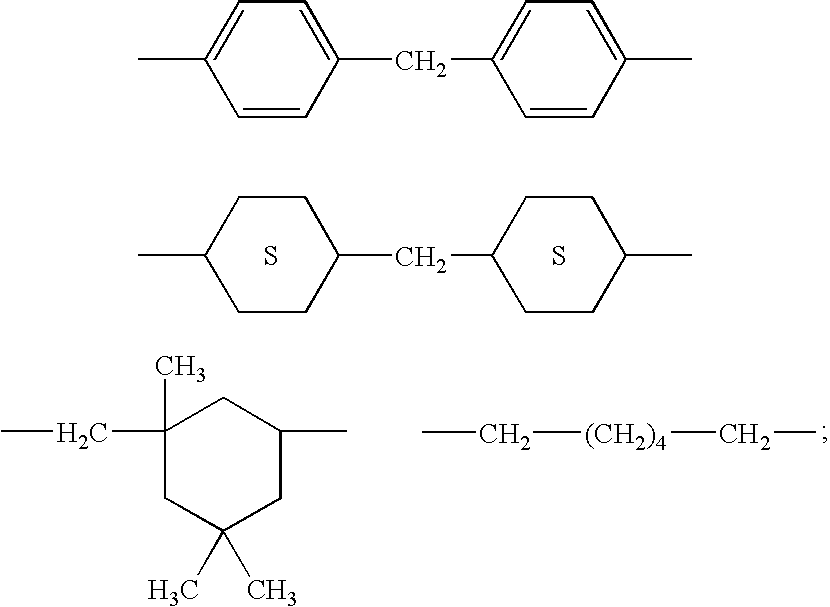

Method for manufacturing polyether organosilicone segmented polyurethane material, product and application

InactiveCN104448231AGood mechanical propertiesImprove low temperature performanceSurgeryPharmaceutical delivery mechanismRoom temperatureSolvent free

The invention discloses a method for manufacturing a polyether organosilicone segmented polyurethane material, a product and application. The method for manufacturing the polyether organosilicone segmented polyurethane material comprises the following steps that (1), under the condition of protective gas, namely, the solvent-free condition, MDI and PEO-PDMS-PEO are evenly mixed, and copolymerization is carried out under the condition of 70 DEG C to 100 DEG C, and polyether organosilicone block polyurethane prepolymer is manufactured; (2), the polyether organosilicone block polyurethane prepolymer and BDO are mixed evenly, the mixture is poured into a preheated teflon disc, then, the teflon disc is placed in an oven of 110 DEG C to be heated for 1 h, the teflon disc continues to be cured in an oven of 90 DEG C for 12 h after demolding, and the teflon disc is cured for one week at room temperature. The method is simple in step, free of solvents and more environmentally friendly. The polyether organosilicone segmented polyurethane material is excellent in mechanical property, low temperature property and hydrophobic property, no solvent residue exists, and the material can be used as a biological material implanted into a human catheter.

Owner:EAST CHINA UNIV OF SCI & TECH

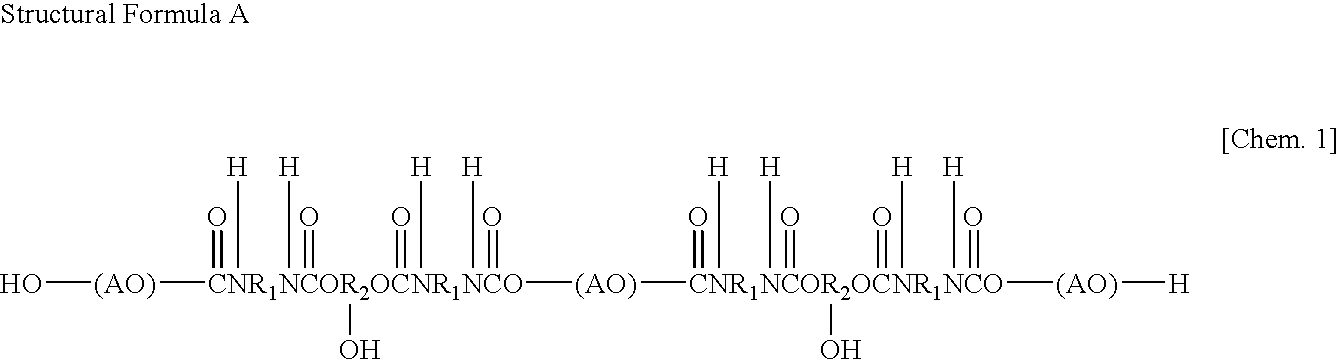

Nano-bentonite modified watersoluble polyurethane paint and manufacture method thereof

InactiveCN101245222ALarge specific surface areaHigh activityPolyurea/polyurethane coatingsEmulsion paintsPolyolSodium Bentonite

The invention discloses a nano bentonite modified waterborne polyurethane coating, which comprises: 55 to 75g of polyether polyol, 10 to 30g polyisocyanate, 3.5 to 7.5g of hydrophilicity chain expanding agent, 1.5 to 3.5g of crosslinking agent, 1.5 to 5.5g of salt forming agent, 0.8 to 3.8g of nanometer bentonite, 170 to 270g of deionized water; the particle size of nanometer bentonite is 20 to 100nm. The nano bentonite modified waterborne polyurethane coating is bonded with segmented polyurethane by hydrogen bond formation, reinforces the acting force between molecules, improves cohesive force of hard segment domain after film forming, improves degree of phase separation of soft and hard segment domain, has excellent mechanical property, and strong ultraviolet and ageing resistant function.

Owner:李伟

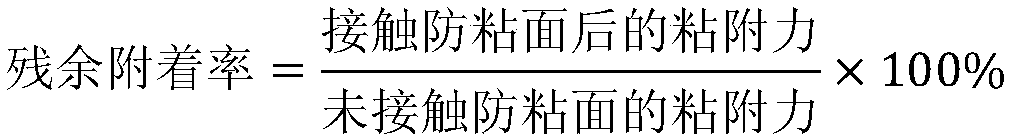

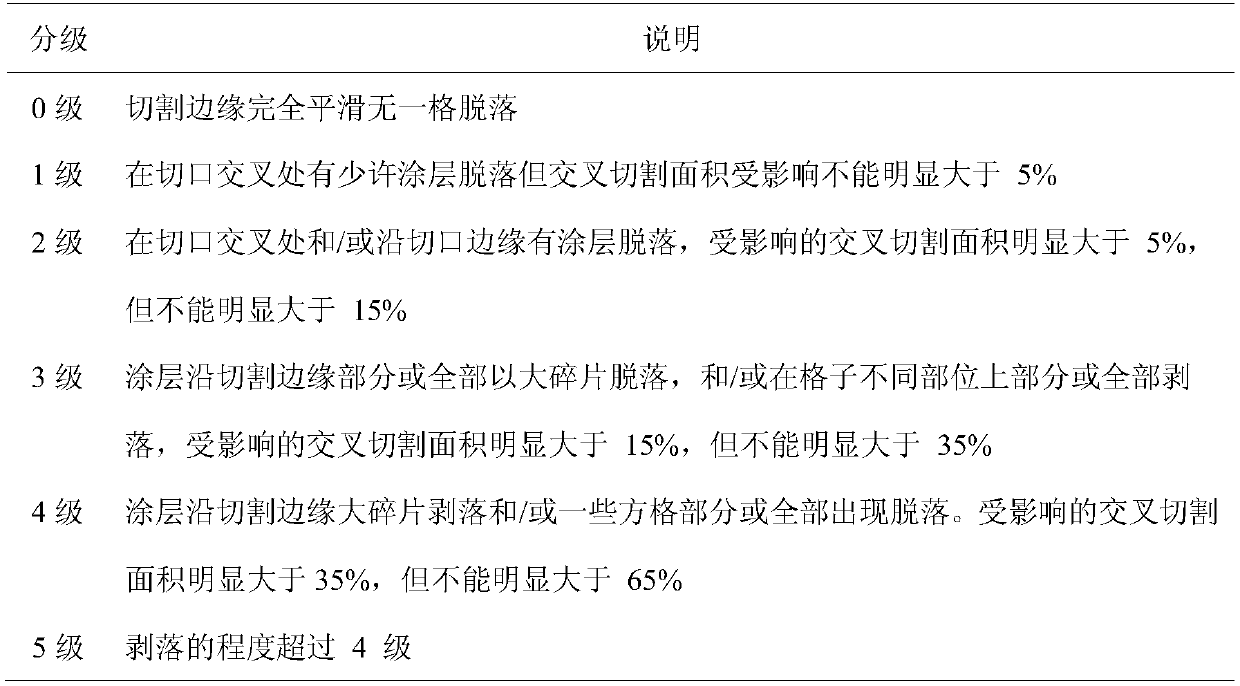

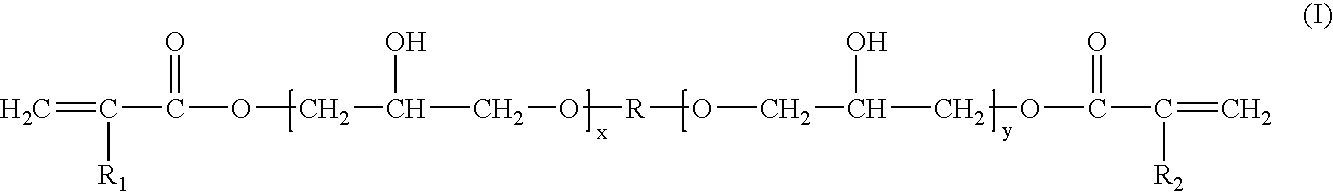

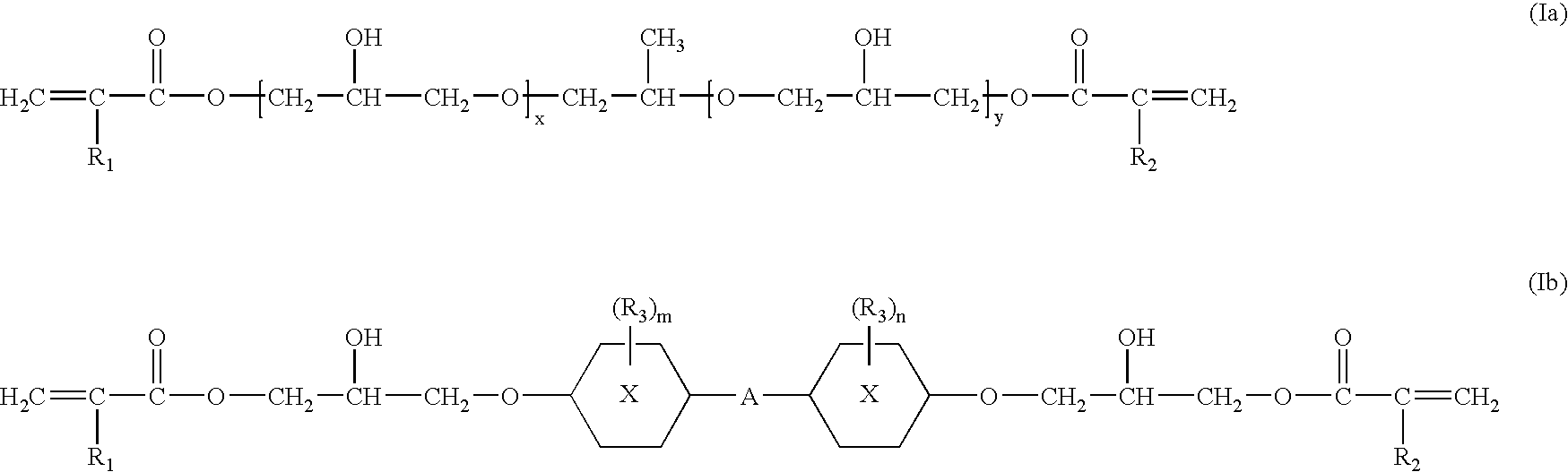

Preparation method of ultraviolet light polymerization fluorosilicone release film for optical display

ActiveCN108676189ALow release forceLow hazePolyurea/polyurethane coatingsFilm/foil adhesive release linersPolyethylene glycolUltraviolet lights

The invention relates to a preparation method of an ultraviolet light polymerization fluorosilicone release film for optical display. The method comprises the following steps of firstly performing polymerization reaction on hydroxyalkyl silicone oil, fluorine-containing dihydric alcohol and diisocyanate under the effects of organic tin catalysts; then, adding polymerization inhibitors and acrylichydroxyl ester for termination so as to prepare fluorosilicone segmented polyurethane acrylate oligomers; next, active diluent monomers and photoinitiators are added for uniform mixing; a release agent is obtained; the release agent is uniformly coated onto an organic substrate; after ultraviolet light curing, the release film is obtained. The ultraviolet light polymerization fluorosilicone release film for optical display has the advantages that the release force is light; the fog degree is low; the light transmission rate and the residue attachment rate are high; the attaching force of the coating film on the polyethylene glycol terephthalate film is at the grade 1; the release film can be widely used for formation components of various displays of polarizers for tablet displays, organicEL and the like; the preparation method is simple; the addition of organic solvents is not needed in the coating curing process; the harm of solvents to the human body and the environment can be effectively avoided.

Owner:SOUTHEAST UNIV

Coatings for implantable medical devices comprising hydrophilic substances and methods for fabricating the same

A segmented polyurethane and an amphiphilic random or block copolymer are disclosed. The segmented polyurethane and the amphiphilic random or block copolymer can be used for fabricating a coating for an implantable medical device such as a stent.

Owner:ABBOTT CARDIOVASCULAR

Fusible bicomponent spandex

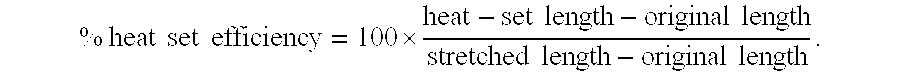

ActiveUS20160122907A1Solving the Insufficiency of ElasticityResists seam slippageWarp knittingFilament/thread formingSegmented polyurethaneHeat sensitive

Included are segmented polyurethane elastic fibers or spandex fibers, capable of bonding to polymer fiber such as nylon or polyamide fibers, in addition to bonding to itself, for apparel textile applications. More particularly the invention relates to bicomponent spandex fibers, with a heat resistant core and a heat sensitive sheath, spun from polymer solutions. The nylon fabrics containing such spandex fibers have enhanced stretch performance and improved surface appearance after heat treatment to activate the fusing and bonding between nylon fibers and spandex fibers.

Owner:THE LYCRA CO LLC

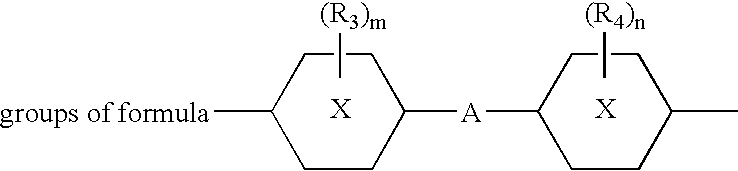

Spandex having low heat-set temperature and materials for their production

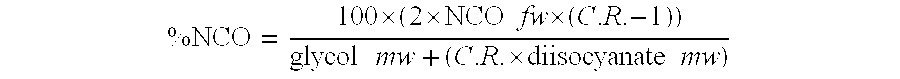

InactiveUS20060135724A1Improve efficiencyProduct can be usedMonocomponent polyurethanes artificial filamentEthylenediamineSaturated Level

Segmented polyurethane / ureas useful in the production of spandex with improved heat set are produced by chain extending an isocyanate-terminated prepolymer with a diamine chain extender that includes: (1) greater than 25 to 75 equivalent percent of an asymmetric aliphatic and / or cycloaliphatic diamine and (2) a linear diamine such as ethylene diamine in the presence of a solvent. The isocyanate-terminated prepolymer having an isocyanate group content of from about 2.25 to about 4 is produced by reacting a stoichiometric excess of an isocyanate with an isocyanate-reactive component that includes: (1) from about 25 to about 75 equivalent percent of a polyoxypropylene diol having a molecular weight in excess of 1500 Da and an average unsaturation level of less than about 0.03 meq / g and (2) from about 25 to about 75 equivalent percent of a polytetramethylene ether glycol having a molecular weight of at least 600 Da.

Owner:BAYER MATERIALSCIENCE AG +1

Photochromic compositions, preparation thereof and articles made therefrom or coated therewith

The present invention relates to novel cross-linkable or crosslinked photochromic compositions, articles made from or coated with the compositions and method of making the compositions. The compositions contain (i) at least one segmented or non-segmented polyurethane-type or polyurethane-urea-type linear polymer having at least one non-terminal moiety that comprises at least one unsaturated group; and (ii) an effective amount of at least one photochromic organic compound, advantageously selected from spiroxazines, chromenes, spiropyrans fulgides and fulgimides.

Owner:CORNING INC

Fusible inkjet recording element and printing method

InactiveUS7264856B2Improve wear resistanceImprove waterproof performanceCultivating equipmentsCoatingsPolymer scienceSegmented polyurethane

An inkjet recording element comprising, over a porous, ink-receiving layer, a fusible, porous topmost layer comprising a film-forming, hydrophobic binder and fusible, polymeric particles of a non-segmented polyurethane, or salt thereof, comprising repeat units derived from a diisocyanate and a diol component comprising a mixture of diols, said diol mixture comprising: an anionically-substituted diol selected from carboxylic acid-, sulfonic acid-, and phosphonic acid-substituted diol and an ether containing short chain aliphatic diol, wherein the polyurethane has a Tg greater than about 70° C.

Owner:EASTMAN KODAK CO

Gel for ultrasonic phantom

InactiveUS20090286216A1Satisfactory ultrasonic characteristicPromote absorptionUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesPutrefactionSegmented polyurethane

A gel for an ultrasonic phantom is provided which has satisfactory ultrasonic characteristics, does not fluctuate in ultrasonic characteristics over long, and is free from germ multiplication, alteration, putrefaction, etc.The gel is a gel for ultrasonic phantoms which comprises: a segmented polyurethane gel having alkylene oxide segments which are mostly or wholly liquid at ordinary temperature; and a nonvolatile organic gel-swelling medium not participating in a urethane-forming reaction, the medium being contained in the segmented polyurethane gel. Due to the nonvolatile organic gel-swelling medium, the liquid segments and the like are kept in an extended state and the distance between the segments is increased. The gel hence has satisfactory ultrasonic characteristics concerning ultrasonic attenuation rate, propagation velocity, etc. The gel does not change in swelling-medium content with time and hence retains the satisfactory ultrasonic characteristics over long. Furthermore, the gel is free from germ multiplication, alteration, putrefaction, etc. because of the organic gel-swelling medium contained therein.

Owner:TAKIRON CO LTD

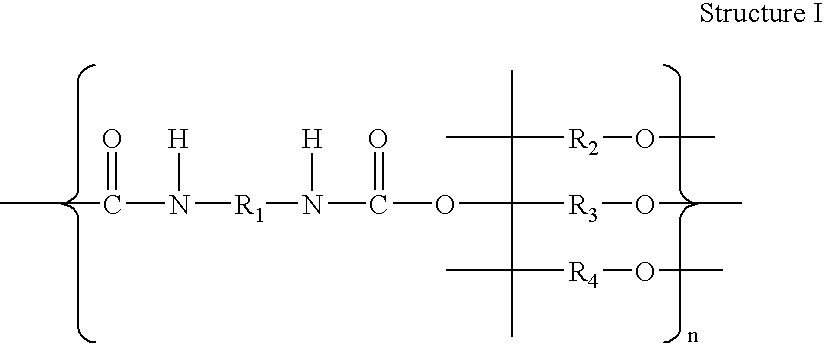

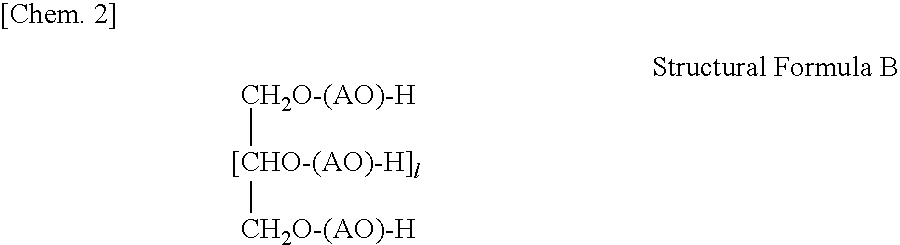

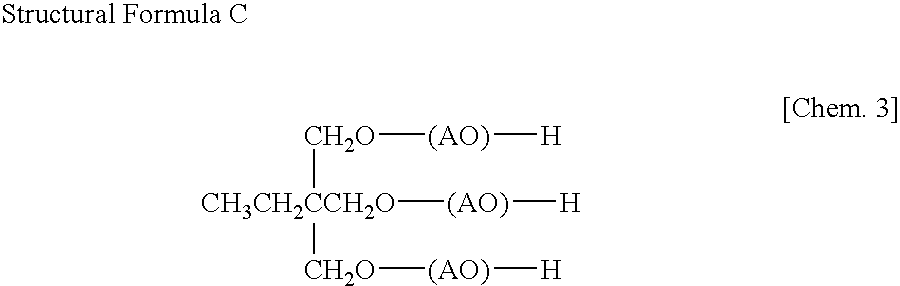

Novel degradable polyurethane biological material and preparation method and application thereof

InactiveCN108409938AImprove the function of repair and regenerationReduce risk of inflammatory responseSuture equipmentsAbsorbent padsChemical structureWound dressing

The invention discloses a novel degradable polyurethane biological material, a preparation method thereof and an application thereof in the preparation of degradable implantable / non-implantable medical instruments. The novel material is an alternatively segmented polyurethane polymer material prepared from biodegradable polyester glycol and hydrophilic polyether glycol and is prepared through selective coupling reactions between aliphatic polyester glycol and diisocyanate terminated hydrophilic polyether (or between aliphatic polyester glycol and diisocyanate terminated aliphatic polyester blocks). The biological material has a controllable and predictable chemical structure and regular polymer chain arrangement, also has a surface micro-phase patterned structure, can be widely used in many medical and non-medical instrument fields, and has an excellent performance in application fields such as peripheral nerve repairing conduit, meniscus repair, anti-adhesion film, meninx, eyelid reconstruction stent, wound dressing, composite bone porous repairing stent, soft / hard tissue regeneration, and the like.

Owner:许开天

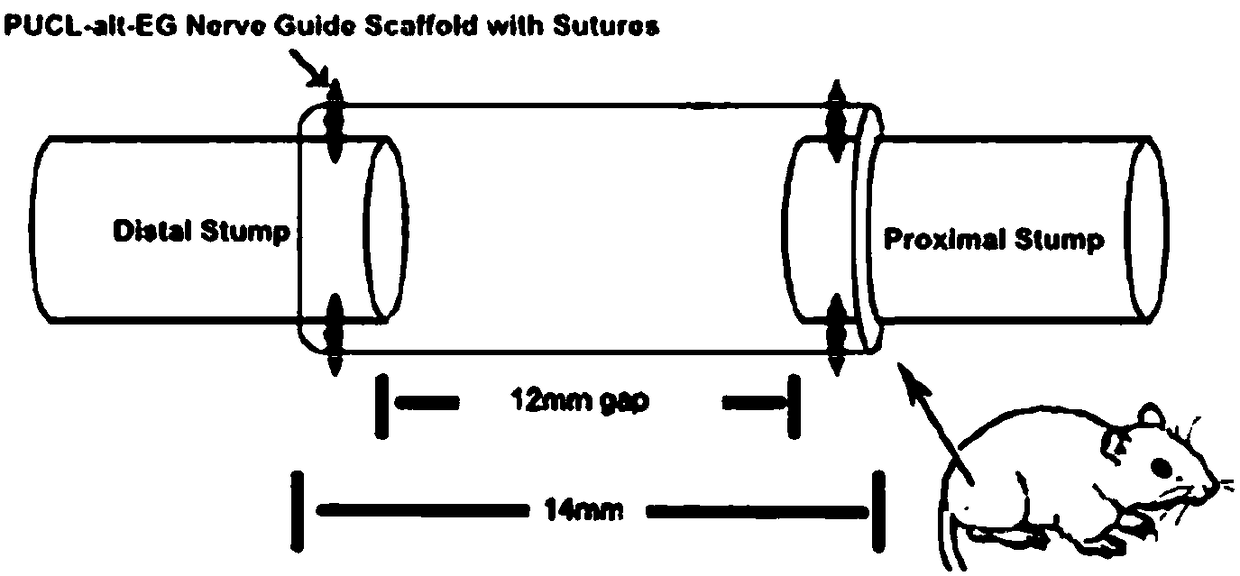

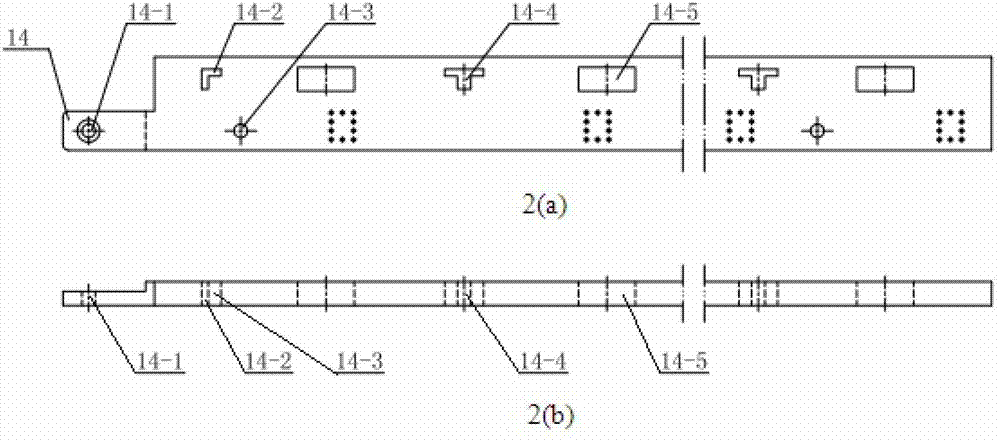

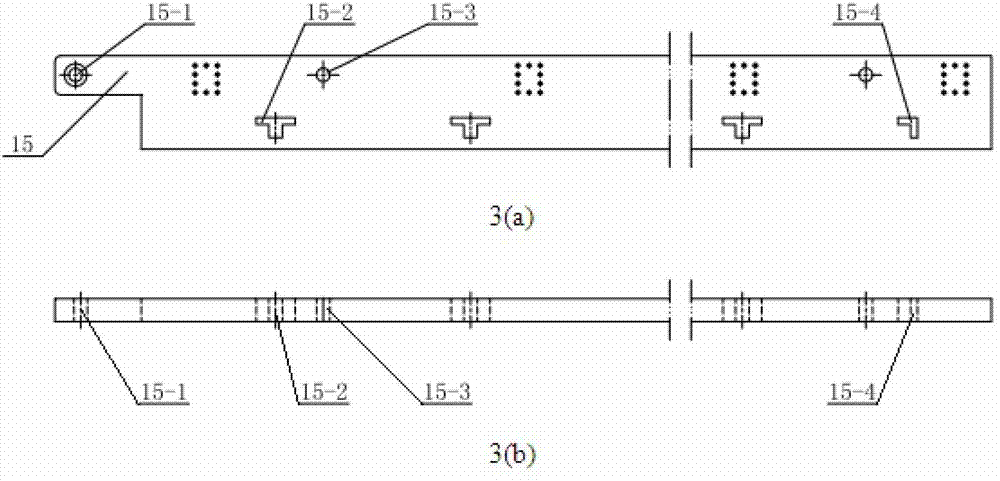

Bilateral-sector-support flip-flow screen

InactiveCN103240223AReduce processing complexityAchieve anti-corrosion effectSievingScreeningMotor driveReduction drive

The invention discloses a bilateral-sector-support flip-flow screen. The bilateral-sector-support flip-flow screen mainly comprises a brake, a speed reducer, a motor, two eccentric shafts, four connecting rod, a swing rod, an inner screen frame sector support, an outer screen frame sector support, an inner screen frame, an outer screen frame, screen fixing steel angles, a sector support guide rail, a segmented polyurethane screen surface and the like. The two eccentric shafts are connected with the swing rod by the four connecting rods to form a crank swing rod mechanism. When the motor drives the eccentric shafts to rotate through the speed reducer, under the action of the connecting rods, the swing rod swings around a swing rod hinge hole back and forth so as to drive the inner screen frame and the outer screen frame to move relatively; and since two ends of the segmented polyurethane screen surface are fixed by the screen fixing steel angles of the inner screen frame and the outer screen frame, tension and relaxation scratching movement of the segmented polyurethane screen surface is realized. The inner screen frame support and the outer screen frame support can form an ejection surface with a certain inclination angle when the segmented polyurethane screen surface is tensioned, so that materials can bear large self weight and high impact pressure when forwarding and penetrating the screen. The bilateral-sector-support flip-flow screen has the advantages of novel working principle, simple structure, high bearing capacity and high reliability.

Owner:中国矿业大学盱眙矿山装备与材料研发中心 +1

Polyurethane/urea for producing spandex and its production method

Segmented polyurethane / ureas useful for the production of spandex are produced by chain extending, in the presence of a solvent, an isocyanate-terminated prepolymer prepared by reacting a stoichiometric excess of an isocyanate with an isocyanate-reactive component which includes: (1) from about 5 to about 30 equivalent percent of a polyoxypropylene diol having a molecular weight of at least 1500 Da and an unsaturation level less than or equal to 0.03 meq / g; (2) from about 20 to about 60 equivalent percent of a polytetramethylene ether glycol having a molecular weight less than 1000 Da; and (3) from about 25 to about 65 equivalent percent of a polytetramethylene ether glycol having a molecular weight greater than or equal to 1000 Da.

Owner:BAYER CORP

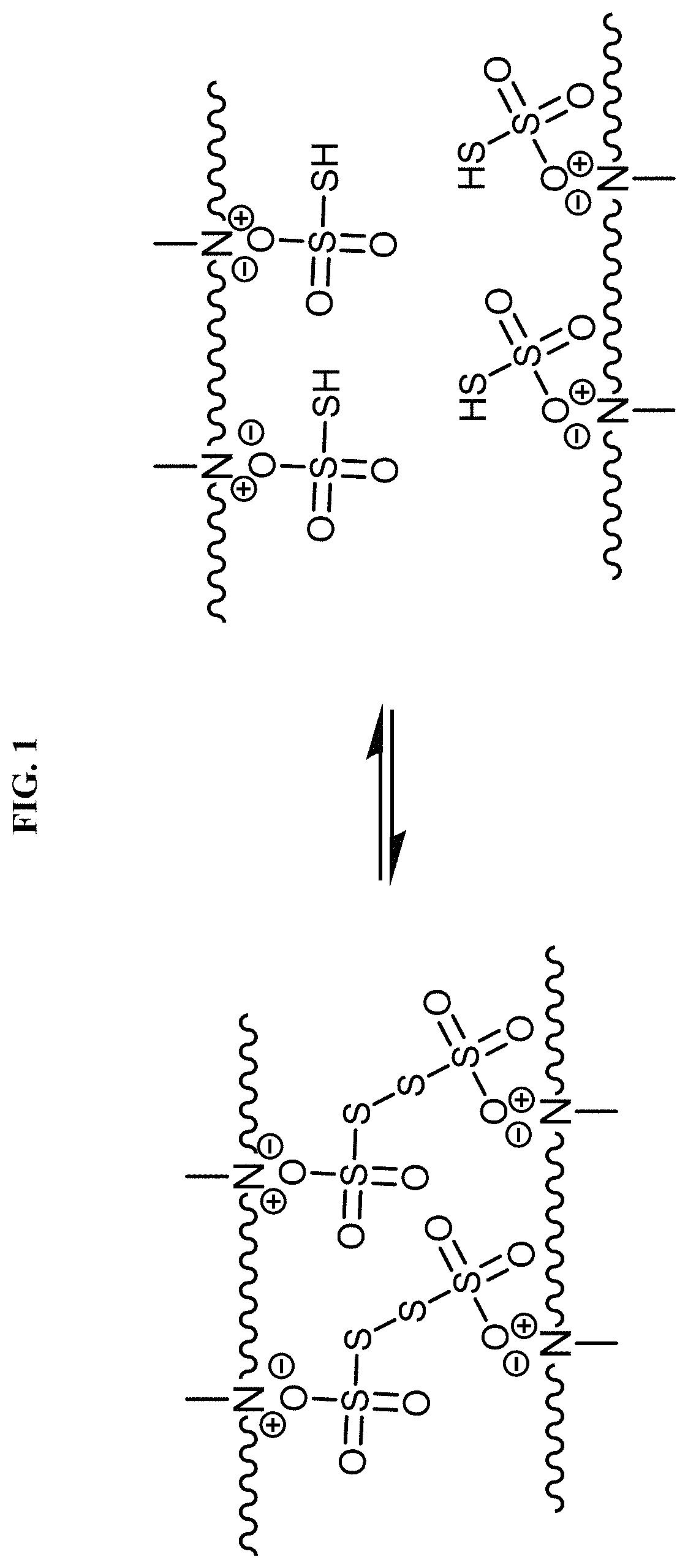

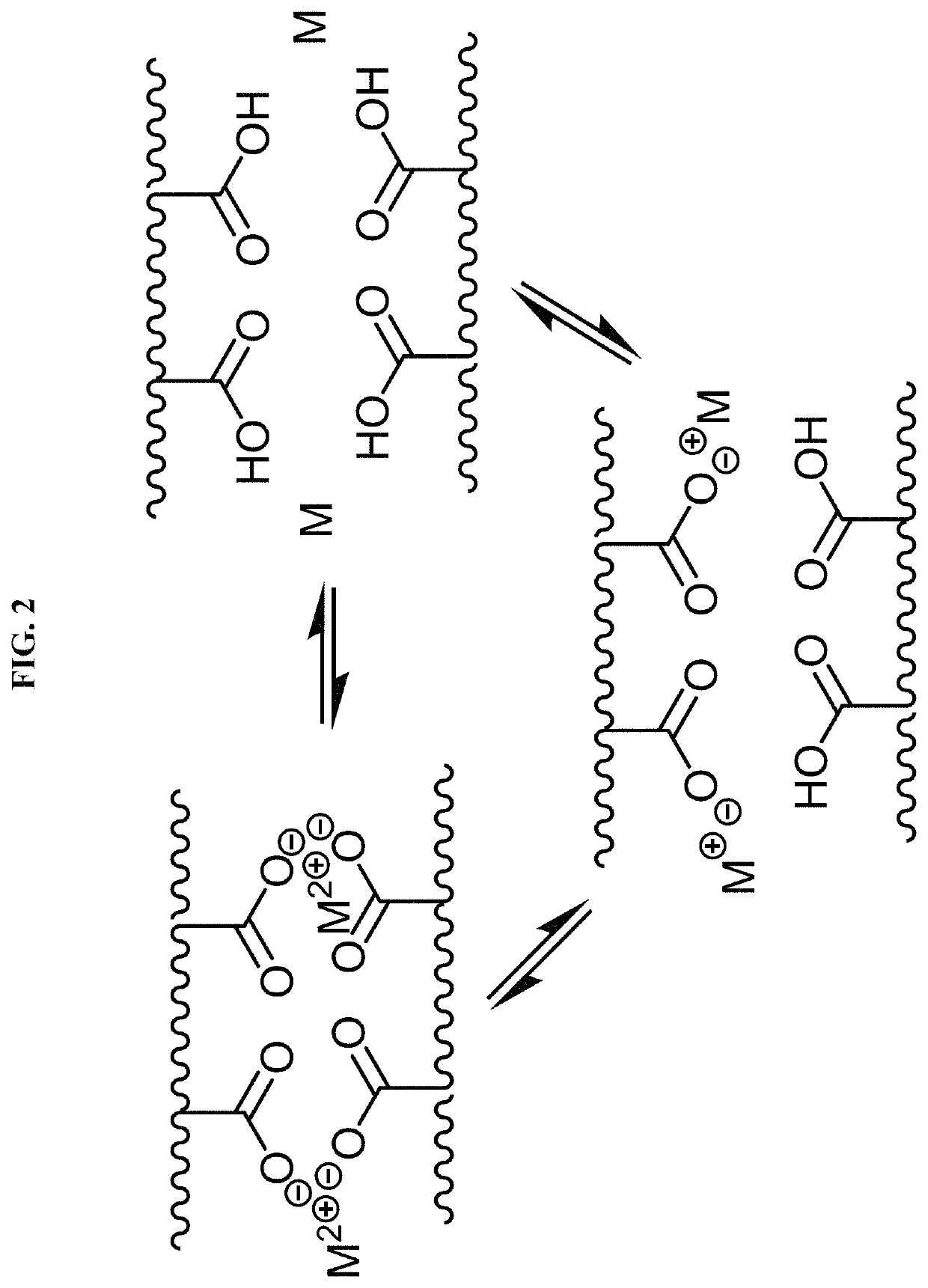

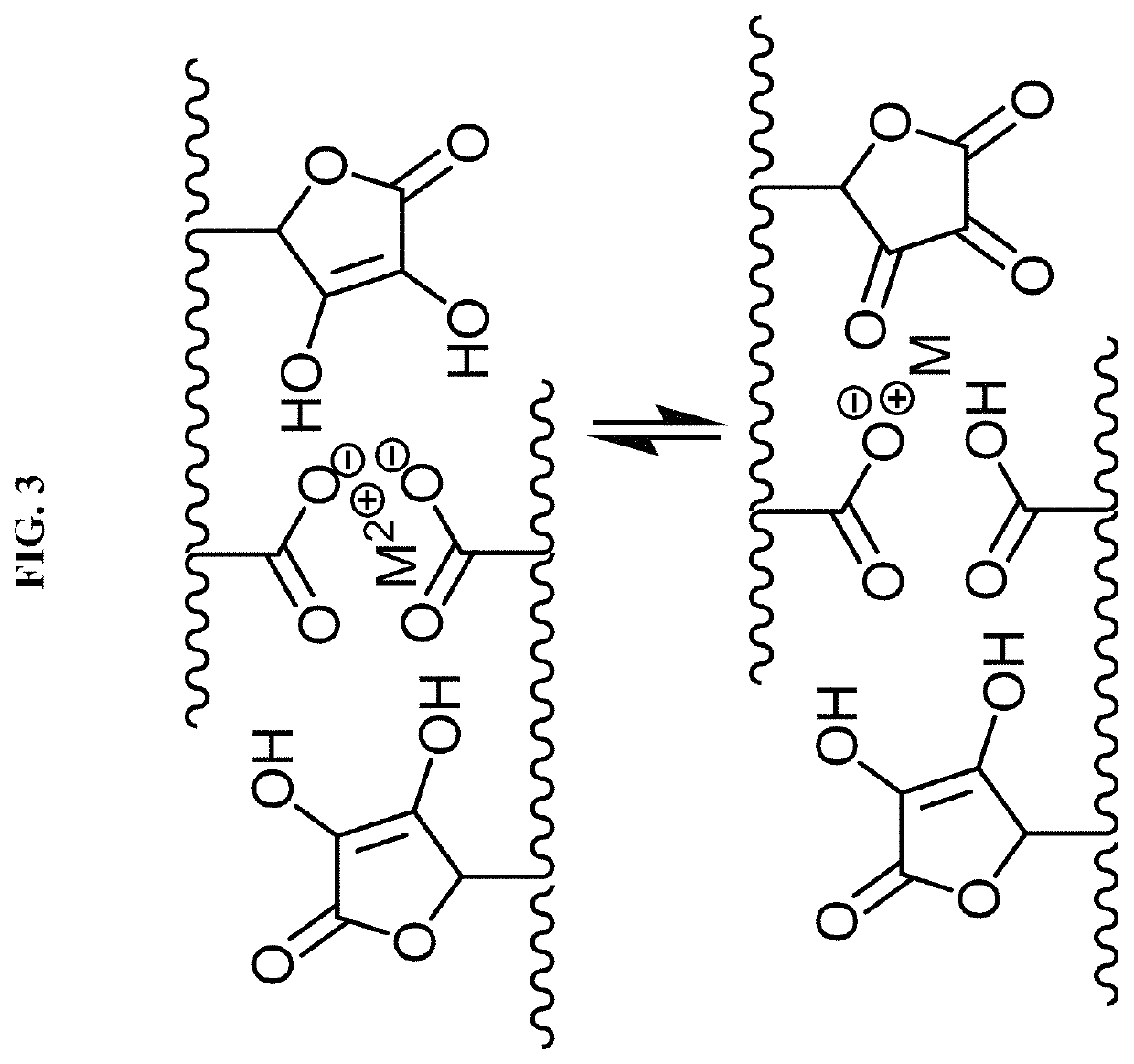

Chemically or environmentally responsive polymers with reversible mechanical properties

This invention provides compositions and methods for reversible ionic crosslinking in polymers, providing tunability of polymer mechanical properties. Some variations provide a polymer composition comprising: a polymer containing a plurality of ionic species disposed along the chain backbone of the polymer, wherein the plurality of ionic species has an ionic charge polarity that is negative or positive; a redox reagent; and a reversible crosslinking agent capable of changing from a first oxidation state to a second oxidation state when in the presence of the redox reagent. The different oxidation states are associated with different coordination numbers between the reversible crosslinking agent and the ionic species contained in the polymer. This difference provides reversible ionic crosslinking. The polymer may be selected from polyurethanes (including segmented and non-segmented polyurethanes), polyacrylates, or polyamides, for example. These polymers are useful for many commercial applications, including coatings and polymer parts.

Owner:HRL LAB

Hydroswellable, segmented, aliphatic polyurethanes and polyurethane ureas

InactiveUS20120208789A1Increase volumeRestoring the function of diseased or defective articulating jointsBiocideSurgical adhesivesSegmented polyurethanePolyethylene glycol

Hydroswellable, absorbable and non-absorbable, aliphatic, segmented polyurethanes and polyurethane-urea capable of swelling in the biological environment with associated increase in volume of at least 3 percent have more than one type of segments, including those derived from polyethylene glycol and the molecular chains are structurally tailored to allow the use of corresponding formulations and medical devices as carriers for bioactive agents, rheological modifiers of cyanoacrylate-based tissue adhesives, as protective devices for repairing defective or diseased components of articulating joints and their cartilage, and scaffolds for cartilage tissue engineering.

Owner:POLY MED

Gel for ultrasonic phantom

InactiveCN101316556AIncrease distancePromote absorptionUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesTemporal changeSonification

It is intended to provide a gel for an ultrasonic phantom which has favorable ultrasonic characteristics that can be sustained over a long period of time without alteration and is free from bacterial contamination, denaturation, putrefaction, etc. Namely, a gel for an ultrasonic phantom which comprises a segmented polyurethane gel having alkylene oxide segments, which are mostly or entirely in the form of a liquid at room temperature, and a nonvolatile organic gel expansion medium, which would not participate in the reaction of the urethane, contained therein. Owing to the nonvolatile organic gel expansion medium, the liquid segments, etc. are maintained in the spread state and thus the spaces among the segments are enlarged, which brings about favorable ultrasonic characteristics such as ultrasonic attenuation rate and transmission speed. Since the content of the expansion medium shows no temporal change, these favorable ultrasonic characteristics are maintained over a long period of time. Because of containing the organic gel expansion medium, the gel for an ultrasonic phantom is free from bacterial contamination, denaturation, putrefaction, etc.

Owner:TAKIRON CO LTD

Polyurethane/ureas useful for the production of spandex and a process for their production

InactiveUS6903179B2Low viscosityGood physical propertiesMonocomponent polyurethanes artificial filamentCeramic shaping apparatusFiberPolymer science

Segmented polyurethane / ureas useful in the production of spandex are produced by chain extending an isocyanate-terminated prepolymer in the presence of a solvent. The isocyanate-terminated prepolymer is formed by reacting a stoichiometric excess of an isocyanate with an isocyanate-reactive component that includes more than 50 equivalent percent of a high molecular weight polyoxyalkylene diol having an unsaturation level no greater than about 0.015 meq / g and up to about 50 equivalent percent of a polytetramethylene ether glycol.

Owner:BAYER MATERIALSCIENCE AG

Method for the preparation of new segmented polyurethanes with high tear and tensile strengths and method for making porous scaffolds

The invention presents a new method to prepare biomedical polyurethanes with high tensile and tear strengths. Such polyurethanes are especially interesting for making foams thereof, e.g. as meniscus implants. A new method, applicable to the biomedical polyurethanes, has been found to make such foams, that can be used as scaffolds. This method is based on salt leaching and phase separation.

Owner:HEIJKANTS RALF GUILLAUME JEAN CATHARINA +3

Method for the preparation of new segmented polyurethanes with high tear and tensile strengths and method for making porous scaffolds

The invention presents a new method to prepare biomedical polyurethanes with high tensile and tear strengths. Such polyurethanes are especially interesting for making foams thereof, e.g. as meniscus implants. A new method, applicable to the biomedical polyurethanes, has been found to make such foams, that can be used as scaffolds. This method is based on salt leaching and phase separation.

Owner:ORTEQ

Process for preparing antimicrobial elastic fiber

Disclosed herein is a process for preparing an antimicrobial elastic fiber. The process comprises: mixing a glass compound, as an antimicrobial agent, containing ZnO, SiO2, and an alkali metal oxide, and having an average particle size of 0.1 m to 5 m, with a dispersant; sand grinding or milling the mixture; and adding the ground or milled mixture to a solution of a segmented polyurethane polymer to prepare an elastic yarn. The process can provide advantageous effects that spinnability is improved and the color of yarn remains unchanged.

Owner:HYOSUNG CORP

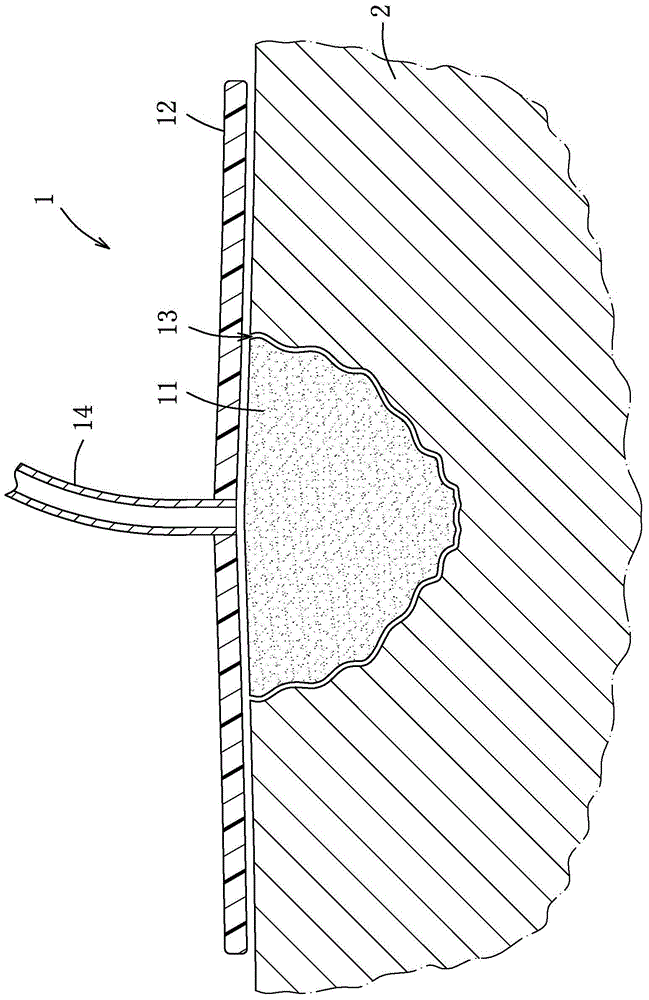

Negative pressure therapeutic apparatus

The invention discloses a negative pressure therapeutic apparatus, which comprises a filling material and an airtight unit. The filling material is made from a hydrophilic polyurethane foaming body which is obtained by foaming hydrophilic polyurethane and a foaming component, and pores in the hydrophilic polyurethane foaming body are non-continuous sealed pores; and the hydrophilic polyurethane is stellate segmented polyurethane which is obtained by promoting a reaction between first polyether polyol and polyisocyanates, and then promoting a reaction with second polyether polyol and hyaluronic acid, wherein the first polyether polyol contains at least three terminal hydroxyl groups. The airtight unit covers the filling material, so that a wound space which is generally sealed and contains the filling material is formed. The negative pressure therapeutic apparatus disclosed by the invention, before implanted into a wound, is unnecessary to cut and trim the filling material for several times; and the negative pressure therapeutic apparatus is capable of effectively promoting wound healing and is capable of avoiding injury caused by adhesion when the therapeutic apparatus is removed and replaced.

Owner:TAICEND TECH

Prepolymer catalysts suitable for preparing spandex fibers

InactiveUS6906163B2Good physical propertiesLow viscosityMonocomponent polyurethanes artificial filamentFiberSegmented polyurethane

Segmented polyurethane / ureas useful for the production of spandex, particularly spandex fibers, are made from isocyanate-terminated prepolymers formed by reacting excess isocyanate with an isocyanate-reactive component satisfying specified compositional requirements in the presence of a catalyst which promotes linear polymerization but does not cause degradation of the polymer. Suitable catalysts include metal salts of organic fatty acids and / or of naphthenic acid. The isocyanate-reactive component includes at least 10 equivalent percent of a polyoxypropylene diol having a number average molecular weight of at least about 1500 Da and an average unsaturation level less than or equal to 0.03 meq / g and up to 90 equivalent percent of a polytetramethylene glycol having a number average molecular weight of at least 200 Da.

Owner:BAYER MATERIALSCIENCE AG

Process for Preparing Antimicrobial Elastic Fiber

InactiveUS20070292684A1Improve spinnabilityImprove antibacterial propertiesMonocomponent polyurethanes artificial filamentFibre treatmentFiberYarn

Disclosed herein is a process for preparing an antimicrobial elastic fiber. The process comprises: mixing a glass compound, as an antimicrobial agent, containing ZnO, SiO2, and an alkali metal oxide, and having an average particle size of 0.1 μm to 5 μm, with a dispersant; sand grinding or milling the mixture; and adding the ground or milled mixture to a solution of a segmented polyurethane polymer to prepare an elastic yarn. The process can provide advantageous effects that spinnability is improved and the color of yarn remains unchanged.

Owner:HYOSUNG CORP

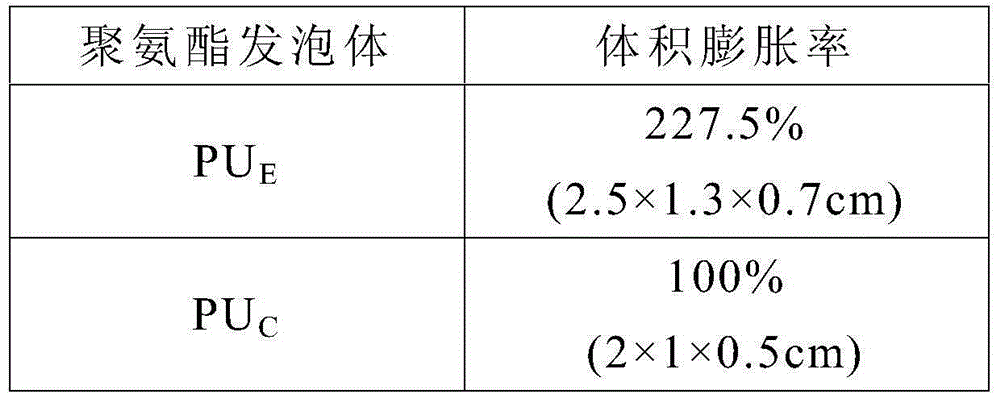

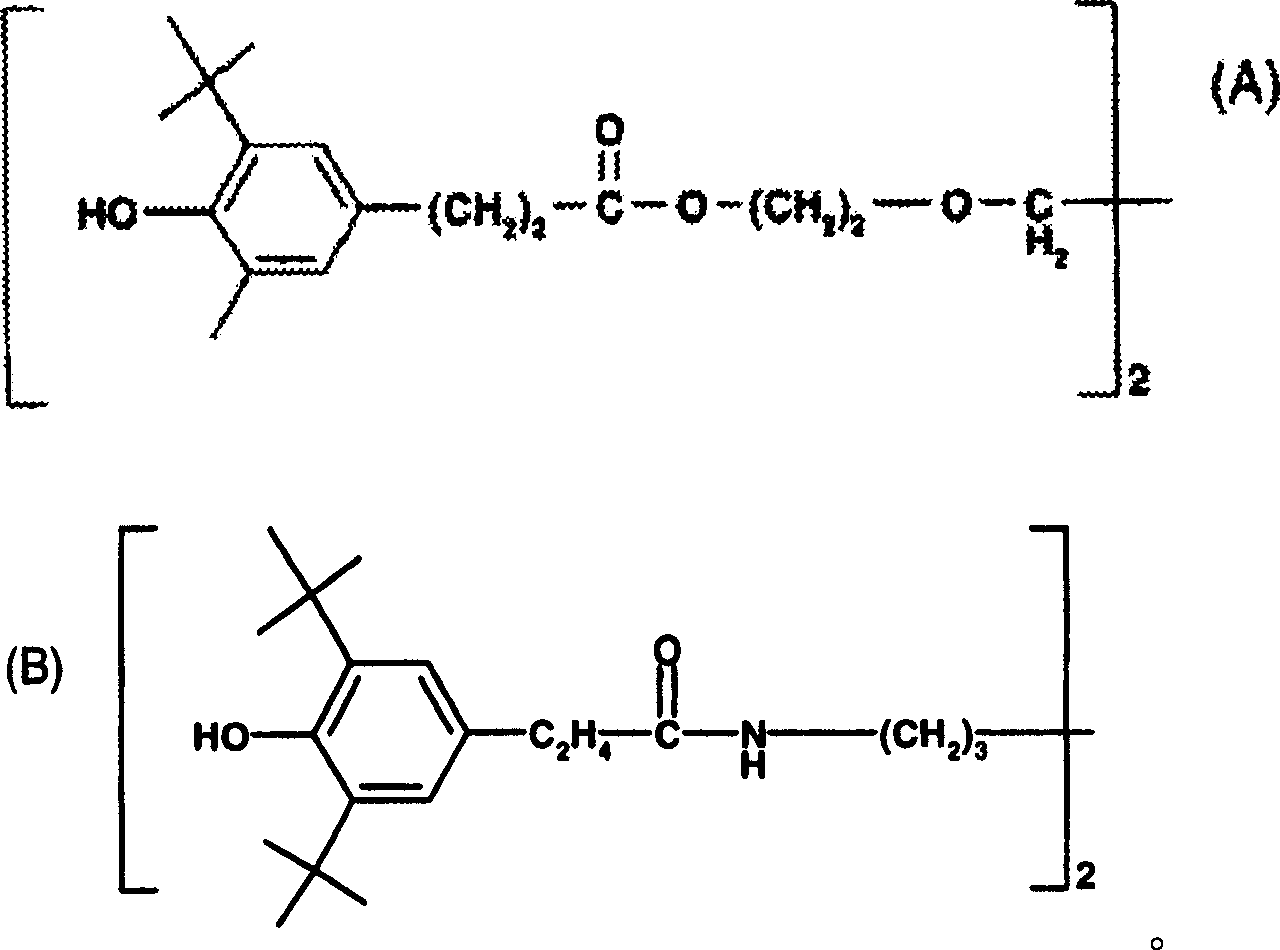

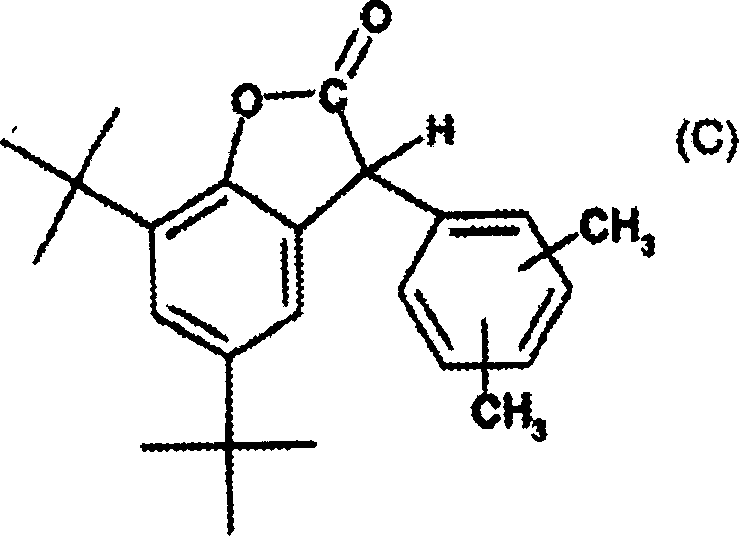

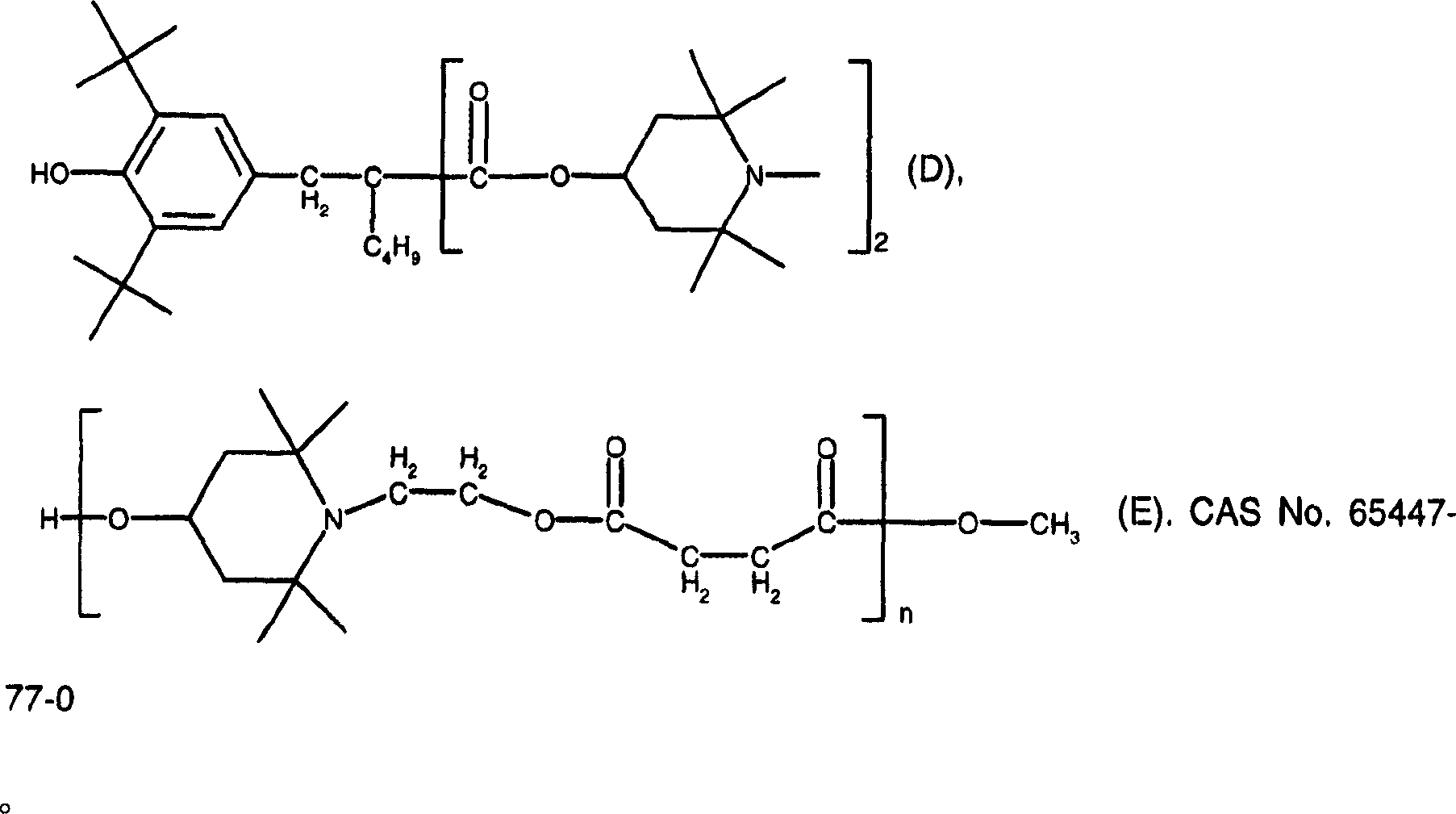

Composition and process for improving heat and weathering stability of segmented polyurethane polymers

The present invention relates to the stabilization of segmented polyurethanes by the addition of a combination of antioxidants, benzofuranones and or sterically hindered amines and a hydrazine or hydrazide.

Owner:CIBA SPECIALTY CHEM HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com