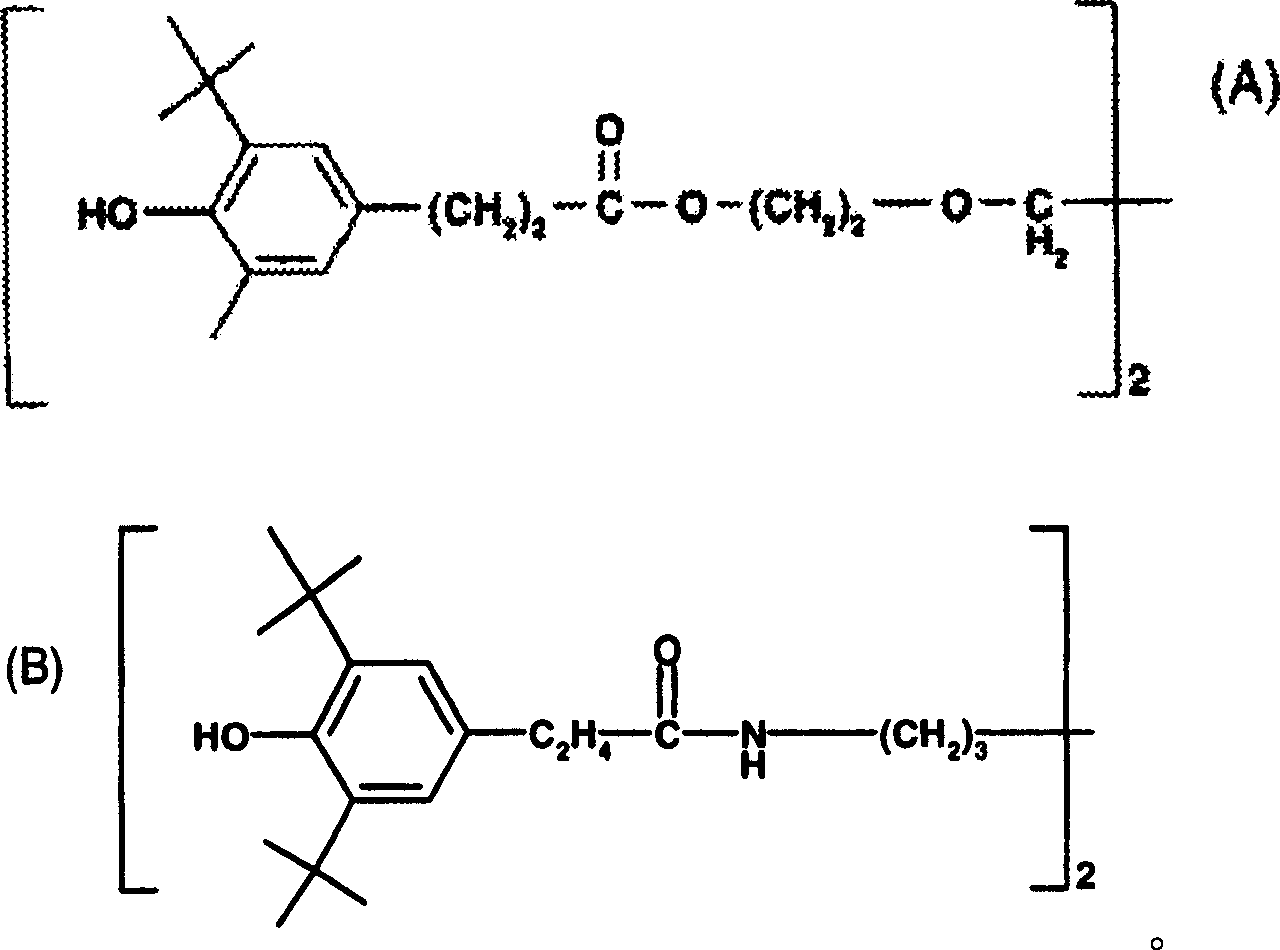

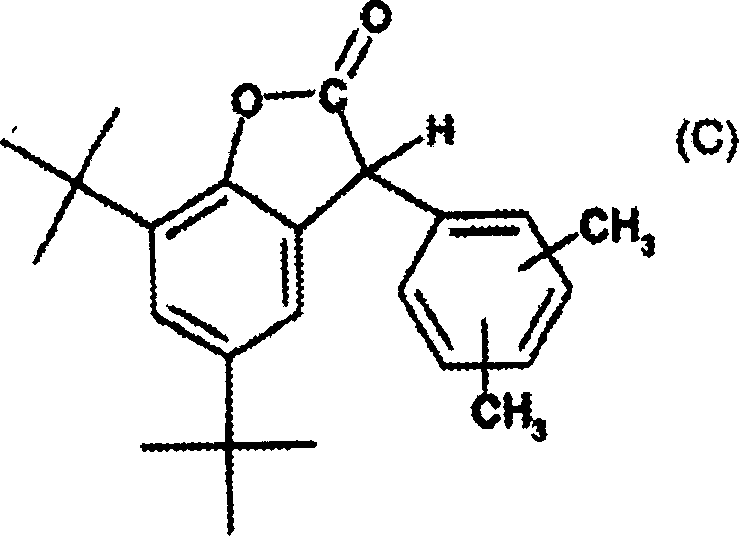

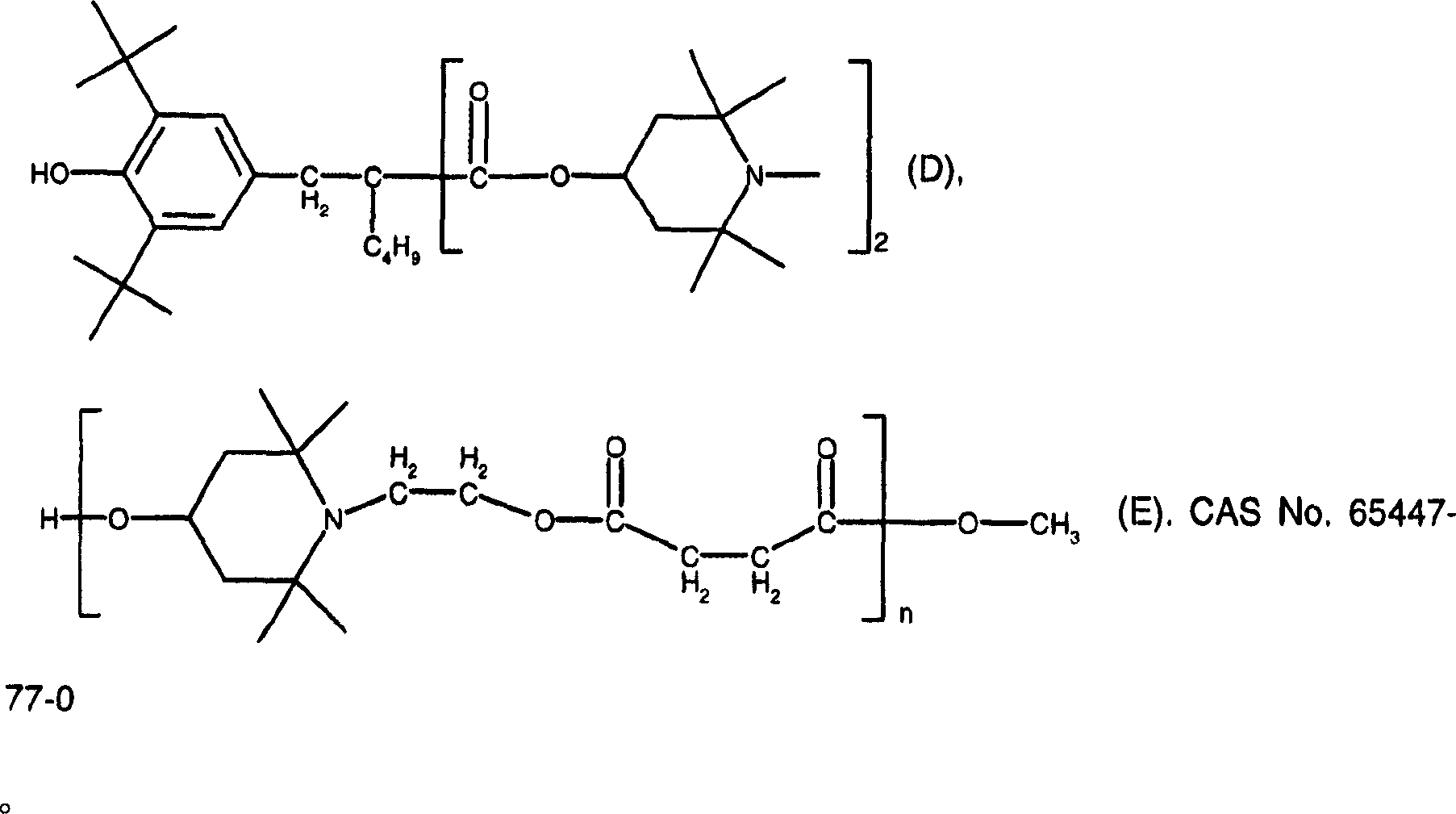

Composition and process for improving heat and weathering stability of segmented polyurethane polymers

A technology of polyurethane and composition, applied in the field of stabilized segmented polyurethane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following examples illustrate the invention.

[0055] Experimental conditions

[0056] raw material and abbreviation :

[0057] PTMEG is poly(tetramethylene ether) glycol alcohol

[0058] MDI is 4,4-methylene-bis(phenylisocyanate)

[0059] DMAC is N,N-dimethylacetamide,

[0060] Ethylenediamine, diethylamine.

[0061] Preparation of spandex

[0062] PTMEG and MDI were mixed at a ratio of 1.58 moles of MDI per mole of polyether polyol and held at about 60°C for 120 minutes to produce an isocyanate-terminated polyether. The prepolymer was cooled and dissolved in DMAC to give a mixture containing 40% solids. At room temperature, the mixture of ethylenediamine and diethylamine in DMAC was slowly poured into the above mixture, cooled in a water bath and vigorously stirred.

[0063] The resulting segmented polyurethane solution was stirred at 100°C for 5 minutes and had 29% solids.

[0064] A portion of the solution is taken from the bulk polyurethane soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com