Novel polyolefin packaging glue film composite and application thereof

A technology for encapsulating adhesive films and polyolefins, which is used in adhesives, adhesive additives, non-polymer adhesive additives, etc., which can solve the problem of difficult to achieve recycling of waste components, difficult to achieve online defect repair of components, and increase in the price of matrix resin raw materials. Advanced problems, to achieve the effect of online repairability and recyclability, excellent mechanical punching modulus, and easy processing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

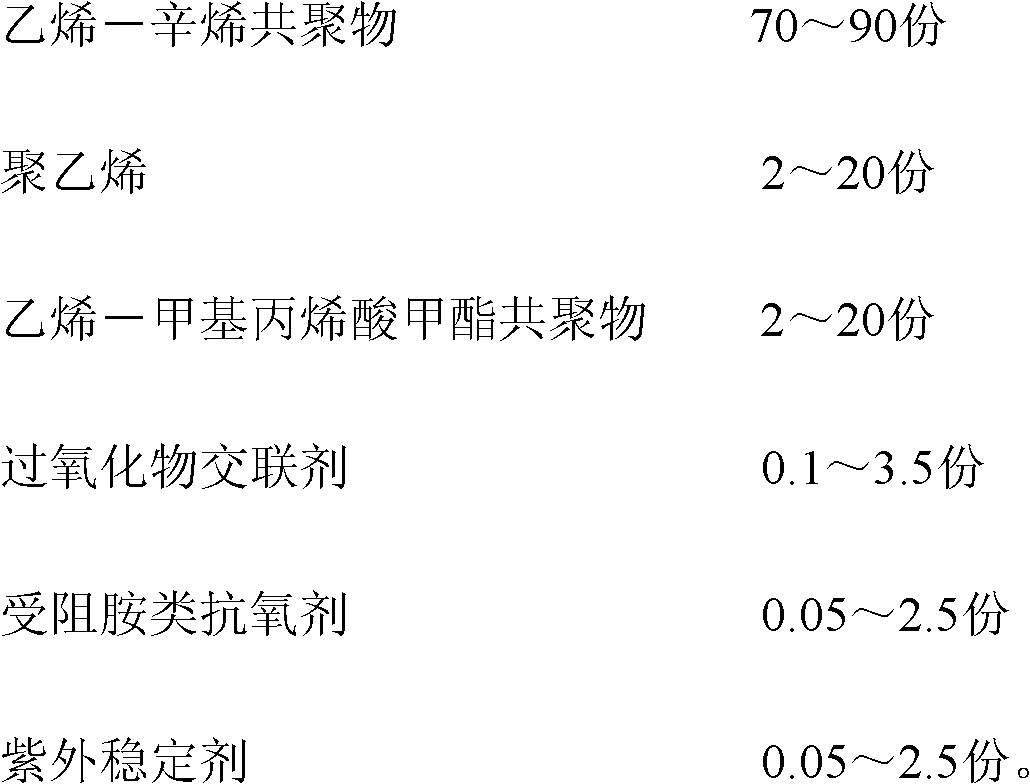

Method used

Image

Examples

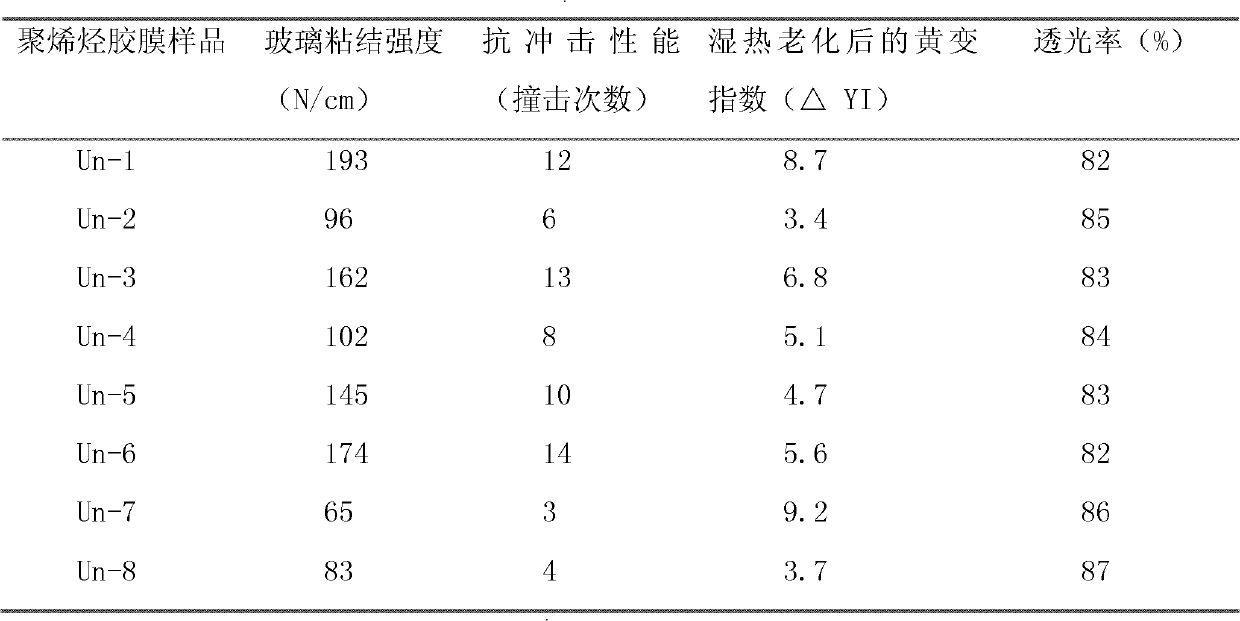

Embodiment 1

[0022] In terms of mass fraction, by 80 parts of ethylene-octene copolymer (U.S. Dow POE 8200), 20 parts of polyethylene (Saudi Arabia SABIC 500026) and 20 parts of ethylene-methyl methacrylate copolymer (U.S. West Lake SP1305 ) into pellets composed of 2 parts of cross-linking agent (2-ethylhexyl) tert-amyl carbonate (Akzo Nobel Peroxide Co., Ltd.), 0.05 parts of UV stabilizer 2-(2-hydroxyl-3 , 5 di-tert-amylphenyl) benzotriazole (U.S. Steam Eight Refining Company UV-328) and 0.5 parts of antioxidant 1,3,5-tri(4-tert-butyl-3-hydroxyl-2, 6-Dimethylbenzyl)-1,3,5-triazine-2,4,6(1H,3H,5H)-trione / bis(2,4-dicumylphenyl)pentaerythritol diethylene Phosphate compound (CYANOX 2777), mix well.

[0023] The above mixture is blended and extruded in an extruder, and the temperature is controlled at 140°C. The extruded product is cast, cooled, cut, and rolled to obtain a 0.5mm thick polyolefin packaging film, which is marked as Un -1.

Embodiment 2

[0025] In terms of mass fraction, by 90 parts of ethylene-octene copolymer (POE 0210 of Exxon Mobil Corporation of the United States), 10 parts of polyethylene (Saudi Arabia SABIC 200024) and 10 parts of ethylene-methyl methacrylate copolymer ( In the granule that U.S. West Lake SP1307) forms, add 1.5 parts of linking agent o-tert-amyl-o-(2-ethylhexyl)-single-peroxycarbonate ( TAEC), 0.1 part of UV stabilizer bis-2,2,6,6-tetramethylpiperidinol sebacate (Tinuvin 770) and 0.1 part of antioxidant 2,6-di-tert-butyl-4-methyl base phenol, mix well.

[0026] The above mixture is blended and extruded in an extruder, and the temperature is controlled at 140°C. The extruded product is cast, cooled, cut, and rolled to obtain a 0.5mm thick polyolefin packaging film, which is marked as Un -2.

Embodiment 3

[0028] In terms of mass fraction, it is composed of 70 parts of ethylene-octene copolymer (Japan Mitsui POE DF640), 15 parts of polyethylene (SK FT411) and 20 parts of ethylene-methyl methacrylate copolymer (West Lake SP1330 in the United States) In the pellets, add 1.5 parts of cross-linking agent tert-butyl peroxyneodecanoate ( 23C75), 0.1 part of UV stabilizer 2,2'-dihydroxy-4,4'-dimethoxybenzophenone and 0.05 part of antioxidant 1,3,5-tri(4-tert-butyl-3 -Hydroxy-2,6-dimethylbenzyl)-1,3,5-triazine-2,4,6(1H,3H,5H)-trione / bis(2,4-dicumylbenzene Base) pentaerythritol diphosphite compound (CYANOX XS4), mix evenly.

[0029] The above mixture is blended and extruded in an extruder, and the temperature is controlled at 140°C. The extruded product is cast, cooled, cut, and rolled to obtain a 0.5mm thick polyolefin packaging film, which is marked as Un -3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com