Method for manufacturing polyether organosilicone segmented polyurethane material, product and application

A technology of polyether silicone and polyurethane materials, which can be used in medical formulations, catheters, medical science, etc., can solve the problems of poor mechanical properties, poor low temperature resistance, and poor hydrophobic properties of materials, and achieve excellent mechanical properties and low temperature Excellent performance and hydrophobicity, the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

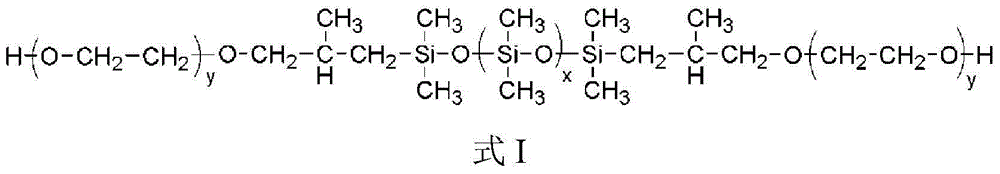

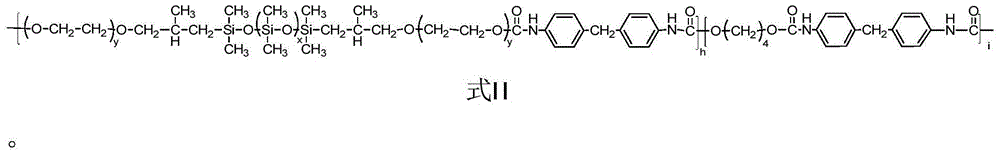

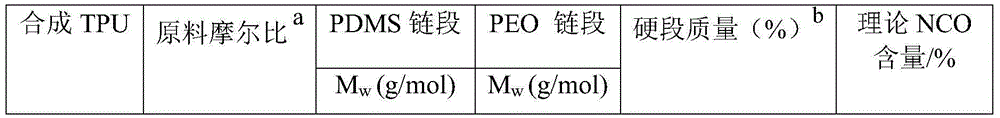

[0038] Polyether-silicone block structure with a molecular weight of 2270, in polyurethane prepolymer When the group mass fraction is 5.85%, the NCO / OH molar ratio is 1.02, and the hard segment content is 30%, the polyurethane elastomer containing polyether-organic silicon block is prepared and its application in biomaterials.

[0039] The preparation method of the polyether-organic silicon block polyurethane elastomer in this embodiment comprises the following steps:

[0040] Step 1: Preparation of modified polyurethane prepolymer containing 2270 molecular weight polyether-silicone block

[0041] 2270 molecular weight dihydroxyl-terminated polyether-silicon block PEO-PDMS-PEO (Momentive product) and MDI monomer, according to the composition of the molar ratio, see Table 1, prepared by prepolymer synthesis bulk polymerization. The initial reactant 60.38 grams (0.028 moles) of PEO-PDMS-PEO with a molecular weight of 2270, and 37.4 grams (0.151 moles) of MDI were added to a fo...

Embodiment 2

[0051] When the polyether-silicone block structure with a molecular weight of 2640, the -NCO group mass fraction of the polyurethane prepolymer is 6.20%, the molar ratio of NCO / OH is 1.02, and the hard segment content is 30%, the polyether-containing - Silicone segmented polyurethane elastomers and their applications in biomaterials.

[0052] The preparation method of the polyether-organic silicon block polyurethane elastomer in this embodiment comprises the following steps:

[0053] Step 1: Preparation of modified polyurethane prepolymer containing 2640 molecular weight polyether-silicone block

[0054] 2640 molecular weight dihydroxyl-terminated polyether-silicon block PEO-PDMS-PEO (Momentive product) and MDI monomer, according to the composition of the molar ratio, see Table 3, prepared by prepolymer synthesis bulk polymerization. The initial reactant 61.78 grams (0.023 moles) of PEO-PDMS-PEO with a molecular weight of 2640, and 35.2 grams (0.142 moles) of MDI were added t...

Embodiment 3

[0063] The polyether-silicone block structure with a molecular weight of 3380, the -NCO group mass fraction of the polyurethane prepolymer is 6.55%, the molar ratio of NCO / OH is 1.02, and the hard segment content is 30%. - Silicone segmented polyurethane elastomers and their applications in biomaterials.

[0064] The preparation method of the polyether-organic silicon block polyurethane elastomer in this embodiment comprises the following steps:

[0065] Step 1: Preparation of modified polyurethane prepolymer containing polyether-silicone block with molecular weight of 3380

[0066] 3380 molecular weight dihydroxyl-terminated polyether-silicon block PEO-PDMS-PEO (Momentive product) and MDI monomer, according to the composition of the molar ratio, see Table 5, prepared by prepolymer synthesis bulk polymerization. The initial reactant 58.81 grams (0.017 moles) of PEO-PDMS-PEO with a molecular weight of 3380, and 32.7 grams (0.132 moles) of MDI were added to a four-necked flask ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com