Novel degradable polyurethane biological material and preparation method and application thereof

A biomaterial, polyurethane technology, applied in the field of biomedical polymer materials, can solve the problems of lack of selective arrangement and combination of blocks, difficult to control material properties, etc., and achieve the effects of high surface energy, high crystallinity, and enhanced mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Synthesis of Alternating Block Polyurethanes (Alt-PU) and Random Block Polyurethanes (Ran-PU) Based on Aliphatic Polyesters and Hydrophilic Polyethers:

[0059] Dissolve the aliphatic polyester diol in the organic solvent (chloroform) in the three-necked flask first, and then use the hydrophilic polyether-diisocyanate prepared by the end-capping reaction, according to the ratio of 1:1 with the diol The molar equivalent is slowly dropped into the flask, and after reacting at 30-100° C. for 8-72 hours, the alternating block polyurethane Alt-PU is obtained. Above-mentioned reaction also can directly be carried out in reaction raw material body, also can use the organotin catalyst of 1 / 100000 to 1 / 100,000 (weight ratio), as 2-ethylhexanoate tin, butyltin dilaurate etc., reflect The hydroxyl and isocyanate groups in the system should have an equal molar ratio.

[0060] Use aliphatic polyester diol and hydrophilic polyether as the reaction body, add tin-containing catalyst, ...

Embodiment 2

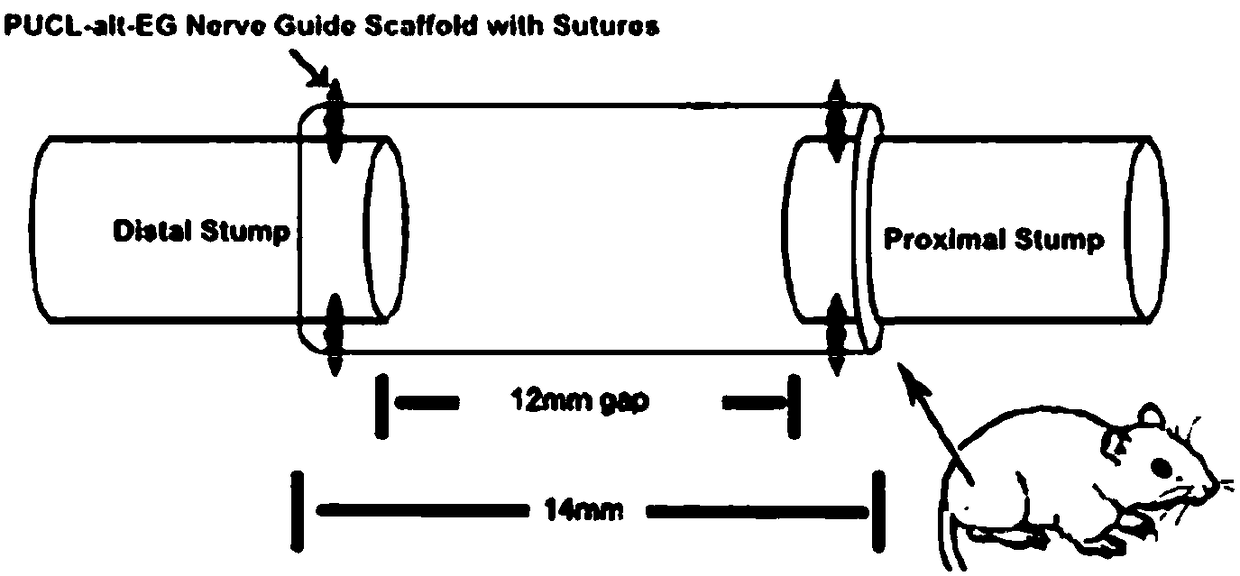

[0063] Alternating block polyurethane (Alt-PU) and random block polyurethane (Ran-PU) biomaterials prepared in Example 1 are applied to the preparation of nerve repair sockets:

[0064] Porous nerve repair sockets were prepared by using dip coating and salt immersion methods, using a stainless steel wire with an outer diameter of 1.5 mm as a mold, and then the polymer coating on the resulting mold was air-dried for 2 days, vacuum-dried for 2 days, and then desiccated. The salt was leached out in deionized water, freeze-dried and demoulded to obtain the nerve repair socket.

[0065] Nerve repair sleeve, also known as nerve repair catheter or nerve repair sheath; it can also be called nerve repair covering sheet and nerve protection open tube. The nerve repair sleeve prepared by the alternating block polyurethane (Alt-PU) has a microporous pipeline structure, a microporous sheet structure and a microporous opening with a porosity of 10-99% and a pore size of 100 nm to 500 μm (mi...

Embodiment 3

[0083] The alternate block polyurethane (Alt-PU) biomaterial prepared in Example 1 is applied to the preparation of eyelid support, and the manufacturing method is liquid-solid phase separation and freeze-drying method:

[0084] Put a certain amount of Alt-PU material into a beaker and add organic solvent until Alt-PU completely dissolves into a transparent solution. Pour the solution into a stainless steel mold, control the thickness of the poured liquid surface, place the mold containing the solution in an ice-water mixing incubator at -20-0°C for 1-10 hours, take it out and place it in a -10-4°C for 1- After 24 hours, move to a freeze dryer for freeze-drying, then freeze-dry for 1-24 hours, take out the stainless steel mold and put it in a normal temperature vacuum dryer to dry for 1-48 hours, take out the molded bracket, and then cut the bracket into 1cm 2 Bracket, get 0.7mm×1cm 2 Eyelid implants. The eyelid implant bracket has a porous film structure with a porosity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com